Requirements of ohsas 18001

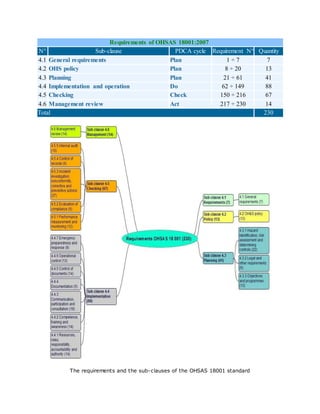

- 1. Requirements of OHSAS 18001:2007 N° Sub-clause PDCA cycle Requirement N° Quantity 4.1 General requirements Plan 1 ÷ 7 7 4.2 OHS policy Plan 8 ÷ 20 13 4.3 Planning Plan 21 ÷ 61 41 4.4 Implementation and operation Do 62 ÷ 149 88 4.5 Checking Check 150 ÷ 216 67 4.6 Management review Act 217 ÷ 230 14 Total 230 The requirements and the sub-clauses of the OHSAS 18001 standard

- 2. The PDCA cycle of Deming

- 3. OHSAS 18001 - Requirements and comments N° Sub- clause Requirement PDCA cycle, links, comments 4 OH&S management system requirements 4.1 General requirements Plan 1 4.1 Establish the occupational health and safety management system (OHSMS) Start with an overview of the current situation; ongoing commitment of management to its highest level; benefits and challenges explained to staff 2 4.1 Document the OHSMS Cf. sub-clause 4.4.4 3 4.1 Implement the OHSMS Cf. sub-clause 4.4 4 4.1 Maintain the OHSMS When changes in processes, products, requirements, infrastructure 5 4.1 Continually improve the OHSMS Cf. sub-clause 4.6 6 4.1 Determine how the OHSMS will fulfill these requirements Consider factors, conditions and constraints that impact on health and safety of personnel 7 4.1 Define and document the scope of the OHSMS Cf. sub-clause 4.5.4 4.2 OH&S policy Plan 8 4.2 Define the OH&S policy Cf. sub-clause 4.5.4; define OH&S policy which is an inescapable implication, direct and documented by top management to establish its principles of action 9 4.2 Authorise the OH&S policy By top management to its highest level 10 4.2 a The OH&S policy is appropriate Is adapted to the activities, work environment; is realistic but takes into account the company's vision 11 4.2 b The OH&S policy includes a commitment to prevention By top management to its highest level 12 4.2 b The OH&S policy includes a commitment to continual improvement By top management to its highest level 13 4.2 c The OH&S policy includes a commitment to comply with legal and other requirements Cf. sub-clause 4.3.2 14 4.2 d The OH&S policy provides a framework for the OH&S objectives Cf. sub-clause 4.3.3 15 4.2 e The OH&S policy is documented Cf. sub-clause 4.5.4; the OH&S policy and

- 4. objectives are formalized in a relevant and simple document 16 4.2 e The OH&S policy is implemented 17 4.2 e The OH&S policy is maintained When changes in processes, products, requirements, infrastructure 18 4.2 f The OH&S policy is communicated Declaration, posters, booklets 19 4.2 g The OH&S policy is freely available To interested public 20 4.2 h The OH&S policy is reviewed Cf. sub-clause 4.6 4.3 Planning Plan 4.3.1 Hazard identification, risk assessment and determining controls Top of the page 21 4.3.1 Establish the procedure hazard identification Cf. sub-clause 4.4.5; list of hazards; the procedure required for the hazard identification answers the questions who, when, how, under what conditions identify, plan, implement and maintain control of OH&S activities of the OH&SMS 22 4.3.1 Implement the procedure hazard identification "Identify the hazards is decrease the risks" 23 4.3.1 Maintain the procedure hazard identification When changes in processes, products, requirements, infrastructure 24 4.3.1 a Take into account routine and non- routine activities "No-risk situations do not exist" 25 4.3.1 b Take into account activities of all persons on the workplace 26 4.3.1 c Take into account human factors Behavior, habits, traditions 27 4.3.1 d Take into account the identified hazards of outside origin Halted general services (water, electricity, gas) 28 4.3.1 e Take into account hazards in the vicinity of the workplace This can be an environmental aspect (air emissions, water discharges, noise and other) 28 4.3.1 f Take into account infrastructure, equipment and materials Including those related with customer, contractor 30 4.3.1 g Take into account changes in the organization, activities or materials 31 4.3.1 h Take into account changes of the OHSMS 32 4.3.1 i Take into account legal obligations relating to risk assessment and implementation of controls Cf. sub-clause 4.3.2 33 4.3.1 j Take into account work environment Ergonomy of workstations 34 4.3.1 a Define the methodology for hazard Consider the scope and nature for a

- 5. ' identification proactive operation 35 4.3.1 b ' Provide the rating of risks List of risks associated with identified hazards 36 4.3.1 b ' Apply controls Cf. sub-clause 4.4.6 37 4.3.1 Analyse changes prior to implementation Identify hazards and assess risks of changes 38 4.3.1 Determine controls taking into account risk assessment 39 4.3.1 Reduce risk giving consideration to hierarchy of controls First eliminate then substitute, replace, integrate safety, report, warn, use of PPE (personal protective equipment) 40 4.3.1 Document results of hazard identification, risk assessment and determined controls Cf. sub-clause 4.5.4 41 4.3.1 Keep up-to-date results of hazard identification When changes in processes, products, requirements, infrastructure 42 4.3.1 Take into account risks in the OHSMS 4.3.2 Legal and other requirements Top of the page 43 4.3.2 Establish the procedure legal requirements Cf. sub-clause 4.4.5; the required procedure for review of legislation answers the questions who, when, how, under what conditions identify, access, plan, implement and maintain the legal watch of requirements related to OH&S aspects; use several sources 44 4.3.2 Implement the procedure legal requirements Communicate the information - cf. sub- clause 4.4.3 45 4.3.2 Maintain the procedure legal requirements "Ignorance of the law excuses no one. Latin proverb" 46 4.3.2 Take into account legal requirement in the OHSMS Cf. sub-clause 4.5.2 47 4.3.2 Keep up-to-date legal requirements Communicate these requirements to staff, suppliers and contractors; list of requirements 48 4.3.2 Share information on legal requirements With suppliers and other interested parties 4.3.3 Objectives and programme(s) Top of the page 49 4.3.3 Establish OH&S objectives Opportunity to improve its public image 50 4.3.3 Implement OH&S objectives Commitment to preventions 51 4.3.3 Maintain OH&S objectives When changes in processes, products,

- 6. requirements, infrastructure 52 4.3.3 The objectives are measurable and consistent with the OH&S policy Cf. sub-clause 4.2 53 4.3.3 When determining OH&S objectives take into account applicable legal requirements and OH&S risks Cf. sub-clauses 4.3.2 et 4.3.1 54 4.3.3 Take into account internal and external constraints Define performance indicators; consider technology used, views of interested parties 55 4.3.3 Establish programmes So to be able to achieve objectives; resources, tasks, time-frame 56 4.3.3 Implement programmes Communicate internally their progress 57 4.3.3 Maintain programmes When changes in processes, products, requirements, infrastructure 58 4.3.3 a Attribute roles and responsibilies 59 4.3.3 b Include resources Considerations and financial constraints 60 4.3.3 b Include time-frame Time to hold 61 4.3.3 Review programmes Changes if necessary; Cf. sub-clause 4.6 4.4 Implementation and operation Do 4.4.1 Resources, roles, responsibility, accountability and authority Top of the page 62 4.4.1 The ultimate responsibility of the OHSMS rests with top management "Responsibility cannot be shared. Robert Heilein" 63 4.4.1 Ensure resources to establish, implement, maintain and improve the OHSMS Cf. sub-clause 4.6 ; "Health is priceless, but has a cost" 64 4.4.1 Attribute roles, responsibility, accountabilities and authorities Clear and available internally job descriptions, organization chart 65 4.4.1 Document roles, responsibility, accountabilities and authorities Cf. sub-clause 4.5.4 66 4.4.1 Communicate roles, responsibility, accountabilities and authorities cf. sub-clause 4.4.3 67 4.4.1 Appoint a management representative Cf. sub-clause 4.5.4 68 4.4.1 Attribute roles, responsibilities and authorities to the management representative Cf. sub-clause 4.5.4 69 4.4.1 a Establish the OHSMS Cf. sub-clause 4.1 70 4.4.1 a Implement the OHSMS Cf. sub-clause 4.1 71 4.4.1 a Maintain the OHSMS When changes in processes, products, requirements, infrastructure 72 4.4.1 b Reports to top management on the performance of the OHSMS and On a regular basis

- 7. improvement opportunities 73 4.4.1 Communicate the identity of top management appointee cf. sub-clause 4.4.3 74 4.4.1 Demonstrate commitment to the continual improvement of the OHSMS This applies to all executives 75 4.4.1 Empower staff on OH&S aspects over which they have control Pay attention to his own safety but also to other 4.4.2 Competence, training and awareness Top of the page 76 4.4.2 Train staff working on activities that may impact on OH&S Being competent is to apply knowledge and skills 77 4.4.2 Retain records of staff competence Cf. sub-clause 4.5.4 78 4.4.2 Identify training needs Including as internal auditors - cf. sub- clause 4.5.5 79 4.4.2 Provide training Identify and fulfil competence improvement needs (training programme) 80 4.4.2 Evaluate the effectiveness of the training Demonstrated competence, enhanced awareness 81 4.4.2 Retain records Cf. sub-clause 4.5.4 82 4.4.2 Establish the training procedure Cf. sub-clause 4.4.5; the required procedure for training answers the questions who, when, how, under what conditions identify needs, raise employee awareness, achieve competence 83 4.4.2 Implement the training procedure Cf. sub-clause 4.3.2 84 4.4.2 Maintain the training procedure When changes in processes, requirements 85 4.4.2 a Make persons aware of the OH&S consequences of their activity and behaviour Commitment of top management to his highest level 86 4.4.2 b Make persons aware of the importance in achieving conformity to the OH&S requirements Cf. sub-clause 4.4.7; response to emergencies 87 4.4.2 c Make persons aware of the potential consequences of departure from specified procedures Show the link between individual responsibility and health and safety impacts 88 4.4.2 a ' For the trainings take into account differing levels of responsibility, ability, languages Promote images 89 4.4.2 b ' For the trainingd take into account differing levels of risk 4.4.3 Communication, participation and consultation Top of the page

- 8. 4.4.3.1 Communication 90 4.4.3.1 Establish the communication procedure Cf. sub-clause 4.4.5; the procedure required for communication answers the questions who, when, how, under what conditions identify, plan, implement and maintain communication about OH&S aspects and OH&SMS; assess the effectiveness of communication at least once annually 91 4.4.3.1 Implement the communication procedure "Good news walk, bad ones run. Swedish proverb" 92 4.4.3.1 Maintain the communication procedure When changes in processes, products, requirements, infrastructure 93 4.4.3.1 a Communiquer internally Particula attention to feedback from staff ( surveys, suggestion box) 94 4.4.3.1 b Communiquer externally Contractors, visitors (customers, regulation organizations) 95 4.4.3.1 c Receive requests from interested parties Interested parties can be customers, suppliers, regulation authorities, regional organizations 96 4.4.3.1 c Document requests from interested parties Cf. sub-clause 4.5.4 97 4.4.3.1 c Respond to requests from interested parties Including emergencies - Cf. sub-clause 4.4.7 4.4.3.2 Participation and consultation 98 4.4.3.2 Establish the procedure participation and consultation Cf. sub-clause 4.4.5 99 4.4.3.2 Implement the procedure participation and consultation Active employee involvement to improve the OH&SMS 100 4.4.3.2 Maintain the procedure participation and consultation When changes in processes, products, requirements, infrastructure, staff, representatives 101 4.4.3.2 a Involve workers in hazard identification And assessing risks and determining the means of control 102 4.4.3.2 a Involve workers in incident investigation The staff knows best the working conditions 103 4.4.3.2 a Involve workers in the development and review of OH&S policies and objectives Staff are informed at the outset of the various proposals 104 4.4.3.2 a Consult workers where changes affect their OH&S Including when choosing means of control 105 4.4.3.2 a The workers are represented on OH&S matters

- 9. 106 4.4.3.2 Inform workers about their representative on OH&S matters 107 4.4.3.2 b Consult contractors about changes that affect their OH&S New hazards, new means of control, various changes 108 4.4.3.2 Consult interested parties on OH&S matters Emergency provisions, neighborhood hazards, legal requirements 4.4.4 Documentation Top of the page 109 4.4.4 a Include OH&S policy and objectives Cf. Cf. sub-clauses 4.2 and 4.3.3 110 4.4.4 b Include scope of the OHSMS Cf. sub-clause 4.1 111 4.4.4 c Include the main elements of the OHSMS and their interactions For example in the OH&S manual (which is not mandatory) 112 4.4.4 d Include documents and records required by the OHSMS Cf. sub-clauses 4.4.5 and 4.5.4 113 4.4.4 e Include documents of processes of risk management Can be combined with other documents from other management systems 4.4.5 Control of documents Top of the page 114 4.4.5 Control OH&SMS documents The 12 mandatory procedures are: - hazard identification (cf. sub-clause 4.3.1) - legal requirements (cf. sub-clause 4.3.2) - training (cf. sub-clause 4.4.2) - communication (cf. sub-clause 4.4.3 ) - control of documents (this sub-clause) - operational control (cf. sub-clause 4.4.6) - emergency situations (cf. sub-clause 4.4.7 ) - measuring and monitoring (cf. sub-clause 4.5.1) - evaluation of compliance (cf. sub-clause 4.5.2 ) - incidents and nonconformities (cf. sub- clause 4.5.3) - control of records (cf. sub-clause 4.5.4) - internal audit (cf. sub-clause 4.5.5 ) You can combine several procedures into one 115 4.4.5 Control records of the OH&SMS Cf. sub-clause 4.5.4 116 4.4.5 Establish the procedure control of documents The mandatory procedure for documents answers questions, when, how, under what conditions write, identify, verify, validate, distribute and retain documents 117 4.4.5 Implement the procedure control of documents Master list of documents

- 10. 118 4.4.5 Maintain the procedure control of documents When changes in processes, products, requirements, infrastructure 119 4.4.5 a Approve documents By the authorized person 120 4.4.5 b Update and re-approve documents Following any change 121 4.4.5 c Identify changes and revisions Change and indices (versions) management of documents is done by a person with responsibilities and authorities established 122 4.4.5 d Ensure that the right document is at the right place "The right document, at the right place, at the right moment" and with the right version 123 4.4.5 e Ensure that documents are legible and identifiable Codification is updated, each document is clear, simple to understand, easy to categorize 124 4.4.5 f Identify documents of external origin Documents of external origin (standards, laws, decrees, specifications) are under control (list, location, version) 125 4.4.5 f Control the distribution of external origin List (folder) 126 4.4.5 g Prevent use of obsolete documents Expired documents (obsolete) are retained, archived, destroyed or locked up so that we can not use them in normal cases 127 4.4.5 g Identify obsolete documents Red stamp 4.4.6 Operational control Top of the page 128 4.4.6 Determine activities to manage the OH&S risks Control measures, including staff training - cf. sub-clause 4.4.2 129 4.4.6 Include the management of change Cf. sub-clause 4.3.1 130 4.4.6 a Implement operational controls Consider all activities of the company (management, realization and support processes) and feedback 131 4.4.6 a Maintain operational controls Cf. sub-clause 4.3.2; establish operational monitorings 132 4.4.6 a Integrate operational controls into the OHSMS Maintenance of equipment, floor space, environment (air, temperature, humidity), emergency plans, protective equipment (PPE) 133 4.4.6 b Implement controls of purchased goods Prevention and protection measures of hazardous materials, criteria for approval before purchase 134 4.4.6 b Maintain controls of purchased goods Specific requirements communicated to supplier 135 4.4.6 c Implement controls related to contractors and visitors Supplier evaluation and selection criteria

- 11. 136 4.4.6 c Maintain controls related to contractors and visitors When changes in processes, products, requirements, infrastructure 137 4.4.6 d Implement procedures where their absence could lead to deviations from OH&S requirements Cf. sub-clause 4.4.5; the procedure required for operational control answers the questions who, when, how, under what conditions identify, plan, implement and maintain the company's activities (management, realization and support processes) 138 4.4.6 d Maintain procedures where their absence could lead to deviations from OH&S requirements When changes in processes, products, requirements, infrastructure 139 4.4.6 e Implement operating criteria where their absence could lead to deviations from OH&S requirements Specific equipment, work instructions, skills, forms of hazardous materials, PPE 140 4.4.6 e Maintain operating criteria where their absence could lead to deviations from OH&S requirements Periodic evaluation of the effectiveness of operational control used; proposal for new means if needed 4.4.7 Emergency preparedness and response Top of the page 141 4.4.7 Establish the emergency procedure Cf. sub-clause 4.4.5; the procedure required for emergency situations answers questions, when, how, under what conditions identify, plan, implement and maintain preparedness and response to potential emergencies and their impact on OH&S 142 4.4.7 Implement the emergency procedure Identify potential hazards, define methods to respond, communicate action plans, test the ability to respond, train staff 143 4.4.7 Maintain the emergency procedure When changes in processes, products, requirements, infrastructure 144 4.4.7 a Identify emergency situations List of emergency situations 145 4.4.7 b Respond to emergency situations Response sheets; most appropriate methods, including abnormal conditions 146 4.4.7 Mitigate OH&S consequences of emergency situations List of measures and actions for every potential situation 147 4.4.7 Take into account the needs of interested parties List of support organizations (coordinates) 148 4.4.7 Test periodically how to respond to emergency situations Cf. sub-clause 4.4.2 149 4.4.7 Review and, where necessary, revise preparedness and response to After analysis of tests undertaken and occured; cf. sub-clause 4.5.3

- 12. emergency situations 4.5 Checking Check 4.5.1 Performance measurement and monitoring Top of the page 150 4.5.1 Establish the procedure measurement and monitoring Cf. sub-clause 4.4.5; the mandatory procedure for monitoring and measuring answers questions, when, how, under what conditions identify, plan, implement and maintain the verification OH&S performance of all company's activities through the analysis of data collected 151 4.5.1 Implement the procedure measurement and monitoring "If you can't measure it, you can't manage it. Peter Drucker" 152 4.5.1 Maintain the procedure measurement and monitoring When changes in processes, products, requirements, infrastructure 153 4.5.1 a Provide for qualitative and quantitative measures Number of incidents, illnesses, compliance with OH&S policy commitments, skills assessment 154 4.5.1 b Monitor the performance of the OH&SMS Cf. sub-clauses 4.4.6 and 4.5.5 155 4.5.1 c Monitor the effectiveness of controls On health and on safety 156 4.5.1 d Include proactive measures of performance Evaluation of compliance, training, monitoring results, internal audits, programme implementation 157 4.5.1 e Include reactive measures of performance Incidents, illnesses, work stoppages 158 4.5.1 f Keep records of results of monitoring and measurement Cf. sub-clause 4.5.4 159 4.5.1 Establish the procedure for calibration and maintenance of equipment Cf. sub-clause 4.4.5; Monitoring and measuring equipment (hardware and software) are calibrated and verified regularly, the staff is qualified, the methods used are appropriate 160 4.5.1 Maintain the procedure for calibration and maintenance of equipment When changes in equipment, software and methods 161 4.5.1 Keep records of calibration and maintenance Cf. sub-clause 4.5.4 4.5.2 Evaluation of compliance Top of the page 162 4.5.2.1 Establish the procedure evaluation of compliance Cf. sub-clause 4.4.5; "Safety is never for ever", the mandatory procedure for evaluation of compliance answers the questions who, when, how, under what conditions identify, plan, implement and

- 13. maintain the evaluation of compliance with applicable legal requirements and other requirements to which the company subscribes 163 4.5.2.1 Implement the procedure evaluation of compliance Evalute the status of compliance; cf. sub- clauses 4.3.2 and 4.5.5 164 4.5.2.1 Maintain the procedure evaluation of compliance When changes in processes, products, requirements, infrastructure 165 4.5.2.1 Keep records of evaluations to legal requirements Cf. sub-clause 4.5.4 166 4.5.2.2 Evalute compliance with other requirements Cf. sub-clause 4.3.2; procedure separated or combined with sub-clause 4.5.2.1 167 4.5.2.2 Keep records of evaluations to other requirements Cf. sub-clause 4.5.4 4.5.3 Incident investigation, nonconformity, corrective action and preventive action Top of the page 4.5.3.1 Incident investigation 168 4.5.3.1 Establish the procedure control of incidents Cf. sub-clause 4.4.5; the procedure required for the control of incidents answers the questions who, when, how, under what conditions identify, correct and investigate incidents and their causes, evaluate need of actions, eliminate root causes, review the effectiveness of actions, communicate results 169 4.5.3.1 Implement the procedure control of incidents Cf. sub-clauses 4.3.2 and 4.5.5 ; real and potential consequences, frequency, responsibilities and authorities 170 4.5.3.1 Maintain the procedure control of incidents When changes in processes, products, requirements, infrastructure 171 4.5.3.1 a Determine deficiencies related with occurence of incidents Anything that can contribute to the occurrence of an incident 172 4.5.3.1 b Identify the need for corrective action What could be achieved if the action is applied? Are the needed resources available? 173 4.5.3.1 c Identify opportunities for preventive action After analysing theinvestigation results 174 4.5.3.1 d Identify opportunities for continual improvement Propose at management review - Cf. sub- clause 4.6 175 4.5.3.1 e Communicate the results of investigations Cf. sub-clause 4.5.4 176 4.5.3.1 Perform investigations in a timely

- 14. manner 177 4.5.3.1 Treat corrective and preventive actions in accordance with the procedure control of nonconformities Cf. paragraphe 4.5.3.2 178 4.5.3.1 Keep the results of investigations Cf. sub-clause 4.5.4 4.5.3.2 Nonconformity, corrective action and preventive action 179 4.5.3.2 Establish the procedure control of nonconformity Cf. sub-clause 4.4.5; the procedure required for the control of nonconformities answers the questions who, when, how, under what conditions identify, plan, implement and maintain control of noconformities, corrective and preventive actions 180 4.5.3.2 Implement the procedure control of nonconformity identify and treat nonconformities, determine and eliminate root causes, evaluate the need for action, implement actions, evaluate the effectiveness of actions, find improvement opportunities 181 4.5.3.2 Maintain the procedure control of nonconformity When changes in processes, products, requirements, infrastructure 182 4.5.3.2 a Identify nonconformities "Any problem hides an opportunity for improvement"; identification and segregation of nonconforming product for treatment or OH&S requirement not followed 183 4.5.3.2 a Correct nonconformities Mitigate OH&S consequences 184 4.5.3.2 b Investigate nonconformities To find the cause 185 4.5.3.2 b Determine the cause of nonconformity Methods to find the causes of nonconformities (Ishikawa diagramme) 186 4.5.3.2 b Take actions to avoid recurrence of nonconformities Set deadlines and responsibilities 187 4.5.3.2 c Evaluate the need for preventive actions What could be achieved if the action is applied? The resources needed are they available? 188 4.5.3.2 c Implement preventive actions The goal is to prevent occurrence of a potential nonconformity; before the implementation assess potential risks 189 4.5.3.2 d Keep the results of actions Cf. sub-clause 4.5.4 190 4.5.3.2 Communicate the results of actions Cf. sub-clause 4.4.3.1

- 15. d taken 191 4.5.3.2 e Review the effectiveness of actions taken Set deadlines and responsibilities 192 4.5.3.2 Assess risk of proposed actions prior to implementation Cf. sub-clause 4.3.1 ; if new hazards are identified 193 4.5.3.2 Adapt actions to the magnitude of problems and OH&S risks Make arrangements with respect to real effects (watch out for excess of zeal) 194 4.5.3.2 Change the OH&SMS documentation Cf. sub-clause 4.4.4 4.5.4 Control of records Top of the page 195 4.5.4 Establish OHSMS records The recordings are filled without delay. Without them it's hard (impossible) to demonstrate compliance with the requirements of the OHSMS 196 4.5.4 Maintain OHSMS records Evidence that the OHSMS is living and improving its performance continually 197 4.5.4 Establish the procedure control of records Cf. sub-clause 4.4.5; "Spoken words fly away, written ones stay. Latin proverb"; the procedure required for records answers questions, when, how, under what conditions identify, use, store, distribute, protect, retain and dispose of records 198 4.5.4 Implement the procedure control of records 199 4.5.4 Maintain the procedure control of records Cf. sub-clause 4.3.2; when changes in processes, products, requirements, infrastructure 200 4.5.4 Ensure that records are legible, identifiable and traceable The simplest answer to this requirement is to use a computer or computer system (virus protection and backup required) 4.5.5 Internal audit Top of the page 201 4.5.5 Conduct planned audits Annual programme for internal audits; find opportunities to improve the OHSMS; use ISO 19 011 202 4.5.5 a 1 Determine whether the OHSMS conforms to OHSMS requirements Cf. sub-clause 4.3.2 203 4.5.5 a 2 Determine whether the OHSMS is implemented Hazards are identified, risks assessed, control methods inplemented 204 4.5.5 a 2 Determine whether the OHSMS is maintained Lagal watch updated 205 4.5.5 a 3 Determine whether the OHSMS is meeting OH&S policy and objectives Check compliance of processes 206 4.5.5 b Report results of audits to Input of management review - Cf. sub-

- 16. management clause 4.6 207 4.5.5 Plan the audit programme The audit programme focuses on sensitive activities without forgetting the results of previous audits 208 4.5.5 Establish the audit programme The programme covers the entire scope of the OHSMS 209 4.5.5 Implement the audit programme Every audit is planned, the scope established, the auditor appointed 210 4.5.5 Maintain the audit programme Additional audit if unusual nonconformity 211 4.5.5 Establish the procedure internal audit Cf. sub-clause 4.4.5; the procedure required for audits answers the questions who, when, how, under what conditions plan (audit programme), define the criteria, scope, frequency and audit methods 212 4.5.5 Implement the procedure internal audit Train auditors - cf. sub-clause 4.4.2 213 4.5.5 Maintain the procedure internal audit When changes in processes, products, requirements, infrastructure 214 4.5.5 Include planning and conducting audits, reporting results and keeping records Cf. sub-clause 4.5.4 215 4.5.5 Include audit criteria, scope, frequency and methods All this information is in the audit plan; add the audit objective, schedule and participants 216 4.5.5 Ensure objectivity and impartiality of the audit process "No-one is a judge in his own case. Latin proverbe" ; auditors don't audit their own activity 4.6 Management review Act 217 4.6 Review the OHSMS by top management "No system is perfect"; usually once or twice a year, review the entire OHSMS to monitor the achievement of OH&S objectives 218 4.6 Assess opportunities for improvement of the OHSMS Review opportunities (occasions, conditions, possibilities, circumstances) for continual improvement of the OH&SMS and the need for changes 219 4.6 Keep the records of the management reviews Cf. sub-clause 4.5.4 ; the report contains the agenda, participants, the information presented, the discussions and decisions 220 4.6 a Include results of audits and evaluations of compliance Cf. sub-clauses 4.5.5 and 4.5.2 221 4.6 b Include the results of participation and consultation Cf. sub-clause 4.4.3.2

- 17. 222 4.6 c Include information from interested parties Including complaints 223 4.6 d Include the OHSMS performance Cf. sub-clause 4.5.1 224 4.6 e Include the level of achievement of objectives Cf. sub-clause 4.3.3 225 4.6 f Include the status of investigations and actions Cf. sub-clause 4.5.3 226 4.6 g Include follow-up actions from previous management reviews Finalized and postponed actions 227 4.6 h Include changes in requirements Consider, evaluate and analyze any changes that may impact on the OHSMS (new products / processes, new customers, new features and / or responsibilities, legal and regulatory developments) - Cf. sub-clause 4.3.2) 228 4.6 i Include improvement recommendations Suggestions, views, opinions, proposals from all staff or external interested parties 229 4.6 Include decisions and actions on continual improvement of the OHSMS Evaluate, plan and implement: changes in resources (human and financial), environmental policy, objectives and targets and improvement actions 230 4.6 Make available outputs of the management review for communication and consultation Decisions are communicated internally