2016 06-07-flexible-and-efficient-production-with-am-sirris-intro

•

0 j'aime•549 vues

Flexible and efficient production with Additive Manufacturing - Additive manufacturing portfolio @ Sirris (Thierry Dormal, Sirris)

Signaler

Partager

Signaler

Partager

Télécharger pour lire hors ligne

Recommandé

Recommandé

Contenu connexe

Tendances

Tendances (8)

Plastics and composites: Overview and opportunities for the maritime sector

Plastics and composites: Overview and opportunities for the maritime sector

Grundfos - Michael Lei - Plastic Engineering Day 2021

Grundfos - Michael Lei - Plastic Engineering Day 2021

Product informations | Minox X-lite | Optics Trade

Product informations | Minox X-lite | Optics Trade

En vedette

En vedette (20)

Sirris Smart coating roadshow - Slips introduction 1

Sirris Smart coating roadshow - Slips introduction 1

Sirris Smart coating roadshow - Slips introduction 2

Sirris Smart coating roadshow - Slips introduction 2

Sirris 2016 04-12 automated coating deposition by a teach-by-demonstration- s...

Sirris 2016 04-12 automated coating deposition by a teach-by-demonstration- s...

Sirris 2016 04-12 towards succesfull coating application-sirris

Sirris 2016 04-12 towards succesfull coating application-sirris

Invisible but functional - water resistent coatings

Invisible but functional - water resistent coatings

2016 06-07-flexible-and-efficient-production-with-am-jtekt

2016 06-07-flexible-and-efficient-production-with-am-jtekt

2015 12-02-optiwind-offshore-wind-turbine-modelling-lms-samsef-siemens

2015 12-02-optiwind-offshore-wind-turbine-modelling-lms-samsef-siemens

2015 11-19-case study-motor_replacement_on_extruder_danfoss

2015 11-19-case study-motor_replacement_on_extruder_danfoss

2016 05 26 Robo8 inspiration day_interactieve sessie

2016 05 26 Robo8 inspiration day_interactieve sessie

2015 12-02-opti wind-test-setup-validation-estimation-techniques-drivetrains-...

2015 12-02-opti wind-test-setup-validation-estimation-techniques-drivetrains-...

2015 12-02-innovative-tools-wind-turbine-performance-assesment-3 e

2015 12-02-innovative-tools-wind-turbine-performance-assesment-3 e

20151202 optiwind design validation-optimization-wp5-foundation-monitoring-wp...

20151202 optiwind design validation-optimization-wp5-foundation-monitoring-wp...

Sirris 2016 04-12-coating possibilities in the smart coating application lab ...

Sirris 2016 04-12-coating possibilities in the smart coating application lab ...

2015 12 02_optiwind_optimization-operations-maintenance-offshore-wind-farms-k...

2015 12 02_optiwind_optimization-operations-maintenance-offshore-wind-farms-k...

Similaire à 2016 06-07-flexible-and-efficient-production-with-am-sirris-intro

Anubis Manufacturing Consultants Corporation uses EOS Additive Plastic Laser Sintering for Nylon 12 Flow Meter FastenersAnubis Manufacturing Consultants Corporation uses EOS Additive Plastic Laser ...

Anubis Manufacturing Consultants Corporation uses EOS Additive Plastic Laser ...Machine Tool Systems Inc.

Alan Norbury, Central Technology Officer for Siemens UK, presented on the Siemens' digital journey and the vision for the future.Britain's 4th Industrial Revolution: Vision to Reality, Alan Norbury

Britain's 4th Industrial Revolution: Vision to Reality, Alan NorburyWMG centre High Value Manufacturing Catapult

Fused deposition modelling (FDM) has become a prevalent technique to additively manufacture polymer that can provide design freedom and creativity. However, like any other AM technologies, FDM has its own challenges. The inherent void, surface roughness and dimensional accuracy during manufacturing can lead to tolerance rejection, cracking or failure during the product life. Also, the resultant anisotropic material properties are inherent in the layer-by-layer manufacturing features. Therefore, it is important to understand and simulate FDM process, in which complex thermo-mechanical interaction takes place due to rapid heating/cooling.

The current work will first provide a brief overview of the current polymer AM simulation solutions, validation protocols, and standardization efforts. Secondly, a simulation framework using Abaqus will be presented to replicate the FDM process that can provide insight into how the process parameters affect product quality. Currently, simulation solutions has the capability to model the polymer extrusion process with that can capture the layer-by-layer element activation feature and varying free surface in heating and cooling. Finally, an example study will be presented to show how modifying process parameters such as raster angle, contour width and layer thickness affect the transient thermal, deformation and residual stress field. Accordingly, optimal processing parameters can be identified based on the criterion of minimizing distortion and residual stresses. Simulation of transient temperature and stress field in the polymer extrusion...

Simulation of transient temperature and stress field in the polymer extrusion...Arindam Chakraborty, Ph.D., P.E. (CA, TX)

Similaire à 2016 06-07-flexible-and-efficient-production-with-am-sirris-intro (20)

ICME THE BACKBONE FOR LIGHTWEIGHT VEHICLE DEVELOPMENT

ICME THE BACKBONE FOR LIGHTWEIGHT VEHICLE DEVELOPMENT

Addimadour - centre d’excellence sur les technologies de fabrication additiv...

Addimadour - centre d’excellence sur les technologies de fabrication additiv...

New solutions for disassembly, remanufacturing and testing automotive metal p...

New solutions for disassembly, remanufacturing and testing automotive metal p...

Dragon Sourcing case study Supporting New Factory launch

Dragon Sourcing case study Supporting New Factory launch

How does sourcing services help to start a new company in China?

How does sourcing services help to start a new company in China?

Anubis Manufacturing Consultants Corporation uses EOS Additive Plastic Laser ...

Anubis Manufacturing Consultants Corporation uses EOS Additive Plastic Laser ...

Britain's 4th Industrial Revolution: Vision to Reality, Alan Norbury

Britain's 4th Industrial Revolution: Vision to Reality, Alan Norbury

Industry 4.0: Navigating the Manufacturing Revolution in ASEAN

Industry 4.0: Navigating the Manufacturing Revolution in ASEAN

Simulation of transient temperature and stress field in the polymer extrusion...

Simulation of transient temperature and stress field in the polymer extrusion...

Plus de Sirris

Plus de Sirris (20)

2021 01-27 - webinar - Corrosie van 3D geprinte onderdelen

2021 01-27 - webinar - Corrosie van 3D geprinte onderdelen

2021/0/15 - Solarwinds supply chain attack: why we should take it sereously

2021/0/15 - Solarwinds supply chain attack: why we should take it sereously

Challenges and solutions for improved durability of materials - Opin summary ...

Challenges and solutions for improved durability of materials - Opin summary ...

Challenges and solutions for improved durability of materials - Hybrid joints...

Challenges and solutions for improved durability of materials - Hybrid joints...

Challenges and solutions for improved durability of materials - Corrosion mon...

Challenges and solutions for improved durability of materials - Corrosion mon...

Challenges and solutions for improved durability of materials - Concrete in m...

Challenges and solutions for improved durability of materials - Concrete in m...

Challenges and solutions for improved durability of materials - Coatings done...

Challenges and solutions for improved durability of materials - Coatings done...

2018 11-07-verbinden-ongelijksoortige-materialen-hupico multimaterial welding

2018 11-07-verbinden-ongelijksoortige-materialen-hupico multimaterial welding

2018 11-07-verbinden-ongelijksoortige-materialen-bil ongelijksoortige materia...

2018 11-07-verbinden-ongelijksoortige-materialen-bil ongelijksoortige materia...

2018 11-07-verbinden-ongelijksoortige-materialen-sirris bil-flanders_make_mmj

2018 11-07-verbinden-ongelijksoortige-materialen-sirris bil-flanders_make_mmj

2018 11-07-verbinden-ongelijksoortige-materialen-ku leuven-lijmen

2018 11-07-verbinden-ongelijksoortige-materialen-ku leuven-lijmen

Slotevent ‘Verbinden van ongelijksoortige materialen’ - Lcv lasercladding for...

Slotevent ‘Verbinden van ongelijksoortige materialen’ - Lcv lasercladding for...

Slotevent ‘Verbinden van ongelijksoortige materialen’ - Juno industries mecha...

Slotevent ‘Verbinden van ongelijksoortige materialen’ - Juno industries mecha...

Slotevent ‘Verbinden van ongelijksoortige materialen’ - Castolin verbinden v...

Slotevent ‘Verbinden van ongelijksoortige materialen’ - Castolin verbinden v...

Masterclass Mechatronics 4.0 - Indoor and outdoor localisation and positionin...

Masterclass Mechatronics 4.0 - Indoor and outdoor localisation and positionin...

Dernier

Dernier (20)

Boost Fertility New Invention Ups Success Rates.pdf

Boost Fertility New Invention Ups Success Rates.pdf

Apidays Singapore 2024 - Building Digital Trust in a Digital Economy by Veron...

Apidays Singapore 2024 - Building Digital Trust in a Digital Economy by Veron...

Bajaj Allianz Life Insurance Company - Insurer Innovation Award 2024

Bajaj Allianz Life Insurance Company - Insurer Innovation Award 2024

Strategize a Smooth Tenant-to-tenant Migration and Copilot Takeoff

Strategize a Smooth Tenant-to-tenant Migration and Copilot Takeoff

Automating Google Workspace (GWS) & more with Apps Script

Automating Google Workspace (GWS) & more with Apps Script

Understanding Discord NSFW Servers A Guide for Responsible Users.pdf

Understanding Discord NSFW Servers A Guide for Responsible Users.pdf

Tata AIG General Insurance Company - Insurer Innovation Award 2024

Tata AIG General Insurance Company - Insurer Innovation Award 2024

ProductAnonymous-April2024-WinProductDiscovery-MelissaKlemke

ProductAnonymous-April2024-WinProductDiscovery-MelissaKlemke

Why Teams call analytics are critical to your entire business

Why Teams call analytics are critical to your entire business

The 7 Things I Know About Cyber Security After 25 Years | April 2024

The 7 Things I Know About Cyber Security After 25 Years | April 2024

Exploring the Future Potential of AI-Enabled Smartphone Processors

Exploring the Future Potential of AI-Enabled Smartphone Processors

Repurposing LNG terminals for Hydrogen Ammonia: Feasibility and Cost Saving

Repurposing LNG terminals for Hydrogen Ammonia: Feasibility and Cost Saving

Top 5 Benefits OF Using Muvi Live Paywall For Live Streams

Top 5 Benefits OF Using Muvi Live Paywall For Live Streams

Workshop - Best of Both Worlds_ Combine KG and Vector search for enhanced R...

Workshop - Best of Both Worlds_ Combine KG and Vector search for enhanced R...

TrustArc Webinar - Stay Ahead of US State Data Privacy Law Developments

TrustArc Webinar - Stay Ahead of US State Data Privacy Law Developments

Mastering MySQL Database Architecture: Deep Dive into MySQL Shell and MySQL R...

Mastering MySQL Database Architecture: Deep Dive into MySQL Shell and MySQL R...

2016 06-07-flexible-and-efficient-production-with-am-sirris-intro

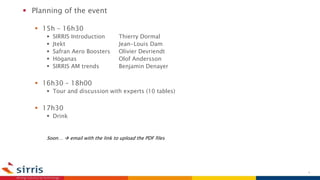

- 1. Planning of the event 15h – 16h30 SIRRIS Introduction Thierry Dormal Jtekt Jean-Louis Dam Safran Aero Boosters Olivier Devriendt Höganas Olof Andersson SIRRIS AM trends Benjamin Denayer 16h30 – 18h00 Tour and discussion with experts (10 tables) 17h30 Drink Soon… email with the link to upload the PDF files 1

- 2. T-ADD service portfolio 7/06/2016 Thierry Dormal Program Manager T-ADD SIRRIS

- 3. 3 1990 – 2015 Rapid Prototyping Rapid Tooling Additive Manufacturing 3D Printing Direct Manufacturing

- 4. 4 Prototypes Direct Part Production 0 1000 2000 3000 4000 5000 6000 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 2013 2014 2015 Product and services revenues from AM Direct part production Direct Part Production 2010: 20 % 2015: 51 % Compiled from Wohlers Associates data M$

- 5. Evolution of AM • From prototype to real part production • From time reduction to higher product performance • From plastic to high performance alloys • From shapes to consistent qualified parts • From 3D Printing to an integrated production process

- 6. 6 1990 • One of the first stereolithography machine in EU (3DSystems) 1994 • One of the first FDM machine in EU (Stratasys) • EU projects based on Rapid Tooling & SLA moulds 1996 • SLS : PA Sintering (EOS) • DMLS: the first direct metal solution (with metal binder) 2000 • Technological breakthrough: Optoform and Prometal 2008 • LBM EBM and Laser cladding – Ti Alu Steel Inconel • Bi-materials and composite technology (Connex 500) • Bio-ceramic applications 2015 - 2020 • New strategy towards AM transfer & AM integration SIRRIS T-ADD - A bit of history Rapid Prototyping Rapid Tooling Rapid Manufacturing Additive Manufacturing

- 7. Sirris | 25 years of Additive Manufacturing Most complete installed base in EU Metals Polymers Ceramics More than 10 additive technologies in house Team of 20 independent experts © sirris | www.sirris.be | info@sirris.be | 7

- 8. 9.06.16© sirris | www.sirris.be | info@sirris.be | 8 1. Material extrusion: the material is selectively dispensed through a nozzle or orifice. 2. Material jetting: droplets of build material are selectively deposited. 3. Binder jetting: a liquid bonding agent is selectively deposited to join powder materials. 4. Sheet lamination: sheets of material are bonded to form an object. 5. Vat photopolymerization: a liquid photopolymer in a vat is selectively cured by light- activated polymerization. 6. Powder bed fusion: thermal energy selectively fuses regions of a powder bed. 7. Directed energy deposition: focused thermal energy is used to fuse materials by melting as the material is being deposited 4 selected processes in the ASTM/ISO list

- 9. ICT& Design tools Process Leading-edge Applications / Components Materials Post- Process © sirris | www.sirris.be | info@sirris.be | 9 Sirris T-ADD projects Process Leading-edge Applications / Components Materials Post- Process Certification Validation Company stimulation

- 10. VIS – Design for AM FEDER – Iawatha Riatas ICT& Design tools Process Leading-edge Applications / Components ESA - AM Nano satellites ESA - AGHP ESA - Siam Materials Post- Process Any-Shape 4.0 © sirris | www.sirris.be | info@sirris.be | 10 Sirris T-ADD projects Process Leading-edge Applications / Components Materials Post- Process FEDER – TipTopLam FEDER – Iawatha Exiatas ESA Scamp Cornet TCAM Skywin Aero+ Skywin FASAMA Skywin 3SA Skywin INHex Skywin FasOPT Skywin AMassy GreenoMat - Recylclad Marshall ThermAM EraNet - Ceracell RW Collective - QUALAM First - OSAM InterReg PolyValves CORNET Opp3D Biowin Bioptos Certification Validation Company stimulation GT AVATAR Vanguard InterReg NWE VITAMIN Cwality EasyAM (GeonX) Antenne Norme Prénormatif POWDERAM

- 11. 11 T-ADD 2015 - industrial activity - 500 industrial projects - 150 companies - > 25 new companies / year discovering AM - Growing demand in - Performance (materials & processes) - AM Design of new products or services based on AM - Technology transfer for specific technology and materials - Qualification (technology, materials & products) - Post-processing (surface quality, accuracy,…) - AM integration (internal needs or service providers)

- 12. AM transfer • Scan opportunities • Cases 1on1 • Educate • Qualification AM integration • Chain automation • Chain demonstration • Chain integration Efforts 0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100% 2015 2016 2017 2018 2019 2020 AM Integration AM Transfert AM Demo AM demo • Sensibilization • Demonstration • Benchmarking TRL 7-9 TRL 6-9 TRL 4-9 Sirris ADD : Effort evolution 2015 - 2020 TRL 4-8Digipreneurship

- 13. 13 • AM oriented design based on specific AM rules • Prototypes for development and then real direct AM production • No way to go back to conventional way of working for series production • Lattice Structures, topology optimization and components reduction • After 3 years: 80 % components of the helicopter are produced by AM Flying Cam

- 14. 14 Test bench for anti-ice system • Trials and validation of the anti-ice process in flight condition • 46 parts & 112 sensors AM benefits: • Hollow components with cables and sensors • Flexible & functional • Much faster to build • No 2D drawings required Safran Aero Boosters

- 15. 9.06.16 15© sirris | www.sirris.be | info@sirris.be | Safran Aero Boosters Challenge • Positioning in additive manufacturing Sirris contribution • Support for technology selection • Technology transfer (process, powder handling) • Understanding of pros & cons of metal AM • Case studies with real parts Business impact • AM Integration in the company with a long term development plan

- 16. 16 Smart drilling machine for aerospace applications •Technical reasons to use AM Mechanical properties of Titanium Designed for weight optimization Integration of functions Vibration reduction • New company (integrated in BMT Aerospace) created for one single product. AMT Titastar

- 17. Intervertebral cages with bioceramic material 17 • Material formulation : HA/TCP (Bone substitute) • Process development: paste polymerization • 0.1mm tolerance / Fully controlled porosity • ISO13485 compliance • >10.000 parts / year in 2012 2013 2014 • New company created by Kasios in Gilly for production + Cerhum Intervertebral bone replacement (HA/TCP) Kasios

- 18. 18 Date : 14-07- 15 Validation of LBM with Titanium material for space parts • Feasibility – Aerospace Qualification – Traceability • Integration in the building process • Set up of a certification methodology • Topology Optimization • 5 axis Post milling on AM parts for surface quality and high local accuracy 153 x 144 x 50mm Vol = 56cm³ Propriété Thalès Alenia Space Fabrication: Sirris Propriété Thalès Alenia Space Fabrication: Sirris Thales Alenia Space

- 19. Sirris 2016 – Service offering Explore the potential of AM - Feasibility study, benchmarking, - New applications and opportunities, new business models,… Design for AM - Design rules for each AM technology, - Weight reduction, process simulation, - Topology optimization, lattice structures, channels,… Optimize, implement & transfer AM Technologies for production - Enhance the use of AM technologies, materials, powder handling, post processing - Enhance process reliability and repeatability with certification procedures - AM integration and automation of the full chain Reduction of repetitive projects with low added value >> transfer to Service Providers, creation of new start-up 19

- 20. 20 Thierry Dormal Program Manager T-ADD Thank you That’s it for now… Any questions ?

- 21. Planning of the event 15h – 16h30 SIRRIS Introduction Thierry Dormal Jtekt Jean-Louis Dam Managing Director Jtekt Torsen Europe Safran Aero Boosters Olivier Devriendt Projects & Incubation, Dept Innovation Höganas Olof Andersson Manager Biz Dev High Alloy powders SIRRIS AM trends Benjamin Denayer Senior Biz Developer 16h30 – 18h00 Tour and discussion (10 tables) 17h30 Drink 21

- 22. 22

- 23. 20/12/2007© sirris 2007 | www.sirris.be | info@sirris.be | 23