Training Within Industry (TWI): Job Safety (JS) Poster

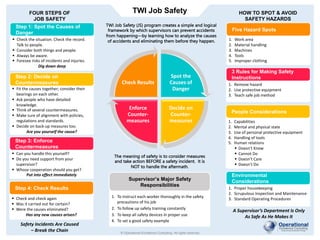

The TWI Job Safety (JS) Poster describes the four steps of Job Safety based on the tried and tested Training Within Industry (TWI) methodology. The TWI JS program creates a simple and logical framework by which supervisors can prevent accidents from happening--by learning how to analyze the causes of accidents and eliminating them before they happen. The poster comes in two themes: color and monochrome. Formatted in PDF and in editable PPTX, the poster can be easily printed on an A3 or A4-sized paper from an office copier machine and displayed on employee workstations, or distributed together with your workshop handouts. The TWI JS Poster complements the 'TWI Program: Job Safety (JS) Training' presentation materials and the TWI JS Pocket Cards. It serves as a takeaway and summary of your occupational health and safety presentation. Contents in the TWI JS poster include: 1. What Is The TWI Job Safety Program 2. The Four Steps of Job Safety 3. How To Spot & Avoid Safety Hazards 4. Supervisor's Major Safety Responsibilities

Recommandé

Recommandé

Contenu connexe

Tendances

Tendances (20)

Similaire à Training Within Industry (TWI): Job Safety (JS) Poster

Similaire à Training Within Industry (TWI): Job Safety (JS) Poster (20)

Plus de Operational Excellence Consulting

Plus de Operational Excellence Consulting (20)

Dernier

Dernier (20)

Training Within Industry (TWI): Job Safety (JS) Poster

- 1. TWI Job Safety © Operational Excellence Consulting. All rights reserved. TWI Job Safety (JS) program creates a simple and logical framework by which supervisors can prevent accidents from happening—by learning how to analyze the causes of accidents and eliminating them before they happen. § Check the situation. Check the record. Talk to people. § Consider both things and people. § Always be aware. § Foresee risks of incidents and injuries. Dig down deep Step 1: Spot the Causes of Danger § Fit the causes together; consider their bearings on each other. § Ask people who have detailed knowledge. § Think of several countermeasures. § Make sure of alignment with policies, regulations and standards. § Decide on back-up measures too. Are you yourself the cause? Step 2: Decide on Countermeasures § Can you handle this yourself? § Do you need support from your supervisor? § Whose cooperation should you get? Put into effect immediately Step 3: Enforce Countermeasures § Check and check again § Was it carried out for certain? § Were the causes eliminated? Has any new causes arisen? Step 4: Check Results The meaning of safety is to consider measures and take action BEFORE a safety incident. It is NOT to handle the aftermath. Spot the Causes of Danger Decide on Counter- measures Enforce Counter- measures Check Results Safety Incidents Are Caused – Break the Chain A Supervisor’s Department Is Only As Safe As He Makes It FOUR STEPS OF JOB SAFETY 1. To instruct each worker thoroughly in the safety precautions of his job 2. To follow up safety training constantly 3. To keep all safety devices in proper use 4. To set a good safety example Supervisor’s Major Safety Responsibilities 1. Work area 2. Material handling 3. Machines 4. Tools 5. Improper clothing Five Hazard Spots HOW TO SPOT & AVOID SAFETY HAZARDS 1. Remove hazard 2. Use protective equipment 3. Teach safe job method 3 Rules for Making Safety Instructions 1. Capabilities 2. Mental and physical state 3. Use of personal protective equipment 4. Handling of tools 5. Human relations § Doesn’t Know § Cannot Do § Doesn’t Care § Doesn’t Do People Considerations 1. Proper housekeeping 2. Scrupulous Inspection and Maintenance 3. Standard Operating Procedures Environmental Considerations

- 2. TWI Job Safety © Operational Excellence Consulting. All rights reserved. TWI Job Safety (JS) program creates a simple and logical framework by which supervisors can prevent accidents from happening—by learning how to analyze the causes of accidents and eliminating them before they happen. § Check the situation. Check the record. Talk to people. § Consider both things and people. § Always be aware. § Foresee risks of incidents and injuries. Dig down deep Step 1: Spot the Causes of Danger § Fit the causes together; consider their bearings on each other. § Ask people who have detailed knowledge. § Think of several countermeasures. § Make sure of alignment with policies, regulations and standards. § Decide on back-up measures too. Are you yourself the cause? Step 2: Decide on Countermeasures § Can you handle this yourself? § Do you need support from your supervisor? § Whose cooperation should you get? Put into effect immediately Step 3: Enforce Countermeasures § Check and check again § Was it carried out for certain? § Were the causes eliminated? Has any new causes arisen? Step 4: Check Results The meaning of safety is to consider measures and take action BEFORE a safety incident. It is NOT to handle the aftermath. Spot the Causes of Danger Decide on Counter- measures Enforce Counter- measures Check Results Safety Incidents Are Caused – Break the Chain A Supervisor’s Department Is Only As Safe As He Makes It FOUR STEPS OF JOB SAFETY 1. To instruct each worker thoroughly in the safety precautions of his job 2. To follow up safety training constantly 3. To keep all safety devices in proper use 4. To set a good safety example Supervisor’s Major Safety Responsibilities 1. Work area 2. Material handling 3. Machines 4. Tools 5. Improper clothing Five Hazard Spots HOW TO SPOT & AVOID SAFETY HAZARDS 1. Remove hazard 2. Use protective equipment 3. Teach safe job method 3 Rules for Making Safety Instructions 1. Capabilities 2. Mental and physical state 3. Use of personal protective equipment 4. Handling of tools 5. Human relations § Doesn’t Know § Cannot Do § Doesn’t Care § Doesn’t Do People Considerations 1. Proper housekeeping 2. Scrupulous Inspection and Maintenance 3. Standard Operating Procedures Environmental Considerations

- 3. © Operational Excellence Consulting. All rights reserved. 3 Operational Excellence Consulting is a management training and consulting firm that assists organizations in improving business performance and effectiveness. Based in Singapore, the firm’s mission is to create business value for organizations through innovative design and operational excellence management training and consulting solutions. For more information, please visit www.oeconsulting.com.sg