Know Your Supplier - Rubber & Tyre Machinery World June 2016 Special

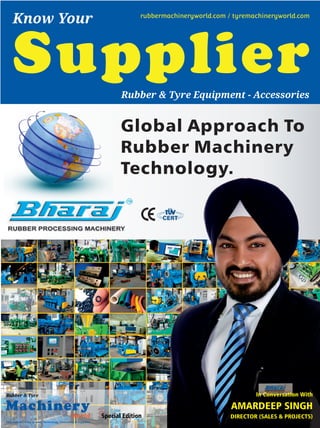

- 1. Special Edition Global Approach To Rubber Machinery Technology. Information On Equipment, Technology, Innovation & Suppliers Machinery World Rubber & Tyre In Conversation With AMARDEEP SINGH DIRECTOR (SALES & PROJECTS) Supplier Know Your rubbermachineryworld.com / tyremachineryworld.com Rubber & Tyre Equipment - Accessories

- 5. Supplier Know Your Rubber & Tyre Equipment - Accessories Contents KNOWLEDGE-ON-THE-GO Through A Gadget Of Your Choice RUBBERTYREMACHINERYWORLD INFORMATIONONEQUIPMENT,TECHNOLOGY,INNOVATIONSUPPLIERS ........... And MoreINFORMATION PORTAL | E-MAGAZINES | INTERVIEWS | KNOWLEDGE PARTNERS | DOWNLOADS 5 29 13 Things You Should Know About Hydraulic Power Pack INSIGHT 36 The Biggest Problem With Heat Transfer Efficiency on Rubber Machinery (And How You Can Fix It) TIPS June 2016 8 COVER STORY Global Approach To Rubber Machinery Technology Conversation with Amardeep Singh, Director (Sales Projects) on Bharaj Machineries solutions for global rubber and tyre industry.

- 7. Make in India is an initiative launched by the Government of India in 2014 to encourage multi-national and national companies to manufacture their products in India. While this initiative has garnered significant international attention and keenly watched, some Indian machinery companies have been steadily building up their repute with global approach and right technology. In this special edition of Know Your Supplier’s cover story, we feature one such company Bharaj Machineries Pvt. Ltd., through an interactive conversation with Amardeep Singh, Director - Sales Projects. Established in 1982 with a vision, to always produce most advanced and quality machineries for the rubber industry, Bharaj has transformed into a giant machinery supplier. They are a preferred choice for many rubber related industries starting from Tyre, Automotive, Sports, Footwear, Pharmaceutical, Aerospace and Specialized Silicon Rubber Industry with exports to USA, UK, France, Canada and many Asian Countries. Their aspirations to be leaders in their various business segments is filled with passion and backed with technology. In addition, we have two other topics from our portal titled ‘Insight’ and ‘Tips’ sections. Our last issue with a new cover theme (standardized in line with our other editions) along with these two additional sections were well-accepted and read. I hope you find this issue equally knowledge enriching. As always, I welcome your feedback on rubbermachineryworld@gmail.com. Best Regards Prasanth Warrier | Editor’s Note | Global Approach Indian machinery companies, like Bharaj Machines have been steadily building their repute with global approach and right technology. 7 rubbermachineri rubbermachineryworld +Rubbermachineryworld1 grp/home?gid=8252803 rubbermachineri (Disclaimer: The pictures and statements in our special supplements are shared by the respective companies and/or sources mentioned. Rubber Tyre Machinery World does not verify/vouch for their genuineness, hence will not be liable for any misrepresented data) Know Your Supplier | JUNE 2016

- 8. HQ Mumbai India | BHARAJ | AT A GLANCE 8 Know Your Supplier | JUNE 2016 Serving Global Rubber Industry from Tyre, Automotive, Pharmaceutical, Footwear, Sports, Aerospace, to Specialized Silicon. By TUV, CRISIL, and INDIAN EXPORT HOUSE (By Ministry of Commerce Industry) - Indian Leadership Award (2010-11) - Bharatiya Udyog Ratan Award (2010-11) - Export Merit Award (2010-11) - Outstanding Performance in Exports (2014-15) Factory: 30,500 Sft. Corp. Ofce: 2,400 Sft. STATE-OF-THE-ART Manufacturing. CUSTOMER-ORIENTED Technology Service. 1982Privately Owned 35 Exports PERCENT 65Repeat Buyers PERCENT 50 Market Share* PERCENT 25Of Selected Eqpt. DAYS DELIVERY 15Eqpt. Installations + COUNTRIES 10of Satised Customers + GLOBAL BRANDS Customized MARKED EQPT - INDIA'S FIRST 4 ROLL Z-TYPE CALENDER WITH COMPLETE LINE FOR TYRE CORD. - INDIA'S FIRST CE APPROVED SILICON RUBBER MILL - VARIABLE FRICTION RATIO. - INDIA'S FIRST SPECIALIZED CLEAN ROOM SILICON MACHINERY. - INDIA'S FIRST 25 MM SILICON EXTRUDER. - INDIA'S FIRST DISPERSION KNEADER WITH INTERMESHING ROTORS. KEY MILESTONES Members of FEDERATION OF INDIAN EXPORT ORGANISATIONS

- 9. 9 based in Mumbai, India manufacturesBharaj Machineries Pvt. Ltd. and supply high-quality and advanced machineries for the rubber industry. They specialise in rubber mould manufacturing, rubber moulding, extrusion and mixing technology. We gather from our conversation with Amardeep Singh, Director (Sales Projects) Bharaj Machineriesof , that they are the first choice for many rubber related industries starting from Automotive, Sports, Tyre, Aerospace, Pharmaceutical, Footwear, and Specialized Silicon Rubber Industry. This interview captures their growth and aspirations to be leaders in their various business segments. Bharaj has gradually and consistently built a strong name in Rubber Tyre Industry with sizeable exports. What are the challenges that you face these days on sustaining this momentum? Since our founder and chairman, Balraj Singh Bharaj, started Bharaj Machineries Company Pvt. Ltd in 1984, our core vision has always been to produce high quality and advanced machineries for the rubber industry. We today have expertise in rubber mould manufacturing, rubber moulding, extrusion and mixing technology, thus evolving ourselves into a formidable machinery supplier or repute for the rubber industry in India and abroad. Bharaj manufactured machineries are considered as a first choice for many rubber related industries starting from Automotive, Sports, Pharmaceutical, Footwear, Aerospace, Tyre, and Specialized Silicon Rubber Industry; who are quality-oriented and seek precision and performance in their products. We a well known brand in various developed countries to like USA, UK, France, Canada and many Asian Countries. When we operate at such a scale, it Bharaj manufactured machineries are considered as a first choice for many rubber related industries. | BHARAJ | Know Your Supplier | JUNE 2016

- 10. | BHARAJ | Know Your Supplier | JUNE 2016 is quite natural to face price competition from machineries of Chinese and SE countries, where the domestic market has slumped. This is because there are customers who still make buying-decisions only on initial price. Educating them is a challenge. What are the major strengths of Bharaj? How do you add value to equipment buyers? The rubber industry has always considered Bharaj as a reputed name in Quality Technology. This is because our continuous RD has always kept us ahead of competitors. We introduce new models and upgrade existing technology regularly. We offer complete solution in rubber mould manufacturing, rubber moulding, extrusion and rubber mixing areas. Depending on the equipment, we offer quick delivery to our customers. Some of our equipment is delivered in as low as 25 days. Our response time to support service requests is less than 48 hours. Bharaj designs and manufactures latest technology rubber machinery that saves power, compact in size, has low maintenance, requires minimum labour through smart automation and are user-friendly. Image: Bharaj Make BMK-75 Liter Heavy Duty Dispersion Kneader (Back Feeding and Front Discharge Type) 10 @Bharaj @Bharaj

- 12. | BHARAJ | Know Your Supplier | JUNE 2016 Buyers would need technical inputs and customization. What level of pre-sales support does Bharaj offer? We deeply respect and value every equipment buyers' desire for optimum technology in his production floor. Hence, basis our long-standing experience in rubber mould manufacturing, rubber moulding, extrusion and mixing technology, we recommend the right machinery with right features that gives our customers the best return on his investment. This means we consult him on equipment selection to match his production process, share layout drawings and take great care to clarify his genuine queries in the most practical manner feasible. Depending on availability, we arrange equipment visits for our prospects either at our 30,500 Sft ultra- modern and state-of-the-art manufacturing plant near Mumbai or at any of customer sites. What products and services can a prospective equipment buyer expect when they approach you? Yes, we offer complete solutions in rubber mould manufacturing, rubber moulding, extrusion and rubber mixing areas. Bharaj designs and manufactures latest technology rubber machinery that saves power, compact in size, has low maintenance, requires minimum labour through smart automation and are user friendly. Our prospects can choose from a range of Cold Feed Extruders (Plain/Vent Types), Heavy duty Rubber Mixing Mills, Rubber Dispersion Kneaders, Hot Feed Extruders, Refiner Mills, Cracker Mills, Grinding Mills, Calenders with complete lines, Batch-Off Units, Vulcanizers, Bale Cutters, Conveyors, Stock Blenders, Vacuum Compression Type Rubber Moulding Machines, etc. Image: Bharaj Make CE Approved Rubber Mixing Mill With Variable Friction And Variable Ratio, Digital Nip Gap Indication and Peripherally Drilled Rolls. 12 We recommend the right machinery and features to give our customers the best RoI. @Bharaj @Bharaj

- 13. Image: Bharaj Make 6 x 13 Lab Mill. | BHARAJ | Know Your Supplier | JUNE 2016 Do you invest in RD? Where are your RD investments and efforts directed? Bharaj designs and manufactures latest technology rubber machinery that saves power, compact in size, has low maintenance, requires minimum labour through smart automation and are user friendly. RD is the crucial for our new launches and product refinement. Our accomplishments and new launches include, - India's first silicon rubber mill. - India's first 4 roll calender with complete line for tyre cord. - India's first 25 mm silicon extruder. - India's first dispersion kneader with intermeshing rotors. - India's first tyre tread cooling line rubber batch off units. Today, our RD investments are directed in areas of high-end software, precise process engineering and overall equipment improvements basis our customer's feedback. RD is the crucial for our new launches and product refinement. Image: Bharaj Make 50 Tons Lab Press. 13 @Bharaj @Bharaj @Bharaj@Bharaj Image: Bharaj Make 4-Roll Open Z-Calender.

- 14. | BHARAJ | Know Your Supplier | JUNE 2016 Which are your fast moving products? Which machinery of yours have larger exports? The wide range of quality machinery made by Bharaj is well-accepted worldwide. Our competitively- priced equipment performs consistently and we extend prompt back-up. We export to developed countries like USA, France, UK, Canada and many Asian countries. And we offer complete solutions in rubber mould manufacturing, rubber moulding, extrusion and rubber mixing areas. I would say that our Mills, Calenders, Presses and Extruders are high in demand. 14 Image: Bharaj Make 120MM CFE with Tube Head. Image: Bharaj Make 90MM Cold Feed Extruder Pin Barrel Type. @Bharaj @Bharaj@Bharaj

- 15. “Complete your Plant with your desired technology to your complete satisfaction on-time through us.” Your Partner in for Rubber Processing MachineryMALAYSIA For your green-field and brown-field expansion or research projects in raw rubber and other technical rubber goods, we can source for you the right machinery to meet your technology requirements, and be your single-window support for after-sales service communication and training in Malaysia. For crucial projects, we train our personnel on the machinery we supply, to give you quick support. In addition, we are established and licenced contractors in Mechanical,Telecommunications, Electrical and Civil Works. Hence, we offer you on turnkey basis - from equipment supply, material handling at site, equipment relocation, erection and installation, services and utilities to equipment commissioning. to know more on ourContact me today team, the equipment brands we partner with, our esteemed clients and full range of services for your rubber related projects. IKATAN TEKUN SDN. BHD. Ahmad Fezal Bin Zakaria Sales Project Manager IKATAN TEKUN SDN. BHD. 1st, Floor, Bangunan Sapura,Lot 2, Jalan Enggang, Kawasan Perindustrian PKNS, Hulu Kelang, 54200, Kuala Lumpur, Malaysia. Tel: (+6) 03 - 425.6 5.589 | Fax: (+6) 03 - 425.7 5.589 * fezal@ikatantekun.com ) (+6) 017-362.79.71 AUTUSCONSULTING@2016

- 16. | BHARAJ | Know Your Supplier | JUNE 2016 16 How do you compete technologically on your product offerings? Starting as a small manufacturing unit, today Bharaj Machineries has evolved into a well-respected machinery supplier for the rubber industry in India as well as in the Global Market in the areas of rubber mould manufacturing, rubber moulding, extrusion and mixing technology. We focus on providing high quality machinery at a competitive price. The wide range of quality machinery made by Bharaj is well-accepted worldwide. Our competitively-priced equipment performs consistently and we extend prompt back-up. We export to developed countries like USA, UK, France, Canada and many Asian countries. Hence, it is also apt to mention here that Bharaj manufactured machineries are considered as a first choice for many rubber related industries starting from Automotive, Sports, Pharmaceutical, Footwear, Tyre, Aerospace and Specialized Silicon Rubber Industry. Depending on the equipment, we offer quick delivery to our customers. Some of our equipment is delivered in as low as 25 days. We focus on providing high quality machinery at a competitive price. The wide range of machinery made by Bharaj is well-accepted worldwide. @Bharaj@Bharaj

- 17. | BHARAJ | Know Your Supplier | JUNE 2016 When a customer places a service request, how do you handle it? We now have a dedicated service department for responding the service query immediate and resolving the problem is totally depends upon the nature of service call. How do you ensure that you deliver high quality solutions and services to your customer? As I mentioned before, we focus on providing high quality machinery at a competitive price. Our dedicated service department gives prompt back-up support for our customer's after-market needs. We design and manufacture latest technology rubber machinery that saves power, compact in size, has low maintenance, requires minimum labour through smart automation and are user friendly. We are certified by leading bodies like TUV, ISO, CRISIL and also an accredited export house. Our quality department works with stringent norms right from raw-material sourcing to equipment final finish. We design and manufacture latest technology rubber machinery that saves power, compact in size, has low maintenance, requires minimum labour through smart automation and are user friendly. Image: Bharaj Make Sheeting Line of 75 Liter Kneader and 22x60 Mixing Mill 17 @Bharaj@Bharaj

- 18. | BHARAJ | Know Your Supplier | JUNE 2016 VISION: To increase the productivity by supplying smart, cost effective machines. (L-R): Amardeep Singh Bharaj (Director - Sales Projects), Balraj Singh Bharaj (Founder Chairman), and Jaspal Singh Bharaj (Director - Technical) 18 As process partners with comprehensive industry knowledge, our teams of specialists provide good quality products, thus achieving the optimisation of technology, systems expertise. In this manner we strengthen the competitive strength of our customers throughout the world. MISSION: To offer the market our best efforts in tune with highly sophisticated technical products and services. As global market expects from an International player .

- 19. 1.DISPLAYYourProductsRegularlytoBuyers. 2.COMMUNICATEYourCompetenciesDifferently. 3.ATTRACTMoreBuyerstoYourBrandInformatively. Because we publish digitally on our portal and promote on social media differently, Buyers get all information of Your Products Solution anytime and anywhere - on any smart gadgets they use (Phone, Tab, Laptop or Desktop). For more details and your customized advertising, please email us at engage@rubbermachineryworld.com On-The-Go With Your Info ReachMachineryBuyersFast.Anytime.Anywhere. ADVERTISE On RUBBERTYREMACHINERYWORLD INFORMATIONONEQUIPMENT,TECHNOLOGY,INNOVATIONSUPPLIERS OptimizedRoIOfYourEquipmentMarketingForRubberTyreIndustry InfoPortal|DigitalMagazines|SocialMarketing Machinery World Rubber Tyre Know A LEADERIn 10 Questions Rubber Tyre Information On Equipment, Technology, Innovation Suppliers Machinery World Rubber Tyre Technology Innovation Special Edition Supplier Know Your rubbermachineryworld.com / tyremachineryworld.com Rubber Tyre Equipment - Accessories

- 21. | BHARAJ | Know Your Supplier | JUNE 2016 What are your infrastructure and capabilities? Bharaj has a ultra –modern and state- of-the-art manufacturing plant near Mumbai measuring 30,500 Sft and 2400 Sft corporate office. Our plant is equipped with high tech CNC machines and other latest equipments, gadgets to make the best quality product. We are certified by TUV and also offer CE marked customized machinery. Would you say Bharaj is innovative? Bharaj is indeed innovative. We listen carefully to our clients process related problems adopt them to make it process friendly. Every second machine has something new to offer. We believe in giving more value on our products. Image: India’s first fully Automatic Tyre Cord Calender Line Every second machine has something new to offer. Are you launching any new products this year? Any expansion plans? Yes. Bharaj believes in designs and manufactures latest technology rubber machinery that saves power, compact in size, has low maintenance, requires minimum labour through smart automation and are user friendly. We are expanding our product range that includes new line-ups. It's all under wraps for now. However, you can expect Bharaj to make a grand announcement of the launch of our new range of machinery shortly. 21 @Bharaj@Bharaj

- 22. | BHARAJ | Know Your Supplier | JUNE 2016 22 Image: Bharaj Make 22x66 Three-Roll Calender Line. Trelleborg Group (World Wide), Bridgestone Tyres, Ceat Tyres, Anand Group, Metzeller, Dupont, Loadstar, Parker, Gates India, Momentive Performance Materials, Wacker Silicons, etc Key Customers - CE and Non-CE Equipment - Vacuum / Compression Type Rubber Moulding Machine - Cold Feed Rubber Extruders (Plain / Vent / Pin Barrel / Co-Extrusion) - Heavy Duty Rubber Mixing / Refiner / Cracker / Grinder Mills - Rubber Dispersion Kneaders - Hot Feed Rubber Extruders - Silicon Rubber Extruders, Mills and Strainers - Calenders with complete lines (2, 3 4 Rolls) - Batch-Off Units / Vulcanizers / Bale Cutters / Conveyors / Rotocures - Tread Cooling Lines Product Range @Bharaj@Bharaj

- 23. - Quick Deliveries, and Prompt Back-up Support - Designs that are power-saving, compact, requires minimum labour, and has zero maintenance. - Latest Technology machinery that are user-friendly. USP’s | BHARAJ | Know Your Supplier | JUNE 2016 - Design, Manufacturing, Supply, Commissioning of Rubber Machinery in the areas of rubber mould manufacturing, rubber moulding, extrusion and mixing technology. - After Market Sales, Spares Service Support. Core Competencies 23 @Bharaj@Bharaj Image: Bharaj Make Star Blade Cutter - Heavy Duty - 40 Tons.

- 24. InfoPortal|DigitalMagazines|SocialMarketing 1.DISPLAYYourProductsRegularlytoBuyers. 2.COMMUNICATEYourCompetenciesDifferently. 3.ATTRACTMoreBuyerstoYourBrandInformatively. ADVERTISE On Because we publish digitally on our portal and promote globally, Buyers get all information of Your Products Solution anytime and anywhere - on any device (Phone, Tab or Computer). Or email us at engage@rubbermachineryworld.com And SELL MORE For more details and your customized advertising, please visit http://rubbermachineryworld.com A Story Every Has....Machinery Every Has...Technology And As Equipment Supplier, Denitely Have...YOU Let Equipment Buyers Know You, Your Products Your Technology Better. WhatIsYourStoryToday? Equipment Marketing Redefined ReachMachineryBuyersFastIn3Steps MM RUBBER Rubber Machinery World http://rubbermachineryworld.com http://tyremachineryworld.com MM TYRE Tyre Machinery World Machinery World Rubber Tyre Know A LEADERIn 10 Questions Rubber Tyre Information On Equipment, Technology, Innovation Suppliers Machinery World Rubber Tyre Technology Innovation Special Edition Supplier Know Your rubbermachineryworld.com / tyremachineryworld.com Rubber Tyre Equipment - Accessories

- 25. | BHARAJ | Know Your Supplier | JUNE 2016 Image: Bharaj Team during a Trial (Top) Plant Factory Building (Left) Varied Product Range (Bottom) Our plant is equipped with machines, latest equipments and gadgets to make the best quality product. @Bharaj@Bharaj 25

- 26. | BHARAJ | Know Your Supplier | JUNE 2016 What changes do you see happening in the rubber processing machinery industry? How are you positioning and preparing Bharaj for these changes? I feel that there is a big transition phase with customers emphasizing on electricity consumption cost, and demand for maintenance-free equipment. Newer designs are more compact suiting the customized requirements of our customers. We are expanding our product range that includes new line-ups focusing on rubber machinery that are efficient, high in productivity and user friendly. Image: Fully automatic compression moulding machinery 26 What's your approach towards communication? How easy is it for your existing customers and future buyers to reach you and exchange information? We believe in transparent and quick communication. Bharaj team members are always available for our customers and reachable on phone or email irrespective of our normal office working hours. We are expanding our product range that includes new line-ups focusing on rubber machinery that are efficient, high in productivity and user friendly. @Bharaj@Bharaj

- 27. | BHARAJ | Know Your Supplier | JUNE 2016 Is Bharaj in good financial health and sufficiently funded to grow? Yes, Bharaj is good financial healthy and is sufficient funded to grow. Where do you see Bharaj in the next 10 years? Our vision is to increase the productivity of our customers by supplying smart, cost effective machines. Over the next few years, I see Bharaj emerging as a strong leader in our various business segments with dedicated divisions catering to different markets. What is your advice on equipment selection to buyers of rubber and tyre machinery? Capital machinery is a very important part of any company, it is going to earn money every minute, saving something on initial Amardeep Singh Bharaj Director (Sales Projects) RMW capital equipment should not be the motto, one should keep in mind production capacities. Our vision is to increase the productivity of our customers by supplying smart, cost effective machines. Over the next few years, I see Bharaj emerging as a strong leader. ........... And More NEW INFORMATION DIFFERENTLY Every Month With Machinery World Rubber Tyre Know A LEADERIn 10 Questions Rubber Tyre RUBBERTYREMACHINERYWORLD INFORMATIONONEQUIPMENT,TECHNOLOGY,INNOVATIONSUPPLIERS Information On Equipment, Technology, Innovation Suppliers Machinery World Rubber Tyre Technology Innovation Special Edition Supplier Know Your rubbermachineryworld.com / tyremachineryworld.com Rubber Tyre Equipment - Accessories 27

- 29. | INSIGHT | Things You Should Know About Hydraulic Power Pack https://rubbermachineryworld.com/2016/03/16/13-things- you-should-know-about-hydraulic-power-pack/ 13 This section is bought to you in association with our brand display partners 29 If you have seen or used an Internal Mixer, Bale Cutter, Press, or any Hydraulic machinery then you have witnessed a Hydraulic Power Pack in operation. Here are 13 things you should know about Hydraulic Power Pack. Image Source: RMF Know Your Supplier | JUNE 2016

- 30. | INSIGHT | 1.By definition, hydraulic power packs are self-contained power-units used instead of a built-in power supply, to transmit power from one location to another and thus run your rubber machinery. A hydraulic system employs enclosed fluid to transfer energy from one source to another, and subsequently create rotary motion, linear motion, or force. 2.Hydraulic power packs come in different shapes and sizes; some are very large and stationary whereas others are smaller and compact. The mechanical characteristics and specifications of a hydraulic power pack dictate the type of applications for which it can be effective. 3.You can identify hydraulic power packs through its main components. Because irrespective of the size of the unit, all power packs will have the following; ▪ A hydraulic reservoir (or tank) which holds the enclosed oil. This is a storage unit designed with enough volume for the oil in the pipes to drain into it. They also ensure this oil is stored and maintained in the best possible condition. Reservoirs will come in different sizes. Common auxiliaries for a reservoir include filler/breathers and drain ports, level gauge, level switches and inspection covers. ▪ Regulators that control and maintain the amount of pressure that the hydraulic power pack delivers. These are very vital. ▪ Pressure Supply lines and Relief lines. The supply line supplies fluid under pressure to the pump and the relief lines relieve pressure between the pump and the valves. The relief lines also control the direction of flow through the system. ▪ Motor to power a pump ▪ A pump to perform two actions. Firstly, it creates a vacuum at the pump inlet and with the help of atmospheric pressure, forces fluid from the reservoir into the inlet line. This fluid is then fed to the pump. The pump then delivers this fluid to the pump outlet and force feeds it into the hydraulic system. 4.Some of the important factors that influence a hydraulic power unit's performance are pressure limits, power capacity, and reservoir volume. In addition, its physical characteristics including size, power supply, and pumping strength are also significant considerations. Reputed suppliers take great care to ensure that a large, durable hydraulic power unit is built for functioning under a range of environmental conditions. Electric Motor Accumulator Hydraulic Valve Manifold Block Pressure Switch Air Breather Pressure Gauge Adaptor Pressure Gauge Web Image only for representation. All Copyright belongs to Original Owners. Know Your Supplier | JUNE 2016 30

- 32. | INSIGHT | 5.Hydraulic power packs have other components like ▪ Filters: Filtration is a critical part of a hydraulic power pack, ensuring wear is minimised and efficiencies are maintained. Basic suction strainers do not allow large contaminants to enter the pump. Pressure filters are normally configured at the pump outlet and ensure only filtered oil enters the hydraulic system. Contamination within the system is filtered out by the return filter before it enters the hydraulic reservoir. ▪ Pressure Control valves that limit or control the hydraulic pressure within the hydraulic system. ▪ Directional Control hydraulic valves (manual, electrical, pneumatic or hydraulic operated) direct the oil flow around the system to operate actuators, motors or other functions. ▪ Cooling is another other key consideration, where efficiencies within a system or machine will produce heat in the oil; this must be cooled to ensure long life and high-efficiency. ▪ Accumulators: These are containers that can be attached to the hydraulic actuators. They collect oil from the pump and are intended to build and maintain fluid pressure to supplement the pumping system. ▪ Coolers and Heaters: As part of the temperature regulation process, an air cooler can be installed near or behind the filter unit to prevent temperatures from rising above operational parameters. Likewise, a heating system, such as an oil- based heater, can be used to elevate temperatures when necessary. ▪ Power Unit Controllers: The hydraulic controller unit is the operator interface containing power switches, displays, and monitoring features. It is necessary for installing and integrating a power unit into a hydraulic systems, and can usually be found wired into the power unit. Oil level and temperature protection switch, Pressure switches and filter clogging switches are quite common. 6.Hydraulic power packs come with a variety of valve connections. This means that you can power a variety of rubber and tyre machinery by using the appropriate valves. Most manufacturers segregate their models into a 'standard', 'mini', 'micro' or 'bespoke' power pack categories. 7.When picking a hydraulic power pack there are a variety of pumps and options to pick from. Hence, it is important to pick the right power pack to meet your machines needs. It is also important to consider a power pack that will help maximise productivity and minimise cost. Geared Coupling Gear Pump Suction Filter Tank-Top Filter Heat Exchanger Check Valve Web Image only for representation. All Copyright belongs to Original Owners. Know Your Supplier | JUNE 2016 32

- 34. | INSIGHT | 8. In rubber and tyre machinery, you would need custom design of your hydraulic power packs depending on the features you select and how you select. For eg, you could either opt for a single power pack for your drop door and hydraulic ram operations of a mixer; or choose separate power packs for individual operations depending on the circumstances at your plant. 9. Your supplier should review the pressure and flow data together with you. And they should also take load profiles and the thermal budget into account. Doing this ensures that you get a power pack that precisely meets your technical requirements and operates economically. 10.It is ideal if you or your machinery supplier get everything integrated from a single source. Because, fewer interfaces means your hydraulic system gets built faster. Your costs are lower, too. 11.Experts recommend use of high- efficiency low-noise internal gear pumps when designing power packs. Your supplier may consider accumulator charging technology or variable speed drives as may be the case for your application. Multiple pressure circuits are another option. 12.Hydraulic power packs require regular maintenance to ensure they work properly and safely for extended periods of use. Maintaining hydraulic power packs is relatively simple. You should check the tubing for any noticeable problems such as dents or cracks. You should also inspect the reservoir to check for any corrosion or rust. And do regularly change the hydraulic fluid as per recommended maintenance schedule of your hydraulic power pack 13.Hydraulic power packs must be installed and mounted in a clean and dry location void of any standing water or accumulated run-off. Summarizing, you should opt for a power pack that has low power consumption, requires very little installation space, and operates with low cooling requirements. This would mean that your operating costs are very low for the unit and it's easy to integrate into your main machinery. All of these would help you procure power packs featuring high reliability and availability on the one hand, and easy and cost-effective integration into your rubber machinery on the other. Did I miss some aspects? Would you like to add more to this list? Comment on our web portal to share your knowledge with us and other readers too. This section is bought to you in association with our brand display partners RMW Know Your Supplier | JUNE 2016 34

- 35. Excellent Capability for Customized Heavy Rollers. Please contact4th Axes Precision CNC Machining ROLLERS, SCREWS, FIXTURES MOULDS FOR ALL YOUR RUBBER AND PROCESSING MACHINERY. GET CUSTOM MACHINED SubAero Precision Machining (An ISO 9001:2008 Certified Company) Corp Office: 8/Trivedi Niwas, New Nagardas Road, Andheri (East), Mumbai - 400 069, India. Ph: +91-22-28256599, +91-22-28378478 (Fax) www.subaero.com | Email: info@subaero.com ■ IN-HOUSE CAD CAM STUDIO ■ 3 AND 4 AXIS MACHINING CAPABILITIES ACCURATE AND RELIABLE INSPECTION■ REPORTS THROUGH IN-HOUSE CNC CMM ■ SKILLED AND TRAINED MANPOWER TIMELY DELIVERY■ 24x7 POWER BACK-UP■ AT OUR STATE-OF-THE-ART CNC MACHINING CENTERS, WE GUARANTEE YOU HURCO DCX 32 Vertical Machining Centre UNFAILING PARTNER AND DEPENDABLE SUPPORT FOR YOUR DESIGN TO MANUFACTURING NEEDS AUTUSCONSULTING@2016

- 36. Image: Image from Web only for representation 36 | TIPS | Know Your Supplier | JUNE 2016

- 37. | TIPS | Know Your Supplier | JUNE 2016 The Biggest Problem with Heat Transfer Efficiency in Rubber Machinery (And How You Can Fix It) https://rubbermachineryworld.com/2015/11/18/the-biggest- problem-with-heat-transfer-efficiency-in-rubber-machinery/ 37

- 38. Rubber processing has a bizarre energy pattern, when seen from a layman's perspective. Because you add heat into your process and then you cool down! Heat addition and removal is repeated in each of your subsequent stages as well. When you process rubber, energy is consumed across the value chain – right from transport of raw rubber, to the various processing operations (be it rubber mixing, rubber extrusion, rubber calendering, moulding etc) to convert into your suitable product and then transportation of your product. This implies that you need to cool down your rubber processing machinery regularly, which simultaneously involves heat exchange from a hot medium to a cooler medium. And the most common medium to cool is water. But where there's water, you will face water-related problems caused by its mineral deposits. These deposits could give you varying degrees of water-related problems that affect your operating efficiencies and/or even leading to more costly equipment downtime issues. This could be in your Rubber Machinery like Mixer, Mixing Mill Rolls, Calender Rolls, Press, Extruder, Heat Exchangers, Moulds, and factory equipment like Boilers, Chillers, Compressors, and TCU's or other Ancillary Units, etc. You would notice that the mineral deposits accumulate quickly regardless of screens or treatment actions adopted. Even a thin coating of water scale will act to insulate the water system's surface and retard the transfer of heat. Hence, scaling is the biggest problem affecting the heat transfer efficiency in rubber machinery. Even a thin coating of water scale will act to insulate the water system’s surface and retard the transfer of heat. | TIPS | Source: Tangram 38 Know Your Supplier | JUNE 2016

- 39. AMCL MACHINERY LIMITED SERVICE TO THE NATION FOR FOUR DECADES For all your enquiries please contact: AMCL MACHINERY LIMITED Works: Plot No.A1/1, MIDC, Butirobi-441122, Nagpur Mumbai office: 202, Ackruti Centre Point, MIDC Central Road, Andheri (East), Mumbai-400 093. Contact person: Mr. S.H. Mehta Mobile No. +91-9004697430. Email: Website: www.amcl.inshmehta@amcl.in • Rubber Mixer – 76 liter and 270 liter. • Mixing Mills – 16, 22, 26 and special sizes • Hot feed extruders – 6 and 8 • Rubber Calenders – 2/3 rolls. • Bias Tyre Building machine – RB1/RB3 • Automatic LCV Tyre Building Machine – RB1619 • Automatic Truck Tyre Building Machine-RB2022 • Mechanical Tyre Curing Presses – Scooter to Truck size • Bladder Curing Presses • Tube Splicers Product Range

- 40. To increase heat transfer efficiency, lower maintenance cost, conserve overall energy consumption and thus enhance the usable life of your machinery, removing scales in all your water-cooled or water-heated rubber and tyre equipment is very important. In a simple rubber machinery like the mixing mill, the presence of scales on rolls leads to localized hot spots affecting your mixing quality. In the case of boilers, scales can be very damaging leading to even boiler rupture. When water scale, lime and rust deposits accumulate on the water side of chambers, rotors and the drop door of the Mixer, it causes temperature of your rubber stock to rise and gradually lead to a loss in production. Different machinery has different safe and effective method to remove scales. Recently, | TIPS | Image: RYDLYME 40 Know Your Supplier | JUNE 2016

- 41. KELACHANDRA MACHINES (MFRS. OF RUBBER INDUSTRIAL MACHINERY) Chingavanam - 686 531, Kottayam, Kerala. India. Phone Off: +91- 481-2430325. Fax: +91- 481-2430596 e-mail: km1912@gmail.com

- 42. I was shown an instruction sheet, from one of the descalers (RYDLYME), on the process to descale a rubber mixer that I found interesting. Here's the process reproduced. I hope you too find it informative. 1. Take mixer out of service. 2. Close water supply valve at header as shown in the sketch above. 3. Drain all water from all sections of mixer. 4. Connect Descaling Solution pump discharge hose to water header. Header usually supplies all circuits. 5. Connect return hoses to drain lines from all circuits and place into the Descaling Solution receiver. 6. Close water supply valves to gate and jacket circuits. 7. Start pump and pump the descaling solution into rotors to purge the water from this circuit to sewer. When the descaling solution begins to discharge from this hose, return to the receiver. 8. Open water supply valve to gate and maintain Descaling Solution circulation through this circuit. 9. Open water supply valve to jacket and maintain Descaling Solution circulation through this circuit. 10. If any circuit is NOT flowing properly, restrict Descaling Solution flow in other circuits until flow returns to normal in this circuit. 11. Circulate a total of 120 Litres of Descaling Solution through all circuits of mixer until clean. This will require approximately four hours pumping time. 12. It is suggested to periodically rotate the rotors during Descaling Solution cleaning to assure that the Descaling Solution is in contact with all of the lobes of the rotor. 13. Upon completion of cleaning, flush all Descaling Solution from all circuits with fresh water. 14. Disconnect the Descaling Solution pump and all hoses. The mixer is now ready to be returned to service. 15. Periodic descaling will keep the temperatures of the mixer within acceptable limits, assuring you a better product and minimize burnt or improperly mixed stock. 16. Clean out the Descaling Solution System and store for future use. Summarizing, scaling is the biggest problem with heat transfer efficiency in your rubber machinery. Descaling or cleaning the scales helps you fix this issue. Hence incorporating descaling solutions into your preventive maintenance program is recommended to keep your equipment running effectively and economically. To increase heat transfer efficiency, lower maintenance cost, conserve overall energy consumption and thus enhance the usable life of your machinery, removing scales in all your water- cooled or water-heated rubber and tyre equipment is very important. | TIPS | 42 Know Your Supplier | JUNE 2016 RMW

- 43. Rubber And Tyre Machinery Now Has An Online Address MM RUBBER Rubber Machinery World http://rubbermachineryworld.com http://tyremachineryworld.com MM TYRE Tyre Machinery World http://rubbermachineryworld.com http://tyremachineryworld.com FREE Access On All Your Devices - Power Your Business Forward With Authentic Information On - Equipment Allied Machinery - Technology - Equipment Suppliers - Read, Absorb Implement Ideas From - Insightful Interviews Of Leaders - Informative Articles - Special e-Editions e-Books - Short Updates Curated from the World Of Machinery Every Thursday In Your Inbox - Resourceful Downloads For Day-to-Day Use - Plan For Your Conferences Expo from event dates - Book Store with Best Rubber Books For Your Quick Buy - Key Documents/Directories to take Powerful Business Decisions Available For Purchase. - Left-Oriented Clean Layout for your easy reading. - Follow Us on Twitter, Google+, LinkedIn Pinterest. Attention: Equipment Buyers Users JOIN OUR READERS FROM 130+COUNTRIES SUBSCRIBE TODAY FOR FREE BENEFIT

- 46. Email: engage@rubbermachineryworld.com ©2016 – ePublished by Rubber Machinery World in JUNE 2016 Content For Free eDistribution Download INFORMATION ON EQUIPMENT, TECHNOLOGY, INNOVATION SUPPLIERS ........... And More Practical Solution www. .comracsol KELACHANDRA MACHINES Know More On EQUIPMENT SUPPLIERS And Their SOLUTIONS For YOU Stay Updated On Rubber Tyre Machinery And Their Suppliers. ........... And MoreINFORMATION PORTAL | E-MAGAZINES | INTERVIEWS | KNOWLEDGE PARTNERS | DOWNLOADS Rubber And Tyre Machinery Now Has An Online Address MM RUBBER Rubber Machinery World http://rubbermachineryworld.com http://tyremachineryworld.com MM TYRE Tyre Machinery World ........... And More