Dyeing Machine Guide

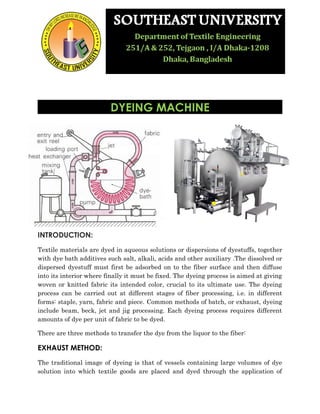

- 1. DYEING MACHINE INTRODUCTION: Textile materials are dyed in aqueous solutions or dispersions of dyestuffs, together with dye bath additives such salt, alkali, acids and other auxiliary .The dissolved or dispersed dyestuff must first be adsorbed on to the fiber surface and then diffuse into its interior where finally it must be fixed. The dyeing process is aimed at giving woven or knitted fabric its intended color, crucial to its ultimate use. The dyeing process can be carried out at different stages of fiber processing, i.e. in different forms: staple, yarn, fabric and piece. Common methods of batch, or exhaust, dyeing include beam, beck, jet and jig processing. Each dyeing process requires different amounts of dye per unit of fabric to be dyed. There are three methods to transfer the dye from the liquor to the fiber: EXHAUST METHOD: The traditional image of dyeing is that of vessels containing large volumes of dye solution into which textile goods are placed and dyed through the application of

- 2. heat and various chemicals. The modern embodiment of these’ long liquor’ processes is what we refer to here as exhaust dyeing, the ‘exhaustion’ being the depletion of dye from the dye bath due to its absorption by the textile. Typical, but not mandatory, aspects of modern exhaust dyeing equipment are Pumped circulation of the dye liquor A sealed system which can be pressurized Microprocessor control of heating and flow. In exhaust dyeing, all the material contacts all the dye liquor and the fibers absorb the dyes. The dye concentration in the bath therefore gradually decreases. The degree of dye bath exhaustion as a function of time describes the rate and extent of the dyeing process. The machines used in exhaust dyeing method are as follows:

- 3. BATCH FORM / OPEN WIDTH FORM/ FABRIC FORM DYEING: WINCH DYEING MACHINE: Winch dyeing machines comes with the lucrative options of low cost design, simplicity in operation and maintenance yet uncompromising features when it comes to versatility. Mostly woolen fabrics are dyed by using Winch Dyeing machine. The dyeing machine derives its name "Winch" as the fabric rope gets circulated in the machine by way of a mechanical action of a horizontal rotor or reel, called as a winch or sometimes wince. The cross-section of the winch rotor may be circular or elliptical. As shown in the diagram below, the winch dyeing machine has a front compartment; a perforated partition separates it from the main dyeing chamber. It is this front compartment where dyestuff and dyeing auxiliary additions are made. Gradually they move to main dyeing vessel from there. The process works like this first a series of fabric ropes are immersed in the dye bath. This fabric ropes must be of equal lengths. A part of each rope is then taken over two reels or over the winch itself. In the subsequent course of dyeing operation a rope of fabric is circulated through the dye bath and the winch. The dyestuff and auxiliaries are dosed manually or automatically according to the recipe method. A schematic representation of a beck or winch is shown in Figure, in which the fabric in a continuous loop form (referred to as a ‘rope’ due to the twisted configuration it tends to adopt) is circulated over two rollers and through the dyeing liquor, spending most of the time in the dyeing liquor. These machines are the original fabric dyeing equipment with much of the construction being made of wood prior to the advent of stainless steel. The winch or beck dyeing machine is quite simple and serves for all scouring, bleaching, dyeing, washing-off and softening processes. The machine contains a length of fabric with the ends sewn together, which is compressed to form a continuous rope. This rope passes from the dye bath over two elevated reels and then falls back into the bath The first roller is free-running (jockey or fly roller). The second (winch reel) is driven and controls the rate of rope transport and the extent of pleating where the rope accumulates below and behind the winch. Both reels extend the full length of the machine and accommodate several fabric ropes running side by side. The fabric rope is held on the winch by friction and its own weight.

- 4. JET DYEING: It was found that in using Winch machines, there were some inherent problems. So the Jet dyeing machines when they came up in the 1970’s were specifically designed to overcome those shortcomings. In the Jet dyeing machine the reel is completely eliminated. A closed tubular system exists where the fabric is placed. For transporting the fabric through the tube a jet of dye liquor is supplied through a venture. The Jet creates turbulence. This helps in dye penetration along with preventing the fabric from touching the walls of the tube. As the fabric is often exposed to comparatively higher concentrations of liquor within the transport tube, so little dye bath is needed in the bottom of the vessel. This is just enough for the smooth movement from rear to front. Aqueous jet dyeing machines generally employs a driven winch reel along with a jet nozzle.

- 5. The following diagram explains the functioning of a Jet dyeing machine: Types of Jet Dyeing Machine: 1. Overflow Dyeing Machine 2. Soft-flow Dyeing Machine 3. Airflow Dyeing Machine OVERFLOW DYEING MACHINE: A typical Overflow Dyeing Machine works like this. A winch that is not motor driven usually is located in the top side of the machine where the fabric is hanged. A longer length of textile is made to hang from the exit side of the winch as compared to the inlet side. By applying the force of gravitation the longer length of textile is pulled downward more strongly than the shorter one. Consequently the fabric is soaked in the bath without any sort of tension. The following diagram well illustrates the working

- 6. SOFT FLOW DYEING MACHINE: In the soft flow dyeing machine water is used for keeping the fabric in circulation. The conception difference of this equipment from a conventional jets that operates with a hydraulic system is that the fabric rope is kept circulating during the whole processing cycle (right from loading to unloading). There is no stopping of liquor or fabric circulation for usual drain and fill steps. The principle working behind the technique is very unique. There is a system for fresh water to enter the vessel via a heat exchanger to a special interchange zone. At the same time the contaminated liquor is allowed channel out through a drain without any sort of contact with the fabric or for that matter the new bath in the machine. Technical features: Very low liquor ratio- around 1:1(wet fabric) Can reach high temp. up to 140 C Easily dye 30 to 450 g/mt.sq.of fabrics(woven & knitted fabrics) Number of very soft flow nozzles No pilling effect Wide capacity

- 7. AIR FLOW MACHINE: This is another development of the very popular jet dyeing machines. The main difference between the Air Flow Machine and Jet Dyeing machine is that the airflow machine utilizes an air jet instead of the water jet for keeping the fabric in circulation. Typically the fabric is allowed to pass into the storage area that has a very small amount of free liquor. This results in a reduction in consumption of water, energy and chemicals. The figure below shows how in an Airflow Machine the bath level is always under the level of the processed textile. Here the fabric does not remain in touch with the liquor (the bath used is below the basket that holds the fabric in circulation). This invariably means that the bath conditions can be altered without having any impact on the process phase of the substrate. JIG OR JIGGER DYEING MACHINE: The jig or jigger is one of the oldest machines for processing woven fabrics in open-width form. A Jig Dyeing machine is an efficient dyeing technique. It is also known

- 8. by the name of jigger. Jig Dyeing machine processes fabrics in open width to avoid creasing problems in fabric dyeing. The process works like this. The Jig Dyeing machine operates by transferring the fabric back and forth. This happens from roller to roller via the medium of a dyebath, which is located at the base of the machine. As soon as the second roller gets full, the direction of movement of fabric can be reversed. In Jig dyeing, the duration of the process is measured on the basis of the number of passages or ends of the fabric passing through the dye bath from roller to roller. The end in dyeing parlance is known as the passing of fabric through a dye liquor from one roller to the other one. Fabric is transferred from one roller to the other through a small volume of liquor. The jig has a small bath containing the dye liquor (200 to 750 l) and gives a very low liquor-to-goods ratio of around 1:1. It is therefore useful for those dyes used on cellulosic fibers that normally give only low to medium exhaustion. Jig dyeing is a form of pad–roll dyeing repeated several times. Only a few meters of the total length of fabric are in the bath solution at any moment and dyeing occurs almost entirely in the roll of fabric outside the bath. The rate of dyeing depends on the amount of liquor retained by the fabric, the degree of exhaustion in the dwell period, and the extent of liquor exchange during the next dip. The latter is usually around 60–70%, but may be less for heavy fabrics. Figure: - Illustration of Jig or jigger Dyeing Machine. Types of jig dyeing machine: 1. Atomospheric Jigs. 2. High temperature Jigs KIER DYEING MACHINE: Kiers came in many forms, the most popular being a cylindrical iron vessel placed vertically and holding two tons of fabric. Liquor percolates through the fabric and is

- 9. pumped back, via a multitubular heater, to spray on the fabric. The machine is included here as historically it holds an important place in scouring and bleaching practice. In the Western world it has been superseded by other equipment. Garrett in a classic paper stated that for successful use of kiers it is essential to have all air excluded from the kier and: (1) The correct quantity of cloth in the kier; (2) The correct loading of the kier; (3) The correct rate of liquor circulation; (4) The correct liquor ratio; (5) The correct steam pressure and volume; The fabric is rope washed after processing and, if bleaching is to follow scouring, the kier must be reloaded with intermediate washing. Iron vessels are unsuitable for peroxide bleaching and so the machine must be suitably passivated using silicate cement Figure: - Schematic Diagram of a Typical Kier Dyeing Machine YARN FROM MACHINE: HANK DYEING MACHINE:

- 10. Hank dyeing machine are mostly used for dyeing of patterned wool carpets. There are mainly four types of Hank Dyeing machines used. They are the following, single stick Hussong-Type Machines the double-stick machine, double-stick cabinet machine, and lastly circular carrier machine. Out of this four, the first category of Hussong-Type Machines is the most popular one. The diagram is illustrated below. Figure: Hank dyeing machine. A major reason for the decline of hank dyeing is the problem of unwinding. After dyeing, the wet hanks are centrifuged, hung on poles or hooks, and passed through a hot air oven. They must then be mounted on a rotating frame to unwind the yarn. After package dyeing, yarn can be more easily unwound at much higher speed by pulling it over the top of a stationary bobbin. PACKAGE DYEING MACHINE: A package dyeing machine is typically a cylindrical vessel, about 2 m high and 2 m wide, with a rounded bottom and lid. The yarn is wound into cheeses, cones or cakes using perforated former tubes. A series of technical developments in the recent years has resulted into package dyeing being developed into a highly sophisticated as well as an economic process. Latest design Package Dyeing machines are amenable to accurate control and automation. These features would likely to lead to increases in the application of package dyeing. The dye flows through to the yarn package with the help of the deliberate perforations in the tube package. Once full exhaustion is brought about, the carrier of colored yarn is consequently removed from the vessel. A large centrifuge removes excess water from the packages. Finally the yarn is dried using an infra red drying oven. The image shows the process working of a Package dyeing machine.

- 11. BEAM DYEING MACHINE: The beam dyeing machine operates with the same principle as that of package dyeing machine. It can be effectively used to dye yarn or fabric. The process works like this, fabric or yarn in open width is rolled on to a perforated beam. The beam then subsequently slid into a vessel that is closed and pressurized. The color impregnates the fabric as the dye liquor is allowed to go on circulating through the perforations in the beam. Usually the beam machines are designed in such a manner so as to hold a single beam or multiple beams in a batch. In principle, beam dyeing is similar to package dyeing but with a single large pakage.This dyeing method is widely practiced for those fabrics that might crease, extend or abrade when dyed in machines where the fabric is in motion. Beam dyeing under pressure is easier than jig pressure dyeing.

- 12. Figure: - Sectional diagram of a high-temperature beam dyeing machine CONTINUOUS DYEING METHOD: Continuous dyeing is a method of dyeing fabrics in which, in an uninterrupted sequence, they are first impregnated with dyes and chemicals followed by a fixation step and rinsing and drying. The impregnation of fabric with dye is generally carried out in a padder as described in the previous section. Fixation can occur by a number of mechanisms such as steaming, baking or simply exposure to the atmosphere. Steaming is a very common component of continuous dyeing ranges for cotton fabrics, the aqueous high-temperature environment allowing the diffusion of dyestuff molecules into the fiber. Continuous dyeing methods are suited to high production volumes and respond quickly to the demands of fashion. Virtually all cotton dyes can be applied by continuous methods and, as mentioned in previous sections, it is the most important process for application of vats, sulphur dyes and azoic combinations. Figure: wash box A Continuous dyeing process typically consists the following. Dye application, dye fixation with heat or chemicals and finally washing. Continuous dyeing has been found to be most suitable for woven fabrics. Mostly continuous dye ranges are designed for dyeing blends of polyester and cotton. The step of padding plays a key role in the operation of continuous dyeing. Sometimes Nylon carpets are also dyed

- 13. in continuous processes, but the design ranges for them is unlike that for flat fabrics. Warps are also dyed in continuous process. Some continous method: Pad- steam =padding +steamer+washing Pad dry-steam =padding+stenter frame+washing Wet steam Thermosol continuous dyeing TAK & Space continuous method Now some are describe bellow: THERMOSOL CONTINUOUS MACHINE: A continuous dye range has been found useful and economically sustainable for dyeing long runs of a given shade. One important factor that separates continuous dyeing from batch dyeing is the tolerance factor for color variation. That is more for continuous dyeing as compared to batch dyeing. This is so because of two reasons a) the speed of the process. b) Presence of a large number of process variables which affects dye application. The process that is illustrated below is designed for dyeing of blended fabric of polyester and cotton. Some of the popular methods in continuous dyeing process are Pad-steam, Wet-steam, thermosol dyeing, TAK dyeing, space dyeing, and pad-steam dyeing long chain warp dyeing etc.

- 14. CONTINUOUS DYEING CARPET: Continuous dyeing carpet method is used for solid-color cut-pile carpet. Continuous dyeing is one of the fastest, most cost-effective means of color application. Long expanses of tufted carpet travel through huge machinery to be wet and scoured. After some of the water is extracted, the carpet moves under a dye applicator that flows dye liquor onto it at a rate of 50' per minute. Next, the carpet is put into a wet heat steamer to fix the dye, after which it is washed, extracted and dried. The majority of the continuous dyed carpet equipment used in the world today is manufactured by two companies in Gemany, Kusters and Fleissner. This type of continuous dyeing method is favored over beck dyeing due to the fact that costs are lower for utilities, labor, and raw materials. The reason for this is that beck dyeing requires more water, about 6 times more water in fact, for processing the same number of pounds of dyed fiber as compared to a continuous dyeing line. The need for more water brings the need for more energy to heat the water, and more chemistry to treat the water and carpet fibers adequately for the dyeing process SEMI CONTINUOUS METHOD: In the process of semi-continuous dyeing that consists of pad-batch, pad-jig, pad-roll the fabric is first impregnated with the dye-liquor in, what is called a padding machine. Then it is subjected to batch wise treatment in a jigger. It could also be stored with a slow rotation for many hours. In the pad-batch this treatment is done at room temperature while in pad-roll it is done at increased temperature by employing a heating chamber. This helps in fixation of the dyes on to the fibre.

- 15. A schematic diagram is given here for the semi-continuous dyeing process After this fixation process, the material in full width is thoroughly cleansed and rinsed in continuous washing machines. There is only one point of difference between Continuous and semi-continuous dyeing process is that in semi-continuous dyeing, the dye is applied continuously by padding. The fixation and washing remaining discontinuous. Liquor Ratio in semi-continuous dyeing is not of much importance and is not taken as a parameter. One of the widely used techniques for semi-continuous dyeing process is the Pad batch dyeing. A semi continuous method for production of viscose textile fibers in which spinning is conducted at a rate of 500 m/min with take-up to a centrifuge is examined. Here 10-20 twisted fibers are joined into roving, treated on continuous aggregates, and after drying in drums are taken up on warping beams weighing 10-20 kg. The fibers made by the semi continuous method have high uniformity of dyeing and high strength of 28-30 cN/texs. PAD BATCH DYEING: Pad Batch Dyeing is one of the widely used techniques for semi-continuous dyeing process. It is mainly used in the dyeing of cellulosic fibre like cotton or viscose (knit and woven fabric) with reactive dyes. Pad batch dyeing is a textile dyeing process that offers some unique advantages in the form of versatility, simplicity, and flexibility and a substantial reduction in capital investment for equipment. It is primarily a cold method that is the reason why it is sometimes referred to as the cold pad batch dyeing The technique or process used in pad-batch dyeing starts with saturating first the prepared fabric with pre-mixed dye liquor. Then it is passed through rollers. The

- 16. rollers, or padders, effectively force the dyestuff into the fabric. In the process, excess dye solution is also removed. After removal of excess dye stuff the fabric is subsequently "batched". This batching is done by either storing it in rolls or in boxes. It takes a minimum of 4-12 hours. The batches are generally enclosed by plastic films. This prevents absorption of carbon dioxide and water evaporation. Finally as the reaction is complete the fabrics are washed. This is done by becks, beams, or any other washing devices. COLD PAD DYEING PROCESS: The technique or process used in pad-batch dyeing starts with saturating first the prepared fabric with pre-mixed dye liquor. Then it is passed through rollers. The rollers, or padders, effectively force the dyestuff into the fabric. In the process, excess dye solution is also removed. After removal of excess dye stuff the fabric is subsequently "batched". This batching is done by either storing it in rolls or in boxes. It takes a minimum of 4-12 hours. The batches are generally enclosed by plastic films. This prevents absorption of carbon dioxide and water evaporation. Finally as the reaction is complete the fabrics are washed. This is done by becks, beams, or any other washing devices. CONCLUSION: The assignment of exhaust method, continuous method &semi- continuous method is very important for our study. Dyeing operations are used at various stages of production to add color and intricacy to textiles and increase product value. Most dyeing is performed either by the finishing division of vertically integrated textile companies, or by specialty dyehouses. Specialty dyehouses operate either on a commission basis or purchase greige goods and finish them before selling them to apparel and other product manufacturers. Textiles are dyed using a wide range of dyestuffs, techniques and equipment. `````````````````````````````````````````````````````````` References:

- 17. - Cotton: science and technology (Edited by S. Gordon and Y-L.Hsieh) -Internet browsing.