Report work on retaining wall

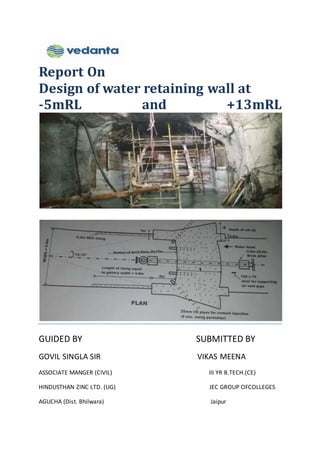

- 1. Report On Design of water retaining wall at -5mRL and +13mRL GUIDED BY SUBMITTED BY GOVIL SINGLA SIR VIKAS MEENA ASSOCIATE MANGER (CIVIL) III YR B.TECH.(CE) HINDUSTHAN ZINC LTD. (UG) JEC GROUP OFCOLLEGES AGUCHA (Dist. Bhilwara) Jaipur

- 2. Content ACKNOWLEDGEMENTS TIME LINE OF PROJECT INTROUCTION THEORTICAL ASPECTS OF DAMS CONSTUCTION Design consideration Estimation of dam thickness Estimation of thickness of dam based on the Crushing strength Estimation of thickness of dam based on the Shear strength Estimation of thickness of dam based on the tensile strength of its material Estimation of depth of cut ANALYSIS OF RAINFALL DATA AND POSSIBLE WATER HEAD AT DAM CALCULATION OF WATER HEAD FOR DAM EVALUATION OF DAM THICKNESS AND DEPTH OF CUT CONSTUCTION AND DESIGN OF DAM GROUND MONITORING PLAN CONCLUSIONS

- 3. ACKNOWLEDGEMENT I express my gratitude to management of Hindustan Zinc Limited, Vedanta Resources who has shown confidence on me and bestowed upon me this valuable task. I want to express my deepest gratitude and special thanks to Mr. Praveen Kumar Jain, Location Head, Rampura Agucha Mines for allowing me to carry out my project at their esteemed organization. I would like to express my sincerethanks to my project mentor Mr. Govil Singla Associate Manager - Civil, Rampura Agucha Underground Mines) for his kind guidance throughoutthe courseof the project. Without his help I was helpless. I am also thankful to Mr. Nathu Singh Choudhary, Manager – Mining, RAUG Mines; Mr. Amit Jain, Manager - Mechanical and all other engineers of RAUG Mine with whom I interacted during the internship. I am also thankful to Ms. Urvashi Jindal and Ayush Diwedi Executive, Human Resources Department, for her continued support and invaluable encouragement. I perceive this opportunity as a big milestone in my career development. I shall always be indebted to Vedanta Resources for providing me this opportunity.

- 4. Timeline of the Project 03/06/2016 – 12/06/2016 •Overview and understanding of mine •Visit of all the respective departments 13/06/2016 – 12/07/2016 •Underground Visit •Data Collection 13/07/2016 – 20/07/2016 •Analysis of Collected Data •Identification of parameters affecting 22/07/2016 – 26/07/2016 •Report Preparation and Submission

- 5. INTRODUCTION Hindustan Zinc Limited is planning to extract lead- zinc deposit by underground stopping methods at deeper horizons below the currently operating open-pit mine. The open pit has reach an RL of +80mRL and is planned to go further deep up to -40mRL with a depth of about 440m from the surface. The mine management has planned for exploiting the continuing ore body by underground trail stopping. The current pit bottom is at about +80mRL. The ultimate pit shall go beyond the trial stopping level between -5mRL and +13mRL. As the pit planned to be deepened down to -40mRL the entries to the stopping region need to be plugged to prevent flooding of pit water into the underground working. Currently the trail stopping level between -5mRL and +13mRL is completed in the central portion between 390N and 420S with all the primary stops extracted in this region and all the intervening secondary stops remaining like supports rib pillar. In the current study the above scenarios of isolation requirement are analysed. The possibility of water accumulation in the pit and water head development are analysed for the above scenario. Further, water retaining bulk head are designed using well established statutory norms for temporary and permanent bulk head requirements. Finally some recommendations on its mode of construction and a ground monitoring scheme are made.

- 6. Fig. A schematic LVS showing the proposed production plan from open pit and Underground.

- 7. THEORETICAL ASPECTS OF DAM CONSTUCTION Design consideration In mines, underground dams are constructed mainly to prevent inundation of dip side working by isolating the adjacent flooded areas. They are also used to flood a portion of a mine in the case of a fire and to limit the amount of pumping and to keep water under control so that it may be drawn off as and when required. In some instance a dam is also fitted with bulk head door whilst approaching old working. The factors which govern the design of a dam are the size of roadway, the nature of adjacent strata, the estimated water pressure and form of dam. Care should be taken while estimating the maximum water pressure on the dam. The most important parameter in the design of an underground dam is the estimation of its safe thickness under a given set of conditions. The factors which are normally considered are: a) The maximum water head to be resisted b) The nature and the geotechnical properties of the surrounding strata c) The crushing strengths of the materials to be used d) The cross-sectional area of the gallery e) The form of dam –flat or straight, cylindrical or arched and f) The type of the dam –temporary or permanent

- 8. Estimation of dam thickness Various approaches have been adopted to estimate the safe thickness of dam. Estimation of the thickness of a dam based on the crushing strength Kalmykov suggests the following equation to estimation the safe thickness of a cement concrete wedge shaped straight dam: t = 𝐵+ℎ 4 tan∝ (√ 4𝜆𝑝𝐵ℎ 4𝜎 𝑓 (𝐵+ℎ)2 + 1-1) where t= thickness of the dam B= width of the gallery α= angle of inclination of dam σ= ultimate crushing strength of concrete λ= coefficient of overloading = 1.25 k= coefficient of strength variation = 0.6 p= water pressure of dam f= safety factor

- 9. The Director-General of Mine Safety in India recommends the following empirical equation for estimating the thickness of cement concrete dams t = 0.3𝑝𝐵1.5 𝜎′ t= thickness of dam in ft σ’= safe permissible crushing strength of cement concrete Professor Aldis in the UK suggests the following equation to estimate the thickness of a cylindrical dam t= r(1- √1 − 20𝑝 𝜎 ) where r= the shorter or the external radius of dam p=total water pressure on the dam σ= ultimate crushing strength of concrete Estimation of the thickness of a dam based on the shear strength The thickness of a rectangular dam to resist shear is t= 𝐵ℎ𝑝 2(𝐵+ℎ) 𝜎 𝑓⁄ where σ= ultimate crushing strength of concrete f= safety factor

- 10. Estimation of the thickness of a dam based on the tensile strength of its material Peele suggests that the thickness of a dam can be estimated by the use of the thick beam formula t=√ 𝑝𝐵2 2𝜎𝑡′ where, σt’= the safe permissible tensile strength of dam concrete R.N. Gupta also propose a formula for the estimation the thickness of a dam t=3 4⁄ √ ℎ2 𝐾𝑝(𝑀+1) 𝜎𝑡 𝑓 𝑚 where p= water pressure of dam f= safety factor m= poison number of the dam material K= coefficient which depends on the ratio of the two sides of the dam σt= ultimate tensile strength of concrete

- 11. Fig. Comparison b/w calculation equations for the thickness of the dam Estimation of depth of cut The depth of cut to be provided on the four sides can be estimated from the following expression: e=t tan 𝛼 where e= depth of cut t= thickness of the dam α= abutment side angle of dam (generally α= 12 to 20 degree)

- 12. ANALYSIS OF RAINFALL DATA AND POSSSIBLE WATER HEAD AT RAM Initially the possibility of water accumulation in the open pit is analysed from the available rainfall data in the region for past 10 - 12 years. The daily recording of rainfall in the region for past 12 years (2003 to 2014) is given below: Maximum rainfall recorded for a day : 225mm Maximum rainfall recorded for a month : 420mm Maximum rainfall recorded for a year : 1017 mm Cummulative rainfall in the past 12 years (2003 to 2014) : 8044mm Catchment area of the current pit (2014 - 2015) : 16,42,395 sq.m. The volume of open pit with respect to the height of water head from pit bottom has been estimated for the pit about 400m and for a height of 100m from pit bottom. The corresponding pit volume and water head for the maximum rainfall data is shown below: Max. possible volume of rain &water head in the pit in a day : 3.69 lakh m3 ; 4m Max. possible volume of rain &water head in the pit in a month: 6.89 lakh m3 13m Max. possible volume of rain&water head in the pit in a year: 16.7 lakh m3 28m Cumulative volume of rain for 12 years: 132.1 lakh m3 ; 92m

- 13. Fig. Pit volume v/s water head for the entire pit. Fig. Pit volume with respect to height for 100m from pit bottom

- 14. Apart from the rainfall, the other factors controlling the water head development in the pit include ground water seepages into the pit, water percolating into the strata from the pit and also the water evaporation rate. These factors may be in some case cancels each other and therefore will not be significant in the calculations. W total = W R +(W gw-in - W gw-out -W E) where W total : total water accumulation in the pit W R : rain water Wgw-in : ground water seepages into the pit Wgw-out: ground water percolating into strata from the pit WE : quantity of water evaporation out of the pit The annual water pumping data and the estimation of the rainfall volume based on current pit area of Rampura Agucha Mines:

- 15. Fig. Pumping and rain fall data based on current pit area The pit area was significantly lower in the yester years; hence the rainfall volume calculated may be higher than the pumping data of the previous years. The most significant observation is that for the recent years, the rainfall volume estimated matches well with the water pumped out from the pit. This indicates that the other factors(K) is self- compensatory in this case, and it is safe to calculate the water head based on the rain water data. CALCULATION OF WATER HEAD FOR RAM Water head formation has been seen in three scenarios as given below: 1. Water head in the working pit -5mRL and +13mRL footwall drive during the remaining stopping in north and south side of trail stopping level. 2. Water head in the working pit at +20mRL near decline connection to the central portion of trial stopping level.

- 16. 3. Water level in ultimate pit +20mRL decline connection to north 1and south side of trail stopping level for permanent isolation. Calculation of the water head in all the three scenarios has been done as given below: Water Head in the working pit for isolation of North and South side stopping The requirement of bulk head to safely isolate North and South stopping in the trial stopping horizon is limited to 2-3 years, as threes stopping are expected to be exhausted in the year 2016-2017. These bulk heads are to be constructed in the footwall drives of -5mRL and +13MRL in the South side and in +13mRL in the North side; there is no connection currently existing in the North side of -5mRL footwall drive. The roof of the top drill drives and cross-cut exist at +18mRL. The 60m barrier between the open pit bottom and the top drill drive shall be breached when the pit is deepened to +70mRL. In a working pit, there will be regular pumping of water to continue production from of open pit. The Maximum period for which the pumping may be stopped, in the worst scenario, shall be for a period of 7 days, or at the maximum for a month. Though must unlikely, if on year cumulative maximum rainfall data is considered, a maximum of 1.017m of rain ( year 2011) corresponding to about 28m of water head in the work pit work pit (till year 2020) may be at +100mRL (+70mRL+30m). Hence the water head to be considered for temporary bulk head design at -5mRL and +13mRL shall be 105m and 87m respectively.

- 17. As the pit is deepened and widened, this likely water level in the working pit remains the highest possibility. The bulk head requirement for the footwall drivages at -5mRL and +13mRL shall be only temporary in nature(less than 5 years). Water level for decline connection at centre portion (+13mRL) For complete isolation of the central stopping region between 390Nand 420S of trial stopping level, the decline connections need to be plugged at about +20mRL. This isolation water dams will be serve temporarily during the North and South side stopping in the same level. The decline is connected to the bottom level at about +70mRL. Further after the stopping is completed and the pit is deepened to its ultimate bottom level of -40mRL, the bulk heads will serve for permanent isolation of the central stopping region between -5 and +13mRL. For the temporary isolation phase of the decline connection to the central region, the maximum possible water head to be considered will be same as that of the footwall drives towards North and South trial stopping which means the maximum water level in the pit at +100mRL need to be considered. The bulk heads are to be constructed about +20mRL in the decline accesses, the maximum possible water head, which to be guarded against is therefore 80m up to the period of 5 years on a temporary basis. For permanent isolation, the ultimate pit bottom needs to be considered, which will be at -40mRL by the end of year 2020. When the pit is exhausted, there may be chance that more water may be accumulated in the pit. Considering past 12 years rainfall record, the water accumulation in the pit for about 12 years without water pumping may lead to a water head of about 92m from the pit bottom. Taking some additional precautions and uncertainties, one may considered a 100m height of water accumulation in the ultimate pit, which means the maximum possible height of water level could be up to

- 18. +60mRL. The permanent bulk heads in the central decline access at (+20mRL) should be designed therefore for 40m of water head. Hence it is advisable to construct the bulk heads taking the temporary requirement withmaximumof 80mwater head and permanent requirement with maximum of 40m water head and permanent requirement with maximum of 40m water head, whichever is large. Water level for decline connection at south and north side (+13mRL) After temporarily isolating the central stopping region, stopping shall continue in North and South side of the samelevel till 2016-17 by connecting the decline to South and North side +13mRL. It also necessary to permanently plug the stopping level. The water head calculation for these permanent bulk heads will be same that of the permanent dams of the central decline access. Hence, the maximum possible water head which may be encountered by these bulk heads shall be about 40m.

- 19. EVALUATION OF DAM THICKNESS AND DEPTH OF CUT 1The dam thickness has been evaluated using DGMS formula for safety factor of 8.0 for temporary dams and safety factor of 15.0 for permanent dams as given below: T=(H*W*√W)/(8*S) Roadway dimension of 5.6mX 5.3mis taken and a compressivestrength of only 25.8 MPa is used here, which means for SF=8.0, the crushing strength (S) taken in the above formula is 3.23 MPa and that for SF=15.0 it will be 1.72 MPa. Following dam thickness are obtained for three scenarios discussed earlier. In +13mRL and -5mRL footwall drives towards North and South sides The maximum possiblewater head calculated for working pit : 105m for -5mRL and 87m for +13mRL. Safety factor: 8.0 Thickness of dam (t) = 5.3m at -5mRL and 4.4m at +13mRL Depth of cut (d) = 1.5m at -5mRL and 1.25m at +13mRL In +20mRL decline connection at Central portion The maximum possible water head for working pit : 80m

- 20. Safety factor : 8.0 Thickness of temporary dam : 4.0m Depth of cut : 1.15m Maximum possible water head for ultimate pit : 40m Safety factor : 15.0 Thickness of permanent dam : 3.8m Depth of cut : 1.1m In +20mRL decline connection at South and North side Maximum possible water head for ultimate pit : 40m Safety factor : 15.0 Thickness of permanent dam : 3.8m Depth of cut : 1.1m Construction And Design Of Dam Arch shaped bulk head dams are suggested for effective protection against the water head. A schematic showing the construction and design of the bulk heads is given figure as a part and longitudinal section views. The pressure grouted methods should be adopted for effective sealing of the roadways and preventions of seepages while constructing the bulk head.

- 22. GROUND MONITORING PLAN The roadway near all the bulk to a distance of 10-20m need to be monitored using borehole extensometers (telltales) and convergence indicators. CONSLUSIONS AND RECOMMENDATIONS From the empirical calculation for the thickness of the water dam and depth of the cut following conclusions and recommendations are made: 1. The 60m barrier between the current working open pit and the underground trial stopping level will be breached when the pit is deepened to +70mRL. Hence the proposed stopping areas in the North and South sides of the trial trail stopping level and the central decline connection needs to be plugged at the footwall drives in +13mRL and - 5mRL and near the decline access to +13mRL using temporary bulk heads prior to deepening the open pit. 2. From the analysis of rainfall data and pumping from the open pit in the recent years it can be concluded that rain water alone falling into the pit pretty much accounts for the possible water accumulation in the pit. The other factor such as groundwater seepages into the pit, percolation from the pit to the neighbouring strata and evaporation from the pit compensate each other.

- 23. 3. The maximum possible water level in the working pit will be at +100mRL when the pit bottom is at +70mRL. When the pit is deepened, this level will only further reduce. 4. It is recommended that here to use M30 grade of concrete for the dam construction, a crushing strength of only 25.86Mpa was considered in the calculation which means the SF=8.0, the crushing strength taken is 3.23MPa and for SF=15.0 it will be 1.72MPa. 5. The depth of cut (d) into the roadway sides, floors and roof required for ensuring good contact of the dam with the rock mass. 6. During construction, it should be ensured that the rock mass which housethe dam is strong, freefromfissures and not likely to be disturbed by the subsequent workings. 7. Dam should be of arch shape and made up of M30 cement concrete. Pressure grouting needs to be used using injection holes to ensure complete filling to the top of the notched region. 8. The dam must be fitted with a drain pipe of 150 to 200mm diameter, an air vent pipe, and pressure gauge and control valves. Any weak rock mass found in the sides, roof and floor should be strengthened by the cement injection, fully grouted bolts, and shotcrete. 9. It should be ensured that peak particle velocities near the dam sites should not exceed 25mm/s due to the blasting from the open pit as well as underground.