LAB REPORT EXPERIMENT 1 FOOD CHEMICAL ANALYSIS.docx

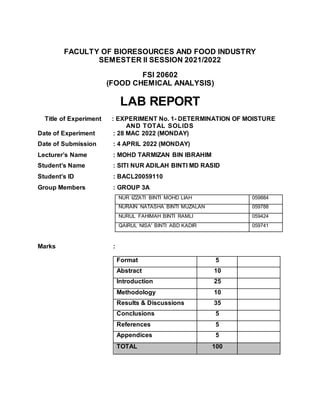

- 1. FACULTY OF BIORESOURCES AND FOOD INDUSTRY SEMESTER II SESSION 2021/2022 FSI 20602 (FOOD CHEMICAL ANALYSIS) LAB REPORT Title of Experiment : EXPERIMENT No. 1- DETERMINATION OF MOISTURE AND TOTAL SOLIDS Date of Experiment : 28 MAC 2022 (MONDAY) Date of Submission : 4 APRIL 2022 (MONDAY) Lecturer’s Name : MOHD TARMIZAN BIN IBRAHIM Student’s Name : SITI NUR ADILAH BINTI MD RASID Student’s ID : BACL20059110 Group Members : GROUP 3A NUR IZZATI BINTI MOHD LIAH 059884 NURAIN NATASHA BINTI MUZALAN 059788 NURUL FAHIMAH BINTI RAMLI 059424 QAIRUL NISA' BINTI ABD KADIR 059741 Marks : Format 5 Abstract 10 Introduction 25 Methodology 10 Results & Discussions 35 Conclusions 5 References 5 Appendices 5 TOTAL 100

- 2. ABSTRACT The moisture (or total solids) content of foods is important to food manufacturers for a variety of reasons. Moisture is an important factor in food quality, preservation, and resistance to deterioration. Determination of moisturecontent also is necessary to calculate the content of other food constituents on a uniform basis (e.g., dry weight basis and wet weight basis). The dry matter that remains after moisture analysis is commonly referred to as total solids. Moisture content of foods can be determined by a variety of methods, but obtaining accurate and precise data is commonly a challenge. In this experiment, we will use oven drying method and drying method (moisture analyser). These various methods of analysis have different applications, advantages, and disadvantages. Type of food samples that could be analyse by different groups are muffin, peanut and roti sardine to know the % of moisture content and % total solids. It is recommended that all analyses be performed in triplicate, as time permits. At the end of experiment, one of the best methods will be chosen due to several factors. INTRODUCTION Moisture content is one of the most commonly measured properties of food materials. It is important to food scientists for a number of different reasons. For example, Legal and Labelling Requirements. There are legal limits to the maximum or minimum amount of water that must be present in certain types of food. Second, Economic. The cost of many foods depends on the amount of water they contain. Water is an inexpensive ingredient, and manufacturers often try to incorporate as much as possible in a food, without exceeding some maximum legal requirement. Microbial Stability. The propensity of microorganisms to grow in foods depends on their water content. For this reason, many foods are dried below some critical moisture content. Next, Food Quality include chemical and physical appearance. The texture, taste, appearance and stability of foods depends on the amount of water they contain. Last but not least, Food Processing Operations. A knowledge of the moisture content is often necessary to predict the behaviour of foods during processing, e.g. mixing, drying, flow through a pipe or packaging. Therefore, it is important for food scientists to be able to reliably measure moisture contents. A number of analytical techniques have been developed for this purpose, which vary in their accuracy, cost, speed, sensitivity, specificity, ease of operation, etc. The moisture content value obtained is highly dependent on the type of oven used conditions within oven, and the time and temperature of drying. Non water volatiles can be lost during drying, but their loss is generally a

- 3. negligible percentage of the amount of water lost. The choice of an analytical procedure for a particular application depends on the nature of the food being analyzed and the reason the information is needed. Foods are heterogeneous materials that contain different proportions of chemically bound, physically bound, capillary, trapped or bulk water. In addition, foods may contain water that is present in different physical states which are gas, liquid or solid. The fact that water molecules can exist in a number of different molecular environments, with different physicochemicalproperties, can be problematic for the food analyst trying to accurately determine the moisture content of foods. Many analytical procedures developed to measure moisture content are more sensitive to water in certain types of molecular environment than to water in other types of molecular environment. This means that the measured value of the moisture content of a particular food may depend on the experimental technique used to carry out the measurement. In this experiment, we will use oven drying method and drying method (moisture analyser) to determine the moisture content and total solids in certain food. Objectives for this experiment are to determine the moisture content of food samples using drying oven method and to determine the moisture content of food samples using Moisture Analyser. APPARATUS Crucibles (or similar porcelain or metal dishes) Drying oven Dessicator Balance Crucible tongs Moisture analyser MA 150Q Sartorius Sample pan METHODOLOGY A. Oven drying method

- 4. 1. Sample was grined as finely as possible or homogenise in a blender. 2. The sample was mixed thoroughly. 3. Crucible was dried with cover for 4 hours in an oven at 105 o C. The crucible was cooled in a dessicator and after it has attained room temperature, weighed it soon. 4. 3g of homogenised samples were weighed into the crucible (balance sensitivity 0.0001 g). 5. The sample uncovered was placed in oven at 105 o C. The drying time about 6 hours, for dried samples (feeds). The drying time about 24 hours to constant, for wetted samples (muscle tissue). 6. The crucible was removed and cooled in a dessicator and after attained room temperature, weighed it soon. B. Drying method (Moisture Analyser) 1. The Moisture Analyser was switched on. 2. The sample chamber was opened and a new sample pan was positioned. 3. The TARE button was pressed to sets reading to zero. 4. About 2g of sample was placed and evenly distributed in the sample pan. The sample chamber was closed. 5. The ENTER button was pressed to start the drying process. 6. The result display for moisture %L was read and recorded, at the end of drying process. 7. The sample chamber was opened and the pan was carefully lifted to remove the sample. RESULTS A. Sample 1 – Muffin Table 1: Oven Drying Method Sample Trial W1 (g) W2 (g) W3 (g) % Moisture % Total Solids 1 58.2193 61.3004 60.6427 21.35 78.65

- 5. Muffin 2 60.4383 63.5150 62.8596 21.30 78.70 3 59.3670 62.4277 61.7804 21.15 78.85 Mean 59.3415 62.4144 61.7609 21.27 78.73 Table 2: Drying Method(Moisture Analyser) Sample Trial % Moisture Mass of sample (before) g Time (mins) Muffin 1 19.85 2.079 8.2 2 18.49 2.036 7.4 3 18.07 2.045 5.8 Mean 18.80 2.053 7.1 B. Sample 2 - Peanut Table 1: Oven Drying Method Sample Trial W1 (g) W2 (g) W3 (g) % Moisture % Total Solids Peanut 1 65.1204 68.1452 68.0793 2.18 97.82 2 64.3773 67.3905 67.3133 2.56 97.44 3 57.0300 60.0382 59.9898 1.61 98.39 Mean 62.1759 65.1913 65.1275 2.12 97.88

- 6. Table 2: Drying Method(Moisture Analyser) Sample Trial % Moisture Mass of sample (before) g Time (mins) Peanut 1 2.53 2.059 3.3 2 2.72 2.022 3.0 3 2.42 2.072 3.0 Mean 2.56 2.051 3.1 B. Sample 3 – Roti Sardin Table 1: Oven Drying Method Sample Trial W1 (g) W2 (g) W3 (g) % Moisture % Total Solids Roti Sardin 1 53.2339 56.2475 55.3198 30.78 69.22 2 53.0304 56.0443 55.1200 30.67 69.33 3 61.9360 64.9577 64.0329 30.56 69.44 Mean 56.0668 59.0832 58.1576 30.67 69.33 Table 2: Drying Method(Moisture Analyser) Sample Trial % Moisture Time (mins) 1 26.59 18.6 2 27.00 17.8

- 7. Roti Sardin 3 26.45 19.0 Mean 26.68 18.5 DISCUSSIONS Determination of moisture content and total solids can be performed by using oven drying method and drying method (Moisture Analyser). In the oven drying method, samples are heated by convection. This means the samples are at the same temperature as the drying oven. When using a moisture analyser, the sample heats up and dries by absorbing infrared radiation from the heating element. The comparison between both methods are, for oven drying method a known weight of food sample is dried to constant weight in an oven and the loss of weight is equated to the moisture content of the food. But, the disadvantage of this method is, it requires extended heating periods and cooling phases, meaning it usually takes hours to produce results. Procedures are laborious and tedious, involving many manual steps. While for drying method (Moisture analyser), measurement of moisture content based on thermogravimetric method. In theory, on the vaporization of water during the drying process; this measurement does not distinguish weight loss of water from loss of volatile components or sample decomposition. Moisture analyzers measure the loss-on-drying of a material by using the change in weight from prior to heating a sample, and after heating it. For this reason, moisture content as measured by thermogravimetric techniques includes all substances that vaporize when heating a sample, and is measured as weight loss during the heating process. Therefore, the term moisture content is used, rather than water content when using a thermogravimetric device. From the analysis of the data presented in Table 1 – Oven drying method for sample 1 (muffin), 2 (peanut) and sample 3 (roti sardin) it is found that average % moisture is 21.27%, 2.12 % and 30.67% respectively. This means peanut has less moisture content compare to muffin and roti sardine. Besides that, concentration lowers the water activity in food by using evaporation, reverse osmosis, ultrafiltration or freeze concentration. Drying lowers the water activity and moisture content in food using evaporation. Many dried foods are concentrated before being dried. From this experiment, we obtained average amount of % total solids are 78.73, 97.88, 69.33 for muffin, peanut and roti sardine respectively. The purpose we calculated the % total

- 8. solids are to know the percentage of solid in certain products and to observe either the products are in solid, liquid or gas. In addition, the dry matter that remains after moisture removal is commonly referred to as total solids. This analytical value is of great economic importance to a food manufacturer, and there are legal limits as to how much water must or can be present in some foods (Mauer, L.J., Bradley, R.L., 2017). Based on the Table 2 – Drying method (moisture analyser) for sample 1 (muffin), sample 2 (peanut) and sample 3 (roti sardine) we got average % moisture is 18.80%, 2.56% and 26.68% respectively. By using this method, we observed that roti sardine had greater amount of % moisture compared to muffin and peanut. It is clearly this 26.68% moisture is not free water. No amount of pressure will squeeze water out of the bread. Furthermore, average drying time (mins) for peanut are shorter rather than muffin and roti sardine which is 3.1 mins, 7.1 mins and 18.5 mins respectively. Standardized methodology needed for moisture determinations because different methods will give different results. By standardizing we are able to compare across multiple labs/experiments. Instrument based on infrared principles also should be practice in laboratory. However, it is a must to test the accuracy of the instrument first to meet my satisfaction and company standards. If the results determined using this instrument is nearly with normal methods used, I still will repeat the experiment for few times to be really satisfied. For the information, the equipment determines moisture of a sample by heating and drying it with infrared irradiation and displays the moisture content measured from changes in mass due to evaporation. Extra safety precautions are required while handling this experiment such as wear glove when you want to weigh the crucible to avoid moisture from hand and weigh 3g of homogenized sample with balance sensitivity is 0.0001g to get the accuracy and consistency value during experiment. CONCLUSIONS In a nutshell, Moisture analyzers are faster than most other methods of measuring moisture content. They efficiently dry a sample by transferring energy through both radiation (the transmission of energy in the form of waves or particles through a medium and convection (heat transfer by mass motion). This is because, it is easy to use. Moisture analyzers are easy to use compared to other methods, such as wet chemistry or using an oven and a balance, which could take hours because of the intricate nature of the task. Last but not least, time efficient. A

- 9. conventional drying oven, on the other hand, uses mostly convection to dry a sample. Both metal and halogen heating elements radiate energy in the infrared spectrum. But, by using the moisture analyser the moisture content of a sample can be measured in minutes rather than hours. REFERENCES Bradley, R. L. (2010). Moisture and total solids analysis. In Food analysis (pp. 85-104). Springer, Boston, MA. G.V. Barbosa-Canovas, L. Ma, B. Barletta, Food Engineering Laboratory Manual, Technomic Publishing Co., PA., 2017, Chapter 7-9, pp.63-104. Mauer, L. J., & Bradley, R. L. (2017). Moisture and total solids analysis. In Food analysis (pp. 257-286). Springer, Cham. Nielsen, S. S. (2010). Determination of moisture content. In Food analysis laboratory manual (pp. 17-27). Springer, Boston, MA. Voicu, G., Constantin, G. A., Tudor, P., Stefan, E. M., & Zabava, B. S. Aspects Regarding the Determination of the Moisture Content of Cereal and Granular Materials with Apparatus with Infrared Radiations. APPENDICES Picture 1: Reading for muffin’s sample by using drying method (Moisture Analyser) for trial 1

- 10. Picture 2: Reading for muffin’s sample by using drying method (Moisture Analyser) for trial 2 Picture 3: Reading for muffin’s sample by using drying method (Moisture Analyser) for trial 3