Timber ppt final

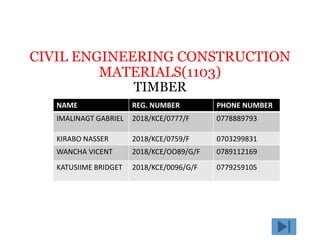

- 1. CIVIL ENGINEERING CONSTRUCTION MATERIALS(1103) TIMBER 1 NAME REG. NUMBER PHONE NUMBER IMALINAGT GABRIEL 2018/KCE/0777/F 0778889793 KIRABO NASSER 2018/KCE/0759/F 0703299831 WANCHA VICENT 2018/KCE/OO89/G/F 0789112169 KATUSIIME BRIDGET 2018/KCE/0096/G/F 0779259105

- 2. DEFINITION Timber is wood which retains its natural physical structure and chemical composition and its suitable for various engineering works. Structure of timber 2

- 3. Classification of Timber • Mode of Growth a.exogens (exogenous) – these trees grow outward. coniferous trees deciduous trees b.endogens (endogenous) – these trees grow inwards. • modulus of elasticity • durability high durability moderate durability low durability 3

- 4. Classifications of Timber • seasoning characteristics • high refractory (class a)(likely to be damaged severely) • moderately refractory (class b)(have a tendency to split or crack during seasoning) • non refractory (class c)(rapidly seasoned without any trouble) • grading 4

- 5. General properties of timber o Color – a darker color in wood indicates greater durability. o Odor – it is present only on freshly cut trees. o Hardness – is the ability of wood to withstand indentations caused by harder bodies. o Density – densest woods are generally the strongest. o Texture - In hardwoods, the texture depends upon the size and distribution vessels and rays. In softwoods, it is determined by the size and distribution of tracheid. 5

- 6. General properties cont.… Workability- the relative case in which wood is shaped cut and fastened together than the others. Warping- is the general term used to describe any variation from a true surface. Moisture content- is a percentage of the mass of water over the mass of wood fiber in a piece of timber. 6

- 7. 1. Tracheid - These are hollow, needle-shaped units closely packed together so that a cross-section through them resembles a honeycomb. 2. Storage Tissues (Rays and Wood Parenchyma Cells) - They are too small to be seen individually and are not of much in identification. 3. Resin Canals - these canals are not cells but are cavities in the wood lined by the parenchyma cells. 4. Growth Rings - these are normally distinct in softwoods. 7

- 8. Structures of Hardwoods 1. Pores or Vessels – these are tubular elements running in a vertical direction and serve to conduct water and mineral nutrients. 2. Parenchyma or Soft Tissues - these are storage tissues and consist of small, thin-walled, rectangular or brick-shaped cells. These are vertically aligned. 3. Rays - are groups of horizontally aligned parenchyma cells running in a radial direction and their function is horizontal conduction and storage. 4. Intercellular cells – These are long tubular cavities seen in the horizontal or vertical direction. 8

- 9. Qualities of good timber • 1. Hardness A good quality timber should be hard enough to resist deterioration. • 2. Strength it should have sufficient strength to resist heavy structural loads. • 3. Toughness it should have enough toughness to resist shocks due to vibrations. It should not break in bending and should resist splitting. Timbers having narrow annual rings, are generally the strongest. • 4. Elasticity it should have the property of elasticity so as to regain its original shape after removal of loads. This is a very important property to be considered if the timber is used in making sport goods. • 5. Durability it should be able to resist attacks of fungi and worms and also atmospheric effects for a longer period of time. 9

- 10. Qualities of good timber cont.… • 6. Defects timber should be prepared from the heart of a sound tree and be free from sap, dead knots, shakes and other similar defects. • 7. Fibres and structure it should have straight and closed fibres and compact medullary rays. It should give a clear ringing sound when struck. Dull heavy sound is an indication of internal decay. Its annual rings should be uniform in shape and colour. Structure of a timber • 8. Appearance and colour freshly cut surface should give sweet smell and present shining surface. It should have dark color, as light colored timbers are generally weak in strength. • 9. Shape and weight it should retain its shape during the process of seasoning. Heavy timbers are always stronger than light weight timbers. • 10. Workability it should be well seasoned and easily workable. Teeth of saw should not get clogged during the process of sawing. It should provide smoothened surface easily. 10

- 11. Felling and Conversion 11 • Felling and Transporting the Timber Felling is done by a clean saw cut as near to the base as possible. Transporting the log to saw mill is done either by road transport using big trucks Sawing. Is the splitting of wood into timber. Conversion; this is the cutting of timber into marketed sizes and shapes. Methods of conversion Ordinary or Flat conversion Tangential conversion Radial conversion Quarter or Rift conversion Combination conversion

- 12. • The quarter sawn is far more expensive because of the need to double (or more) handle the log. There is also more wastage. It is however more decorative and less prone to cup or distort. Note also there are two ways of sawing the quarter. • Through and through produces mostly tangentially sawn timber and some quarter sawn stuff. (See diagram) tangential timber is the most economical to produce because of the relatively less repetitive production methods. It is used extensively in the building industry 12

- 13. • Moisture Content - It s one of the most important characteristics of timber that affects its use on the site performance. • Equilibrium Moisture Content (EMC) - moisture content of wood changes in response to the temperature and humidity of its surroundings. • Fiber Saturation Point (FSP) – when the cell cavities are empty but the cell walls still retain their bound water. 13

- 14. Seasoning of timber Defn: Seasoning of timber is the process by which moisture content in the timber is reduced to required level. A well-seasoned timber has 15% moisture content in it. The methods include; 1. Natural/Air seasoning. Natural seasoning is the process in which timber is seasoned by subjecting it to the natural elements such as air or water. Natural seasoning may be water seasoning or air seasoning. 2. Artificial /Kiln seasoning. Natural seasoning gives good results but takes more time. So, artificial seasoning of timber is developed nowadays. By artificial seasoning, timber is seasoned with in 4-5 days. Here also different methods of artificial seasoning are there and they are as follows. Seasoning by Boiling, Chemical seasoning, Kiln seasoning and electrical seasoning. 14

- 15. Advantages of seasoning It ensures that no shrinkage takes place before the timber is used It ensures the moisture content of timber is below the dry rot safety line 20% Dry timber is easier to work with than wet timber Using seasoned timber gives a more reliable and is less likely to split or distort (dry timber is stronger and stiffer than wet timber) Wet timber will not readily accept glue, paint or polish. etc. 15

- 16. Disadvantages of seasoning • Some seasonings methods contain a chemical called TCP and this may be detrimental to health if over exposed. • Seasoning is not always uniform in all the sections of timber. • Some seasoning methods are very slow process like natural seasoning. • Some seasoning methods are expensive like electrical methods. 16

- 17. Mechanical Properties 17 • Tensile Strength Timber is stronger in tension along the grain but it’s quite difficult to determine this because of the difficulties in conducting test. • Compressive Strength The strength along the grain is important for columns, props, and post. • Shear Strength Shear strength is important in the case of the beam and slabs. • Bending Strength or Flexural Strength This refers as the strength of the timber as a beam.

- 18. 18 • Brittleness is use to describe the property of suffering little deformations before breaking. • Hardness is important in case of timber for paving blocks flooring bearings and other similar purposes. • Stiffness This property is important to determine the deflection of a timber under a load

- 19. Defects in Timber 19 Defects caused in timber may be basically classified into two categories: Internal Defects These are due to factors affecting the growing tissue or the tree. External Defects These take place due to external agents or subsequent treatment of timber.

- 21. knots 21 The central part or stem of a tree is majorly used in the conversion of timber. Branches from the stem are removed and whole rounded stem is taken. But the base of branches forms a mark on the stem which results dark colored stains on the surface after conversion. Examples include; Live knots, dead knots, decay knots, Loose knots.

- 22. Defects in Timber due to natural forces cont’d 22 • Shakes- or cracks are caused by the rupture of tissues resulting in partial or complete separation of the fibers along the grain. » Star Shakes » Heart Shakes » Cups Shakes » Ring Shakes » Radial Shakes

- 23. Classification of Defects in Timber 23 Rind Galls- these are typical curved swelling formed upon the trunk of the tree by successive layer of the sapwood. Upsets- are clipping or buckling of fibers caused by crushing of fibers when the trunk is felled violently over a rocky surface. Twisted or Spiral Grain- fibers or wandering hearts are caused by the prevalent wind turning or twisting the tree at its young age constantly in one direction. Wind Cracks- are shakes on the outside of a log due to the shrinkage of the exterior surface caused by the atmospheric influences.

- 24. Defects Due to Seasoning 24 • Bow- a curvature of the timber in the direction of its length. • Cup- a curvature in the transverse direction of the timber. • Twist- a spiral distortion along the length of the timber. • Spring- a curvature of the timber in its own plane. • Case Hardening- it is due to the unequal drying of the exterior surfaces under compression and the interior surfaces under tension due to rapid drying. • Split- separation of the fibers along the grain and extends from one end of the plank to the other. • Honey Combing- separation of the fibers in the interior due to drying stresses. • Collapse - the cells of timber are flattened due to excessive shrinkage

- 25. Defects Due to Manufacturing or Use • Chipped or Torn Grain- a defect caused by the breaking away of timber below the surface of the dressing by the action of the planning tool. • Chip Mark- indentation on the finished surface of the timber caused by the chips or other small pieces of the timber being carried around on the planning knife edges. • Wane- the original round surface of a tree which remains on finished plank. • Boxed Heart- the pith at the center fully enclosed within one piece in the process of conversion. 25

- 26. Decay of Timber/Defect associated with fungi • Decay or Rot - is usually caused by the presence of sap or by the alternate dry and wet condition of the timber. Forms of Decay Wet rot Dry rot Due to fungal attack Due to insects Wet Rot - This is a decomposition of sap and fibers of the living tree set up by the access of water through wounds in the barks. Dry Rot - This is a decomposition of converted timber induced by the commonest and most destructive dry rot fungi or weeping fungus. 26

- 27. 27

- 28. Decay of Timber Due to fungal Attack A fungus starts its life as a tiny seed or spore, one of millions produced at the fruiting stage. o Fungi are system plant organisms which live on and attack timber causes it to rot or decay. o Fungi can only exist in following condition: • Air for their respiration • Moisture • Suitable Temperature • Food Supplies 28

- 29. Defects of Timber by insects a) Beetles: b) Small insects form holes of size about 2mm diameter and attack sap wood of all species of hard woods. Tunnels are formed in all directions in sapwood by the larvae of these beetles and converted into fine flour like powder. They do not disturb outer cover and looks sound. c) Marine borers: d) These make holes or bore tunnels in wood for taking shelter. The wood attacked by marine borers loses color and strength e) Termites: f) White ants are very fast in eating away the wood from the core of the cross section. They make tunnels inside in different directions and usually do not disturb the outer shell or cover 29

- 30. Seasoning of Timber • REASONS OF SEASONING -To reduce movement of timber, to reduce the tendency to split. -To make it immune from attack by insects. -To increase strength, durability, workability and resilience. -To make the timber receptive to finish like preservatives, paints, and varnish. -To reduce weight and minimize cost of transportation. -To make the timber burn readily, if used as a fuel. 30

- 31. Preservation of Timber • Preservatives Types: • Oil Type coal tar creosote with or without admixture of petroleum, coal tar, fuel oil or other suitable oils having high boiling range. • Organic solvent type consist of toxic chemical compounds dissolved in a non- aqueous solvent like volatile oils, spirits, naphtha etc. • Water-soluble(leachable) these preservatives are inorganic salts soluble in water. • Water-soluble (Fixed) These consists of the various salt described above with the addition of fixative salt, usually sodium or potassium dichromate. 31

- 32. Preservation of Timber • Characteristics of a Good Preservative o It should be strongly toxic to insects and fungi. o It should penetrate readily into the timber. o It should not be soluble in water nor should it change in composition under o ordinary climatic condition. o It should cover a large surface area with a comparatively small quantity of preservative. o It should have no destructive influence on the strength of the timber. o It should be harmless to human beings. o It should not render the timber treated with it more inflammable. oIt should not be non-corrosive to metals. oIt should be pleasant in color and give an attractive appearance to the wood work. oIt should be highly resistant to water and dampness. oIt should be economical and available readily 32

- 33. Preparation of Timber for Treatment • Methods of Treatment • Surface Application • Soaking • Hot and Cold Process • Boucherie Process • Diffusion Process • Pressure or Pneumatic Process •Full Cell or Bethel Process •Empty Cell Process •Choice of Treatment 33

- 34. Fire-proofing of Timber • Timber about a particular thickness, cannot support self-sustained combustion and continue to burn only when external heat is applied. • Timber cannot be made fire proof but can only be made fire resistant. • It is supposed that the fire-proofing chemicals act in one of the following ways: The melting point of the chemicals is low so that it melts and forms a barrier to the supply of oxygen to the inside. The chemical decomposes under heat, yielding non-inflammable gases that dilute the inflammable gases. This retards the ignition of inflammable point. The chemical vaporizes at sufficiently low temperature, absorbing sufficient heat that the temperature of wood does not rise to decomposition point. 34

- 35. Commontimber 35 Teak - The sapwood is pale yellowish or greyish-white in color and is distinguished from heartwood. The heartwood is golden brown and turns a dull deeper brown on exposure. Deodar - The sapwood is white to creamy white and is distinct from the heartwood which is light yellowish brown turning to pinkish brown on exposure. Chirr - The sapwood is white to creamy white and is distinct from the heartwood which is light yellowish brown turning to pinkish brown on exposure. Kail - The yellowish in white to greyish sapwood is white to pale-yellowish white in color and is distinct from the heartwood which is light pinkish-red to light red. Sal - The sapwood is pale-yellowish or brownish white and is distinct from the heartwood which is brown or reddish brown. Mango - This is brown in color.

- 36. • Advantages of Timber 36 •It is readily available. Timber is a natural material used in many forms for building and construction. It is readily available, and can be easily sourced from many building material suppliers all over Australia. •It is safe. Since it comes from a natural source, timber is non-toxic. It is safe to handle and even as it ages, it will not cause damage to the environment. It is safe to reuse or recycle and maximises Green Star Energy rating and carbon credits. Most timbers these days are endorsed or sustainably harvested to return a great life cycle. •It is easy to work. Due to its lightness, density and grain structure, and the fact we have been using timber in buildings from the early ages we have highly developed machinery to cut, drill and prepare timber to the required size and shape. Even hardwood timbers are relatively easy to work with compared to other building materials such as steel. •It is cost effective. Timber is the cost effective alternative to many other materials, if you consider the life cycle of timber it has less steps to process than many other building materials, therefore less to produce. •It is versatile and visually appealing. As timber comes in many different grades and species this gives timber a huge reach across many different uses and appeals. Structural and visual grade timbers are often chosen for outdoor structures. •It is naturally anti-corrosive. Unlike steel and other highly used building materials timber does not corrode in salt air or heavy industrial environments.

- 37. Availability and Uses Of Timber • Advantages of Timber I. Timber has better insulating properties than any other materials. II. Durability of timber can be very high, if properly seasoned and preserved. III.Timber constructions are light in weight and can be made economical. IV.For aesthetic and decorative appearance. 37

- 38. Wood Products 38 • Veneers - thin sheet of wood, 0.4 mm to 0.6 mm in thickness obtained by different knife cutting process. i. Rotary veneers ii. Cutting sliced veneers • Plywood - is made by gluing together veneers. Plywood grades and sizes Boiling water proof (BWP) grade Boiling water resistance (BWR) grade Warm water resistance (WWR) Cold water resistance (CWR) grade

- 39. Wood Products cont.… 39 • Advantages of plywood I. It has a good strength both across as well as along the grain. II. Plywood has better splitting resistance due to grains in adjacent layers running at the right angle and nailing and screwing even closed to the edges in safe. III.Can easily be bending to a curvature limited by the tensile and the compressive strength of the other plies. IV.The face piles made at different heartwoods show great aesthetic variety in V. grain pattern and color.

- 40. Wood Products cont.… 40 • Hardboard - manufactured from raw materials like wood waste, veneer manufacturing, furniture making. Sizes of hardboards Medium hardboard Normal hardboard Tempered hardboard • Particle boards - is a board manufactured from particles of wood or other lingo cellulose materials. • Block board – these are boards having a core made up strips of wood each not exceeding 25 mm. • Other boardsBatten board – it is a board having a core made up of strips of wood usually 8 cm wide each laid separately or glued or otherwise joined to form a slab. • Lamin board – it is a board having core strips, each not exceeding 7 mm in thickness.

- 41. Wood Products cont.… 41 • Adhesives Synthetic Resins – it has a composition consisting substantially of phenolic or amino plastic resins including a hardening agent, fortifier, filler or extender. Four types of synthetic resin o Boiling Water Proof (BWP) o Boiling Water Resistant (BWR) o Warm Water Resistant (WWR) o Cold Water Resistant (CWR)

- 42. Wood Products cont.… 42 Classification According to their Uses Gap filling adhesive – suitable use in situation where the surfaces to be joined may or may not be in continuous contact. Close contact adhesive – where the surfaces to join can be brought into closed contact by means of adequate pressure. • Anima Glue – it is generally obtained from hides and bones of animals. • Vegetable Glue – it is made from natural grains and starch-bearing roots, potato, corn, wheat, etc. with acid like Sodium Hydroxide (NaOH).