random

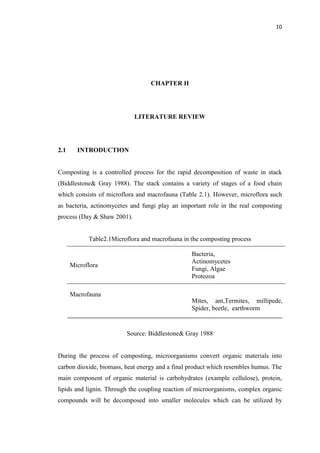

- 1. 10 CHAPTER II LITERATURE REVIEW 2.1 INTRODUCTION Composting is a controlled process for the rapid decomposition of waste in stack (Biddlestone& Gray 1988). The stack contains a variety of stages of a food chain which consists of microflora and macrofauna (Table 2.1). However, microflora such as bacteria, actinomycetes and fungi play an important role in the real composting process (Day & Shaw 2001). Table2.1Microflora and macrofauna in the composting process Bacteria, Actinomycetes Microflora Fungi, Algae Protozoa Macrofauna Mites, ant,Termites, millipede, Spider, beetle, earthworm Source: Biddlestone& Gray 1988 During the process of composting, microorganisms convert organic materials into carbon dioxide, biomass, heat energy and a final product which resembles humus. The main component of organic material is carbohydrates (example cellulose), protein, lipids and lignin. Through the coupling reaction of microorganisms, complex organic compounds will be decomposed into smaller molecules which can be utilized by

- 2. 11 microbial cell (Golueke 1991). The metabolism of microbes results in the increase of temperature in the compost stack because the heat released by metabolism of microbes is captured faster than that released to the environment (Miller 1991). The increase in temperature will enhance the degradation process (Biddlestone& Gray 1988). 2.2 THEMICROBIOLOGYOF COMPOSTING It has long been known that composting is primarily a microbiological process. If one has the chance to read the work by(Waksman et al.1939), most likely he will get impressed with the amount of knowledge about the microbiology of the process that already existed by that time. The understanding that composting is, above all, a microbiological process is of paramount importance since this is actually the basis for good process management (Finstein 1980, de Bertoldiet al. 1983,Golueke 1991). This was one of the strongest basis for the development of the rutgers system of composting (Finstein 1980), where process rate is controlled by maintenance of an appropriate process temperature by forced aeration and it has been one of the guiding principles in most of the composting systems available nowadays. Although small animals like earthworms or small insects can be found in composting, most of the organic matter degradation is carried out by microbes. There are three main groups ofmicrobes involvednamely bacteria, fungi and actinomycetes which may be facultative or strict aerobic (Huang et al. 2000).They may have individual preferential substrates andenvironmental conditions for growth.The materials subjectedfor composting usually contain an indigenous population of microorganisms derived from the atmosphere, water or soil (Gray &Bidlestone 1973). Once materials are piled for composting, feeding of this microbiological population on the substrates leadto the production of heat and is accumulation in the pile, causing process temperature to rise (Finsteinet al. 1987a.,Rynket al. 1992).Microbial activity and the resulting heat generation trigger a change in the environmental conditions and substrate composition along process time, which in turn causes a succession of mixture of microbialpopulations to occur (Waksman et al. 1939, Gray &Bidlestone 1973, Silveira1999,Tiquiaet al. 2002,Nakasakiet al. 2005, Klammeret al. 2008,Chroniet al. 2009).Microbial populations can be subdivided by the temperature ranges of their activity: i)psychrophiles, preferring temperatures below 20ºC; ii) mesophiles, for a

- 3. 12 temperature range in between 20ºC and 40ºC; and iii) thermophiles, above 40ºC (Gray &Bidlestone 1973). 2.3 BIOPROCESS COMPOSTING Microorganisms require carbon material, macronutrient such as nitrogen, phosphorus and potassium and other few side elements for their growth. Carbon is the main energy source for microorganisms while small constituents from carbon will be inserted into the cell. Some of the energy formed will be used for microbial metabolism and the rest of it will be released as heat. Nitrogen is an important element for microorganism because it is a component of protein, nucleic acid, amino acid, enzymes, and co-enzymes which are needed for development and cell function (Golueke 1991). During composting, the carbon source which is dissolved and biodegradable such as monosaccharide, starch and lipid will be used by microorganism in the early stage of composting. pH value will decrease because the organic acid formed as a result of microbial decomposition compound during the process of degradation. Microorganisms will later start the process of protein degradation, resulting in ammonia being released and rise in pH value. After the biodegradable source of carbon is used up, the compound which takes more time for biodegradable such as cellulose, hemicellulose and lignin will undergo biodegradable and part of it will be converted into humus (Crawford 1983). Ammonia formed will undergo different process depending on the condition of compost mixture. For example, if it is possible to be dissolved (example NH4+) will be later immobilized by microorganisms by using ammonium as nitrogen source and subsequently changing it back to organic nitrogen. At temperature below 40 0C and also at a suitable ventilation, ammonia is possible to be converted to nitrate (NO3-) by nitrating bacteria. During nitration, nitrating bacteria will lower down pH caused by the released oh hydrogen ion. The process can be simplified as follows: Nitrosomonasbacteria: 2NH4++ 3O22NO2-+ 4H+ + 2H20

- 4. 13 Nitrobacterbacteria: 2NO2- + O22NO3- The lack of oxygen will cause the microorganisms to utilize nitrate as oxygen source which will cause the occurrence of denitration and halts nitration. At a higher temperature and pH exceeding 7.5, ammonia can be vaporized and released (Sanchez- Monederoet al. 2001). Microorganisms have the tendency to utilize organic molecule which is dissolved in water. If the moist content falls below the critical level, the microbial activity will decrease and it will be dormant (not active temporarily). On the contrary, high moisture content will cause the ventilation of compost to be less efficient, causing leaching of nutrient and the process to be anaerobic (Golueke 1991). Humidity is also important is the storage of energy in the stack of compost (Schaub& Leonard 1996). Composting process can be either more aerobic or more anaerobic. The decomposition is faster and lesser foul if the process is more aerobic. This condition results in a process which is more aerobic to be conducive in order to stabilize the larger scaled waste. Biochemical equation for an aerobic process in shown as below (Day & Shaw 2001; Polprasert 1989): Organic material + O2+ aerobic microbes CO2 + NH3 + H20 + Product + Energy On the other hand, a more anaerobic process is easier and less costly although the degradation is time consuming and more have more foul. The biochemical equation for an anaerobic process is shown below (Day & Shaw 2001; Polprasert 1989): Organic material + anaerobic microbes CO2 + NH3 + H2S + Product + Energy + CH4 Composting is a microbiological process which relies on the increase and decrease of temperature.Day and Shaw (2001) stated that microorganisms in a compost stack is divided into three categories, namely cryophilic or psychrophilic (0-250C),

- 5. 14 mesophylic (25-45 0C) and thermophylic (>45 0C). Generally, mesophylic and thermophylic microorganisms are prone to domination in stack compost. The temperature profile for composting is shown as in Figure 2.1. At optimum condition, composting will go through three phases namely, mesophylic phase, thermophylic phase (happens from few days to few months) and cooling and maturation phase (can happen for few months). Figure2.1 Profile of Temperature and Microbial Growth in Compost Stack Source: Polprasert 1989 The period of each phase relies on natural factors or the condition of organic material which is compost and the effectiveness of the process which is determined by degree of ventilation and stirring (Golueke 1991). The addition of starting compost can eliminate long mesophylic phase and hence speeding up the composting process (Agamuthuet al. 2000). The active composting phase is considered ended when the mixture temperature is stabilized and reaching atmospheric temperature (Sanchez- Monederoet al. 2001). The population of microorganisms in the stack also changes during the composting process as portrayed in Figure 2.2.

- 6. 15 When composting is not done properly, the breeding and spread of pathogens can occur. According to Federal Biosolid Technical Regulation, U.S., to reduce the risk of pathogens, limit system (windrow) is compulsory to have a minimum temperature of 55 0C at a compost stack for 15 days, whereas the minimum temperature of 55 0C in the reactor for 3 days (Day & Shaw 2001). Figure2.2The Change in Overall Population of Microorganisms (total of bacteria,actinomycetes and fungi) during Sludge-saw dust Composting. Source: Day & Shaw 2001 2.4 SUITABLE MATERIALS FOR COMPOSTING Any waste material with high organic matter content is a potential replacement used for centuries to stabilize human and animal wastes.Recently it has been used for sewage sludge,industrial wastes (e.g. food, pulp & paper),yard and garden wastes.Municipal solid wastes (up to 70% organic matter by weight),softprunings, clippings, leaves, woody prunings (finely shredded),straw based farmyard and horse manure, pure wool jumpers, paper shredded mixed with grass cuttings are used sparingly.Kitchen waste includes waste from fruit, peelings, teabags, egg shells and

- 7. 16 bedding from vegetarian pets such as rabbits.When selecting materials for your compost, avoidusing coal ash, metal, glass and plastic, nappies,the roots of persistent weeds like bindweed and couch grass, leaves with persistent disease such asblackspot, meat or fish and cooked food, especially meat as this attracts vermin (home composting). 2.5 COMPOSTING SYSTEM Composting system can be classified into reactor and non-reactor. There are two types of non-reactor system namely long rows (windrow): stirred system and air static system. Long rows refer to stirred system which is usually done manually. In an air static system, sludge is piled on a perforated pipe. Air will be forced by air compressor into the perforated pipe so that there is direct contact between sludge and air in order to activate the microbes (Hassounehet al. 1999).In a reactor system, compost will be circled by container (reactor) and the flow of substance will be directed according to reactor design. The reactor is usually closed even though there are researches which uses open reactor system (Papadimitriou et al. 1997). For a vertical reactor, raw materials are inserted from the top of the reactor while air is supplied from the bottom so that all substances get sufficient air. In general, reactor is used for organic material without sludge. In a horizontal reactor, the reactor is placed in a horizontal or slightly inclined with small gradient so as to ease the flow of substances in a reactor. The direction of feed and air feed is opposite in order to maximize the contact time. The final compost is collected near the air nozzle (Hassounehet al. 1999). Table 2.2 shows the summary of composting system of commercial scale. A non-reactor system is less costly but requires a bigger space (Furhacker&Haberl 1995;Haug 1993). Although it is costly and requires skilled labor, the reactor system has a good control which makes it more suitable for sludge composting in a larger quantity (Bhamidimarri&Pandey 1996; Haug 1993). In order to increase process efficiency and to reduce cost, only active composting is usually carried out on reactor system while maturation process is carried out on limit system (Furhacker&Haberl 1995; Vourinen&Shaharinen 1997).

- 8. 17 2.5.1 RotatingDrumReactorinComposting Rotating drum reactor has been long used in composting field either by batch or continuous in a large and small scale. Compared to the batch process, continuous process has the ability to manage a larger quantity of material and eliminate the mesophilic phase (Schulze 1962). Table 2.2 .Commercial-scale composting system Decomposing system System’s Information Category Rotating row Not a Reactor A long narrow piles is rotated regularly and passively ventilated. Static and passive stack Not a Reactor Free standing piles is turned occasionally ventilation or not at all and aerated without the aid of passive ventilation. Static pile and long row Not a Reactor Piles and the long row with the help of with the help of passive passive air like perforated pipe and air forced-air plenum. Aerated piles and bins Not a Reactor Short barrels and free standing piles with forced ventilation and without rotated. Stack, long row and Not a Reactor Long row or free standing piles or short barrel with turnaround barrel forced air system. Material will be and ventilation fixed or sometimes rotated. Stirred horizontal layers Reactor Material will be composed in long layers with a turnaround narrow, usually with forced ventilation and continuous movement. Aerated containers Reactor Material will be included in various containers with forced ventilation. Aerated-stirred Reactor The commercial container stirred, aerated containers by force and material is moved continuously. Silo or reactor tower Reactor Forced air system that leads to the movement of material vertically from top to bottom. Rotating drum Reactor Drum is rotated slowly to stir the material permanently or intermittently and move the material through the system. Source: Rynk& Richard 2001

- 9. 18 Rotating drum reactor differs in size, design and process management. Rotating drum reactor has common basic technique which is to increase decomposition by mixing up the materials in the reactor (Rynk& Richard 2011). Rotating drum reactor (RDB) is a complex multiphase reaction system Figure 2.3 which includes substrate layer, head space gas, and drum wall. In general, substrate layer covers 10%-40% of bioreactor volume (Hardin et al. 2000). Schulze (1962) filled up 67% of RDB’s volume during composting of sewage sludge. RDB is usually rotated to 2-3 rpm although there are values as low as 3 revolutions per day and there were also revolution values as high as 40-50 reported before. Drum may contain internal blades in order to increase mixing action caused by rotation (Hardin et al. 2000). Figure 2.3 Showing the multiple phase and matter and energy flow in a rotating drum reactor. Source: Hardin et al. 2000 In a composting process, rotation functions as to expose the materials to fresh air to increase oxygen and also to release heat and product gases from decomposition. Forced ventilation is commonly used to supply fresh air and to eliminate gaseous products. In a few cases, a short drum can obtain sufficient air by exchange of passive air through the opening at the end. When forced ventilation is carried out, air will be directed to compost or the opposite side of where the compost is fed to the output.

- 10. 19 Drum system are needed for composting less homogeneous materials such as municipal waste.These drums are of diameter 3 m or more and have a length of more than 50 m. Some drums can be used in parallel.Smaller drum system can be used to feed a more homogeneous as excrement, dead animals and leftover food. This unit range is from 1.5 to 3 m in diameter and 3 to 15 m long. Rotating drum reactor has a shorter retention time of 3 to 5 days. In practice, the drum works on the early stages of composting. Material removed from the drum is usually cured in the limit, an aerated pile composting system or second composting system. Drum starts feed composting quickly and uniformly in a high and controlled temperature environment. Drum is effective especially to homogenize heterogeneous mixture such as municipal waste. Lack of ventilation causes the production of an organic acid and a decrease in pH in the drum. This is why drum is used in early stages of composting. In few cases, composting time is extended to a few weeks and this in turns allows aerobic degradation of many acids with the decrease in ventilation rate. In other cases, compost will reach maturity after 3 to 5 days in the drum. The materials released from this short retention time may be useful on only certain applications for example application on soil during winter and autumn. However,according to compost maturity analysis, the period of several weeks is necessary in agriculture application (Rynk& Richard 2001). One of the important features of rotating drum reactor is its ability to produce granulate products. In industries such as fertilizer, the granulation process is successfully done in rotating drum reactor (Walker et al. 2003; Hanafiet al. 2000). Granulate products are important in order to reduce dust and this will minimize the risk of material loss, inhalation and blast. It also improves the flow, is manageable, increasedensity and speeds up the mixing of materials (Ivesonet al. 2001). 2.5.1.1 RotatorComposter Design and Description Used in This Study Rotator composter reactor system as shown in Figure 2.4 consists of 3 main components. There are rotator drum, air compressor and gas absorber. Rotator drums functionally facilitated with 3 phase motor. There are 8 inner blades with length of 5

- 11. 20 cm each in order to enhance the mixing in the reactor. On the other hand, air compressor functionsas to provide air to the reactor, hence the function of gas absorber is to absorb gas and air resulting from the process inside the reactor. Absorber used in this reactor is charcoal. The characteristic of each components of the reactor is as shown in Table 2.3. Mixing of palm oil mill effluents (POME) and empty fruit bunches (EFB) is inserted through the feeding part. Figure 2.4Rotatorcomposter reactor system Table 2.3 Rotatorcomposter reactor system specifications Rotator Composter System Material Stainless steel Length 3m Diameter 0.6 m Initial active volume 0.4 m3 Maximum rotation 2 rpm (rotation per minute) To be continued…

- 12. 21 Continued… Air Compressor Model SWAN DR 115 Ability 122 liter/min Speed 1450 rpm (rotation per minute) Cycle 50 Hz Motor Model CHENTA, Taiwan Volt 400 V Current 9.1 A Cycle 3.50 Hz 2.5.2 Bin-composting This type of composting can be done easily even at home provided that there is enough space to install the composter. The composter can be installed in the garden or on a balcony. Composter is a simple box, made of wood or plastic that can also be home-made. It has a lid to prevent rodent and other animals from eating the compost feedstock and is in contact with soil to enhance biological activity.In general, yard trimmings, preferably shredded and food waste can be added to the composter. Nevertheless, a few restrictions on what kind of organic waste should be put in the composter must be observed. Meat, fish, dairy products and sanitary material (e.g. diapers) are to be avoided because they are likely to attract vermin. Besides that, the temperature in the compost heap is usually too low to kill potential pathogens present in such waste and contamination must be avoided (USEPAEnviro.com 2006).Composter can be more sophisticated: the composter might have a forced aeration system or be automatically turned on. It might also have an odor-control system as well as a leachate collection system. In this study, the composter size is90 cm high and its width is 60. The composter has system of natural ventilation at its bottom and the plasticcompost bin is made of dark color so as to absorb as much heat

- 13. 22 from the Sun as seen in Figure 2.5. Through access doors at thebottom, the finished compost can be moved out. The organic waste was poured from the upper part of thecomposter and it involves waste collected from wet market with removed non composting materials(such as plastics, metal etc.) which has been chopped or shredded into smaller sizes for faster decomposition andhas been well mixed. Figure 2.5 Bin composter 2.5.2.1 Types of compost bins There are several types of compost bins available as follows. Description of each bin is explained in details. 1. Worm Bins Worm composting is unique because it uses only food scraps and not yard waste. It is ideal for people with very small yards or with no yard. Plastic storage bins with holes drilled on the bottom and on the sides are good for starting out. Homemade wood bins are easy to make. Manufactured bins with layers help in separating worms from compost work reasonably well and can be kept indoors but they can be expensive (Compost Bins). 2. Heaps This is the simplest composting method.However, compost in a heap may take up more space than a bin. It is not recommended for food scraps as four-legged critters

- 14. 23 are likely to visit looking for a meal. To keep it from drying out in summer and getting too wet during the winter, a heap or open pile should be covered (Compost Bins). 3. Hoops This type of bin is not costly and can be made from lengths of wire fencing or from woodenpallets. Hoops are enclosed and are tidier than a heap andcan be moved and covered easily.However, they are generally not animal resistant. Hoops are easy to take apartand reassemble when turning or removing compost (Compost Bins). 4. Tumbler or Spinner These self-contained barrels, drums or balls rotate for easy mixing and fast decomposition. They are more costly than other systems. Although most models are easy to turn, end-over-end models can be nearly impossible to turn and poorly balanced when they are full. Tumblers and spinners are suitable for small spaces and are usually animal resistant. Since they must be loaded in batches, you will either have to store fresh materials or use two tumblers. The materials in one will be decomposing while the other is being loaded (Compost Bins). 5. Multi Bin System This is a great system for a household or community space generating a significant amount of waste. It is efficient,allowing you to have three working piles at different stages of decomposition. It is easy to turn and harvest. This style bin can be made animal resistant (Compost Bins). 6. One Bin System A one-bin system canbe square, circular or cone shapedand can be commercial or homemade. Most commercial bins have lids andgood ventilation.They are of animal resistant.These bins are good for smaller yardswhere there is a small amount ofmaterial to be composted. Bins aid inmoisture and heat retention. Manyprefer the neat appearance of enclosed bins.Although some have small doors near the base, turningthe material and/or removing the compost typicallyrequires lifting the bin up and over the material and reloading it (Compost Bins).

- 15. 24 Figure 2.6 Types of compost bins 2.6 OPTIMUM FACTORS FOR THE COMPOSTING PROCESS Composting process control is very important in order to achieve a short processing time at a lower cost, consistent results and free from pathogens and odour (de Bertoldiet al. 1985). The composting of sludge is controlled by few factors such as temperature, ratio of C to N (C/N), moisture content, free air space, pH, ventilation, rotation and material adapter like stools, wood dust, flying ash and etc. These factors rely on each other (Figure 2.7) (Campbell et al. 1990). Figure 2.7 Schematic of granulation process Source: Iveson et al. 2001

- 16. 25 2.6.1 Temperature Temperature in the composting material is a function of the rate of heat evolution and heat loss to the environment (Miller 1992; Liang et al. 2003). The temperature in the compost pile is very important to be controlled because it affects metabolism and microbial population (Liang et al. 2003; Campbell et al. 1990). Temperatures between 30 and 50 0C increase microbial activity based on the highest oxygen consumption (de Bertoldiet al. 1983). Temperature below 20 0C and more than 60 0C is proven to decrease microbial activity (Liang et al. 2003). However, the normal operating temperature range used are as follows: >55 0C to maximize sanitation, 45-55 0C to 0 maximizebiodegradation rate and 35-45 C to maximize microbial diversity (Stentiford1996). For sludge composting, temperature was found to be responsible for sludge drying (Buchanan et al. 1999; Walker et al. 1999). Figure 2.8. Major Factors which affect decomposition in composting Source: Campbell et al. 1990

- 17. 26 2.6.2 Ratio of C to N Sewage sludge with a low C/N ratio causes ammonia to become steam and temperature to not reach thermophilic temperatures (Qiao& Ho 1997). The high ammonia emissions can also cause toxicity in microbes and reduce the rate of biodegradation of cellulose (Shin &Jeong 1996). Available carbon source such as green waste and sucrose is added to sludge to improve the C/N ratio (Qiao& Ho 1997). When C/N ratio exceeds 35, microorganisms must go through a long lifecycle to oxidize excessive carbon to a suitable C/N ratio for their metabolic process to be achieved (de Bertoldiet al. 1983). This causes the composting process to become longer. Additional resources for nitrogen source such as stool or urea will reduce the composting time and cause the end result to be better as the ground adapter material (Hackett et al. 1999; Jokelaet al. 1997). At optimum conditions, thermophilic phase in stack is achieved in a shortertime and dehydration of material will be more effective (Jokelaet al. 1997; Walker et al. 1999). Metcalf and Eddy (1991) mentioned that excellent C/N ratio is of range 25- 35. In a larger scale, C/N ratio of 43 can also be considered since thermophilic temperature can be achieved within 24 hours and rate of water elimination is high (Jokelaet al. 1997). Sludge composting and solid waste from farm using ventilated limits with C/N ratio of about 18 was found not to hinder degradation of microbes (Tiquia& Tam 2001). Table 2.4 shows the early C/N ratio for a few composting process.

- 18. 27 Table2.4 Initial ratio of C/N used in variety composting processes. Sludge Suitable Ratio Composting References materials of Time, day C:N Pulp and Paper Mill Flying ash 70 245 Hackett et al. 1999 Pig Farms Waste 18 77 Tiquia& Tam 2000 Olive Mill Solid waste 27 60 Papadimitriou et al. of olive industry 1997 Sewage Waste 25 50 Pera et al. 1991 Cow Dung Peat moss 16 20 Yu et al. 1991 Cow Dung Paper 18 20 Yu et al. 1991 Wood dust 25 18 Liao et al. 1997 Pig faeces Peat moss 16 14 Lau et al. 1992 Grape residue Chicken manure 14 25 Ferrer et al. 2001 Vinasse (sugar industry) Cotton residue 19 70 Diaz et al. 2002 Gelatin-grenetine industry Urea and wood 30 55 Hoyos et al. 2002 dust Olive Mill Cotton residue 23 182 Paredes et al. 2002 Sewage Sugar, clay, and 13 50 Qiao& Ho 1997 wood dust Paper Mill Domesticated 64 168 Charest & poultry waste Beauchamp 2002 Source: Hackett et al. 1999 &Jokelaet al. 1997 2.6.3 Moisture Content and Free Air Space Sludge differs from organic materials because it does not contain fibre and is not capable of supporting high moisture content. When the free space in compost is filled with water, sludge will have a weaker structure and acts like a plastic. This will cause aerobic composting to stop and oxygen transfer will be prohibited. Aerobic composting will occur when the spaces are filled with air. There are five methods of lowering down moisture content of sludge which are recycling of materials that have been composted, the addition of bulking agents such as wood dust, the fixed use of agitation for compost aeration,addition of dry adapter and lastly, the drying of sludge before being composted (Buchanan et al. 1999).

- 19. 28 Liang et al. (2003) mentioned that moisture content is to be given more priority for monitoring compared to temperature in order to increase microbial activity. Optimum moisture content will fasten oxygen transfer hence increasing microbial activity, fastens decomposition and reduces odour (Goldstein 2002; Liang et al. 2003; Schaub& Leonard 1996; Tiquiaet al. 1996). An optimum moisture content is needed to overcome early cooling problems and also to avoid increase in bulk density (Goldstein 2002). Liang et al. (2003) mentioned that the minimum moisture content for sludge-saw dust composting is 50% in order to obtain microorganisms exceeding 1.0 mg g-1 hour-1. According to Metcalf and Eddy (1991), moisture content cannot exceed 60% for non-reactor system and 65% for reactor system. Goldstein (2002) stated that optimum moisture content for composting mixture of sludge and wood dust in aerated static pile is 55-65%. Table 2.5 shows the initial moisture content for few composting processes. Moisture content (MC) and free air space (FAS) affect the air movement and oxygen transfer in decomposing materials. Free air space is defined as ratio of gas volume to total volume. Free air space is closely related to other physical characteristics such as porosity (the ratio of vacant space volume with total volume), structure and bulk density. Biddlestone and Gray (1988) reported that the minimal porosity is 30%. Optimal bulk density for sewage sludge composting using reactor system and non-reactor system are 400-500 kg/m3 and 475-593 kg/m3respectively (Goldstein 2002; Schulze 1962). Haug (1993) combined free air space (%), porosity (P, %) and MC (%) through the following equation: FAS = P (1 - ) ----- (1) Whereby, P = 100 (1 - ) ----- (2) Where is bulk density (g cm-1) and is the particle density (g cm-1). Combining equation (1) and (2) results in,

- 20. 29 FAS = 100 (1 - )( 1 - ) ----- (3) Rearranging equation (3), MC = 100 - ( ) ----- (4) Moisture content (%) can be expressed in terms of FAS (%). Free air space of compost can be increased by adapter materials such as recyclable compost product and bulking agents such as saw dust. There are evidences stating that minimum moisture content for certain materials are related to the percentage of minimum free air space.Ventilation is difficult to attain in the initial stage of decomposition before steaming is carried outfordrying the mixture andtoincrease the volume of space. Addition of adapter materials can speed up the rate of composting process (Buchanan et al. 1999). Table2.5 Initial moisture of various composting process Sludge Adapter Initial Composting Reference Materials moisture time, day content, % Pulp and Fly ash 53 245 Hackett et al. paper mill 1999 Pig Farms Waste 65 77 Tiquia& Tam 2000 Olive Mill Solid waste of 51 60 Papadimitriou et olive fruit al. 1997 industry Sewage Waste 62 50 Pera et al. 1991 Cow Dung Peat moss 64 20 Yu et al. 1991 Cow Dung Paper 69 20 Yu et al 1991 Fish waste Wood dust 60 18 Liao et al. 1997 Sewage Glucose + wood 59 50 Qiao& Ho 1997 dust + clay Pig Faeces Peat moss 66-69 14 Lau et al. 1997 Gelatine- Urea and Sawdust 71 55 Hoyos et al. 2002 grenetineindu stry

- 21. 30 2.6.4 pH pH values are important since they play a huge role in affecting the soil acidity as well as composting process. An optimal pH value for sludge composting is in between 6 to 9 (Metcalf & Eddy 1991). If the pH is too alkaline, this will result in extreme rise in temperature which will lead to death of bacteria and volatilization of ammonia. When pH values are not in this range, bacterial activity will experience retardation and degeneration will slow down or stop entirely (Schaub& Leonard 1996). Addition of materials such as cotton waste and fly ash to the sludge will increase its pH value (Diaz et al. 2002; Hackett et al. 1999). Table 2.6 shows the pH value for few composting processes. Table2.6 Initial pH value for multiple composting process Sludge Adapter Initial pH Composting Reference material value time, days Pulp and Fly ash 8.9 245 Hackett et al. paper mill 1999 Pig Farms Waste 8.6 77 Tiquia& Tam 2000 Olive Mill Solid waste of 7.2 60 Papadimitriou olive fruit et al. 1997 industry Sewage Waste 7.0 50 Pera et al. 1991 Sewage Glucose + 7.0 50 Qiao& Ho wood dust + 1997 clay Paper Mill chicken 7.5 168 Charest & droppings Beauchamp 2002 2.6.5 Aeration Aeration is required for metabolic heat production from aerobic microbial. However, excessive air supply rate will increase cost and cause loss of heat from the compost pile while too little ventilation will cause anaerobic process (Polprasert 1989). In

- 22. 31 addition, aeration is important to remove the main waste product, carbon dioxide and water (Haug 1993). Table 2.7 shows the rate of aeration in few composting processes. Failure in aeration system can cause a slow decomposition, a process with high odour, a delay in achieving maximum temperature, a lower maximum temperature and low rate of water removal (Diaz et al 2002; Ferreret al. 2001; Haug 1993). According to Campbell et al. (1990), aeration rate depends on biodegradation properties of compost mixture. The harder the biodegradation, the lower the rate of optimum air required. For sludge composting, the proposed value is between 300-700 m3 air/tones of volatile compounds (VC)/days (Biddlestone& Gray 1988; Schulze 1962). Daily aeration with rate exceeding 1 000 m3 air/min tones of (VC)/days will cause cooling effect in composting (Campbell et al. 1990; Lau et al. 1992). Aeration is carried out either through natural passive air movement or by forced air. Passive aeration uses absorbing and natural air movement. Forced air depends on the fan to move the air through composting materials. There is a possibility of a third mode which is pure oxygen gas being injected into the reactor (Rynk& Richard 2001). Natural aeration or passive occur when there is diffusion and natural air movement. Natural or passive aeration is driven by at least three mechanisms namely molecular diffusion, wind and thermal convection. Oxygen is absorbed into the material because there is more oxygen in the outer than in the compost media. On the other hand, carbon dioxide will diffuse out. However, this process is slow and might give an impact to the aerated pile. If the compost pile is exposed, oxygen transfer is carried out by the wind (Haug 1993). Thermal convection is the main mechanism in most passive aeration composting system. Heat generated from the composting process raises the temperature of the gas causes a reduction in the density of the material.Hot gas moves out of the composting process, creating space and the cold outside air will enter. Ventilation rate is determined by the temperature difference between the gas in the ambient air and the air flow resistance of compost media. Thus, the actual air flow in

- 23. 32 the compost heap is dependent on the production of heat to drive the heat convection and the existence of the physical structure of the porous media in compost (Rynket al. 1992). Forced aeration can be supplied in a positive or negative way. Positive forced aeration is forcing air into the compost material while negative forced aeration is sucking the air out of the compost material. Positive forced aeration is good for air movement while negative aerationis suitable for inhaling the odour (Rynk& Richard 2001). Forced aeration can be performed continuously or intermittently depending on the requirements of the process.Continuous aeration can reduce the rate of air flow, reduce temperature fluctuations and oxygen.However, continuous aeration will cause the slope of the composting environment, causing extreme drying and cold areas that remain in the air in (Rynk& Richard 2001). Aeration can also be supplied intermittently so that the maximum temperature in the process can be achieved for longer time and final compost will be safer (Lau et al. 1992). 2.6.6 Rotation Rotation can be conducted using the front loading tractor. Rotation provides ventilation, reduced particle size, ensuring that the material experiences the highest temperature, renewing microbial activity, increasing porosity and producing a more uniform compost heap (Biddlestone& Gray 1991; Diaz et al. 2002; Hackett et al. 1999; Thambirajah&Kuthubutheen 1989). It is also the primary mechanism for aeration and temperature control systems for composting using bounds (Tiquiaet al. 1997). Heap of pile which is rotated experiences reduction in volume by 55 to 72% (Larneyet al. 2000). The loss is found in mass of C, K and Na (Tiquiaet al. 2002). Maturation process is achieved at a faster rate for composting of faeces by rotation (Tiquiaet al. 1997).

- 24. 33 The rate of rotation also contributes to the effectiveness of composting. It is suggested that inversion of 3-4 days in a week is necessary for composting (Tiquia et al. 1997; Wong et al. 2001). High frequency of rotation leads to electrical conductivity and low NH4-N content and also a low rate of thermophilic phase because of heat loss by evaporation and volatilization of ammonia in the stack (Wong et al. 2001). The disadvantages of using front loading are that it takes a longer time and uses a large space (Biddlestone& Gray 1991; Tiquia& Tam 1998). Rotation can also be carried out in rotating drum. The main function of rotation in composting is that it exposes materials to fresh air, increases oxygen and dissipates the heat and gas from the product of composting (Rynk& Richard 2001). Rotation in the rotating drum can also reduce air pollution (Tiquia& Tam 1998) and ease the mixing process. However, the rate of rotation has to be minimized because frequent rotation will produce large lumps. In the composting of sludge- waste, the rotation of rotating drum was carried out for 5 minutes after the materials were added and also 5 minutes before the materials were removed (Schulze 1962). In the research by Smarset al. (2001), the rotation was limited to only 10-20 minutes per day. 2.6.7 Adapting Materials Adapting materials such as sawdust, paper, fruit waste and etc. greatly influence the decomposition process for active composting, maturation and storage (Eklind&Kirchman 2000). There are two types of adapter namely structural adapter and energyadapter. Structural adapter acts as a bulk weight reduction and increases air space thereby improving its aeration. Energy adapter increases the amount of biodegradable organic matter in the compost mixture (Liao et al. 1997). Adapter materials are necessary in composting because they influence the pH, C/N ratio, humid content and air supply to aerobic bacteria (Golueke 1991). Therefore, adapter materials are significant in improving microbial degradation process and also in producing good quality compost so as to ensure its compatibility as fertilizer and soil

- 25. 34 adapter (Liao et al. 1997). The release of ammonia from mass of compost has been reduced by addition of woody material, peat and vermiculate (Bhamidimarri&Pandey 1996; Liao et al. 1997; Qiao& Ho 1997). Coal fly ash is found to reduce the potential of the metal reactions (availability) in sewage sludge composting (Wong et al. 1997). Composting studyofvinasse (sludge sugar industry) mixture and grape residue was performed in the reactor system. Increase in amount of vinasse (0-40% wet weight) was studied for 43 days. The increase in quantity of vinasse did not affect the pH value. Evolution of organic materials show higher loss and higher capability of biodegradation when vinasse mixture having a lesser volume. Loss of Nitrogen increased when quantity of vinasseinin the mixture increased. The optimum rate of vinassewas found to be in between 10-20% (Diaz et al. 2002). Composting of vinasseand cotton waste was carried out by adding vinasse (0-80% mass) in the reactor for 23 days. It was found that 20-30% of vinasse is the optimum condition since the final product was of good quality, higher rate of biodegradation and the minimum loss of N (Diaz et al. 2003). Ash was mixed at 0-50% (dry weight) together with sewage sludge and composted for three months. The emission of carbon dioxide for every amount of ash was found to be similar except for 50% of ash. However, the emission of carbon dioxide experienced a reduction as the quantity of ash was increased. This indicated a decrease in microbial activity. The increment in content of salt and pH was believed to cause this inhibition. Rise in more than 25% (dry weight) resulted in a decrease in the growth of thermophilic bacteria and the production of carbon dioxide.Dry ash of lesser than 25% in amount is compatible for composting of ash-sludge (Fang et al. 1999; Wong et al. 1995; Wong et al. 1997). Shin and Jeong (1996) have reported studies of food waste composting with various amounts of paper of 33%, 50% and 67% (wet weight). Mixture which contained 33% of paper was found to have inhibitory impairment due to excessive release of ammonia. From this study, it was found that the highest degradation of cellulose is 61% when the paper content in the mixture is high.

- 26. 35 One of the commonly used adapter materials in the composting process is wood waste such as sawdust and bark.Wood waste takes a longer time to be biodegradedand is usually burned to be disposed. There are numerous studies on reuse and recycling of sawdust such as making fuel, liquid absorbent, building additives and etc. Wood waste is less suitable as a soil adapter since its C/N ratio is high. However, by adding nitrogen source such as sludge, wood waste can be converted into soil adapter materials (Siddiqui&Alam 1990). The use of wood waste as an adapter material in the composting process appears to increase the porosity, ability to hold nutrients, reducing odour and enhancing its energy when applied at the appropriate amount (Bhamadimarri&Pandey 1996; Liao et al. 1994; Tiquia& Tam 2000). Wood waste was found to have the ability to reduce pathogens more effectively compared to other agricultural waste during composting of sewage sludge (de Sales-Papa 2002). The difference in composition of different wood tissues from species to species resultsintheinconsistent rate of decomposition of wood dust on every different species. Liao et al. (1997) reported that sawdust from hardwood is more readily biodegradable compared to sawdust from softwood. Sawdust from hardwood is better inholding nitrogen. However, it produces a higher concentration of phenol during the process of composting. In sewage sludge composting, usage of sawdust is more suitable as a bulking agent compared to hay and grass (Furhacker&Haberl 1995). Waste wood has the highest reduction of organic matter, dries the sludge and reduces pathogens compared to other materials (de Sales-Papa 2002). In swine waste composting, wood waste is partially decomposedin swine waste providing sufficient empty air space and thus allowing delivery of oxygen to the microorganisms (Tiquia& Tam 1998). Bhamadimarri&Pandey 1996 reported that wood dust has the ability to absorb moisture, providing carbon source, withhold nutrients and providing the appropriate porosity in the compost pile. Furhacker and Haberl (1995) reported that volume of wood waste must be more than 33% in sewage sludge composting using rotating drum. If the density of the

- 27. 36 sludge and wood waste is estimated to be 700 kg/m3and 100 kg/m3 respectively, then the minimum amount of wood waste needed is 10%.Liao et al. (1994) havecarried out the composting of fish waste by using 25%, 33% and 50% by weight of sawdust. The end result had a C/N ratio of less than 20 except for when sawdust of 50% was used. The pH value of compost with sawdust of 50% is lower than the others because of low ammonia content. 2.7 COMPOST MATURATION According to Commision of the European Communities (CEC 1986), compost is the product of a stable composting process and free from pathogens which is beneficial for plant growth. It has undergone an early and fast decomposition process and also the process of humification. Humification is the process of partial conversion of the original material into humus which is a humicsubstance andis relatively inert (Tuomelaet al. 2000). The usage of immature compost will prevent the uptake of nutrientsby the microbial population which will further cause nitrogen deficiency in plants. Other than contributing to excess of carbon source, the presence of phytotoxicitymaterials such as ammonia and organic acid will speed up the decomposition process of immature compost which in turn will have a negative impact to the soil and plants. Plants interact with the retarded environment by lowering down metabolic rate, decrease in root respiration, drop in nutrient absorption and lowers down the synthesis and transport of gibrelin and cytokinins (Jimenez & Garcia 1989). According to Jimenez and Garcia (1989), the techniques of observing compost maturity is divided into five namely,physical tests, microbial activity research, methods of compost humic fractions, chemical method and biological method. The physical test includes observation of physical characteristics of compost mixture such as its temperature, odour and colour. Microbial activity research includes counting of total microorganisms, respirometric research, biochemistry parameters for microbial activity and analysis of biodegradable material. On the other hand, method of compost humic fraction covers chromatography test and photocalorimetric method. Chemical

- 28. 37 method includes C/N ratio (solid state), pH, cation exchange capacity and the presence of nitrate and nitrite. Example of biological method is the test of germination of seed to detectphytotocity. The maturation process greatly depends on the composting materials and not on the type of system (reactor or non-reactor) used (de Bertoldiet al. 1983).Faeces- straw composting in rotary rotating drum requires three months of composting for compost maturation using the row system (Vourinen&Shaharinen 1997). Furhacker and Haberl (1995) composted sewage sludge with wood chips for 4 to 5 days and the maturation process took 6 months. Composting of paper industry sludge with faeces using row system failed to undergo maturation after 6 months based on C/N ratio and calometric test (Charest & Beauchamp 2002). Table 2.7 shows the time taken for composting process in multiple systems. Table2.7Duration of composting process for combination of systems and materials System Mixture Range of Usual Maturation composting composting time time Static stack Leaves 2-3 years 2 years - Livestock manure 6 months – 2 1 year - years Aerated static Sludge + wood 3-5 weeks 4 weeks 1-2 months pile waste Leaves 6 months-1 9 months 4 months Bounds, year irregular Livestock manure 4-8 months 6 months 1-2 months round Bounds with Livestock manure 10-12 weeks - 1-2 months passive Fish waste + peat ventilation 8-10 weeks - 1-2 months Stirred layer Sludge+compound 2-4 weeks 3 weeks 1-2 months waste or Faeces+wood dust Rotating Sludge and/or 3-8 days - 2 months drum solid waste Source: Carr et al. 1995

- 29. 38 2.8 COMPOST AS SOIL ADAPTER MATERIAL The addition of direct waste into the soil will cause a change in the ecosystem of the growing plant. The waste which is not composted and added to the soil causesmicroflorato decompose them and produce transition metabolites which will inhibit the growth. In addition, a tussle between microorganisms and soil nitrogen, a high carbon to nitrogen ratio and the production of ammonia in the soil will occur (de Bertoldiet. al 1983). These conditions can be improved by the production of good compost. Compost releases nutrients at a slower rate (Keeling et al. 1994; Maeda et al. 2003).Sikora and Enkiri (2000) described the rate of mineralization of sludge compost to beabout 9.3% to 29% of the total nitrogen.Composting has many uses in the field of agronomic, horticulture and forestry. It can be used for field crops, tree seedlings, plants in the greenhouse, nursery plants, flowers and herbs grown on the land. It can also be used to maintain organic matter, structure and fertility of agricultural land, to support urban landscape, to reclaim abandoned land such as mining areas, to create a landscape and to close the landfill space (Rynk 1992). Function of compost in the soil and in the relationship of the land-plant interaction is different with conventional fertilizer even though compost has nutrients like N, P, and K. The main purpose is not to enrich the soil compost with this element but isto supply humus and improve soil structure (de Bertoldiet. al 1983). Humus is an organic material that is relatively stable. It is very important in maintaining good soil structure, especially in fine-textured soils.It increases the cation exchange capacity, resulting in the loss of elements such as potassium, calcium, and magnesium (Tisdale & Nelson 1975). Application of sludge-waste composting in city has found to improve soil-water content, water holding capacity, saturated hydraulic conductivity, compression, aggregation, total porosity and pore size distribution (Aggelides&Londra 2000; Yadavet al. 2002). Atiyehet al. (2001) stated the potential of compost to supress soil-borne plant pathogen. Table 2.8 indicates the various types of compost quality which is produced from sludge. Compost is easier to be applied to soil, easily maintained, easily stored and transported as compared to sludge/waste

- 30. 39 without composted. It is also a soil medium adapter which is not costly (Hackett et al. 1999; Van Heerdenet al. 2002). Table 2.8 Quality of compost of sludge for soil adapter materials Type of Adapter Organic N, % P, K, Note Reference sludge Materials Material ppm ppm % Gelatin Wood dust 55-58 2.4- 2000- 4000 No odour Hoyoset industry 4.3 3000 0- for final al. 2002 4200 compost 0 Paper Livestock 53-58 0.7- 2600- 3000 Achieved Clarest& industry manure 0.9 3700 - compost of Beaucham 4000 B Standard p 2002 Pulp and Fly ash 58-63 Not 100- 870- Application Hackett et paper stated 119 970 for 15m3/ha al. 1999 industry to improve soil nutrient Sewage Horse Not 1.1- 9600- 8200 Addition of Warman& droppings stated 1.2 16000 - compost Termeer 9400 and peat 1996 improves tree growth Olive Cotton 36-88 1.4 - Not Not Adapter Paredes et industry waste/corn 1.7 stated state materials al. 2002 stalk d influences compost product Sugar Grape Not 1.8- 32 1700 Suitable Madejon industry waste/cott stated 2.7 000 0- with et al. 2001 on waste 2000 moderate 0 compost dose application 2.8.1 Plant growth and factors affecting it Growth is interpreted as a progressive development of an organism.Plant growth can be referred as the development of a specific organ or the whole plant. Growth can be

- 31. 40 expressed within the definition of dry weight, length, height or diameter. The factors which affect plant can be divided into two namely genetic and environmental (Tisdale & Nelson 1975). Environmental factors which are important in affecting plant growth are temperature, moisture content, energy radians, atmospheric composition, gas content in the soil, soil reaction, biotic factors and supply of mineral elements.Temperature has a direct impact on plant functions such as photosynthesis, respiration, cell wall permeability, absorption of water and nutrients, transpiration, enzyme activity and protein coagulation. Water is required for construction of carbohydrates, maintaining protoplasm hydration and also as a tool for food and mineral elements translocation.When the temperature or water content is not optimal, then plant growth will decrease.Plants will generally grow well in low light intensity than in high light intensity.However, plants vary in their response to light. Air content consisting of sulphurdioxide, carbon monoxide and hydrofluoric acid can cause toxicity in plants (Tisdale & Nelson 1973). Among the mineral elements which are essential in plant growth are nitrogen, phosphorus and potassium. Nitrogen is an important plant nutrient. It is absorbed by plants in the form of nitrates although it can also be absorbed in the form of ammonium ion and urea.When adequate nitrogen is supplied, plant growth occurs well and are coloured green.However, when the supply of nitrogen is in excess, it can cause slow plant maturity, causing plant fibers to become softer and more susceptible to disease and insect attack.Lack of nitrogen causes the plant to be retarded and yellowish.Initially, the process of plant becoming yellowish will strike the bottom of the plant, followed by parts of plants. When nitrogen deficiency is more critical, plants can also die. Phosphorus is absorbed by plants in the form of ions in the form of orthophosphate, H2PO4- and dissolved organic phosphate. Phosphorus plays a significant role in plant root development. It also accelerates the maturation of plants, increase the quality of product and resistance to disease.Phosphorus deficiency will also retard the overall growth.Plants absorb potassium in the form of K+. Potassium

- 32. 41 deficiency is most easily detected by inhibition of leaf characteristics.In addition, potassium deficiency causes the plant growth to be reduced, reduced resistance to disease, degradation of roots and reduction in photosynthesis. The other important features of potassium are that it maintains an appropriate water-plant relationship and plant metabolism (Tidale& Nelson 1975). Soil structure greatly influences the development of roots and the shoot of plants. The higher the bulk density of the soil, the more compact the soil will be, causing weakened soil structure and smaller air space. High soil bulk density resultsin mechanical resistance to root penetration to increase.This condition usually affects the rate of oxygen absorption into the soil porous space and root respiration is directly associated with the gas supply is adequate and continuous.Water holding capacity of compost/soil shows the maximum moisture that can be supported by the dry soil at standard conditions.The value of water holding capacity is essential to determine the moisture needed for plant growth. Porous area/porosity is the volume fraction of soil/compost that is not filled by a solid material. Porous space is important for air and water movement in the soil (Iswaran 1980). In addition, the amount of oxygen in the soil is also important for plant growth. Soil reaction (soil acidity, pH) affect plant growth by influencing the availability of certain elements needed for plant growth.At acidic pH, the reaction capacity of phosphate, manganese and molybdenum were found to decrease.When nitrogen in ammoniacal form is applied on the surface of the soil at a pH above 7, the ammonia will be lost due to volatilization.In addition, the disease from the soil can also be caused by neutral-alkaline soil conditions. There are many biotic factors that will limit plant growth for farming operations and shows the potential threat to reduce the crop, if not to the destruction of the crops. Imbalance of available nutrients can also increase the incidence of disease and insect infestation (Tisdale & Nelson 1973). 2.8.2 Effect of various amount of compost on plant growth Compost affects physical, chemical and biological characteristics of soil by influencing the permeability, porosity and structure, as well as the redistribution of

- 33. 42 movement and transportof nutrients.Therefore, the occurrence of some of the activities and biosynthetic microbial degradation results in improvement of soil fertility, particularly in terms of the supply of nutrients to plants.Nutrient intake occurs at rhizosphere (zone encircling the land and influenced by plant roots) and it is stimulated by microbial metabolites. Microbial metabolites are capable of influencing or enhancing the influence of the enzymes in plants.Composting improves mineral nutrition, protein synthesis and carbon assimilation and increases the production of the entire plant.In addition, the roots will produce more exudates to the soil. Thus, composting is a new source of energy that stimulates the growth and microbial processes and subsequently, the metabolism and plant growth (Figure 2.9)(Tomatiet al. 1996). Soil reactions to the application of compost depends on a number of factors including the type of compost and composition, level and application method, soil properties and weather conditions (Abdel-Sabour& Abo El-Seoud 1996). Pinamontiet al. (1997) reported that ornament plants were found to grow well with a mix of 50% sewage sludge compost and bark.Hountinet al. (1995) reported that the application of compost with peat shrimp waste exceeding 240 tonnes/ha also showed no increase in the development of barley.However, Klock (1997) reported that trees namely Impatienand Snapdragoncan grow fertilein 100% composted sewage sludge together with farm waste.Applications of droppings on sandy soil can improve crop production of plantation Brassica parachinensis andBrassica chinensiscompared to sandy soils alone and treatment with synthetic chemical fertilizers (Wong & Wong 1987). Composting of sewage sludge is also found to increase the yield of corn and grain(Abdel-Sabour& Abo El-Seoud 1996).

- 34. 43 Figure 2.9 Influence of compost on plant system Source: Tomati et al. 1996 2.9 GENERATED SOLID WASTE Total solid waste that is generated in Peninsular Malaysia is increasing from day to day. The average of solid waste produced can be divided into 45.0 percent food, 24.0 percent plastic, 7.0 percent paper, 6.0 percent steel, 3.0 percent glasses and etc. (Ninth Malaysia Plan). Generation rate of these solid waste differ depending on types of area, total population and occupation or business (Agumuthu 2001).

- 35. 44 2.10 DOMESTIC WASTE Solid wastes that are produced everyday are result of thrown waste of domestic and housing sectors. There are specific categories that have been identified in producing these solid waste including housing waste, commercial waste, construction waste, environmental waste and etc. These waste producedare mainly from housing wastes which includes food waste, papers, plastic which are in the forms of solid, semi-solid, or liquid.Organic materials are easy to decompose, decay at a faster rate and extract odd odour that can disrupt public peace (Agumuthu 2001). 2.10.1 Housing Waste Housing waste produced from activities done by individual in every home are also in forms of solid, semi-solid and liquid. Most of these housing wastes consist of food waste, papers, boxes, plastic and aluminum which are easily decomposed and decayed (Agumuthu 2001). 2.10.2 Business Waste These types of wastes are a result of business activities, management and trading. These wastesare usually in forms of solid/semi-solid and are easily disposed through combustion. Examples of businesswaste are business premises waste and office utilities such as papers, files, stationeries, plastic and etc. (Agumuthu 2001). 2.10.3 Industrial Waste Almost half of waste from industrial sectors and factories exist in forms of solid and liquid. Examples of industrial waste include wood, plastic, scrap metal, sheet metal and etc. Generally, these industrial wastes are divided into two parts, which are danger and non-danger wastes. Danger wastes usually contain chemical substances, biology process waste and also radioactive waste, whereas non-danger waste are of plastics, steel, fiber, and etc. (Agumuthu 2001).

- 36. 45 2.10.4 Construction Waste Constructions waste are mainly produced from constructions of new building, construction sites, road repairing work, building renovation, demolition of old building and etc. Most of the wastes are in solid form such as woods, steel, rock, plaster, concrete and etc.(Agumuthu 2001). 2.10.5 Environmental Waste Most of the environmental wastes produced are in forms of solid. Examples include dried leaves, grasses, tree branches, wood and other waste from gardens and landscape (Agumuthu2001). 2.11 FACTORS INFLUENCING THE REVENUEOF SOLID WASTE According to studies by (Laimanet al. 2005) entitled ‘Revenue and Composition of Solid Waste’ in Mukim Melaka Tengah, Melaka, there are various factors influencing the increasing revenue of solid waste. Amongst them are mainly housing type that involves way of living and eating styles in every house namely the high-class, middle- class, and low-class housing. Besides that, according to Yusof(2007) in Comparative Research between the Usage of Soil and Wood Powder on Organically Kitchen Waste Composting System, among the involving factors that influence the generation of solid waste are geographically, seasonal, attitude of individual and types of residence. 2.11.1 Geographical Factor Generally, the geographical factor of an area or country does affect its weather. For example, Malaysia is a country that is situated on the equator line that is always experiencing moist and hot weather throughout the year. However, the monsoon wind that hit this country will cause the raining season on certain times of the year. On top

- 37. 46 of that, the frequent cooking will increase during these seasons and result in rise of food waste produced than usual. 2.11.2 Seasonal Factor Seasonal factor includes the fruitsseasons, festive, vacations/school breaks and etc. Generally, the rate of waste disposal during these seasons will increase and become the generated factor of solid waste in Malaysia. The solid wastes produced are food wastes generated in large quantity from food prepared by the house residence and also from fruit skin waste from the orchards during fruit seasons. 2.11.3 Society Attitude Factor The attitude of the society and public that underestimates the result of increased solid waste contributes to the increasing generation of solid waste. Generally, the public are unaware of their attitude of throwing rubbish which in real fact is affecting the cleanliness of the environment. 2.11.4 Type of Residence Factor The quality of the environment can easily be affected by the attitude of residence in Malaysia. In studies conducted by Laimanet al.(2005), lifestyles and economic factors can affect the amount of expenses and eating styles whereby it is proven that the higher the expensesand the bigger the size of a family, the more solid wastes are generated. 2.12 SOLID WASTE MANAGEMENT Solid waste management in Malaysia is not systematic and efficient. Generally, the waste produced will be disposed at the disposal site provided. Five years ago, there were 230 disposal site set up in this country. However, only 170 disposal sites are registered to accommodate the rising waste produced. Unfortunately, almost 80% of

- 38. 47 the disposal sites available now will be closed in a period of two to three years in the near future. There are few methods being applied to overcome the increasing amount of solid waste producedin Malaysia such as recycling, composting system of wet waste, and the reduction of reusable waste. For recycling process, either all or some parts of the items are being reused again. 2.12.1 Disposal Sites Solid waste disposal sites are the easiest and cheapest method used. Generally, the disposal sites are operated by dumping the wastes into the Earth and thenby burying them. These disposal sites are usually situated in places of abandon quarry, mining area and loan holes. According to Syarina(2007) the disposal sites are divided into two types which are sanitary and non-sanitary disposal sites. However, almost all disposal sites in Malaysia are non-sanitary disposal sites. This method requires the waste to be trimmed and compressed inside the ground with heavy-machinery. The surface of the waste are then sealed with soil to prevent bad odor. However, this method can contaminate the environment through the diffusion of waste in the ground and then to undergroundwater. On the other hand, sanitary disposal sites are covered with geotextile fiber to prevent waste diffusion into the underground water.This diffusion will then be channeled and treated at a diffusion treatment plant. 2.12.2 Incinerator Incinerator is a type of solid waste disposal that involves waste combustion. This method will convert the solid waste into heat, gases, vapour, ashes, and chemicals. However, there are few places in the world that has stopped this method due to its destructive effect to the environment and also to health. The ashes from the incinerator contain poisonous materials including lead, mercury and cadmium.

- 39. 48 2.12.3 Recycle Recycling is a process ofobtaining or ensuring half of the materials of solid waste can be reused again. The recycled materials include glasses, plastic, paper product and aluminum can. There are multi types of recycling barrels that can be seen in public places to tell the public the importance of recycling. According to Yusof(2007), the success of recycling can reduce the control cost of handling solid waste and environmental pollutions. Malaysia has targeted the rate of recycling to increase by 22% in the year 2020. 2.12.4 Composting System Solid waste in organic form such as plants, food waste and paper products can be recycled using the method of composting system and biological digestion to decompose the organic matter. This method can be easily done and managed to produce fertilize compost product that can be used in agriculture. This method of composting was practiced before the Second World War. However, it is still not usedtraditionally intoday’sworld (Day et al. 1998). 2.13 PALM OIL MILL EFFLUENT SLUDGE (POMES) The market for palm oil industry is continuouslybeing an attractive topic even though it is now sold at about one half of its highest price recorded. In Malaysia, palm oil industry is growing quickly becoming a significant agriculture-based industry. A total of about 80 million tonnes of palm oil and 57.4 tonnes of palm oil mill effluent (POME) was generated in the year 2009 (MPOB 2009). Malaysian government is also supporting the treatment process of palm oil mill effluent (POME) in order togenerate biogas that can be an alternative source of electricity. Moreover, the palm oil industry provides a source of livelihood to rural families throughthe government land schemes and private small holders as well as employment opportunities to agriculture workers in estates (Ma et al., 1993).

- 40. 49 The production of palm oil may result in the generation of huge quantities of highly polluting waste water, also called as palm oil mill effluent (POME). The properties of POME include thick brownish viscous liquid waste but non-toxic as no chemicalsis added during oil extraction. However, it has an unpleasant odour. POME is predominantly organic in nature but highly polluting (Ma 2000). Other than that, POME is a colloidal suspension of 95 – 96 % water, 0.6 – 0.7 % oil and 4 – 5 % total solids including 2–4% suspended solids originating from mixture of sterilize condensate, separate sludge and hydrocyclone wastewater (Ahmad et al. 2003). POME has been identified to be one of the major sources of water pollution due to its high biochemical oxygen demand (BOD) and chemical oxygen demand (COD) concentrations. Hence, Malaysian government had enacted the Environmental Quality Act (EQA) in 1978 and parameter limits were set for the discharge of POME into the environment. The parameter limits are as shown in Table 2.9. Due to the mentioned characteristicsof POME, a wide range of approaches for POME treatment have been developed to alleviate the pollution problems caused by the palm oil industry. The conventional treatment technology of POME employed in most of the palm oil mill factories in Malaysia which is the ponding system of biological treatment have been adapted (Chin et al., 1982). However, with the increasing production in most palm oil mills, the under-sized biological treatment is unable to cope with the increased volume of POME (Ismail 2005). Therefore, a proper POME treatment is needed urgently in order to ensure the sustainable economic growth of palm oil industry without neglecting the precious environment. Table 2.9. Characteristic of POME and its respective standard discharge limit by the Malaysian Department of Environment. Parameters Concentration (mg/L) Standard Limit (mg/L) pH 4.7 5-9 Oil and Grease 4000 50 BOD 2500 100 COD 50000 - Total Solids 40500 - Suspended Solids 18000 400

- 41. 50 The global energy demand is growing rapidly and at present time,about 88% of this demand is met by fossil fuels. Researches have shown that the energy demand will increase during this century by a factor of two or three (EIA 2006). At the same time, concentrations of greenhouse gases in the atmosphere is rising rapidly, with CO2 emission derived from fossil fuels being the most significant contributor. Therefore, environmental pollution due to the use of fossil fuels as well as their gradual depletion makes it necessary to find alternative energy and chemical sources which are environmental friendly. For fossil fuel-derived energy, reduced environmental impacts by providing a clean fuel from renewable feedstock such as energy crops, organic fractions of municipal solid wastes and agro-industrial wastes is necessary (Chynoweth et al. 2001). Palm oil mill effluent (POME) from palm oil mill waste water is one of the obvious wastes in Malaysia. In Malaysia, palm oil is utilized for the production of biodiesel (palm oil methylester or palm oil diesel) for buses and cars and is a major expansion of Malaysian diesel production with 5% palm oil is expected for biodiesel production from the year 2006 (Kalam&Masjuki 2002 ; Reijnders&Huijbregts 2008). The production of biogas through anaerobic digestion offers significant advantages over other forms of bioenergy production. This has been evaluated as one of the most energy efficient and environmentally beneficial technology for bioenergy production (Fehrenbachet al., 2008). The proper control of anaerobic digestion of POME treatment will generate gas and renewable energy. Megatet al.,(1989) and Borjaet al.,(1996) had investigated the performance of anaerobic digestion of POME, whereby 62 – 98 % of COD reduction and 34 – 98 % of methane production was reported depending on feed rate, substrate concentrations and system operation. 2.13.1 Anaerobic Digestion in POME Treatment Anaerobic treatment is the most suitable method for the treatment of effluents containing high concentrations of organic carbon (Perez et al., 2001). A wide range of approaches have been developed for the POME treatment. This is because anaerobic system offers more potential for POME treatment due its high organic content. On the other hand, anaerobic treatment does not require high energy for aeration and

- 42. 51 allowsthe recovery of energy in the form of methane. The conventional way to treat POME which is widely used in Malaysia is the ponding system. Ma et al., (1993) reported that more than 85% of the palm oil mills in Malaysia have adopted ponding system for POME treatment. However, ponding system requires long retentions time and large treatment facilities because the system usually consist of de-oiling tank, acidification, anaerobic and facultative pond with hydraulic retention time (HRT) of 1, 4, 45 and 16 days respectively (Ma &Ong 1985). Another disadvantages by using ponding system as reported by Chin et al., (1996) are the system could not meet the effluent quality requirement. For instance, COD and BOD5 in the effluent were about 1725 and 610 mg/L respectively. Sporadic researches have been performed in order to find approachable solutions for POME treatment. The main aim of the researchers in POME treatment nowadays are to shorten the treatmenttime, lessen the land required and at the same time to collect the useful biogas produced.Borjaet al. (1995) in their research reported on usage of two stages upflow anaerobic sludge blanket (UASB) system in POME treatment. They observed that the optimum organic loading rate (OLR) in order to produce a good methane yield and COD reduction of greater than 90% is 30 g/l.d.COD. In addition, 4.1 g/l.d of acetic acid isproduced at OLR of 16.6.g/l.d.COD at only 0.9 days of hydraulic retention time (HRT). Furthermore, Zhang et al., (2007) examined the integration of biological method and membrane technology in treating POME. In their study, 43% organic matter in POME was converted into biogas and COD reduction efficiency reached 93% in the expended granular sludge blanket (EGSB) system. Najafpouret al., (2005) demonstrated the use of upflow anaerobic sludge fixed film bioreactor (UASFF) in treating POME. Their study showed a high COD removal of 89% and 97% at HRT of 1.5 and 3 days respectively. Besides, the highest organic loading rate (OLR) value of 0.346 l.CH4/g. COD removed of methane yield was obtained. The OLR value gradually increased from 2.63 to 23.15 g COD/l.d in this study.

- 43. 52 Table 2.10Literature on POME treatment using variable of anaerobic reactor System Influent COD removal HRT Methane Reference COD (COD/mg.L) (h or d) Production (mg/L) (%) UASB 30600 94 6.5d 63 Borja and Banks (1994) Anaerobic 30000- 97.8 40d 54.4 Yacob et Pond 40000 al., (2006) AF 25000 80.7 20d 36 Yacob et Digester al., (2005) UASFF 15000– 97 3d 71.9 Najafpour 35000 (2006) CSTR 20000– 80 18d 62.5 Tong and 35000 Jaafar (2005) SBR 11000– 96 20h NM* Chan et 18650 al., (2009) EGSB 79723 91 2d 70 Zhang et al., (2007) UASFF 44300 94 1.5d - 2.2d NM Zinatizade h et al., (2005 Anaerobic 25000 93.3 4.7d 63 Ibrahim et Contact al., (1984) Process Fluidised 15000 78 0.25d NM Borja and Bed Banks (1995) On top of that,Zinatizadehet al., (2005) studied about the kinetic evaluation of POME digestion in high rate upflow sludge fixed film bioreactor. They reported that with HRT ranges between 1 and 6 days, the removal efficiency of COD was between 80.6% and 98.6%. The methane production rate was between 0.287 and 0.384 l.CH4/g. COD removed. Their study also demonstrated the apparent rate constant, K calculated by simplified Monod model which were in the range of 2.9 – 7.41 l.CH4/g. COD. Other literatures on POME treatment using anaerobic treatment is simplified as shown in Table 2.10.

- 44. 53 2.14 NITROGEN FIXING BACTERIA Nitrogen is the most limiting nutrient for increasing crop productivity.Nitrogen is a critical nutrient for virtually all life forms. Input efficiency of nitrogenous fertilizers is low (Prasad et al. 1990) and in turn contributes substantially to environmental pollution. Nitrogen which is present in the atmosphere occupies about 79% of the air. Plants cannot use nitrogen in its gaseous state (Sing 2005). Many industrial important compounds such as ammonia, nitric acids, organic nitrates and cyanides contain nitrogen. However its conversion in utilizable form is very less and requires high amount of energy due to presence of triple bond between two N atoms(Singh 2005). Nitrogen fixing microbes (bacteria and blue green algae) has a natural power to bring about the conversion of N2 into NH3 which is further being incorporated into amino acids and finally into proteins.Nitrogen must be fixed or combined into either ammonia, NH3or nitrate, NO3. Specifically, tree legumes (Nitrogen Fixing Trees, NFTs) are valuable in subtropical and tropical agroforestry. They can be integrated into the agroforestry system to restore nutrient cycling and self-reliance fertility (Craig &Wilkinson 1995). There are many species of Nitrogen Fixing Trees (NFTs) that can provide numerous useful products and functions including food, wind protection, shade, animal fodder, wood fuel and timber in addition to providing nitrogen to the system (MacDicken 1994).Biological nitrogen fixation is the process that changes inert N2into biologically useful NH3. This process is mediated in nature only by bacteria. In legumes and a few other plants, the bacteria lives in small growths on the roots called nodules. Within these nodules nitrogen fixation is done by bacteria and the NH3 produced is absorbed by the plant. Biological nitrogen fixation can take many forms in nature, including in blue green algae which is a bacterium, in lichens, and in free-living soil bacteria (Lindemann 2003). An enzyme called nitrogenase performs this. Nitrogen fixing microorganismsfix nitrogen in five different modes.Through 6 biological nitrogen fixation, 180 x 10 tones nitrogen per year is being added to the soil but this figure is still insufficient to replace completely the use of chemical fertilizers. Various Nitrogen fixing systems shares this global fixation and the estimated contribution of each component is shown in Table 2.11.

- 45. 54 Table 2.11N-fixing systems share this global fixation and the estimate of contribution of each component Nitrogen fixing system Estimated contribution (kg/h/year) Free living 15 Cyanobacteria 7- 80 Aossciative Bacteria 36 Azolla/Anabaena 4.5-450 Frankia 2.0-362 Rhizobium-legume 24-585 2.14.1 Nitrogen Fixing Bacteria - Frankie Nitrogen is a critical nutrient for virtually all lifeforms. We get our nitrogen either directly or indirectly from plants. While nitrogen makes up about 79% of our atmosphere, plants cannot use nitrogen in its gaseous state. It first must be fixed or combined into either ammonia, NH3 or Nitrate, NO3-. The natural nitrogen cycle relies on nitrogen fixing bacteria like those found in the Frankia family of actinobacteria to supply the fixed nitrogen. Fixed nitrogen is often the limiting factor for growth, both in your garden and in the general environment. About 15% of the world's nitrogen fixed naturally is from symbiotic relationships between various species of the Frankia family of actinobacteria and their host plants.The plants that form symbiotic relationships with Frankia are called actinorhizal plants. Scientists have found over 160 plants that host these actinomycetes including alders, Russian olive, bayberry, sweet fern, bitterbush and cliffrose. The Frankia is able to provide most or all of the host plant's nitrogen needs. These nitrogen fixing bacteria and their host plants are often pioneer species on young nitrogen deficient and disturbed soils such as moraines, volcanic flows and sand dunes. They help in creating a reservoir of nitrogen rich soil that the next wave of plants can benefit from. Scientists believe that much of the new nitrogen in temperate forests, dry chaparral, sand dunes, moraines, and mine waste tailings is as a result of the mutualism of Frankia and host plants. They are the main nitrogen fixing relationships

- 46. 55 in large parts of the world and will only become more important as we adjust the climate change. Figure 2.10.Nitrogen fixing bacteria – Frankie 2.14.2 Nitrogen Fixing Trees for Agroforestry Nitrogen fixation is a pattern of nutrient cycle which has successfully been used in perennial agriculture for ages. Legumes, which are nitrogen fixers,are of particular importance in agriculture. The tree legumes (nitrogen fixing trees, hereafter called NFTs) are especially valuable in subtropical and tropical agroforestry. They can be integrated into an agroforestry system to restore nutrient cycling and fertility self- reliance. The "pioneer" plants (plants which grow and thrive in harsh, low-fertility conditions) begin the cycling of nutrients by mining and accumulating available nutrients. As more nutrients enter the biological system and vegetative cover is established, conditions for other non-pioneering species become favorable. Pioneers like nitrogen fixing trees tend to benefit other forms of life by boosting fertility and moderating harsh conditions. NFTs are often deep rooted, which allows them to gain access to nutrients in subsoil layers. Their constant leaf drop nourishes soil life, which in turn can support more plant life. The extensive root system stabilizes soil, while constantly growing