Contenu connexe Similaire à 7.simple connections Similaire à 7.simple connections (20) 1. T.chhay

VII. tMNsamBaØ

Simple Connections

7>1> esckþIepþIm Introduction

kartP¢ab;rbs;eRKOgbgÁúMEdkCaEpñkmYyEdlmansarsMxan;bMput. kartP¢ab;EdlminmanlkçN³

minRKb;RKan; EdleKGaceGayeQμaHfa “weak link” enAkñúgeRKOgbgÁúM GacbegáItnUvkar)ak;CaeRcInkrNI.

kar)ak;rbs;Ggát;eRKOgbgÁúMKWkMrnwgekIteLIgNas; kar)ak;rbs;rcnasm<n§½PaKeRcInKWbNþalmkBIkar

KNnakartP¢ab; nigkarlMGitkartP¢ab;. bBaðaenHbNþalmkBIkarTTYlxusRtUvkñúgkarKNnakartP¢ab;.

kñúgkrNIxøH kartP¢ab;minRtUv)anKNnaedayvisVkrEdlKNnaGgát;rbs;eRKOgbgÁúMeT EtvaRtUv)anpþl;

eGayedayplitkrEdlpÁt;pÁg;sMPar³sMrab;KMerageTAvij. b:uEnþvisVkreRKOgbgÁúMEdlplitbøg;KNna Ca

GñkTTYlxusRtUvkñúgkarKNnaTaMgGs;rYmTaMgkartP¢ab;. kñúgkrNIEdltMNRtUv)anKNnaedayvisVkr

epSgeTot epSgBIvisVkrEdlKNnaGgát;eRKOgbgÁúM dUcenHeKRtUvkarvisVkrEdlmanCMnajc,as;las;kñúg

karKNnakartP¢ab;.

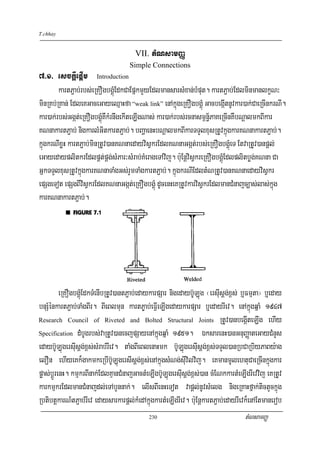

eRKOgbgÁúMEdkTMenIbRtUv)antP¢ab;edaykarpSar nigedayb‘ULúg ¬ersIusþg;x<s; b¤Fmμta¦ b¤eday

bnSMénkartP¢ab;TaMgBIr. BIeBlmun kartP©ab;eFVIeLIgedaykarpSar b¤edayrIev. enAkñúgqñaM 1947

Research Council of Riveted and Bolted Structural Joints RtUv)anbegáIteLIg ehIy

Specification dMbUgrbs;vaRtUv)anecjpSayenAkñúgqñaM 1951. ÉksarenH)anGnuBaØateGayCMnYs

edayb‘ULúgersIusþg;x<s;sMrab;rIev. taMgBIeBlenaHmk b‘ULúgersIusþg;x<s;TTYl)anRbCaRbiyPaBy:ag

elOn ehIyeKk¾gakmkeRbIb‘ULúgersIsþg;x<s;enAkñúgsMNg;sIuvilvij. eKmanmUlehtuCaeRcInkñúgkar

pøas;bþÚrenH. kmμkrBInak;EdlKμanCMnajGactMeLIgb‘ULúgersIusþg;x<s;)an cMENkkartMeLIgrIevvij eKRtUv

karkmμkrEdlmanCMnajdl;eTAbYnnak;. elIsBIenHeTot vapþl;nUvsMelg nigeRKaHfñak;tictYckñúg

RbtibtþkarN_tP¢ab;rIev edaysarkarpþl;kMedAkñúgkartMeLIgrIev. b:uEnþkartP¢ab;edayrIevk¾enAEtmanerob

230 tMNsamBaØ

2. T.chhay

rab;enAkñúg AISC Specfication nig Manual of steel construction edaysarEtsMNg;cas;²eRbItMN

rIev dUcenHkaryl;dwgBIkarRbRBwtþeTArbs;vamansar³sMxan;Nas;sMrab;karvaytMélersIusþg; nigkarCYs

CulnUvsMNg;TaMgenaH. karKNna nigkarviPaKtMNrIevmanlkçN³RsedogKñanwgtMNb‘ULúgFmμtaEdr Et

vaxusKñaRtg;lkçN³sMPar³Etb:ueNÑaH.

tMNpSarmanGtßRbeyaCn_eRcInCagtMNb‘ULúg. kartP¢ab;edaykarpSarmanlkçN³samBaØ nig

RtUvkarrn§ticCagtMNb‘ULúg. kartP¢ab;EdlmanlkçN³sμúKsμajCamYynwgeRKOgP¢ab;Gacman lkçN³

gayRsYlCamYynwgkarpSar dUckrNIkñúgrUbTI 7>1. muneBlEdlkarpSarmanlkçN³eBjniym kar

tMeLIgrUbrag built-up RbePTenHRtUv)anplitedayrIev. edIm,IP¢ab;bnÞHEdksøabeTAnwgbnÞHEdkRTnug

EdkEkg (angle shape) RtUv)aneRbIedIm,IbMElgbnÞúkcenøaHFatuTaMgBIr. RbsinebIeKbEnßmbnÞHEdkBI

elImYyeTot enaHplitplsMercnwgmanlkçN³kan;EtsμúKsμaj. b:uEnþkartP¢ab;edaykarpSarman

lkçN³gayRsYlCag. b:uEnþsMrab;tMNpSar eKRtUvkarkmμkrCMnajxagpSar ehIyvaBi)ankñúgkarGegát

nigcMNayR)ak;eRcIn. EtKuNvibtþienHeKGacedaHRsay)anedaykarpSarenAkñúgeragCagCMnYseGaykar

pSarenAkardæanenARKb;eBlEdlGaceFVIeTA)an. enAeBlEdlkartP¢ab;eFVIeLIgedaybnSMénkarpSar nig

b‘ULúg enaHeKeRcInpSarenAeragCag ehIycab;b‘ULúgenAkardæan. sMrab; single-plate beam-to-column

connectioction EdlbgðajenAkñúgrUbTI 7>2 bnÞHEdkRtUv)anpSarP¢ab;eTAnwgsøabrbs;ssrenAerag

Cag ehIycab;b‘ULúgCamYynwgRTnugrbs;FñwmenAkardæan.

edIm,IBicarNaBIkarRbRBwtþeTAénRbePTepSg²rbs;tMN eKRtUvEbgEckvaeTAtamRbePTénkar

dak;bnÞúk. rUbTI 7>3 a bgðajBI tension member lap splice EdlmaneRKOgP¢ab;rgnUvkMlaMgkat;. dUc

Kña tMNpSarenAkñúgrUbTI 7>3 b RtUvTb;Tl;nwgkMlaMgkat;TTwg. tMNrbs; bracket eTAnwgsøabssr

dUckñúgrUbTI 7>3 c edaykarpSar b¤edayb‘ULúg eFIVeGayeRKOgP¢ab; b¤TwkbnSarrgnUvkMlaMgkat;enAeBl

EdlbnÞúkGnuvtþmkelIva. tMNBÜürEdlbgðajenAkñúgrUbTI 7>3 d dak;eGayeRKOgP¢ab;rgkMlaMgTaj.

kartP¢ab;EdlbgðajenAkñúgrUbTI 7>3 e begáItTaMgkMlaMgkat;TTwg nigkMlaMgTajenAkñúgeRKOgP¢ab;CYr

xagelI. ersIusþg;rbs;eRKOgP¢ab;KWGaRs½yelIfaetIvargnUvkMlaMgkat; b¤kMlaMgTaj b¤k¾kMlaMgTaMgBIr.

231 tMNsamBaØ

3. T.chhay

karpSarmankMlaMgexSaysMrab;kugRtaMgkMlaMgkat; ehIyCaTUeTAvaRtUv)ansnμt;fadac;edaykMlaMgkat;

edayminKitBITisedAénkardak;bnÞúk.

enAeBlEdlkMlaMgkñúgeRKOgP¢ab;mYy b¤kMlaMgkñúgmYyÉktþaRbEvgrbs;TwkbnSarRtUv)ankMNt;

vaCaerOgmYyEdlgayRsYlkñúgkarkMNt;PaBRKb;RKan;rbs;tMN. karkMNt;enHQrelIeKalkarN_én

kartP¢ab;cMbgBIr. RbsinebIExSskmμrbs;kMlaMgpÁÜbEdlRtUvTb;Tl;kat;tamTIRbCMuTMgn;rbs;tMN enaH

EpñknImYy²rbs;tMNRtUv)ansnμt;faTb;Tl;nwgbnÞúkEdlEbgEckesμI ehIytMNEbbenHRtUv)aneKeGay

eQμaHfa tMNsamBaØ. enAkñúgtMNEbbenH ¬EdlbgðajenAkñúgrUbTI 7>3 a nig b¦ eRKOgP¢ab;nImYy²

nigRbEvgÉktþrbs;TwkbnSarnwgTb;Tl;nUvkMlaMgesμIKña*. bnÞab;mkeKGacrklT§PaBTb;Tl;bnÞúkrbs;tM

*

Cak;EsþgvamancMNakp©ittUcenAkñúgtMNTaMgBIrenH EtvaRtUv)anecal

232 tMNsamBaØ

4. T.chhay

NedayKuNlT§PaBTb;Tl;kMlaMgrbs;eRKOgP¢ab;nImYy² b¤RbEvgÉktþarbs;TWkbnSar CamYynwgcMnYn

eRKOgP¢ab;srub b¤RbEvgsrubrbs;TwkbnSar. kartP¢ab;énkMlaMgcakp©it RtUv)anerobrab;enAkñúgCMBUkTI 8

EdlExSskmμrbs;bnÞúkmineFVIGMeBIkat;tamTIRbCMuTMgn;rbs;tMN. kartP¢ab;enAkñúgrUbTI 7>3 d nig e Ca

RbePTéntMNenH. kñúgkrNIenHbnÞúkninRtUv)anTb;Tl;esμIKñaedayeRKOgP¢ab;nImYy² b¤RbEvgÉktþarbs;

TwkbnSareT ehIykarkMNt;énkarEbgEckbnÞúkKWCaktþad¾sμúKsμajkñúgkarKNnaénRbePTtMNenH.

AISC Specification erobrab;BIkartP¢ab;EdlrYmman b‘ULúg rIev nig karpSarenAkñúg Chapter

J, ”Connections, Joints and Fasteners”. EtenAkñúgesovePAenH eyIgmin)anBicarNaBItMNrIeveT.

7>2> Bolted Shear Connections: Failure Mode

munnwgBicarNaBIersIusþg;Cak;lak;rbs;b‘ULúg eyIgRtUvBicarNaBIrebobénkardac;EdlGacekIt

manenAelItMNEdlmaneRKOgP¢ab;rgkMlaMgkat;TTwg. eKmanrebobénkardac;FMBIr³ kardac;rbs;eRKOg

P¢ab; nigkardac;rbs;EpñkEdlRtUvP¢ab;. BicarNa lap joint EdlbgðajenAkñúgrUbTI 7>4 a. kardac;rbs;

eRKOgP¢ab;GacRtUv)ansnμt;fanwgekIteLIgdUcEdl)anbgðaj. kMlaMgkat;TTwgmFümenAkñúgkrNIenHKW

P P

fv = =

A πd 2 / 4

Edl P CabnÞúkEdlmanGMeBIelIeRKOgP¢ab;nImYy² A CaRkLaépÞmuxkat;rbs;eRKOgP¢ab; nig d CaGgát;

p©itrbs;va. enaHbnÞúkenHGacsresrCa

P = fv A

eTaHbICakardak;bnÞúkkñúgkrNIenHmincMcMnucl¥k¾eday k¾cMNakp©itmantMéltUcEdlGacecal)an. kart

enAkñúgrUbTI 7>4 b manlkçN³RsedogKña EtkarviPaKdüaRkamGgÁesrIrbs;eRKOgP¢ab;bgðajfamuxkat;nI

233 tMNsamBaØ

5. T.chhay

mYy²rgEtBak;kNþalbnÞúksrub b¤eKGacniyayfamuxkat;TaMgBIrTb;Tl;nUvkMlaMgsrub. kñúgkrNIenHkM

laMg P = 2 f v A ehIybnÞúkenHRtUv)aneKehAfa double shear. karbEnßmbnÞHenAkñúgkartnwgbegáIn

cMnYnbøg;kat; ehIyvanwgkat;bnßykMlaMgenAkúñgbøg;nImy². b:uEnþ vanwgbegáInRbEvgrbs;eRKOgP¢ab; ehIy

Y

vanwgrgnUvkugRtaMgBt;.

rebobénkadac;mYyeTotsMrab; shear connection Bak;Bn§½nwgkardac;rbs;EpñkEdlRtUv)anP¢ab;

ehIyCaTUeTAvaRtUv)anEbgEckCaBIrEpñk³

!> kardac;EdlbNþalBI karTaj/ kMlaMgkat; b¤m:Um:g;Bt;FMenAkñúgEpñkEdlRtUvtP¢ab;. RbsinebI

Ggát;rgkarTajRtUv)antP¢ab; kMlaMgTajelI gross area nig effective net area RtUv)anGegát.

GaRs½ynwgrUbragénkartP¢ab; block shear k¾RtUv)anBicarNa. eKk¾RtUvRtYtBinitü block shear enA

kñúgkartP¢ab; beam-to-column ¬Edlmanerobrab;enAkñúgCMBUkTI 3 nigTI5 ehIyvak¾RtUv)anerobrab;enA

kñúg AISC J4.3¦. GaRs½ynwgRbePTénkartP¢ab; nigkardak;bnÞúk ral;kartP¢ab;eTAnwg gusset plate

nig framing angle TamTarnUvkarviPaKsMrab; kugRtaMgkat; kugRtaMgTaj kugRtaMgBt; nig block shear.

karKNnakartP¢ab;rbs;Ggát;rgkarTajRtUv)aneFVIeLIgRsbKñaCamYynwgkarKNnaGgát;rgkarTajBI

eRBaHdMeNIrkarTaMgBIrenHTak;TgKñaeTAvijeTAmk.

@> kardac;rbs;EpñkEdlRtUvP¢ab;edaysar bearing EdlbegáIteLIgedayeRKOgP¢ab;. RbsinebI

RbehagmanTMhMFMCageRKOgP¢ab;bnþicbnþÜc ehIyeRKOgP¢ab;RtUv)ansnμt;faRtUv)andak;y:agENnenAkñúg

Rbehag épÞb:HrvageRKOgP¢ab; nigEpñkEdlRtUvP¢ab;nwgekItmaneRcInCagBak;kNþalénbrimaRtrbs;

eRKOgP¢ab;enAeBlEdlbnÞúkGnuvtþ. krNIenHRtUv)anbgðajenAkñúgrUbTI 7>5. kugRtaMgnwgERbRbYlBI

234 tMNsamBaØ

6. T.chhay

GtibrmaenARtg; A eTAsUnüenARtg; B . edIm,IgayRsYl eKeRbIkugRtaMgmFümEdlRtUv)anKNna

edayEckkMlaMgnwgépÞRbeyalb:H.

dUcenH bearing stees RtUv)anKNnaeday f p = P /(dt ) Edl P CakMlaMgEdlGnuvtþmkelI

eRKOgP¢ab;/ d CaGgát;p©iteRKOgP¢ab; nig t CakMras;rbs;EpñkEdlrgnUv bearing. dUcenH bearing load

KW

P = f p dt

karKNna bearing GacmanlkçN³sμúKsμajedaysarvtþmanrbs;b‘ULúgEdlenAEk,r b¤eday

sarcMgayBIrn§eTARCugEKmkñúgTisedArbs;bnÞúkmancMgayxøI dUcbgðajenAkñúgrUbTI 7>6. KMlatrvagb‘U

Lúg nigcMgayBIrn§eTARCugEKmmanT§iBlelI bearing strength.

7>3> Bearing Strength, Spacing and Edge-distance Requirements

Bearing strength minTak;TgnwgRbePTrbs;eRKOgP¢ab;eT BIeRBaHkugRtaMgEdlRtUvBicarNasßit

enAelIEpñkEdlRtUvP¢ab; minEmnenAelIeRKOgP¢ab;eT. sMrab;mUlehtuenH bearing strength k¾dUcCag

tMrUvkarKMlat nig edge-distance k¾minTak;TgnwgRbePTeRKOgP¢ab;Edr ehIyvaRtUv)anBicarNamunkug

RtaMgkat;kñúgb‘ULúg nigersIusþg;Taj.

karpþl;eGayrbs; AISC Specification sMrab; bearing strength k¾dUcCatMrUvkarepSg²sMrab;

b‘ULúgersIusþg;x<s; KWQrelIkarpþl;eGayrbs; specification of the Research Council on Structural

Connections of the Engineering Foundation (RCSC, 1994). kare)aHBum<pSayfμI²rbs;ÉksarenH

minTan;CaEpñkrbs; AISC Specification (AISC, 199a) EtvaRtUv)aneRbIenAkñúgesovePAenH d¾rabNa

manlkçN³minRtUvKña eKnwgeRbIkarpþl;eGayeday AISC. enAeBlsmIkarenAkñúg RSCS

Specification RtUv)anbgðajelxsmIkarmkBIÉksarenaHnwgRtUv)aneRbI ¬]TahrN_/ RCSC Equation

235 tMNsamBaØ

7. T.chhay

LRFD ¦. karerobrab;xageRkam EdlQrelI Commentary EdlENnaMeday RCSC

4.3

Specification nwgBnül;BIeKalkrN_rbs;smIkar RCSC sMrab; bearing strength.

rebobdac;EdlGacekItmanEdl)anBI bearing FM KWkMlaMgkat;rEhk (shear tear-out) enAxag

cugrbs;FatuEdlRtUvtP¢ab; dUcbgðajenAkñúgrUbTI 7>7 a. RbsinebIépÞdac;manlkçN³l¥dUcrUbTI 7>7 b,

failure load enAelIépÞmYyénépÞTaMgBIresμInwg shear fracture stress KuNnwgRkLaépÞkat; b¤

Rn

= 0.6 Fu Lc t

2

Edl 0.6 Fu = shear fracture streesrbs;EpñkEdlRtUvP¢ab;

Lc = cMgayBIRCugEKmrbs;RbehageTAcugrbs;EpñkEdlRtUvP¢ab;

t = kMras;rbs;EpñkEdlRtUvP¢ab;

ersIusþg;srubKW

Rn = 2(0.6 Fu Lc t ) = 1.2 Fu Lc t ¬&>!¦

kMlaMgkat; tear-out enHekItmanenAxagcugrbs;EpñkEdlRtUvtP¢ab; dUcEdlbgðaj b¤enAcenøaH

rn§BIrkñúgTisedAén bearing load. edIm,IkarBarsac;lUtFMrbs;Rbehag eKRtUvkMNt;EdnkMNt;x<s;bMput

rbs; bearing load EdleGayedaysmIkar &>!. EdkkMNt;enHsmamaRteTAnwg fracture stress

KuNnwg bearing area b¤

Rn = C × Fu × bearing area = CFu dt ¬&>@¦

236 tMNsamBaØ

8. T.chhay

Edl C=tMélefr

d = Ggát;p©itb‘ULúg

t = Ggát;rbs;EpñkEdlRtUvtP¢ab;

RCSC Specification eRbIsmIkar &>! sMrab; bearing strength RbQmnwgEdnkMNt;EdleGayeday

smIkar &>@. RbsinebIeKminKitkMhUcRTg;RTay tMélefr C GacykesμInwg 3.0 . RbsinebIkMhUcRTg;

RTayFMRtUv)anKit C GacykesμInwg 2.4 ehIyCaTUeTAvaCatMélEdleKykmkeRbI. tMélenHRtUvKña

nwgsac;lUtrbs;RbehagRbEhl 1 / 4in. = 6mm ¬RCSC, 1994¦. enAkñúgesovePAenH eyIgBicarNa

kMhUcRTg;RTaysMrab;karKNna. RCSC bearing strength sMrab;b‘ULúgeTalGacRtUv)ansMEdgCa φRn

Edl

φ = 0.75

nig Rn = 1.2 Lc tFu ≤ 2.4dtFu ¬RCSC Equation LRFD 4.3¦

Edl Lc = clear distance enAkñúgTisRsbnwgbnÞúkEdlGnuvtþ BIcugénrn§b‘ULúgeTARCugEKmrbs;rn§Edl

enAEk,r b¤eTARCugEKmrbs;sMPar³.

t = kMras;rbs;eRKOgP¢ab;

d = Ggát;p©itb‘ULúg ¬minEmnGgát;p©itrbs;RbehageT¦

Fu = ultimate tensile stress rbs;EpñkEdlRtUvP¢ab; ¬minEmnrbs;b‘ULúg¦

rUbTI 7>8 bgðajbEnßmeTotBIcMgay Lc . enAeBlEdlKNna bearing strength sMrab;b‘ULúg eKRtUv

BicarNacMgayBIb‘ULúgenaHeTAb‘ULúgEdlenAEk,r b¤eTARCugEKmkñúgTisedArbs; bearing load

elIEpñkEdl RtUvP¢ab;. sMrab;krNIEdl)anbgðaj bearing load sßitenAEpñkxageqVgrbs;rn§nImYy².

dUcenHersIusþg; sMrab;b‘ULúg ! RtUv)anKNnaCamYy Lc Edlvas;eTAb‘ULúg @ ehIyersIusþg;sMrab;b‘ULúg @

RtUv)anKNna CamYy Lc Edlvas;eTARCugEKmrbs;EpñkEdlRtUvP¢ab;.

RCSC Equation LRFD 4.3 mantMélsMrab; standard, oversized, short-slotted and long

237 tMNsamBaØ

9. T.chhay

slotted holes CamYynwg slot EdlRsbeTAnwgbnÞúk. eyIgeRbIEt standard holes enAkñúgesovePAenH

¬RbehagEdlmanGgát;p©itFMCagGgát;p©itb‘ULúg 1/16in. = 2mm ¦.

enAeBlEdlKNnacMgay Lc eRbIGgát;p©itRbehagCak;Esþg nigmincaM)ac;bUkbEnßm 2mm dUc

EdlRtUvkarenAkñúg AISC B.2 sMrab;KNna net area rbs;Ggát;rgkarTaj. müa:gvijeTot eRbIGgát;p©it

d + 1 / 16in. = d + 2mm minEmn d + 1 / 8in. = d + 4mm . RbsinebI h bgðajBIGgát;p©itRbehag

enaH

h = d + 1 / 16in.

karKNnarbs; bearing strength BI RCSC Equation LRFD 4.3 GacRtUv)ansMrYlxøHdUcxageRkam.

EdnkMNt;nwgmanRbsiT§PaBenAeBl

1.2 Lc tFu = 2.4dtFu

b¤ eRkayeBlEdlsMrYlehIy

Lc = 2d

TMnak;TMngenHGacRtUv)aneRbIedIm,IKNnaenAeBlEdlEdnkMNt; 2.4dtFu lub³

RbsinebI Lc ≤ 2d eRbI Rn = 1.2Fu Lct

RbsinebI Lc > 2d eRbI Rn = 1.2Fu dt

Spacing and Edge-Distance Requirments

edIm,IrkSacenøaHTMenrrvagex©Ab‘ULúg nigedIm,Ipþl;nUvTIFøaRKb;RKan;sMrab; wrench socket AISC

J3.3 tMrUvfaKMlatBIGkS½eTAGkS½ (center-to-center spacing) rbs;eRKOgP¢ab; ¬enARKb;Tis¦ minRtUv

tUcCag 2 2 3 d ehIyCakarniymKWminRtUvtUcCag 3d Edl d CaGgát;p©iteRKOgP¢ab;. cMgayBIRCugEKm

sMPar³ ¬RKb;Tis¦ Edlvas;BIGkS½rbs;Rbehag RtUv)aneGayenAkñúg AISC Table3.4 CaGnuKmn_eTA

nwgTMhMrbs;b‘ULúg nigRbePTrbs;RCug ¬sheared, rolled or gas cut¦. KMlat nigcMgayeTARCugEKm

EdlsMKal;eday s nig Le RtUv)anbgðajenAkñúgrUbTI 7>9.

238 tMNsamBaØ

10. T.chhay

Summary fo Bearing Strength, Spacing and Edge-Distance Requirements

(standard hole)

a. Bearing strength:

φRn = 0.75(1.2 Lc tFu ) ≤ 0.75(2.4dtFu ) (RCSC Equation LRFD 4.3)

b¤ eyIgGacsresrmüa:geTot

RbsibebI Lc ≤ 2d / φRn = 0.75(1.2 Lc tFu )

RbsinebI Lc > 2d / φRn = 0.75(2.4dtFu )

b. KMlat nigsMgayeTARCugEKmGb,brma³ sMrab;RKb;Tis TaMgRsbnwgExSskmμ nigEkgnwgExS

skmμ

s ≥ 2 23 d ¬CakareBjniym 3d ¦

Le ≥ tMélBI AISC J3.4

sMrab; single- nig double-angle shapes CaTUeTA gage distances RtUv)aneGayenAkñúg Part 9

of the Manual, Volume II (emIlEpñk 3>6)EdlGaceRbICMnYseGaytMélGb,brma.

]TahrN_ 7>1³ RtYtBinitü KMlatb‘ULúg nigcMgayeTARCugEKmsMrab;kartP¢ab;EdlbgðajenAkñúgrUbTI

7>10.

dMeNaHRsay³ BI AISC J3.3, KMlatGb,brmasMrab;RKb;TisTaMgGs;KW

⎛3⎞

2 2 3 d = 2.667⎜ ⎟ = 2in.

⎝4⎠

KMlatCak;Esþg = 2.5in. > 2in. (OK)

cMgayeTARCugEKmGb,brmasMrab;RKb;TisTaMgGs;EdlTTYlBI AISC Table J3.4. RbsinebI

eyIgsnμt; sheared edges ¬krNIEdlGaRkk;CageK¦ enaHcMgayeTARCugEKmGb,brmaKW 1 14 in.

dUcenH

239 tMNsamBaØ

11. T.chhay

cMgayeTARCugEKmCak;Esþg = 1 1 in. (OK)

4

edIm,IKNna bearing strength eRbIGgát;p©itrn§

1 3 1 13

h=d+ = + = in.

16 4 16 16

RtYtBinitü bearing TaMgelIGgát;rgkarTaj nig gusset plate. sMrab;Ggát;rgkarTaj nigEdl

enAEk,rRCugEKmrbs;Ggát;CageK

h 13 / 16

Lc = Le − = 1.25 − = 0.8438in.

2 2

φRn = φ (1.2 Lc tFu ) ≥ φ (2.4dtFu )

⎛1⎞

φ (1.2 Lc tFu )0.75(1.2)(0.8438)⎜ ⎟(58) = 22.02kips

⎝2⎠

⎛ 3 ⎞⎛ 1 ⎞

φ (2.4dtFu ) = 0.75(2.4 )⎜ ⎟⎜ ⎟(58) = 39.15kips > 22.02kips

⎝ 4 ⎠⎝ 2 ⎠

dUcenHyk φRn = 22.02kips / bolt

sMrab;rn§epSgeTot

13

Lc = s − h = 2.5 − = 1.688in.

16

φRn = φ (1.2 Lc tFu ) ≤ φ (2.4dtFu )

⎛1⎞

φ (1.2 Lc tFu ) = 0.75(1.2)(1.688)⎜ ⎟(58) = 44.06kips

⎝2⎠

φ (2.4dtFu ) = 39.15kips < 44.06kips

dUcenHyk φRn = 39.15kips / bolt

sMrab;Ggát;rgkarTaj bearing strength KW

φRn = 2(22.02) + 2(39.15) = 122kips > 65kips (OK)

sMrab; gusset plat nigrn§EdlenAEk,rRCugEKmrbs;bnÞHCageK

h 13 / 16

Lc = Le − = 1.25 − = 0.8438in.

2 2

φRn = φ (1.2 Lc tFu ) ≤ φ (2.4dtFu )

⎛ 3⎞

φ (1.2 Lc tFu ) = 0.75(1.2)(0.8438)⎜ ⎟(58) = 16.52kips

⎝8⎠

⎛ 3 ⎞⎛ 3 ⎞

φ (2.4dtFu ) = 0.75(2.4 )⎜ ⎟⎜ ⎟(58)

⎝ 4 ⎠⎝ 8 ⎠

= 29.36kips > 16.52kips

240 tMNsamBaØ

12. T.chhay

dUcenHyk φRn = 16.52kips / bolt

sMrab;rn§d¾éTeTot

13

Lc = s − h = 2.5 − = 1.688in.

16

φRn = φ (1.2 Lc tFu ) ≤ φ (2.4dtFu )

⎛3⎞

φ (1.2 Lc tFu ) = 0.75(1.2 )(1.688)⎜ ⎟(58) = 33.04kips

⎝8⎠

⎛ 3 ⎞⎛ 3 ⎞

φ (2.4dtFu ) = 0.75(2.4)⎜ ⎟⎜ ⎟(58) = 29.36kips < 33.04kips

⎝ 4 ⎠⎝ 8 ⎠

dUcenHyk φRn = 33.04kips

bearing strength sMrab; gusset plate KW

φRn = 2(16.52) + 2(29.36) = 91.8kips

gusset plate man bearing strength tUcCag bearing strength rbs;Ggát; dUcenH gusset plate lub

φRn = 91.8kips > 65kips (OK)

cMeLIy³ tMrUvkar bearing strength, KMlat nig cMgayeTARCugEKmmanlkçN³RKb;RKan;.

KMlatb‘ULúg nigcMgayeTARCugEKmenAkñúg]TahrN_ 7>1 mantMéldUcKñasMrab;Ggát;rgkarTaj

nig gusset plate. vaxusKñaEtkMras; dUcenH gusset plate lub. sMrab;krNIdUc]TahrN_enH eKRtYt

BinitüEteRKOgbgÁúMNaEdlmankMras;esþIgCag. b:uEnþRbsinebIcMgayeTAcugEKmmantMélxusKña dac;xat

eKRtUvEtRtYtBinitüTaMgGgát;rgkarTaj nig gusset plate.

7>4> b‘ULúgFmμta Common Bolts

eyIgcab;epþImkarerobrab;BIersIusþg;rbs;eRKOgP¢ab;CamYynwg b‘ULúgFmμta EdlxusKñaBIb‘ULúger-

sIusþg;x<s;minRtwmEtlkçN³sMPar³b:ueNÑaHeT EfmTaMgkMlaMgrwtbNþwgb‘ULúgeTotpg. b‘ULúgFmμta Edl

eKsÁal;Ca unfinished bols RtUv)ansMKal;Ca ASTM A307.

Design shear strength rbs; A307 KW φRn / EdlemKuNersIusþg; φ = 0.75 ehIy nominal

shear strength KW

Rn = Fv Ab

Edl Fv = ultimate shearing stress

241 tMNsamBaØ

13. T.chhay

Ab = RkLaépÞmuxkat;rbs;EpñkEdlKμaneFμjrbs;b‘ULúg ¬EdleKsÁal;Ca nominal bolt area

b¤ nominal body area¦

Ultimate shearing stress RtUv)aneGayenAkñúg AISC Table J3.2 KW 24ksi = 165MPa Edl

eGay nominal strength

Rn = Fv Ab = 24 Ab

]TahrN_ 7>2³ kMNt; design strength rbs;kartP¢ab;EdlbgðajenAkñúgrUbTI 7>11 edayQrelI

kMlaMgkat;TTwg nig bearing.

dMeNaHRsay³ kartP¢ab;GacRtUv)ancat;cMNat;fñak;CatMNsamBaØ ehIyeRKOgP¢ab;mYy²RtUv)anBicar-

NaedIm,ITb;Tl;karEbgEckMlaMgesμIKña. kñúgkrNICaeRcInvamanlkçN³gayRsYlkñúgkarkMNt;ersIusþg;

rbs;eRKOgP¢ab;mYy rYcbnÞab;mkKuNnwgcMnYneRKOgP¢ab;srub.

Shear strength: vaCakrNI single shear ehIy design shear strength rbs;b‘ULúgmYyKW

φRn = φFv Ab = 0.75(24 Ab )

Nominal bolt area KW

πd 2 π (3 / 4 )2

Ab = = = 0.4418in 2

4 4

dUcenH design shear strength sMrab;b‘ULúgmYyKW

φRn = 0.75(24 )(0.4418) = 7.952kips

sMrab;b‘ULúgBIrKW

φRn = 2(7.952) = 15.9kips

Bearing strength: edaysarcMgayeTARCugEKmrbs;Ggát;rgkarTaj nigrbs; gusset plate dUcKña enaH

beaing strength rbs; gusset plate nwglub BIeRBaHkMras;rbs;vaesþIgCagkMras;rbs;Ggát;rgkarTaj.

sMrab;karKNna bearing strength eRbIGgát;p©itRbehag

242 tMNsamBaØ

14. T.chhay

1 3 1 13

h=d+ = + = in.

16 4 16 16

sMrab;rn§EdlenAEk,rRCugEKmrbs; gusset plate CageK

h 13 / 16

Lc = Le − = 1.5 − = 1.094in.

2 2

⎛3⎞

2d = 2⎜ ⎟ = 1.5in.

⎝4⎠

edaysar Lc < 2d

⎛3⎞

φRn = φ (1.2 Lc tFu ) = 0.75(1.2 )(1.094)⎜ ⎟(58) = 21.42kips

⎝8⎠

sMrab;rn§déTeTot

13

Lc = s − h = 3 − = 2.188in. > 2in.

16

⎛ 3 ⎞⎛ 3 ⎞

dUcenH φRn = φ (2.4dtFu ) = 0.75(2.4)⎜ ⎟⎜ ⎟(58) = 29.36kips

⎝ 4 ⎠⎝ 8 ⎠

Bearing strength sMrab;tMNKW

φRn = 21.42 + 29.36 = 50.8kips

Bearing strength enHFMCag shearing strength dUcenH shear strength lub ehIyersIusþg;rbs;tMNKW

φRn = 15.9kips

cMNaMfaRKb;tMrUvkarKMlat nigcMgayeTARCugEKmTaMgGs;RtUvEtRKb;RKan;. sMrab; sheared edge cMgay

eTARCugEKmEdlTamTareday AISC Table J3.4 KW 1 14 in. = 30mm ehIykarTamTarenHKWRKb;RKan;

sMrab;TaMg TisbeNþay nigTisTTwg. KMlatb‘ULúgKW 3in = 75mm EdlFMCag 2 2 3 d = 2.667(3 4 )

= 2in. .

cMeLIy³ edayQrelI shear nig bearing, design strength rbs;tMNKW 15.9kips . ¬cMNaMfa sßanPaB

kMNat;d¾éTepSgeTotEdlminTan;)anRtYtBinitüdUcCa kugRtaMgTajenAelI net area rbs;Ggát;Gacnwg

CaGñkkMNt; design strength¦.

]TahrN_ 7>3³ r)arEdk 4 × 3 / 8in. RtUv)aneRbICaGgát;rgkarTajedIm,ITb;Tl;nwg service dead load

8kips nig service live load 22kips . Ggát;enHRtUv)anKNnaeRkamkarsnμt;fa b‘ULúg A307 Ggát;

p©it 3 / 4in. mYyCYrRtUv)aneRbIedIm,IP¢ab;Ggát;enHeTA gusset plate EdlmankMras; 3 / 8in. . TaMgGgát;

rgkarTaj nig gusset plate CaEdk A36 . etIeKRtUvkarb‘ULúgb:unμanRKab;?

243 tMNsamBaØ

15. T.chhay

dMeNaHRsay³ bnÞúkemKuNKW

Pu = 1.2 D + 1.6 L = 1.2(8) + 1.6(22) = 44.80kips

KNnalT§PaBrbs;b‘ULúgmYy. BI]TahrN_ 7>2 shear strength KW

φRn = 7.952kips / bolt

sMrab; eKminsÁal;KMlat nigcMgayeTARCugEKm dUcenHeyIgsnμt;fa EdkkMNt;

bearing strength,

φ 2.4dtFu nwglub enaHeyIgTTYl)an

⎛ 3 ⎞⎛ 3 ⎞

φRn = 0.75(2.4)⎜ ⎟⎜ ⎟(58) = 29.36kips / bolt

⎝ 4 ⎠⎝ 8 ⎠

Bearing strength Cak;EsþgsMrab;tMNenHnwgGaRs½yelItMélrbs; Lc sMrab;b‘ULúgnImYy². enAeBl

EdltMélenHRtUv)ankMNt;enAkñúgkarKNnacugeRkay enaH bearing strength RtUv)anRtYtBinitüeLIg

vijb:uEnþ shear enAEtTMngCalub.

cMnYnb‘ULúgEdlRtUvkarKW

44.80kips

= 5.63bolts

7.952kips / bolt

cMeLIy³ eRbIb‘ULúg A307 Ggát;p©it 3 / 4in. cMnYnR)aMmYyRKab;.

7>5> b‘ULúgersIusþg;x<s; High-Strength Bolts

b‘ULúgersIusþg;x<s;sMrab;tMNrbs;eRKOgbgÁúMmanBIry:agKW ASTM A325 nig ASTM A490 .

karpþl;eGayrbs; AISC sMrab;ersIusþg;x<s;KWCaEpñkxøHrbs;karpþl;eGayrbs; specification of the

Research Council on Structural Connections of the Engineering Foundation (RCSC, 1994).

b‘ULúg A490 man ultimate tensile strength FMCagb‘ULúg A325 ehIyRtUv)ankMNt;faman

nominal strength FMCag. b‘ULúg A490 RtUv)andak;eGayeRbIR)as;ry³eBly:agyUrbnÞab;BIb‘ULúg

A325 RtUv)aneRbICaTUeTA sMrab;eRbICamYyEdkEdlmanersIusþg;x<s; ¬Bethlehem, 1969¦. b‘ULúg

A490 mantMéléføCag A325 b:uEnþCaTUeTAeKRtUvkarvacMnYnticCag.

kñúgkrNIxøH b‘ULúg A490 nig A325 RtUv)antMeLIgCamYynwgkMrittwgEdleFVIeGayBYkvargnUvkM

laMgTajFMEmnETn. ]TahrN_ kMlaMgTajdMbUgenAkñúgb‘ULúg A325 Ggát;p©it 5 / 8in. GacFMesμInwg

19kips = 85KN . bBa¢IénkMlaMgTajGb,brmasMrab;tMNTaMgenaHRtUvkarRtUv)aneGayenAkñúg AISC

Table J3.1, Minimum Bolt Tension. tMélnImYy²esμInwg 70% énersIusþg;TajGb,brmarbs;b‘ULúg.

244 tMNsamBaØ

16. T.chhay

eKalbMNgEdleKRtUvkarkMlaMgTajFMEbbenHKWedIm,ITTYl)ankMlaMgrwtEdlbgðajenAkñúgrUbTI 7>12.

b‘ULúgEbbenHRtUv)aneKehAfa fully tensioned.

enAeBlEdlex©ARtUv)anmYlP¢ab;eTAnwgb‘ULúg EpñkEdlRtUvP¢ab;rgnUvkMlaMgsgát; ehIyb‘ULúglUt.

düaRkaGgÁesrI (free body diagram) enAkñúgrUbTI 7>12 a bgðajfakMlaMgsgát;srubEdlmanGMeBIelI

EpñkEdlRtUvP¢ab;esμInwgkMlaMgTajenAkñúgb‘ULúg. RbsinebIeKGnuvtþkMlaMgxageRkA P kMlaMgkkitnwg

ekItmanenAcenøaHEpñkP¢ab;. kMlaMgGtibrmaEdlGacekItmanKW

F = μN

Edl μ CaemKuNkkitsþaTicrvagEpñkEdlRtUvP¢ab; ehIy N CakMlaMgsgát;EdlmanGMeBIenAelIépÞxag

kñúg. tMélrbs; μ GaRs½ynwglkçxNÐépÞrbs;Edk ]TahrN_dUcCa épÞrbs;vamanlabfñaM b¤manERcHsIu.

dUcenHb‘ULúgnImYy²enAkñúgkartP¢ab;RtUvmanlT§PBedIm,ITb;Tl;nwgbnÞúk P = F . RbsinebIkMlaMgkkit

minFM vanwgminman bearing b¤ shear. RbsinebI P FMCag F slip ekIteLIg enaH shear nig bearing nwg

CHT§iBldl;lT§PaBrbs;tMN.

245 tMNsamBaØ

17. T.chhay

kartMeLIg Installation

etIeKTTYl)ankMlaMgTajFMEdlmanPaBsuRkitedayrebobNa? bc©úb,nñeKmanviFIsaRsþEdl

GnuBaØateGaycMnYnbYnsMrab;kartMeLIgb‘ULúgersIusþg;x<s; (RCSC, 1994).

!> Turn-of-the-nut method. viFIenHQrelIlkçN³bnÞúk-kMhUcRTg;RTay (load-deforma-

tion characteristic) rbs;eRKOgP¢ab; nigEpñkEdlRtUvP¢ab;. ex©AEdlmYlP¢ab;eTAnwgb‘ULúgGaceFVIeGay

b‘ULúglUtsac;. TMnak;TMng stress-strain sMrab;sMPar³b‘ULúgGacRtUv)aneRbIedIm,IKNnakMlaMgTajenA

kñúgb‘ULúg. dUcenHsMrab;RKb;TMhM nigRbePTrbs;b‘ULúg cMnYnCMumYlex©AEdlRtUvkaredIm,IbegáItkMlaMgTaj

GacRtUv)anKNna. Table 5 enAkñúg high-strength bolt specification (RCSC, 1994) eGaynUvcMnYn

CMurbs;ex©AEdlRtUvkarsMrab;TMhMepSg²rbs;b‘ULúgkñúgTMrg;pleFobRbEvgelIGgát;p©it. viFIsaRsþenHeK

eRbI ordinary spud wrench.

@> Calibrated wrench tightening. kñúgviFIsa®sþenHeKRtUveRbI torque wrench. kMlaMgrmYl

EdlRtUvkaredIm,ITTYlkMlaMgTajkMNt;enAkñúgb‘ULúgRtUv)ankMNt;edaykarrwtbNþwgb‘ULúgenHCamYy]b

krN_EdlbgðajkMlaMgTah.

#> Alternated wrench bolts. eKRtUvkar wrench BiessedIm,ItMeLIgb‘ULúg. karRtYtBinitükar

gartMeLIgenHmanlkçN³gayRsYlCaBiess.

$> Direct tension indicators. sMPar³EdleKniymeRbIenAkñúgviFIsaRsþenHKW washer Edlman

protrusion enAelIépÞrbs;va. enAeBlEdleKrwtb‘ULúg protrusion rgnUvkMlaMgsgát;EdlsmamaRteTA

nwgkMlaMgTajenAkñúgb‘ULúg.

7>6> Shear Strength of High-Strength Bolts

Design shear strength rbs;b‘ULúg A325 nig A490 KW φRn EdlemKuNersIusþg; φ = 0.75 . dUc

Kñanwgb‘ULúgFmμtaEdr nominal shear strength rbs;b‘ULúgersIusþg;x<s;RtUv)aneGayeday ultimate

shearing stress KuNnwg nominal bolt area. Etb‘ULúg A307 mindUcb‘ULúg A325 nig A490 Rtg; shear

strength rbs;b‘ULúgersIusþg;x<s;GaRs½ynwgeFμjrbs;b‘ULúgsßitenAkñúgbøg;kat;b¤ minsßitenAkñúgbøg;kat;.

edIm,IsMrYlkñúgkareRbI reduced cross-sectional area enAeBlEdlEpñkEdlmaneFμjrgnUvkMlaMgkat;

TTwg enaH ultimate shearing stress rbs;vaRtUvKuNnwg 0.75 EdlCapleFobRbhak;RbEhlénRkLa

246 tMNsamBaØ

18. T.chhay

épÞEdlmaneFμj elIRkLaépÞEdlKμaneFμj. ersIusþg;RtUv)aneGayenAkñúg AISC Table J3.2 ehIy

RtUv)ansegçbenAkñúgtarag 7>1 . AISC Table J3.2 sMedAeFμjenAkñúgbøg;kat;Ca “not excluded from

shear planes” ehIysMedAeFμjEdlminenAkñúgbøg;kat;Ca “excluded from shear planes”. RbePTTI

mYy eFμjsßitenAkñúgbøg;kat; eKsMedACaRbePTtMN “N” ehIyb‘ULúg A325 énRbePTenHGacsMKal;

eday A325 − N . karsMKal; “X” GacRtUv)aneRbIedIm,IbgðajfaeFμjminsßitenAkñúgbøg;kat;eT ]Ta-

hrN_ A325 − X .

tarag 7>1

Nominal shear strength

eRKOgP©ab; Rn = Fv Ab

US IS

A325/ eFμjenAkñúgbøg;kat; 48 Ab 330 Ab

A325 / eFμjminenAkñúgbøg;kat; 60 Ab 415 Ab

A490 / eFμjenAkñúgbøg;kat; 60 Ab 415 Ab

A490 / eFμjminenAkñúgbøg;kat; 75 Ab 520 Ab

]TahrN_7>4³ kMNt; design strength rbs;tMNEdlbgðajenAkñúgrUbTI 7>13. GegÁt bolt shear,

bearing nig tensile strength rbs;Ggát;. b‘ULúgEdleRbICaRbePT A325 Ggát;p©it 7 / 8in. ehIyeFμj

rbs;vaminsßitenAkñúgbøg;kat;. Ggát;CaRbePTEdk A572 Grade 50 .

dMeNaHRsay³ shear strength sMrab;b‘ULúgmYy

π (7 / 8)2

Ab = = 0.6013in.2

4

247 tMNsamBaØ

19. T.chhay

φRn = φFv Ab = 0.75(60)(0.6013) = 27.06kips

sMrab;b‘ULúgbI

φRn = 3(27.06) = 81.2kips

Bearing strength ³ sMrab;karKNna bearing strength eRbIGgát;p©itrn§

1 7 1 15

h=d+ = + = in.

16 8 16 16

RtYtBinitü bearing EdlekItmanTaMgelI Ggát;rgkarTaj nig gusset plate. sMrab;Ggát;rgkarTaj nig

b‘ULúgEdlenAEk,rRCugEKmCageKrbs;Ggát;

h 15 / 16

Lc = Le − = 1.25 − = 0.7812in.

2 2

2d = 2(7 / 8) = 1.75in.

edaysar Lc < 2d

⎛1⎞

φRn = φ (1.2 Lc tFu ) = 0.75(1.2)(0.7812)⎜ ⎟(65) = 22.85kips

⎝2⎠

sMrab;RbehagepSgeTot

15

Lc = s − h = 2.75 − = 1.812in. > 2d

16

⎛ 7 ⎞⎛ 1 ⎞

dUcenH φRn = φ (2.4dtFu ) = 0.75(2.4)⎜ ⎟⎜ ⎟(65) = 51.19kips

⎝ 8 ⎠⎝ 2 ⎠

Bearing strength sMrab;Ggát;rgkarTajKW

φRn = 22.85 + 2(51.19) = 125kips

KNna bearing strength rbs; gusset plate. sMrab;rn§EdlenAEk,rRCugEKmrbs; gusset CageK

h 15 / 16

Lc = Le − = 1.5 − = 1.031in. < 2d

2 2

⎛3⎞

dUcenH φRn = φ (1.2 Lc tFu ) = 0.75(1.2)(1.031)⎜ ⎟(65) = 22.62kips

⎝8⎠

sMrab;Rbehagd¾éTeTot

15

Lc = s − h = 2.75 − = 1.812in. > 2d

16

⎛ 7 ⎞⎛ 3 ⎞

dUcenH φRn = φ (2.4dtFu ) = 0.75(2.4)⎜ ⎟⎜ ⎟(65) = 38.39kips

⎝ 8 ⎠⎝ 8 ⎠

Bearing strength rbs; gusset plate KW

φRn = 22.62 + 2(38.92 ) = 99.4kips

248 tMNsamBaØ

20. T.chhay

Gusset plate man strength tUcCag dUcenH bearing strength sMrab;tMNKW

φRn = 99.4kips

RtYtBinitü tensile strength rbs;Ggát;rgkarTaj.

Tension on the gross atea:

⎛ 1⎞

φt Pn = φt Fy Ag = 0.90(50 )⎜ 3 × ⎟ = 67.5kips

⎝ 2⎠

Tension on the net area: muxkat;TaMgGs;rbs;Ggát;RtUv)antP¢ab; dUcenHvaminman shear lag eT

dUcenHeyIg)an Ae = An . eRbIGgát;Rbehag

1 7 1

h = d + = + = 1.0in.

8 8 8

Design strength KW

φt Pn = φt Fu Ae = φt Fu t (wg − ∑ h ) = 0.75(65)⎜ ⎟[3 − 1(1.0)] = 48.8kips

⎛1⎞

⎝2⎠

karTajenAelI net section mantMéltUcCageK

cMeLIy³ Design strength rbs;tMNKW 48.8kips

7>7> Slip-Critical Connections

eKcat;cMNat;fñak;kartP¢ab;EdleRbIb‘ULúgersIusþg;x<s;Ca slip-critical connection b¤ bearing-

type connection. Slip-critical connection CakartP¢ab;EdleKminGnuBaØateGayman slip Edlmin

RtUvFMCagkMlaMgkkit. sMrab; bearing-type connection eKGnuBØateGayman slip ehIy shear nig

bearing ekIteLIgFmμta. enAkñúgRbePTeRKOgbgÁúMxøH CaBiesss<an kMlaMgEdlmanGMeBIelItMNGacekIt

eLIgCalkçN³xYb. kñúgkrNIEbbenH fatigue rbs;eRKOgP¢ab;GackøayCaeRKaHfñak;RbsinebIeKGnuBaØat

eGayman slip rYmCamYynwgkarekIteLIgsarcuHsareLIg enaHeKRtUvRtYtBinitü slip-critical connec-

tion. enAkñúgeRKOgbgÁúMCaeRcIn eKGnuBaØateGayman slip ehIy bearing-type connection RtUvEt

RKb;RKan;. ¬b‘ULúg A307 RtUv)aneRbIsMrab;Et bearing-type connection¦. sMrab; slip-critical

connection eKcaM)ac;RtUvEteFVIkartMeLIgeGay)anl¥ edIm,ITTYlnUvkMlaMgTajdMbUgRKb;RKan;dUcEdl)an

erobrab;. AISC J1.11 erobrab;BIsßanPaBkMNt;Edlb‘ULúgersIusþg;x<s;RtUvEtmankMlaMgTajeBj. enA

kñúg bearing-type connection tMrUvkarcaM)ac;EtmYyKt;kñúgkartMeLIgb‘ULúgKWeKRtUvpþl;nUvkMlaMgTaj

249 tMNsamBaØ

21. T.chhay

RKb;RKan;edIm,IeGayépÞb:HKñaGacTb;Tl;Kña)aneTAvijeTAmk. kartMeLIgenHbegáItnUv snug-tight

condition Edl)anerobrab;enAkñúg turn-of-the-nut method.

eTaHbICatamRTwsþI slip-critical connection minRbQmnwg shear nig bearing k¾eday

k¾eKRtUvEtman shear strength nig bearing strength RKb;RKan;sMrab;krNI overload EdlGaceFVIeGay

ekItman slip.

edIm,IkarBar slip eKRtUvmanEdnkMNt;sMrab; service load b¤ factored load. eTaHbICakar

karBar slip mansar³sMxan;sMrab; serviceability requiremnent k¾eday k¾ AISC Specification

GnuBaØateGay slip-critical strength GacQrelI service load b¤ factored load.

dUcEdl)anerobrab;BIxagelI lT§PaBTb;nwg slip CaGnuKmn_énplKuNrvagemKuNkkitsþaTic

nig normal force cenøaHEpñkP¢ab;. TMnak;TMngenHRtUv)anbgðajenAkñúg RCSC Specification Edl

eyIgeRbIenATIenHsMrab; slip-critical connection (RCSC, 1994). Slip-critical strength rbs;tMN KW

φRstr Edl φ = 1.0 sMrab; standard hole ehIy

Rstr = 1.13μTm N b N s (RCSC Equation LRFD 5.3)

Edl μ = mean slip coefficient ¬emKuNkkitsþaTic¦ = 0.33 sMrab;épÞ Class A

Tm = kMlaMgTajrbs;eRKOgP¢ab;Gb,brmaEdl)anBI AISC Table J3.1 b¤ RCSC Table 4

N b = cMnYnb‘ULúgenAkñúgtMN

N s = cMnYn slip plan ¬bøg;kat;¦

épÞ Class A CaépÞEdlmanEdkG‘uksIutenAépÞrbs;va. enAkñúg Specification manENnaMnUvRbePTépÞ

CaeRcIneTot EtenAkñúgesovePAenH eyIgeRbIEt épÞ Class A Edlpþl;nUv slip coefficient

tUcCageKbMput.

Slip-critical design strength sMrab;b‘ULúgmYyén single shear KW

φRstr = φ (1.13μTm N b N s ) = 1.0(1.13)(0.33)Tm (1)(1)

= 0.373Tm kips

]TahrN_ 7>5³ kartP¢ab;EdlbgðajenAkñúgrUbTI 7>14 eRbIb‘ULúg A325 Ggát;p©it 3 / 4in. EdleFμj

rbs;vasßitenAkñúgbøg;kat;. eKminGnuBaØateGayman slip. TaMgGgát;rgkarTaj nig gusset plate Ca

RbePTEdk A36 . kMNt; design strength.

250 tMNsamBaØ

22. T.chhay

dMeNaHRsay³ Shear strength: sMrab;b‘ULúgmYy

π (3 / 4 )2

Ab = = 0.4418in.2

4

φRn = φFv Ab = 0.75(48)(0.4418) = 15.90kips

sMrab;b‘ULúgbYnRKab;

φRn = 4(15.90) = 63.60kips

Slip-critical strength: edaysareKminGnuBaØateGayman slip enaHkartP¢ab;enHRtUv)ancat;Ca slip-

critical. BI AISC Table J3.1 kMlaMgTajkñúgb‘ULúgGb,brmaKW Tm = 28kips . BIsmIkar &>#/

φRstr = 0.373Tm = 0.373(28) = 10.4kips / bplt

sMrab;b‘ULúgbYn

φRstr = 4(10.4) = 41.6kips

Bearing strength: edaysarcMgayeTARCugEKmmanRbEvgdUcKña ehIy gusset palte esþIgCagr)ar enaH

eyIgenwgeRbI gusset plate EdlmankMras; 3 / 8in. edIm,IKNna bearing strength.

Ggát;p©itRbehag

1 3 1 13

h=d+ = + = in.

16 4 16 16

sMrab;RbehagEdlenACitRCugEKmrbs; gusset plate CageK

h 13 / 16

Lc = Le − = 1.5 − = 1.094in.

2 2

⎛3⎞

2d = 2⎜ ⎟ = 1.5in.

⎝4⎠

edaysar Lc < 2d

251 tMNsamBaØ

23. T.chhay

⎛3⎞

φRn = φ (1.2 Lc tFu ) = 0.75(1.2 )(1.094)⎜ ⎟(58) = 21.42kips / bolt

⎝8⎠

sMrab;d¾éTeTot

13

Lc = s − h = 3 − = 2.188in. > 2d

16

dUcenH φRn = φ (2.4dtFu ) = 29.36kips / bolt

Bearing strength sMrab;kartMNKW

φRn = 2(21.42) + 2(29.36 ) = 102kips

RtYtBinitü tensile strength rbs;Ggát;rgkarTaj

karTajenAelI gross area:

⎛ 1⎞

φt Pn = φt Fy Ag = 0.90(36 )⎜ 6 × ⎟ = 97.2kips

⎝ 2⎠

karTajenAelI net area: muxkat;TaMgmUlrbs;Ggát;RtUv)antP¢ab; dUcenHvaKμan shear lag eT enaHeyIg

TTYl)an Ae = An .

Ggát;p©itRbehag

1 3 1 7

h=d+ = + = in.

8 4 8 8

Design strength KW

φt Pn = φt Fu Ae = φt Fu t (wg − ∑ h ) = 0.75(58)⎜ ⎟ ⎢6 − 2⎜ ⎟⎥ = 92.4kips

⎛ 1 ⎞⎡ ⎛ 7 ⎞⎤

⎝ 2 ⎠⎣ ⎝ 8 ⎠⎦

Block shear stredngth: failure blocksMrab; gusset plate manTMhMdUcTMhMsMrab;Ggát;rgkarTajEdr

EtxuxKñaRtg;kMras; ¬rUbTI 7>14 b¦. Gusset plate EdlmankMras;esþIgCagnwgmanersIusþg;tUcCag.

vaman shear-failure plane cMnYnBIr³

Agv = 2 ×

3

(3 + 1.5) = 3.375in.2

8

edaysarvaman 1.5 Ggát;p©itRbehagkñúgmYyCYredkrbs;b‘ULúg

3⎡ ⎛ 7 ⎞⎤

Anv = 2 × ⎢(3 + 1.5) − (1.5)⎜ ⎟⎥ = 2.391in.2

8⎣ ⎝ 8 ⎠⎦

sMrab;RkLaépÞrgkarTaj

Agt =

3

(3) = 1.125in.2

8

3⎛ 7⎞

Ant = ⎜ 3 − ⎟ = 0.7969in.2

8⎝ 8⎠

252 tMNsamBaØ

24. T.chhay

AISC Equation J4-3a eGay

[ ]

φRn = φ 0.6 Fy Agv + Fu Ant = 0.75[0.6(36 )(3.375) + 58(0.7969 )]

= 0.75[72.90 + 46.22] = 89.3kips

AISC Equation J4-3b eGay

[ ]

φRn = φ 0.6 Fy Anv + Fy Agt = 0.75[0.6(58)(2.391) + 36(1.125)]

= 0.75[83.21 + 40.50] = 92.8kips

tY fracture ¬EdlBak;Bn§½nwg Fu ¦ enAkñúgsmIkarTIBIrmantMélFMCagenAkñúgsmIkarTImYy dUcenH AISC

Equation 4.3b lub.

design strength sMrab; block shear = 92.8kips

kñúgcMeNamsßanPaBkMNt;TaMgGs;Edl)aneFVIkarGegát eyIgeXIjfaersIusþg;EdlRtUvKñanwg slip mantM

éltUcCageK.

cMeLIy³ Design strength rbs;tMNKW 41.6kips

]TahrN_ 7>6³ Ggát;rgkarTajkMras; 5 / 8in. RtUv)antP¢ab;eTAnwg splice plate kMras; 1 / 4in. cMnYnBIr

dUcEdl)anbgðajenAkñúgrUbTI 7>15. bnÞúkEdl)anbgðajCabnÞúk service load. eKeRbIEdk A36 nig

b‘ULúg A325 Ggát;p©it 5 / 8in. . RbsinebIeKGnuBaØateGayman slip etIeKRtUvkarb‘ULúgb:unμanRKab;?

GkS½rbs;b‘ULúgnImYy²EdlbgðajKWCaCYrrbs;b‘ULúgkñúgTisTTwgrbs;bnÞHEdk.

253 tMNsamBaØ

25. T.chhay

dMeNaHRsay³ Shear: sMrab; shear, norminal bolt area KW

π (5 / 8)2

Ab = = 0.3068in.2

4

snμt;fa eFμjb‘ULúgsßitenAkúñgbøg;kat;. enaH design strength sMrab;b‘ULúgmYyKW

φRn = φFv Ab × 2planes of shear = 0.75(48)(0.3068)(2) = 22.09kips

Bearing: Beating force enAelIGgát;rgkarTajkMras; 5 / 8in. nwgFMCag bearing force enAelI splice

plate kMras; 1 / 4in. nImYy² BIrdg. edaysarbnÞúksrubenAelI splice plates esμInwgbnÞúkenAelIGgát;

rgkarTaj enaH splice plate nwgmaneRKaHfñak;enAeBlEdlkMras;srubrbs; splice plate esþIgCag

kMras;rbs;Ggát;rgkarTaj. eRbIGgát;p©itRbehag

1 5 1 11

h=d+ = + = in.

16 8 16 16

sMrab;RbehagEdlenAEk,rRCugEKmCageK

h 11 / 16

Lc = Le − = 1.5 − = 1.156in.

2 2

⎛5⎞

2d = 2⎜ ⎟ = 1.25in.

⎝8⎠

edaysar Lc < 2d / bearing strength KW

⎛1 1⎞

φRn = φ (1.2 Lc tFu ) = 0.75(1.2)(1.156)⎜ + ⎟(58) = 30.17kips / bolt

⎝4 4⎠

sMrab;rn§déTeTot

11

Lc = s − h = 3 − = 2.312in. > 2d

16

⎛ 5 ⎞⎛ 1 1 ⎞

dUcenH φRn = φ (2.4dtFu ) = 0.75(2.4)⎜ ⎟⎜ + ⎟(58) = 32.62kips / bolt

⎝ 8 ⎠⎝ 4 4 ⎠

Shearing strength kñúgb‘ULúgmYyKWtUcCagtMél bearing TaMgBIr dUcenHersIusþg;rbs;tMNKW 22.09kips .

bnÞúkemKuNKW

Pu = 1.2 D + 1.6 L = 1.2(25) + 1.6(25) = 70kips

cMnYnb‘ULúgEdlRtUvkar =

total load

load per bolt

70

= = 3.17bolts

22.09

cMeLIy³ eRbIb‘ULúgbYn EdlkñúgmYyCYrmanBIrRKab; enAelIRCugnImYy²rbs; splice. b‘ULúgcMnYn R)aMbI

RKab;GacRtUvkarsMrab;kartP¢ab;enH.

254 tMNsamBaØ

26. T.chhay

]TahrN_ 7>7³ C 6 ×13 EdlbgðajenAkñúgrUbTI 7>16 RtUv)aneRCIserIsedIm,ITb;Tl;nwgbnÞúkTajem

KuN 108kips . Ggát;enHRtUv)anP¢ab;eTAnwg gusset plate kMras; 3 / 8in. CamYynwgb‘ULúg A325

EdlmanGgát;p©it 7 / 8in. . ]bmafaeFμjrbs;b‘ULúgsßitenAkñúgbøg;énkMlaMgkat;TTwg ehIyeKGnuBaØat

eGayman slip sMrab;kartP¢ab;enH. kMNt;cMnYn nigeFVIkartMerobb‘ULúgy:agNaedIm,ITTYl)anRbEvgt

P¢ab; h Gb,brma. eKeRbIEdk A36 .

dMeNaHRsay³ kMNt;lT§PaBrbs;b‘ULúgeTal

kMlaMgkat;TTwg³

π (7 / 8)2

Ab = = 0.6013in.2

4

φRn = φFv Ab = 0.75(48)(0.6013) = 21.65kips

bearing³ edaysarkMras;rbs; gusset plate esþIgCaRTnugrbs;Edk channel dUcenH bearing strength

rbs; gusset plate nwgtUcCagEdk channel. snμt;faRbEvg Lc EdlRsbnwgkMlaMgEdlGnuvtþmantMél

FMCag 2d sMrab;b‘ULúgTaMgGs;. enaH

⎛ 7 ⎞⎛ 3 ⎞

φRn = φ (2.4dtFu ) = 0.75(2.4)⎜ ⎟⎜ ⎟(58) = 34.26kips

⎝ 8 ⎠⎝ 8 ⎠

enaH kMlaMgkat;TTwglub. dUcenH

cMnYnb‘ULúgEdlRtUvkar = 21.65 = 4.99

108

eTaHbICab‘ULúg 5 pþl;nUversIusþg;RKb;RKan;k¾eday k¾eKsakl,gb‘ULúg 6RKab;EdlGacerobCalkçN³

sIuemRTI edaymanb‘ULúg 3RKab;BIrCYr dUcbgðajenAkñúgrUbTI 7>17. ¬b‘ULúgBIrCYrRtUv)aneRbIedIm,I

TTYl)anRbEvgtP¢ab;Gb,brma¦. eyIgmin)andwgfaetIkarKNnamuxkat;Ggát;rgkarTajenHQrelI

karsnμt;eRKOgP¢ab;b:unμanCYr dUcenHlT§PaBTb;karTajrbs;Edk channel CamYynwgb‘ULúgBIrCYrRtUv)an

RtYtBinitümunnwgdMeNIrkarKNnakartP¢ab;bnþ.

255 tMNsamBaØ

27. T.chhay

karTajenAelI gross area:

φt Pn = 0.90 Fy Ag = 0.90(36 )(3.83) = 124kips

net area

An = 3.83 − 2(1.0)(0.437 ) = 2.96in.2

edaysareyIgminTan;sÁal;RbEvgtP¢ab;BitR)akd dUcenHeyIgRtUveRbItMélmFümrbs; U BI

Commentary.

Ae = UAn = 0.85(2.96) = 2.51in.2

kMlaMgTajenAelI net area

φt Pn = 0.75Fu Ae = 0.75(58)(2.51) = 109kips ¬lub¦

dUcenH lT§PaBrbs;Ggát;rgkarTajKWQrelIb‘ULúgBIrCYr.

RtYtBinitüKMlat nigRbEvgeTARCugEKmtamTisEkgnwgkMlaMg. BI AISC J3.3

KMlatGb,brma = 2.667⎛ 7 ⎞ = 2.33in.

⎜ ⎟

⎝8⎠

BI AISC Table J3.4

RbEvgeTARCugEKmGb,brma = 1 18 in.

KMlat 3in. nigRbEvgeTARCugEKm1 12 in. nwgRtUv)aneRbIkñúgTisEkgnwgkMlaMg.

eKGackMNt;RbEvgtP¢ab;Gb,brmarbs;kartP¢ab;edayeRbIKMlat nigRbEvgeTARCugEKmGnuBaØat

Gb,brmakñúgTisbeNþay ¬RsbnwgkMlaMg¦. KMlatGb,brmakñúgTisnImYy²KW 2 2 3 d = 2.33in. .

sakl,g 2 12 in. . RbEvgeTARCugEKmGb,brmaKW 1 18 in. . cMgayGb,brmaTaMgenHnwgRtUv)aneRbI

sMrab;epÞógpÞat; bearing strength rbs;kartP¢ab;. sMrab;karKNna bearing strength eKeRbIGgát;p©it

rn§

1 7 1 15

h=d+ = + = in.

16 8 16 16

sMrab;RbehagEdlenAEk,rRCugEKmrbs; gusset plate CageK

256 tMNsamBaØ

28. T.chhay

h 15 / 16

Lc = Le − = 1.125 − = 0.6562in.

2 2

2d = 2(7 / 8) = 1.75in.

edaysar Lc < 2d bearing strength KW

⎛3⎞

φRn = φ (1.2 Lc tFu ) = 0.75(1.2)(0.6562)⎜ ⎟(58) = 12.85kips / bolt

⎝8⎠

sMrab;Rbehagd¾éTeTot

15

Lc = s − h = 2.5 − = 1.562in. < 2d

16

dUcenH φRn = φ (1.2LctFu ) = 0.75(1.2)(1.562)⎜ 8 ⎞(58) = 30.58kips / bolt

⎛3

⎝ ⎠

⎟

Bearing strength srubsMrab;kartP¢ab;KW

φRn = 2(12.85) + 4(30.58) = 148kips > Pu = 108kips (OK)

rUbTI 7>18 bgðajBIkartP¢ab;sakl,gsMrab;RtYtBinitüemIl block shear enAkñúg gusset plate

¬sMrab;ragGrNImaRtén failure block enAkñúgEdl channel KWdUcKña b:uEnþ gusset plate mankMras;esþIg

Cag¦.

Shear areas:

Agv = (2.5 + 2.5 + 1.125)(2) = 4.594in.2

3

8

ehIyedaysarEtvamanRbehag 2.5 enAtamépÞkat;nImYy²

Anv =

3

[6.125 − 2.5(1.0)](2) = 2.719in.2

8

Tension area

Agt = (3) = 1.125in.2

3

8

ehIy Ant = (3 − 1.0) = 0.75in.2

3

8

RtYtBinitüsMrab; tension yield nig shear fracture CamYynwg AISC Equation J4-3a:

257 tMNsamBaØ

29. T.chhay

[

φRn = φ 0.6 Fy Agv + Fu Ant ]

= 0.75[0.6(36 )(4.594 ) + 58(0.75)] = 0.75[99.23 + 43.50] = 107.0kips

RtYtBinitüsMrab; tension fracture nig shear yield CamYynwg AISC Equation J4-3b:

φRn = φ [0.6 Fu Anv + Fy Agt ]

= 0.75[0.6(58)(2.719 ) + 36(1.125)] = 0.75[94.62 + 40.50] = 101.3kips

tY fracture ¬tYEdlBak;Bn§½nwg Fu ¦ enAkñúgsmIkarTIBIrmantMélFMCagtY fracture enAkñúgsmIkarTImYy

dUcenH smIkarTIBIrlub.

Design strength sMrab; block shear = 101.3kips < 108kips (N.G.)

viFIEdlsamBaØbMputkñúgkarbegáIn block shear strength sMrab;kartP¢ab;enHKWbegáIn shear area eday

begáInKMlatb‘ULúg. RbsinebIeKbegáInKMlat AISC Equation J4-3b enAEtlubdEdl. ebIeTaHbICaKM

latEdlRtUvkarGackMNt;eday trial and error k¾eday k¾eKGacedaHRsayedaypÞal;dUcEdleyIg

nwgeFVIenATIenH. BI AISC Equation J4-3b, eKeGay

0.75[0.6(58)Anv + 40.50] = 108kips

dUcenHeKRtUvkar Anv = 2.974in.2

Anv =

3

(2s + 1.125 − 2.5)(2) = 2.974in.2

8

dUcenH s = 2.67in.

yk s = 3in.

CamYynwgKMlat 3in. net shear area KW

Anv =

3

(3 + 3 + 1.125 − 2.5)(2) = 3.469in.2

8

ehIy block shear strength BI AISC Equation J4-3b KW

[

φRn = φ 0.6 Fu Anv + Fy Agt ]

= 0.75[0.6(58)(3.469 ) + 36(1.125)] = 0.75[120.7 + 40.50] = 120.9kips

edayeRbIKMlat nigRbEvgeTARCugEKmEdl)ankMNt; dUcenHRbEvgGb,brmaKW

h = 1.125 + 2 × 3 + 1.125 = 8.5in

cMeLIy³ eRbIkartP¢ab;lMGitEdlbgðajenAkñúgrUbTI 7>19.

258 tMNsamBaØ

30. T.chhay

kartMerobb‘ULúgenAkñúg]TahrN_ 7>7 manlkçN³sIuemRTIeFobnwgGkS½RsbnwgGkS½TIRbCMuTMgn;.

dUcenHkMlaMgpÁÜbEdlTb;Tl;kMlaMgEdlpþleGayedayeRKOgP¢ab;k¾eFVIGMeBItamGkS½enH ehIyragFrNI-

maRtenHRtUvKñanwgkartP¢ab;samBaØ. RbsinebIeKRtUvkarcMnYnb‘ULúgess ehIyeKeRbIBIrCYr vanwgminman

PaBsIuemRTIeT ehIykartP¢ab;nwgmanlkçN³cakp©it. kñúgkrNIEbbenH GñkKNnamuxkat;nwgmanCMerIs

eRcIn³ ¬!¦ minKitcMNakp©it edaysnμt;faT§BlenHGacecal)an/ ¬@¦ KitcMNakp©it/ ¬#¦ eRbIkartM

erobqøas; (staggered pattern) EdlGacrkSanUvPaBsIuemRTI/ b¤ ¬$¦ bEnßmcMnYnb‘ULúgedIm,ITTYl)an

kartMerobEdlmanlkçN³sIuemRTI. visVkrPaKeRcInRbEhlCanwgeRCIserIsCMerIscugeRkay.

]TahrN_ 7>8³ Ggát;rgkarTajRbEvg 13 ft nigkartP¢ab;rbs;vaRtUv)anKNnasMrab; service dead

load 8kips nig service live load 22kips . eKminGnuBaØateGayman slip sMrab;kartP¢ab;enHeT.

Ggát;enHRtUv)antP¢ab;eTAnwg gusset plate kMras; 3 / 8in. dUcbgðajenAkñúgrUbTI 7>20. eRbIEdkEkg

eTal (single angle) sMrab;Ggát;rgkarTaj. eRbIb‘ULúg A325 nigEdk A572 grade 50 sMrab;Ggát;rg

karTaj nig gusset plate.

dMeNaHRsay³ bnÞúkemKuNEdlRtUvTb;Tl;KW

Pu = 1.2 D + 1.6 L = 1.2(8) + 1.6(22) = 44.8kips

259 tMNsamBaØ

31. T.chhay

edaysarTMhMb‘ULúg nigkartMerobb‘ULúgCHT§iBldl; net area rbs;Ggát;rgkarTaj eyIgnwgcab;epþIm

CamYynwgkareRCIserIsb‘ULúg. yuT§saRsþKWkareRCIserIssMrab;karsakl,g/ kMNt;cMnYnb‘ULúgEdlRtUv

kar/ rYcbnÞab;mksakl,gTMhMepSgeTotRbsinebITMhMEdl)ansakl,gFMeBk b¤tUceBk. Ggát;p©itb‘U

LúgsßitenAcenøaHBI 1/ 2in. ≈ 13mm eTA 1 12 in. ≈ 38mm edayekIneLIgmþg 1 / 8in. ≈ 3mm

sakl,gb‘ULúg 5 / 8in. . Nominal bolt area KW

π (5 / 8)2

Ab = = 0.3068in.2

4

Shear strength KW

φRn = φFv Ab = 0.75(48)Ab = 0.75(48)(0.3068)

= 11.04kips / bolt ¬edaysnμt;faeFμjsßitenAkñúgbøg;kat;¦

edayeKminGnuBaØateGayman slip dUcenHkartP¢ab;enHCa slip-critical. eyIgsnμt;épÞ Class A ehIy

sMrab;b‘ULúgGgát;p©it 5 / 8in. kMlaMgTajGb,brmaKW Tm = 19kips ¬BI AISC Table J3.1). BI RCSC

Equation LRFD 5.3, slip critical strength sMrab;b‘ULúgeTalKW

φRstr = φ (1.13μTm N b N s ) = 1.0(1.13)(0.33)(19)(1)(1) = 7.085kips / bolt

eday slip-critical strength tUcCag shear strength dUcenH slip-critical strength lub. eyIgnwgkM

Nt;cMnYnb‘ULúgedayQrelI slip-critical strength ehIyRtYtBinitü bearing bnÞab;BIeRCIserIsGgát;

¬edaysar bearing strength minGackMNt;)an Tal;EteKsÁal;kMras;Ggát;sin¦. dUcenH

cMnYnb‘ULúg = load per bolt = 7.085 = 6.3bolts

total load 44.8

dUcenHeKRtUvkarb‘ULúgy:agtic 7 RKab;. RbsinebIeKeRbIBIrCYr eKRtUvbEnßmb‘ULúgmYyRKab;edIm,IrkSaPaB

sIuemRTI. rUbTI 7>21 bgðajBIkartMerobb‘ULúgEdlmanCaeRcInTMrg;. kartMerobb‘ULúgTaMgenHeKGaceRbI

)anTaMgGs; EtRbEvgénkartP¢ab;GacRtUv)ankat;bnßyedayeRbITMhMb‘ULúgFM nigcMnYntic.

sakl,gb‘ULúgEdlmanGgát;p©it 7 / 8in. . Nominal bolt area KW

π (7 / 8)2

Ab = = 0.6013in.2

4

Shear strength KW

φRn = 0.75(48)Ab = 0.75(48)(0.6013)

= 21.65kips / bolt ¬edaysnμt;faeFμjsßitenAkñúgbøg;kat;¦

260 tMNsamBaØ

32. T.chhay

kMlaMgTajGb,brmasMrab;b‘ULúg A325 Ggát;p©it 7 / 8in. KW Tm = 39kips dUcenH slip-critical

strength KW

φRstr = φ (1.13μTm N b N s ) = 1.0(1.13)(0.33)(39)(1)(1) = 14.54kips / bolt ¬lub¦

eKRtUvkarb‘ULúgEdlmanGgát;p©it 7 / 8in. cMnYn

44.8

= 3.1bolts

14.54

dUcenHeyIgeRbIb‘ULúg A325 EdlmanGgát;p©it 7 / 8in. cMnYn 4 RKab;. BI AISC J3.3, KMlatGb,brmaKW

⎛7⎞ ⎛7⎞

s = 2.667 d = 2.667⎜ ⎟ = 2.33in. ¬b¤sMrab;karniym/ 3d = 3⎜ ⎟ = 2.62in. ¦

⎝8⎠ ⎝8⎠

BI AISC Table J3.4, cMgayeTARCugEKmKW

Le = 1.5in. ¬edaysnμt; sheared edges¦

edaysakl,gkartMerobdUcbgðajenAkñúgrUbTI 7>22 eRCIserIsGgát;rgkarTaj. Gross area EdlRtUv

karKW

Pu 44.8

Ag ≥ = = 0.996in.2

0.9 Fy 0.9(50)

Effective net area EdlRtUvkarKW

Pu 44.8

Ae ≥ = = 0.9190in.2

0.75Fy 0.75(36)

edaysar effective net area KW Ae = UAn / net area EdlRtUvkarKW

requiredAe

An =

U

BIkartMerobb‘ULúgEdlbgðajenAkñúgrUbTI 7>22/ CamYynwgb‘ULúgeRcInCagBIrkñúgTisénkMlaMgEdlGnuvtþ

tMélmFümrbs; U BI Commentary to the AISC Specification KW 0.85 . ¬enAeBlEdleKeRCIserIs

Ggát;rYcehIy eKGackMNt;tMél U CamYynwg AISC Equation B3-2¦. dUcenH

261 tMNsamBaØ

33. T.chhay

0.9190

An ≥ = 1.08in.2

0.85

cMNaMfa net area EdlRtUvkarKWFMCag gross area EdlRtUvkar. kaMniclPaBGb,brmaEdlRtUvkarKW

L 13(12)

rmin = = = 0.52in.

300 300

sakl,g L3 12 × 2 12 × 14

Ag = 1.44in.2 > 0.996in.2 (OK)

rmin = rz = 0.544in. > 0.52in. (OK)

sMrab;karKNna net area, eRbIGgát;p©itrn§ 7 8 + 18 = 1.0in.

⎛1⎞

An = Ag − Ahole = 1.44 − 1.0⎜ ⎟ = 1.190in.2 > 1.08in.2 (OK)

⎝4⎠

KNna U CamYynwg AISC Equation B3-2:

x

U =1− ≤ 0.9

L

0.785

= 1− = 0.913

9

edaysartMélenHFMCag 0.9 / dUcenHeRbI U = 0.9 . Effective net area KW

Ae = UAn = 0.9(1.190) = 1.071in.2 > 0.9190in.2 (OK)

RtYtBinitü bearing strength. cMgayeTARCugEKmsMrab;EdkEkgesμInwgcMgayeTARCugEKmsMrab; gusset

plate ehIyedaysarEdkEkgmankMras;esþIgCag gusset plate dUcenHeyIgeRbIEdkEkgEdlmankMras;

1 / 4in. sMrab;KNna bearing strength. sMrab;karKNna bearing strength, eyIgeRbIGgát;p©itRbehag

1 7 1 15

h=d+ = + = in.

16 8 16 16

sMrab;RbehagEdlenAEk,RCugEKmGgát;CageK

h 15 / 16

Lc = Lc − = 1.5 − = 1.031in.

2 2

262 tMNsamBaØ

34. T.chhay

2d = 2(7 / 8) = 1.75in.

edaysar Lc < 2d / bearing strength KW

⎛1⎞

φRc = φ (1.2 Lc tFu ) = 0.75(1.2)(1.031)⎜ ⎟(65) = 15.08kips / bolt

⎝4⎠

sMrab;Rbehagd¾éTeTot

15

Lc = s − h = 3 − = 2.062in. > 2d

16

⎛ 7 ⎞⎛ 1 ⎞

dUcenH φRn = φ (2.4dtFu ) = 0.75(2.4)⎜ ⎟⎜ ⎟(65) = 25.59kips / bolt

⎝ 8 ⎠⎝ 4 ⎠

Bearing strength srubsMrab;kartP¢ab;KW

φRn = 15.08 + 3(25.59) = 91.9kips > Pu = 44.8kips (OK)

RtYtBinitü block shear. CamYynwgb‘ULúgEdlP¢ab;enAelIeCIgEvgCamYynwgcMgayKMlat ¬emIlCMBUk

III/ rUbTI 3>22¦ failure block RtUv)anbgðajenAkñúgrUbTI 7>23. Shear area KW

Agv =

1

(1.5 + 9) = 2.625in.2

4

Anv = [1.5 + 9 − 3.5(1.0)] = 1.750in.2

1

4

¬Ggát;p©itRbehagmancMnYn 3.5 ¦

Tension area KW

Agt =

1

(1.5) = 0.3750in.2

4

Ant = [1.5 − 0.5(1.0)] = 0.25in.2

1

4

¬Ggát;p©itRbehagmancMnYn 0.5 ¦

AISC Equation J4-3a eGay

[

φRn = φ 0.6 F y Agv + Fu Ant ]

= 0.75[0.6(50 )(2.625) + 65(0.25)] = 0.75(78.75 + 16.25) = 71.2kips

263 tMNsamBaØ

35. T.chhay

AISC Equation J4-3b eGay

[

φRn = φ 0.6 Fu Anv + Fy Agt ]

= 0.75[0.6(65)(1.75) + 50(0.375)] = 0.75(68.25 + 18.75) = 65.2kips

smIkar J4-3bmantY fracture FMCag dUcenHsmIkarenHlub. dUcenH block shear strength KW

φRn = 65.2kips > Pu = 44.8kips (OK)

cMeLIy³ eRbI L3 1 2 × 2 12 × 1 4 CamYynwgkartP¢ab;enAelIeCIgEvg. eRbIb‘ULúg A325 Ggát;p©it 7 8 in.

dUcbgðajenAkñúgrUbTI 7>24.

7>8> b‘ULúgersIusþg;x<s;rgkarTaj High-Strength Bolts in Tension

enAeBlEdlkMlaMgTajEdlGnuvtþelIb‘ULúgedayKμankMlaMgTajedIm (initial tension) kMlaMg

TajenAkñúgb‘ULúgesμInwgkMlaMgEdlGnuvtþ. b:uEnþ RbsinebIb‘ULúgrgeRbkugRtaMg Epñkd¾FMrbs;kMlaMgEdl

GnuvtþRtUv)aneRbIedIm,Ibn§ÚrkMlaMgsgát; b¤kMlaMgrwt (clamping force) enAelIEpñkEdlRtUvtP¢ab; dUcEdl

kMNt;eday Kulak, Fisher, nig Struik (1987) ehIyRtUv)anbkRsayenATIenH. rUbTI 7>25 bgðajBI

tMNBüÜr (hanger connection) EdlpSMeLIgeday structural tee shape EdlRtUv)ancab;b‘ULúgeTAnwg

søabxageRkamrbs; W-shape nigrgnUvkMlaMgTaj. b‘ULúgeTal nwgcMENkénEpñkEdlRtUvtP¢ab;

RtUv)ansikSamun nigeRkayeBldak;bnÞúk.

264 tMNsamBaØ

36. T.chhay

düaRkamGgÁesrIrbs;kartP¢ab;muneBldak;bnÞúkRtUv)anbgðajenAkñúgrUbTI 7>26 a. ral;kMlaMg

TaMgGs;CakMlaMgkñúg. edIm,IPaBgayRsYl kMlaMgTaMgGs;RtUv)ansnμt;sIuemRTIeFobGkS½rbs;b‘ULúg

ehIycMNakp©itminRtUv)anKit. Rb sinebIeKBicarNaEpñkEdlRtUvtP¢ab;dac;edayELk kMlaMgrYmmankM

laMgTajrbs;b‘ULúg To nigkMlaMgrwt Ekg (normal clamping force) N o EdlbgðajenATIenHRtUv)an

BRgayesμI. edIm,IeGaymanlMnwg eKRtUvkar To = N o . enAeBlEdleKGnuvtþkMlaMgxageRkA kMlaMg

enAelIkartP¢ab;RtUv)anbgðajenAkñúgrUbTI 7>26 b Edl F tMNageGaykMlaMgTajsrubEdlGnuvtþ

mkelIb‘ULúgmYy. rUbTI 7>26 c bgðajkMlaMgEdlmanGMeBIelIdüaRkamGgÁesrIrbs;Epñkénsøabrbs;

structural tee nigEpñkEdlRtUvKñarbs;b‘ULúg. bUkkMlaMgtamTisGkS½b‘ULúg eyIgTTYl)an

T =F+N

kMlaMg F nwgbegáInkMlaMgTajrbs;b‘ULúg ehIyeFVIeGayvalUt)an δ b . kMlaMgsgát;enAkñúg

søabrbs; structurel atee nwgRtUv)ankat;bnßy CalT§plvamanbMlas;TI δ fl EdlmanTisdUc δ b .

TMnak;TMngrvagkMlaMgGnuvtþn_ nigbMErbMrYlkMlaMgTajrbs;b‘ULúgGacRtUv)ankMNt;dUcxageRkam³

BI elementary mechanics of materials, kMhUcRTg;RTaytamGkS½rbs;bnÞúktamGkS½Edl

GnuvtþelIGgát;KW³

265 tMNsamBaØ

37. T.chhay

δ=

PL

AE

¬&>$¦

Edl P=kMlaMgtamGkS½

L = RbEvgedIm

A = RkLaépÞmuxkat;

E = m:UDuleGLasÞic

BIsmIkar &>$ eyIgGacTajrkkMlaMg

AEδ

P=

L

¬&>%¦

dUcenHbMErbMrYlkMlaMgenAkñúgb‘ULúgEdlRtUvKñaeTAnwgkMhUcRTg;RTay δ b KW

A E δ

ΔT = b b b

Lb

¬&>^¦

BIsmIkar &>% eKTTYl)anbMErbMrYlkMlaMg N

A fl E fl δ fl

ΔN =

L fl

¬&>&¦

Edl L fl CakMras;rbs;søab. RbsinEpñkEdlRtUvP¢ab; ¬søabTaMgBIr¦ enAb:HKña kMhUcRTg;RTayrbs;

b‘ULúg δ b nigkMhUcRTg;RTaysøab δ fl nwgesμIKña. edaysar E fl esÞIresμInwg Eb (Bickford, 1981),

ehIy A fl FMCag Ab

A fl E fl δ fl A E δ

>> b b b

L fl Lb

dUcenH ΔN >> ΔT

pleFob ΔN elI ΔT sßitenAcenøaHBI 0.05 eTA 0.1 (Kulak, Fisher, nig Struik, 1987). dUcenH ΔT

minRtUvFMCag 0.1ΔN EdlbgðajfakMlaMgEdlGnuvtþPaKeRcInKWbn§ÚrkMlaMgsgát;rbs;EpñkEdlRtUvtP¢ab;.

KNnakMlaMgEdlRtUvkaredIm,IeFVIeGayEpñkEdlRtUvP¢ab;XøatecjBIKña emIlrUbTI 7>27. enAeBlEdl

EpñkTaMgBIrXøatecjBIKña

T =F

b¤ To + ΔT = F ¬&>*¦

enAeBlEdlCitdl;cMnucEdlRtUvXøatKña sac;lUtrbs;b‘ULúg nigKMlatrbs;søabKWesμIKña

A E A E

ΔT = b b δ b = b b δ fl

L L

¬&>(¦

b b

266 tMNsamBaØ

38. T.chhay

Edl δ fl CakMhUcRTg;RTayEdlRtUvKñanwgkMlaMgsgát;edIm N o . BIsmIkar &>$

N o L fl

δ fl =

A fl E fl

CMnYsvaeTAkñúgsmIkar &>( eyIg)an

⎛ A E ⎞⎛ N o L fl ⎞ ⎛ Ab Eb / Lb ⎞ ⎛

⎟ N o = ⎜ Ab Eb / Lb

⎞

ΔT = ⎜ b b ⎟⎜

⎜ L ⎟⎜ A E

⎟=⎜ ⎟To ≈ 0.1To

⎝ b ⎠⎝ fl fl ⎟ ⎜ A fl E fl / L fl ⎟ ⎜ A fl E fl / L fl ⎟

⎠ ⎝ ⎠ ⎝ ⎠

BIsmIkar &>*

To + 0.1To = F b¤ F = 1.1To

dUcenH enAxN³eBlEdlcab;epþImXøat kMlaMgTajenAkñúgb‘ULúgFMCagkMlaMgTajedImEdlmanenAeBl

tMeLIgb‘ULúgRbEhl 10% . b:uEnþ enAeBlEdlEpñkEdlRtUvP¢ab;Xøatecj kMlaMgxageRkAEdlekIneLIg

nwgRtUv)anTb;edaykMlaMgEdlekIneLIgRtUvKñaenAkñúgb‘ULúg. RbsinebIeKsnμt;fakMlaMgTajenAkñúgb‘U

LúgRtUv)andak;eGayesμIkMlaMgxageRkA ¬RbsinebIKμankMlaMgTajedIm¦ ehIykartP¢ab;rgnUvbnÞúkrhUt

dl;EpñkEdltP¢ab;XøatecjBIKña enaHkMlaMgTajenAkñúgb‘ULúgRtUv)anKNnaticCag 10% . sMrab;krNI

enH b‘ULúgersIusþg;x<s;RtUvrgnUveRbkugRtaMgtamtMélEdlmanenAkñúg AISC Table J3.1 eTaHCakartP¢ab;

enHCa slip-critical b¤minEmnk¾eday. CarYm eKRtUvKNnakMlaMgTajenAkñúgb‘UøLúgedayKitbBa©ÚlTaMgkM

laMgTajedIm.

Prying Action

sMrab;kartP¢ab;PaKeRcInEdleRKOgP¢ab;rgkMlaMgTaj kMhUcRTg;RTayrbs;EpñkEdlRtUvP¢ab;

GacbegáInkMlaMgTajEdlGnuvtþeTAelIeRKOgP¢ab;. RbePT hanger connection Edl)anerobrab;xag

elICaRbePTkartP¢ab;EdlmanlkçN³eFVIkardUcEdl)anerobrab;. kMlaMgTajbEnßmRtUv)aneKehAfa

prying force ehIyRtUv)anbgðajenAkñúgrUbTI 7>28 EdlrUbenHbgðajBIkMlaMgenAelIGgÁesrIrbs;

hanger. muneBlEdlbnÞúkxageRkAGnuvtþ kMlaMgsgát;Ekg (normal compressive force) N o RbmUl

267 tMNsamBaØ

39. T.chhay

pþúMenAelIGgS½rbs;b‘ULúg. enAeBlEdlbnÞúkGnuvtþ RbsinebIsøab flexible RKb;RKan; enaHvanwgxUcRTg;

RTaydUcEdlbgðaj ehIykMlaMgsgát;nwgrMkileTAxagcugrbs;søab. karBRgaykMlaMgeLIgvijenH nwg

EkERbTMnak;TMngrvagbnÞúkTaMgGs; ehIykMlaMgTajrbs;b‘ULúgnwgekIneLIg. b:uEnþ RbsinebIEpñkEdl

RtUvP¢ab;manlkçN³rwgRKb;RKan; vanwgminmankarpøas;bþÚrkMlaMgeT ehIyk¾minman prying action Edr.

eKTTYl)antMélGtibrmarbs; prying force enAeBlEdlkac;RCugrbs;søabenAEtb:HCamYynwgEpñk

EdlRtUvP¢ab;d¾éTeTot.

enAkñúgkartP¢ab;RbePTenH bending EdlekIteLIgeday prying force EtgEtmanlkçN³lub

kñúgkarKNnaEpñkEdlRtUvP¢ab;. AISC J3.6 tMrUveGayKitbBa©Úl prying force eTAkñúgkarKNnakMlaMg

TajEdlGnuvtþelIeRKOgP¢ab;.

viFIsaRsþsMrab;karKNna prying force EdlQrelI Guide to design Criteria for Bolted

and Riveted Joints (Kulak, Fisher, nig Strick, 1987) manenAkñúg Manual in Part 11, “Connec-

tions for Tension and Compression” (Volume II). krNICak;lak;EdlRtUv)anRtYtBinitüCakart

P¢ab; structural tee shape ehIyEdkEkgKUrEdlxñgTl;xñg ( a pair of back-to-back angle) nwg

RtUv)anKitkñúgpøÚvdUcKñaEdr. viFIEdlbgðajenATIenHmanTMrg;xusKñabnþicEtpþl;nUvlT§pldUcKña.

viFIEdleRbIKWQrelIKMrUEdlbgðajenAkñúgrUbTi 7>29. RKb;kMlaMgTaMgGs;KWsMrab;EteRKOgP¢ab;

mYy. dUcenH T CakMlaMgTajemKuNxageRkAEdlGnuvtþeTAelIEtb‘ULúgmYy/ Q Ca prying force Edl

268 tMNsamBaØ

40. T.chhay

RtUvKñanwgb‘ULúgmYy nig Bc CakMlaMgb‘ULúgsrub. Prying force )anrMkileTAcugrbs;søab ehIyvaman

tMélGtibrma.

smIkarxageRkamRtUv)anbMEbkBIsmIkarlMnwgrbs;GgÁesrIkñúgrUbTI 7>29. BIplbUkm:Um:g;Rtg;

muxkat; B-B enAkñúgrUbTI 7>29 b

Tb − M a − a = Qa ¬&>!0¦

BIrUbTI 7>29 c

M b − b = Qa ¬&>!!¦

cugeRkay/ kMlaMglMnwgRtUvkarKW

Bc = T + Q ¬&>!@¦

smIkarlMnwgTaMgbIenHGacbBa©ÚlKñaedIm,ITTYl)ansmIkareTalsMrab;kMlaMgb‘ULúgsrub EdlrYmbBa©Úl

TaMgT§iBl prying force. dMbUgeyIgkMNt;Gefr α CapleFobrvagm:Um:g;kñúgmYyÉktþaRbEvgtam

beNþayGkS½b‘ULúgelIm:Um:g;kñúgmYyÉktþaRbEvgenARtg;épÞKl;. sMrab;GkS½b‘ULúg/ RbEvgCa net length,

dUcenH

269 tMNsamBaØ

41. T.chhay

M b − b / ( p − d ') M b − b ⎛ ⎞ M b −b

α= = ⎜

1

⎜ 1 − d ' / p ⎟ = δM

⎟ ¬&>!#¦

M a−a / p M a−a ⎝ ⎠ a−a

Edl p= RbEvgrgsMBaFrbs;søabsMrab;b‘ULúgmYy ¬emIlrUbTI 7>29 a¦

d ' = Ggát;p©itrbs;Rbehagb‘ULúg

d' net area at bolt line

δ = 1− =

p gross area at web face

(

M a − a = design strength at a − a = φb M p = φb pt 2 F y / 4

f )

eyIgGacbBa©ÚlsmIkarlMnwgbI &>!0-&>!@ edIm,ITTYl)ankMlaMgb‘ULúgsrub/ Bc :

⎡ δα b ⎤

Bc = T ⎢1 + ⎥ ¬&>!$¦

⎣ (1 + δα ) a ⎦

CamYynwg bnÞúkEdlTTYl)anBIsmIkar &>!$ eyIgnwgTTYl)ankMhUcRTg;RTayFMEdleFVIeGaykugRtaMg

TajpÁÜbenAkñúgb‘ULúgminRtYtsIuKñaCamYyGkS½rbs;b‘ULúg. dUcenH kMlaMgkñúgb‘ULúgEdleGayedaysmI-

kar &>!$ minRtUvKñaCamYynwglT§plBiesaFn_. edIm,ITTYl)anlT§plEdlcg;)an luHRtaEtkMlaMg Bc

rMkileTAkan;Kl;rbs; tee edaybrimaN d / 2 Edl d CaGgát;p©itb‘ULúg. dUcenHtMél b nig a RtUv)an

EkERbCa

b' = b −

d

2

nig a' = a + d 2

¬edIm,IeGayRtUvnwglT§plBiesaFn_kan;Etl¥ tMélrbs; a minRtUvFMCag 1.25b eT¦

CamYynwgkarpøas;bþÚrenHeyIgGacsresrsmIkar &>!$ Ca

⎡ δα b' ⎤

Bc = T ⎢1 + ⎥ ¬&>!%¦

⎣ (1 + δα ) a ' ⎦

eyIgGackMNt; α BIsmIkar &>!% edayeGaykMlaMgenAkñúgb‘ULúg Bc esμIeTAnwg design tensil

strength EdleyIgsMKal;Ca B . lT§plEdlTTYl)anKW

α=

[(B / T ) − 1](a' / b') ¬&>!^¦

δ { − [(B / T ) − 1](a' / b')}

1

eKGacmansßanPaBkMNt;BIr³ tensil failure rbs;b‘ULúg nig bending failure rbs; tee. eK

snμt;fa failure rbs; tee ekItmanenAeBlEdlsnøak;)aøsÞic (plastic hinges) ekItmanRtg;muxkat; a-a,

Rtg;Kl;rbs; tee, nigenARtg;muxkat; b-b. edayehtuenHvanwgbegáItCa beam mechanism. m:Um:g;énTI

taMgTaMgenHnwgesμInwg M p EdlCalT§PaBm:Um:g;)aøsÞicénRbEvgrbs;RbEvgrgsMBaFrbs;søabsMrab;b‘U

LúgmYy. RbsinebItMéldac;xatrbs; α EdlTTYl)anBIsmIkar &>!^ tUcCag 1.0 enaHm:Um:g;enARtg;

270 tMNsamBaØ

42. T.chhay

GkS½b‘ULúgtUcCagm:Um:g;enARtg;Kl; tee Edlvabgðajfa beam mechanism minRtUv)anbegáIteT ehIy

sßanPaBkMNt;RtUv)ankMNt;Ca tensile failure rbs;b‘ULúg. kMlaMgb‘ULúg Bc kñúgkrNIenH nwgesμInwg

design strength B . RbsinebItMéldac;xatrbs; α ≥ 1.0 enaH plastc hinges nwgekItmanenARtg; a-a

nig b-b ehIysßanPaBkMNt;KW flexural failure rbs;søabrbs; tee. edaysarEtm:Um:g;Rtg;kEnøgTaMg

BIrenHRtUv)ankMNt;Rtwmm:Um:g;)aøsÞic M p enaH α KYrEtUv)ankMNt;esμInwg 1.0 .

smIkarlMnwgbI &>!0-&>!@ k¾GacRtUv)anrYmbBa©ÚlKñakøayCasmIkarEtmYysMrab;kMNt;kMras;

søab t f . BIsmIkar &>!0 nig &>!! eyIgGacsresr

Tb'− M a − a = M b − b

Edl b' RtUv)anCMnYseGay b . BIsmIkar &>!#

Tb'− M a − a = δαM a − a ¬&>!&¦

eGay M a − a esμInwg design strength eKTTYl)an

pt 2 Fy

f

M a − a = φb M p = φ b

4

Edl t f CakMras;søabEdlRtUvkar. CMnYs M a − a eTAkñúgsmIkar &>!& eyIgTTYl)an

4Tb'

tf =

φb pF y (1 + δα )

Edl φb = 0.90

tf =

4.444Tb'

pF y (1 + δα )

¬&>!*¦

karKNnakartP¢ab;EdlrgnUv prying action CatMeNIrkarKNna trial-and-error. enAeBl

eRCIserIsTMhM nigcMnYnrbs;b‘ULúg eyIgRtUvEtKiteRtomTuksMrab; prying force. kareRCIserIskMras; tee

mankarLM)akCagedaysarvaTak;TgeTAnwgkareRCIserIsb‘ULúg nigTMhM tee. eKGaceRbI Preliminary

Hanger Connection Selection Table EdlmanenAkñúg Part 11 of the Manual sMrab;CYysMrYldl;

kareRCIserIsrUbragsakl,g. enAeBlEdleKeRCIserIsmuxkat;sakl,g/ dwgcMnYnb‘ULúg nigkartMerob

b‘ULúgrYcehIy eKGaceRbIsmIkar &>!% nig &>!* edIm,IepÞógpÞat;.

RbsinebIkMras;søabCak;EsþgxusBItMélEdlRtUvkar tMélCak;Esþgrbs; α nig Bc k¾GacxusBIGVI

EdleK)anKNnaknøgmkEdr. RbsinebIeKRtUvkMlaMgb‘ULúgCak;Esþg EdlrYmbBa©ÚlTaMg prying force

Q enaHeKRtUvkMNt; α eLIgvijdUcxageRkam.

271 tMNsamBaØ

43. T.chhay

M b − b = Tb'− M a − a

BIsmIkar &>!#/

M b −b

α=

δM a − a

Tb'− M a − a Tb' / M a − a − 1

= =

δM a − a δ

edayeGay M a − a esμIwTAnwg design moment eK)an

⎛ pt 2 F y ⎞

⎜ f ⎟

M a − a = φb M p = 0.90⎜ ⎟

⎜ 4 ⎟

⎝ ⎠

Tb'

−1

0.90 pt 2 Fy / 4 ⎛ ⎞

1 ⎜ 4.444Tb' ⎟

enaH α=

f

δ

= ⎜

δ ⎜ pt 2 Fy

− 1⎟ ¬&>!(¦

⎟

⎝ f ⎠

eKGacrkkMlaMgb‘ULúgsrubBIsmIkar &>!%

]TahrN_ 7>9³ WT10.5 × 66 RbEvg 8in. RtUv)anP¢ab;eTAnwg)atsøabrbs;Fñwm dUcbgðajenAkñúgrUbTI

7>30. Hanger enHrgnUvbnÞúkemKuN 90kips . kMNt;cMnYnb‘ULúg A325 Ggát;p©it 7 / 8in. EdlRtUvkar

nigepÞógpÞat;nUvPaBRKb;RKan;rbs; tee. EdkEdleRbICaRbePTEdk A36 .

272 tMNsamBaØ

44. T.chhay

dMeNaHRsay³ RkLaépÞb‘ULúgKW

π (7 / 8)2

Ab = = 0.6013in.2

4

ehIy design strength rbs;b‘ULúgmYyKW

B = φRn = φFt Ab = 0.75(90 )(0.6013) = 40.59kips

cMnYnb‘ULúgEdlRtUvkarKW 90 / 40.59 = 2.22 . cMnYnb‘ULúgGb,brmaEdlRtUvkarKW 4 edIm,IrkSaPaBsIuem-

RTI. BITMhMEdlbgðajenAkñúgrUbTI 7>30

b=

(5.5 − 0.650) = 2.425in.

2

a=

(12.44 − 5.5) = 3.470in.

2

1.25b = 1.25(2.425) = 3.031in. < 3.470in.

yk a = 3.031in.

d 7/8

b' = b − = 2.425 − = 1.988in.

2 2

d 7/8

a' = a + = 3.031 + = 3.468in.

2 2

bnÞúkxageRkAemKuNkñúgmYyb‘ULúg edayKitTaMg prying force KW T = 90 / 4 = 22.5kips .

KNna δ ³

1 7 1

d'= d + = + = 1in.

8 8 8

8

p= = 4in.

2

d' 1

δ = 1 − = 1 − = 0.75

p 4

KNna α ³

B 40.59

−1 = − 1 = 0.8040

T 22.5

a' 3.468

= = 1.744

b' 1.988

BIsmIkar &>!^/

α=

[(B / T ) − 1](a' / b') = 0.8040(1.744) = −4.65

δ { − [(B / T ) − 1](a' / b')} 0.75[1 − 0.8040(1.744)]

1

edaysar α > 1.0 / yk α = 1.0 . BIsmIkar &>!*

273 tMNsamBaØ

45. T.chhay

4.444Tb' 4.444(22.5)(1.988)

tf = =

pF y (1 + δα ) 4(36)(1 + 0.75)

= 0.888in. < 1.035in. (OK)

TaMgcMnYnb‘ULúgEdleRCIserIs nwgkMras;søabKWRKb;RKan; ehIyminRtUvkarkarKNnateTAmuxeToteT.

b:uEnþ edIm,IbgðajBIviFIsaRsþKNna eyIgKNna prying force edayeRbIsmIkar &>!( nig &>!%. BI

smIkar &>!(/

⎛ ⎞

1 ⎜ 4.444Tb' ⎟ 1 ⎡ 4.444(22.5)(1.988) ⎤

α= ⎜ − 1⎟ = ⎢ − 1⎥ = 0.3848

δ ⎜ pt 2 Fy ⎟ 0.75 ⎢ 4(1.035)2 (36 )

⎣ ⎥

⎦

⎝ f ⎠

BIsmIkar &>!%/ kMlaMgb‘ULúgsrub edayKitTaMg prying force KW

⎡ δα b' ⎤

Bc = T ⎢1 + ⎥

⎣ (1 + δα ) a ' ⎦

⎡ 0.75(0.3848) ⎛ 1.988 ⎞⎤

= 22.5⎢1 + ⎜ ⎟⎥ = 25.39kips

⎣ 1 + 0.75(0.3848) ⎝ 3.468 ⎠⎦

Prying force KW

Q = Bc − T = 25.39 − 22.5 = 2.89kips

cMeLIy³ WT10.5 × 66 RKb;RKan;. eRbIb‘ULúg A325 Ggát;p©it 7 / 8in.

RbsinebIkMras;søabminRKb;RKan; eKGacsakl,g tee shape EdlmanTMhMFMCag b¤k¾eRbIcMnYn

b‘ULúgbEnßmedIm,Ikat;bnßy T EdlCakMlaMgxageRkAkñúgmYyb‘ULúg. Prying force enAkñúg]TahrN_

7>9 bEnßmRbEhl 13% eTAelIkMlaMgxageRkA. karecalnUvkMlaMgTajbEnßmenHnwgpþl;nUvplvi)ak

y:agF¶n;F¶r.

7>9> kMlaMgpÁÜbrvagkMlaMgTaj nigkMlaMgTajenAkñúgb‘ULúg Combined Shear

and Tension in Fasteners

enAkñúgsßanPaBCaeRcInkartP¢ab;EtgRbQmnwgkMlaMgkat; nigkMlaMgTaj. tMNEdlTTYlbnÞúk

cMNakp©itRtUv)anerobrab;enAkñúgCMBUkTI 8. b:uEnþ sMrab;tMNsamBaØxøH eRKOgP¢ab;sßitkñúgsßanPaBkMlaMg

pÁÜb. rUbTI 7>31 bgðajBIkMNat; structural tee EdlP¢ab;eTAnwgsøabrbs;ssrkñúgeKalbMNgedIm,I

P¢ab;Ggát;BRgwg (bracing member). Ggát;BRgwgenHRtg;)andak;tMrg;y:agNaedIm,IeGayExSskmμrbs;

kMlaMgkat;tamTIRbCMuTMgn;rbs;kartP¢ab;. bgÁúMkMlaMgbBaÄrnwgeFVIeGayeRKOgP¢ab;rgkugRtaMgkat; ehIy

274 tMNsamBaØ

46. T.chhay

bgÁúMkMlaMgedknwgbegáItkMlaMgTaj ¬EdlGacmankarpSMCamYynwg prying force¦. edaysarExSskmμ

rbs;kMlaMgeFVIGMeBIkat;tamTIRbCMuTMgn;rbs;tMN eRKOgP¢ab;nImYy²RtUv)ansnμt;faTTYlkugRtaMgedaycM

ENkesμI²Kña.

kñúgkrNIbgÁúMkMlaMgepSgeTot eKGaceRbIviFIrUbmnþGnþrkmμ (interaction formula approach) .

ersIusþg;kMlaMgkat; nigersIusþg;kMlaMgTajsMrab;b‘ULúgRbePT bearing KWQrelIlT§plénkarBiesaFn_

nwgRtUv)anykBI elliptical interaction curve EdlbgðajenAkñúgrUbTI 7>32. smIkarrbs;ExSenHKW

2 2

⎡ Pu ⎤ ⎡ Vu ⎤

⎢ ⎥ +⎢ ⎥ = 1.0

⎣ (φRn )t ⎥

⎢ ⎦ ⎢ (φRn )v ⎥

⎣ ⎦

Edl Pu = kMlaMgTajemKuNenAelIb‘ULúg

(φRn )t = design strength rbs;b‘ULúgrgkarTaj

Vu = kMlaMgkat;TTwgemKuNenAelIb‘ULúg

(φRn )v = design strength rbs;b‘ULúgrgkarkat;

bnSMkMlaMgkat; nigkMlaMgTajEdlGacTTYlyk)anKWvaCYbKñaRtg;kEnøgEdlsßitenABIeRkamExS

ekag. enHCatMrUvkarrbs; RCSC Specification Edl

2 2

⎡ Pu ⎤ ⎡ Vu ⎤

⎢ ⎥ +⎢ ⎥ ≤ 1 .0 (RCSC Equation LRFD 4.2)

⎢ (φRn )t ⎥

⎣ ⎦ ⎢ (φRn )v ⎥

⎣ ⎦

275 tMNsamBaØ

47. T.chhay

sMrab; slip-critical connection Edlb‘ULúgrgnUvkMlaMgkat; nigkMlaMgTaj T§iBlrbs;kMlaMg

TajKWbn§Úrbnßy clamping force EdleFVIeGaymankarkat;bnßykMlaMgkkit. AISC Specification

kat;bnßy slip-critical shear strength sMrab;krNIenH. BI AISC Appendix J, slip-critical shear

strength RtUv)anKuNedayemKuN

⎡ Tu ⎤

⎢1 − ⎥ (AISC Equation A-J3-2)

⎣ 1.13Tm N b ⎦

Edl kMlaMgTajemKuNenAelItMN

Tu =

Tm = kMlaMgTajb‘ULúgedImEdl)anBI AISC Table J3.1

N b = cMnYnb‘ULúgenAkñúgtMN

cMNaMfa RCSC Equation LRFD 4.2 Edl)anbgðajenATIenHRtUv)anGnuvtþeTAelIb‘ULúgeTal Et

AISC Equation A-J3-2 Edl)anbgðajenATIenHGnuvtþeTAelItMNTaMgmUl. smIkarnImYy²Gac

RtUv)anEkERbedIm,IGnuvtþsMrab;viFIepSgeTot.

]TahrN_ 7>10³ eKeRbI WT10.5 × 31 Ca bracket edIm,IbBa¢Ún service load 60kips eTAssr

W 14 × 90 dUcEdl)anbgðajenAkñúgrUUbTI 7>31. bnÞúkpSMeLIgedaybnÞúkefr 15kips nigbnÞúkGefr

45kips . eKeRbIb‘ULúg A325 Ggát;p©it 7 / 8in. cMnYn 4 RKab;. TaMgssr nig bracket eFVIBIEdk A36 .

snμt;fatMrUvkarKMlat nigcMgayeTARCugEKmTaMgGs;KWRKb;RKan; edayrYmbBa©ÚlTaMgPaBcaM)ac;sMrab;kar

eRbIR)as; design strengn GtibrmasMrab; bearing ¬dUcCa φ [2.4dtFu ] ¦ nigkMNt;nUvPaBRKb;RKan;rbs;

b‘ULúgsMrab;kartP¢ab;xageRkam³

¬!¦ bearing –types connection EdlmaneFμjsßitenAkñúgbøg;kat;. ¬@¦ slip-critical connection

EdlmaneFμjsßitenAkñúgbøg;kat;.

dMeNaHRsay³ bnÞúkemKuNKW

1.2 D + 1.6 L = 1.2(15) + 1.6(45) = 90kips

¬!¦ sMrab; bearing-type connection EdlmaneFμjsßitenAkñúgbøg;kat; kMlaMgkat;TTwgsrubKW

3

(90) = 54kips

5

kMlaMgkat;TTwgsMrab;b‘ULúgmYyKW

54

Vu = = 13.5kips

4

276 tMNsamBaØ

48. T.chhay

π (7 / 8) 2

nig Ab =

4

= 0.6013in. 2

(φRn )v = φFv Ab = 0.75(48)(0.6013)

= 21.65kips > 13.5kips

Bearing strength ¬søabrbs; tee lub¦ KW

⎛7⎞

φRn = φ (2.4dtFu ) = 0.75(2.4)⎜ ⎟(0.615)(58)

⎝8⎠

= 56.18kips > 13.5kips (OK)

kMlaMgTajsrubKW

4

(90) = 75kips

5

kMlaMgTajsMrab;b‘ULúgmYyKW

72

Pu = = 18kips

4

BI AISC Table J3.2,

(φRn )t = φFt Ab = 0.75(90)(0.6013) = 40.59kips > 18kips (OK)

BI RCSC Equation LRFD 4.2,

2 2

⎡ Pu ⎤ ⎡ Vu ⎤ ⎛ 18 ⎞

2

⎛ 13.5 ⎞

2

⎢ ⎥ +⎢ ⎥ =⎜ ⎟ +⎜ ⎟ = 0.585 < 1.0 (OK)

⎣ (φRn )t ⎥

⎢ ⎦ ⎣ (φRn )v ⎥

⎢ ⎦ ⎝ 40.59 ⎠ ⎝ 21.65 ⎠

cMeLIy³ kartP¢ab;manlkçN³RKb;RKan;Ca bearing-type connection. ¬edIm,IkMueGayBi)akyl;kñúgkar

bnSMbnÞúkrbs;]TahrN_enH prying action minRtUv)anrYmbBa©ÚleTAkñúgkarviPaKeT¦.

¬@¦ sMrab; slip-critical connection, EdlmaneFμjsßitenAkñúgbøg;kat; BIEpñk ¬!¦ shear, bearing/

and tension strength KWmanlkçN³RKb;RKan;. BI RCSC Equation LRFD 5.3, slip-critical strenght

KW

φRstr = φ (1.13μTm N b N s )

BI AISC Table J3.1, kMlaMgTajsMrab;b‘ULúg A325 Ggát;p©it 7 / 8in. KW

Tm = 39kips

RbsinebIeyIgsnμt;épÞb:HCa Class A, slip coefficent KW μ = 0.33 nigsMrab;b‘ULúgbYnRKab;

φRstr = φ (1.13μTm N b N s ) = 1.0(1.13)(0.33)(39)(4 )(1) = 58.17kips

edaysarvamankMlaMgTajenAelIb‘ULúg/ slip-critcal strength RtUv)ankat;bnßyedayemKuN

277 tMNsamBaØ

49. T.chhay

⎛ Tu ⎞ ⎡ 72 ⎤

⎜1 −

⎜ 1.13T N ⎟ = ⎢1 −

⎟ ⎥ = 0.5916

⎝ m b ⎠ ⎣ 1.13(39 )(4 ) ⎦

dUcenHresIusþg;Edl)ankat;bnßyehIyKW

φRstr = 0.5916(58.17 ) = 34.4kips < 54kips (N.G.)

cMeLIy³ kartP¢ab;minmanlkçN³RKb;RKan;Ca slip-critical connection eT.

kartP¢ab;edayb‘ULúgEdlrgnUvkMlaMgkat;TTwg nigkMlaMgTajGacRtUv)anKNnaedaypÞal;.

eKGaceRbI RCSC Equation 4.2 edIm,IedaHRsayTMhMb‘ULúgdUcxageRkam³

2 2 2 2

⎡ Pu ⎤ ⎡ Vu ⎤ ⎛ Pu ⎞ ⎛ Vu ⎞

⎢ ⎥ +⎢ ⎥ =⎜

⎜ φF ∑ A ⎟ +⎜

⎟ ⎜ φF ∑ A ⎟

⎟

⎣ (φRn )t ⎥

⎢ ⎦ ⎢ (φRn )v ⎥

⎣ ⎦ ⎝ t b ⎠ ⎝ v b ⎠

2 2

⎛P ⎞ 1 ⎛V ⎞ 1

=⎜ u

⎜ ⎟

⎟ +⎜ u ⎟

2 ⎜ φF ⎟

⎝ φFt ⎠ (∑ Ab ) ⎝ v ⎠ (∑ Ab )2

Edl Pu =kMlaMgTajsrubenAelItMN

Ft = ultimate tensile stress rbs;b‘ULúg

Vu = kMlaMgkat;TTwgsrubenAelItMN

Fv = ultimate shear stress rbs;b‘ULúg

∑ Ab = RkLaépÞmuxkat;b‘ULúgsrub

CMnYseTAkñúg RCSC Equation LRFD 4.2, eyIg)an

2 2

⎛ Pu ⎞ 1 ⎛V ⎞ 1

⎜

⎜ φF ⎟

⎟ +⎜ u ⎟ ≤ 1 .0

⎝ t ⎠ (∑ Ab )2 ⎜ φFv

⎝

⎟

⎠ (∑ Ab )2

2 2

⎛P ⎞ ⎛V ⎞

b¤ ∑ Ab ≥ ⎜ u

⎜ φF ⎟ +⎜ u

⎟ ⎜ φF ⎟

⎟ ¬&>@0¦

⎝ t ⎠ ⎝ v ⎠

Edl ∑ Ab CaRkLaépÞmuxkat;b‘ULúgsrub

]TahrN_ 7>11³ tMNEdlrgbnÞúkcMp©itrgnUv service load shear force 50kips nig service tensile

force 100kips . bnÞúk CabnÞúkefr nig 75% CabnÞúkGefr. eRKOgP¢ab;rgnUv single shear

25%

ehIy baring strength nwgRtUv)anKNnaCamYynwgEpñkEdlRtUvP¢ab;EdlmankMras; 5 / 16in. . snμt;fa

KMlat nigcMgayeTARCugEKmTaMgGs;manlkçN³RKb;RKan; nigsnμt;faeKGnuBaØateGayeRbI bearing

278 tMNsamBaØ

50. T.chhay

strength Gtibrma φ (2.4dtFu ) . kMNt;cMnYnb‘ULúg A325 Ggát;p©it 3 / 4in. EdlcaM)ac;sMrab;krNIxag

eRkam³

¬!¦ bearing-type connection CamYynwgeFμjsßitenAkñúgbøg;kat;

¬@¦ slip-critical connection CamYynwgeFμjsßitenAkñúgbøg;kat;

épÞb:HTaMgGs;man clean mill scale.

karKNnaenHmin)anBicarNa prying action sMxan;eT.

dMeNaHRsay³ kMlaMgkat;TTwgemKuN = 1.2[0.25(50)] + 1.6[0.75(50)] = 75kips

kMlaMgTajemKuN = 1.2[0.25(100)] + 1.6[0.75(100)] = 150kips

¬!¦ sMrab; bearing-type connection CamYynwgeFμjsßitenAkñúgbøg;kat; smIkar &>@0 eGay

2 2 2

⎛P ⎞ ⎛V ⎞ ⎡ 150 ⎤ ⎡ 75 ⎤

∑ Ab ≥ ⎜ u

⎜ φF ⎟ +⎜ u

⎟ ⎜ φF ⎟

⎟ = ⎢ 0.75(90) ⎥ + ⎢ 0.75(48) ⎥ = 3.046in.

2

⎝ t ⎠ ⎝ v ⎠ ⎣ ⎦ ⎣ ⎦

RkLaépÞrbs;muxkat;eTalKW

π (3 / 4 )2

Ab = = 0.4418in.2

4

dUcenHcMnYnb‘ULúgEdlRtUvkarKW

∑ Ab 3.046

= = 6.89

Ab 0.4418

sakl,gb‘ULúg 7 RKab; ehIyRtYtBinitü bearing:

φRn = φ (2.4dtFu ) × 7

⎛ 7 ⎞⎛ 5 ⎞

= 0.75(2.4)⎜ ⎟⎜ ⎟(58)(7 ) = 171kips > 75kips

⎝ 8 ⎠⎝ 16 ⎠

¬eKminRtUvkarRtYtBinitüKMlat nigcMgayeTARCugEKmsMrab;karKNnacugeRkayeT¦

cMeLIy³ eRbIb‘ULúg 7 RKab;. ¬RbsinebIeKerobb‘ULúgCaBIrCYr enaHeRbIb‘ULúg 8 RKab;edIm,IPaBsIuemRTI¦

¬@¦ sMrab; slip-critical connection, slip-critical strength EdleGayeday RCSC Equation

LRFD RtUv)anKuNedayemKuNkat;bnßyrbs; AISC Equation A-J3-2:

⎛ ⎞

φRstr = φ (1.13μTm N b N s )⎜1 −

Tu

⎜ 1.13T N ⎟ ⎟ ¬&>@!¦

⎝ m b ⎠

BI AISC Table J3.1, sMrab;b‘ULúg A325 Ggát;p©it 3 / 4in. / Tm = 28kips . CMnYs Tm eTAkñúgsmIkar

&>@!/ eyIg)an

279 tMNsamBaØ

51. T.chhay

⎛ Tu ⎞

φRstr = φ (1.13μTm N b N s )⎜1 −

⎜ ⎟

⎟

⎝ ⎠

1.13Tm N b

⎡ ⎤

= 1.0(1.13)(0.33)(28)( N b )(1)⎢1 −

150

⎥

⎣ 1.13(28)N b ⎦

⎛ 4.741 ⎞

= 10.44⎜1 −

⎜ ⎟ = 10.44(N b − 4.741)

⎝ Nb ⎟

⎠

dak;lT§plEdlTTYl)anenH nigkMlaMgkat;TTwgEdlGnuvtþeGayesμIKña enaHeyIgGacrkcMnYnb‘ULúgEdl

RtUvkaredIm,IkarBar slip³

10.44( N b − 4.741) = 75kips

N b = 11.9

edaysarb‘ULúg 7 RKab;RKb;RKan;sMrab; shear, bearing nig tension dUcenHeKminRtUvkarRtYt

BinitüsßanPaBkMNt;TaMgenHeT.

cMelIy³ eRbIb‘ULúg A325 Ggát;p©it 3 / 4in.

7>10> tMNpSar Welded connections

karpSarCadMeNIrkareFVIeGayEpñkEdlRtUvP¢ab;Cab;Kña. ]TahrN_ Ggát;rgkarTajEdlman lap

joint dUcbgðajenAkñúgrUbTI 7>33 a GacRtUv)aneFVIeLIgedaykarpSartamcugTaMgsgçagrbs;EpñkEdl

RtUvP¢ab;. kMBs;d¾tUcbMputrbs;sMPar³RtUv)anrlay eRkayBITukeGayRtCak; eRKOgbgÁúMEdk nig weld

metal eFVIkardUcEpñkEdlCab;KñaenAkEnøgtMN. EdkbEnßmRtUv)andak;BI special electrode EdlCaEpñk

rbs;crnþGKÁisnIeTAelIEpñkEdlRtUvP¢ab; b¤ base metal.

enAkñúgdMeNIrkar shielded metal arc welding (SMAW) EdlbgðajenAkñúgrUbTI 7>34 FñÚ

GKÁisnI (current arc) kat;tamcenøaHrvag electrode nig base metal edayrMlayEpñkEdlRtUvP¢ab;

nigdak;Epñkrbs;eGLicRtUteTAkñúg base metal Edlrlay. Specail coating enAelI electrode begáIt

protective gaseous shield edaykarBar molten weld metal BIGuksIutkmμmunnwgvarwg. eKrMkil

280 tMNsamBaØ

52. T.chhay

electrode kat;tamtMN ehIy weld bead RtUv)andak; TMhMrbs;vaGaRsy½nwgGRtaéndMeNIrrbs;

electrode. enAeBlEdlTwkbnSaRtCak; impuriries elceLIgenAelIépÞ EdlbegáItCa coating EdleK

ehAfa slag ehIy slag enHRtUv)anykecjmunnwglabfñaMelIGgát; b¤EpñkepSg²EdlRtUv)anbegáIteLIg

eday electrode.

CaTUeTA Shielded metal arc welding EdlRtUv)aneFIVeLIgedayéd ehIyCadMeNIrkareKeRbICa

sklenAelIkardæan. sMrab;karpSarenAeragCag eKniymeRbIdMeNIrkarsV½yRbvtþ b¤Bak;kNþalsV½y

Rbvtþ. karRtYtBinitüKuNPaBsMrab;kartP¢ab;edaykarpSarKWmanlkçN³Bi)ak edaykarTwkbnSarEdl

minl¥sßitenABIeRkamépÞ b¤k¾PaBminl¥d¾tictYcEdlmanenAépÞbnSar GaceKcputBIExSEPñkrbs;eyIg)an.

sMrab;karpSarenARtg;kEnøgEdleRKaHfñak;eKRtUvkarCagpSarEdlmanCMnajRtwmRtUv ehIyeKRtUveRbI

bec©keTsBiessdUcCa radiography b¤ ultresonic testion.

281 tMNsamBaØ

53. T.chhay

eKniymeRbIkarpSarBIrRbePTKW fillet weld nig groove weld. Lap joint EdlbgðajenAkñúgrUb

TI 7>33 a nig b RtUv)anbegáIteLIgeday fillet weld . Groove weld RtUv)aneRbIsMrab; butt, tee nig

corner dUcbgðajenAkñúgrUbTI 7>35 a nig b. rUbTI 7>36 bgðajBI plug and slot wled EdleBlxøHva

RtUvkaredIm,IbEnßmBIelIkarpSartam RCug. rn§ragmUl b¤RTEvgRtUv)ankat;ecjBIEpñkmYyedIm,IGacbMeBj

TwkbnSar)an.

kñúgcMeNamkarpSarTaMgBIrRbePTenH eyIgnwgelIkykkar pSar fillet weld mkbkRsaylMGit

enATIenH. karKNnasMrab; complete penetration groove weld minmanlkçN³minsMxan;EdlkarpSar

manersIusþg;dUcKñanwg base metal nigEpñkEdlRtUvP¢ab;. ersIusþg;rbs; partial penetration groove

weld GaRs½yeTAnwgbrimaNén penetration. dMeNIrkarénkarKNna groove weld RsedogKñanwgkar

KNna fillet weld.

7>11> Fillet Welds

karKNna nigkarviPaKsMrab; fillet weld KWQrelIkarsnμt;famuxkat;rbs;TwkbnSarCaRtIekaN

EkgEdlmanmMu 45o dUcbgðajkñúgrUbTI 7>37. TTwgrbs; fillet weld RtUv)ansMKal;eday w . TMhMTWk

nSarbTdæanKWekIneLIgmþg 1 / 16in. = 2mm . eTaHbICaRbEvgrbs;karpSarGacrgnUvbnÞúk tamTiskMlaMg

kat;/ kMlaMgsgát; nigkMlaMgTajk¾eday k¾fillet weld manersIusþg;exSaysMrab;kMlaMgkat; ehIyvaEtg

EtRtUv)aneKsnμt;fadac;edaysarkMlaMgenH. kardac;RtUv)ansnμt;ekItmantambøg;Edlkat;tam throat

rbs;TwkbnSar. sMrab; fillet weld EdlbegáIteLIgCamYy shielded metal arc process, throat CaRb

EvgEkgBIRCugEKm b¤ root rbs;TwkbnSareTAGIub:Uetnus nigmantMélesμI 0.707 dgénTMhMTwkbnSar.

¬Effective throad thickness sMrab;TwkbnSarEdl)anBI arc welding process manTMhMFMCag. dUcenH

kñúgesovePAenH eyIgsnμt;eRbI shielded metal arc welding process¦. dUcenHsMrab;RbEvg L Edlrg

bnÞúk P / kugRtaMgkMlaMgkat;eRKaHfñak;KW

282 tMNsamBaØ

54. T.chhay

P

fv =

0.707 × w × L

Edl w CaTTwgTwkbnSar

RbsinebIeKeRbI weld ultimate shearing stress/ FW enAkñúgsmIkarenH eKGacsresr

nominal load capacity rbs;TwkbnSardUcxageRkam³

Rn = 0.707 × w × L × FW

ehIy nominal design strength KW

φRn = 0.707 × w × L × φFW ¬&>@@¦

ersIusþg;rbs; fillet weld GaRs½yeTAnwgkareRbIR)as; weld metal EdlCaGnuKmn_eTAnwg

RbePT electrode. ersIusþg;rbs; electrode RtUv)ankMNt;Ca ultimate tensile strength rbs;vaCamYy

nwgersIusþg; 60, 70, 80, 90, 100, nig 120ksi b¤ 415, 480, 550, 620, 690, nig 830MPa sMrab;

shielded metal arc welding process. nimitþsBaØasMrab;kMNt; electrod KWGkSr E Edlbnþedayelx

BIr b¤bIxÞg;EdlbgðajBIersIusþg;rbs;vaCa ksi . edaysarEtersIusþg;CalkçN³dMbUgEdl design

engineer ykcitþTukdak; CaTUeTAGkSrBIrxÞg;cugeRkayRtUv)anbgðajeday XX ehIykMNt;sMKal;

køayCa E 70 XX b¤ E 70 EdlbgðajBI electrode CamYy ultimate tensile strength 70ksi . eKKYr

eRCIserIs electrode eGayRtUvKñaCamYynwg base metal. sMrab; grade rbs;EdkEdleRbIR)as;TUeTA

eKBicarNaEt electrode BIrRbePTb:ueNÑaHKW³

eRbI electrode E 70 XX CamYynwgEdkEdlman yield strength tUcCag 60ksi

283 tMNsamBaØ

55. T.chhay

eRbI electrode E80 XX CamYynwgEdkEdlman yied strength 60ksi b¤ 65ksi

nimitþsBaØasMrab; electrode nigkarpþl;eGayrbs; AISC Specification EdledaHRsayCamYy

nwgTwkbnSarRtUv)andkRsg;ecjBI Structural Welding Code rbs; American Welding Society

(AWS, 1996). eKGacrk)annUvlkçxNÐEdlminmanEcgenAkñúg AISC Specification enAkñúg AWS

Code.

Design strength rbs;TwkbnSarRtUv)anbgðajenAkñúg AISC Table J2.5. Ultimate shearing

stress FW enAkñúg fillet weld esμInwg 0.6 dgén tensile strength rbs; weld metal EdlRtUv)ansM

Kal;eday FEXX . dUcenH design stress KW φFW Edl φ = 0.75 nig FW = 0.60FEXX . sMrab;

electrode FmμtaTaMgBIr design strengths (stresses) RtUv)anbgðajdUcxageRkam³

E 70 XX : φFW = 0.75[0.60(70)] = 31.5ksi

E 80 XX : φFW = 0.75[0.6(80 )] = 36ksi

tMrUvkarbEnßmKWfakMlaMgkat;TTwgemKuNenAelI base metal minKYrbegáIt stress FMCag φFBM Edl

φFBM Ca nominal shear strength rbs;sMPar³EdlRtUvP¢ab;. dUcenHbnÞúkemKuNsMrab;tMNRtUv)an

kMNt;Rtwm

φRn = φFBM × area of base metal subject to shear

AISC J5, “Connecting elements” eGay shear yielding strength Ca φRn Edl

φ = 0.90

Rn = 0.6 Ag F y (AISC Equation J5-3)

nig Ag CaRkLaépÞEdlrgkMlaMgkat;TTwg. dUcenH shear strength rbs; base metal CasresrCa

φFBM = 0.90(0.6) F y = 0.54 F y

dUcenH enAeBlEdlbnÞúksßitenAkñúgTisdUcGkS½rbs;TwkbnSar eKRtUveFVIkarGegát base metal edayeRbI

TMnak;TMngénsmIkar &>@#. eKGacBnül;BItMrUvkarenHedayRtYtBinitükartP¢ab; bracket edaykarpSar

EdlbgðajenAkñúgrUbTI 7>38. edaysnμt;fa bnÞúksßitenAEk,rcugEdlpSaredayeyIgGacecalcMNak

p©it. RbsinebITWkbnSarTaMgBIrmanTMhMdUcKña design strength rbs;TwkbnSarmçag²kñúgRbEvgÉktþaGac

RtUv)anrkBIsmIkar &>@@ Ca

0.707 × w × φFW

b:uEnþBIsmIkar &>@#/ ersIusþg;rbs; bracket plate Tb;nwgkMlaMgkat;kñúgmYyÉktþaRbEvgKW

284 tMNsamBaØ