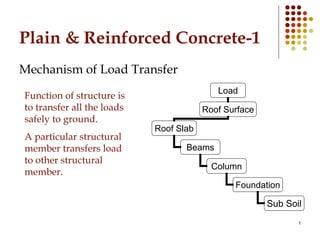

Mechanism of load transfored...PRC-I

- 1. 1 Plain & Reinforced Concrete-1 Mechanism of Load Transfer Load Roof Surface Roof Slab Beams Column Foundation Sub Soil Function of structure is to transfer all the loads safely to ground. A particular structural member transfers load to other structural member.

- 2. 2 Plain & Reinforced Concrete-1 Merits of Concrete Construction 1. Good Control over cross sectional dimensions and Shape One of the major advantage of concrete structures is the full control over the dimensions and structural shape. Any size and shape can be obtained by preparing the formwork accordingly. 2. Availability of Materials All the constituent materials are earthen materials (cement, sand, crush) and easily available in abundance. 3. Economic Structures All the materials are easily available so structures are economical. 4. Good Insulation Concrete is a good insulator of Noise & heat and does not allow them to transmit completely.

- 3. 3 Plain & Reinforced Concrete-1 Merits of Concrete Construction (contd…) 5. Good Binding Between Steel and Concrete there is a very good development of bond between steel and concrete. 6. Stable Structure Concrete is strong in compression but week in tension and steel as strong in tension so their combination give a strong stable structure. 7. Less Chances of Buckling Concrete members are not slim like steel members so chances of buckling are much less. 8. Aesthetics concrete structures are aesthetically good and cladding is not required

- 4. 4 Plain & Reinforced Concrete-1 Merits of Concrete Construction (contd…) 9. Lesser Chances of Rusting steel reinforcement is enclosed in concrete so chances of rusting are reduced. Demerits of Concrete Construction 1. Week in tension Concrete is week in tension so large amount of steel is required. 2. Increased Self Weight Concrete structures have more self weight compared with steel structures so large cross-section is required only to resist self weight, making structure costly. 3. Cracking Unlike steel structures concrete structures can have cracks. More cracks with smaller width are better than one crack of larger width.

- 5. 5 Plain & Reinforced Concrete-1 Demerits of Concrete Construction 4. Unpredictable Behavior If same conditions are provided for mixing, placing and curing even then properties can differ for the concrete prepared at two different times. 5. Inelastic Behavior concrete is an inelastic material, its stress-strains curve is not straight so its behavior is more difficult to understand. 6. Shrinkage and Creep Shrinkage is reduction in volume. It takes place due to loss of water even when no load is acting over it. Creep is reduction in volume due to sustained loading when it acts for long duration. This problem is not in steel structures. 7. Limited Industrial Behavior Most of the time concrete is cast-in-situ so it has limited industrial behavior.

- 6. 6 Plain & Reinforced Concrete-1 Specification & Codes These are rules given by various organizations in order to guide the designers for safe and economical design of structures Various Codes of Practices are 1. ACI 318-08 By American Concrete Institute. For general concrete constructions (buildings) 2. AASHTO Specifications for Concrete Bridges. By American Association of State Highway and Transportation Officials. 3. ASTM (American Standards for Testing and Materials) for testing of materials.

- 7. 7 Plain & Reinforced Concrete-1 Stress Strain Curve of Concrete fc’ 0.85fc’ Stress Strain Crushing 0.0028 to 0.0045, generally 0.003 •The first portion of curve, to about 40% of the ultimate strength fc’, can be considered linear. •The lower the strength of concrete the greater will be the failure strain 0.4 fc’

- 8. 8 Plain & Reinforced Concrete-1 Modulus of Elasticity Concrete is not an elastic material therefore it does not have a fixed value of modulus of elasticity Strain Stress Secant Modulus Tangent Modulus Initial tangent Modulus Tangent and Secant Moduli of Concrete 0.4fc’

- 9. 9 Plain & Reinforced Concrete-1 Modulus of Elasticity (contd…) Secant modulus (Ec) is the one which is being used in design. Ec = 0.043 wc 1.5√fc’ wc = density of concrete in kg/m3 fc’ = specified cylinder strength in MPa For normal weight concrete, say wc = 2300 kg/m3 Ec = 4700√fc’

- 10. 10 Plain & Reinforced Concrete-1 Reinforcing Steel Steel bars are: Plain Deformed (currently in use) Deformed bars have longitudinal and transverse ribs. Ribs provide a good bond between steel and concrete. If this bond fails steel becomes in effective. The most important properties for reinforcing steel are: Young's modulus, E (200 GPa) Yield strength, fy Ultimate strength, fu Size and diameter of bar

- 11. 11 Plain & Reinforced Concrete-1 Steel Bars

- 12. 12 Plain & Reinforced Concrete-1 Reinforcing Steel (contd..) Stress Strain Curve for Steel fy fy/2 fu Strain Stress Strain Hardeningyielding

- 13. 13 Plain & Reinforced Concrete-1 Reinforcing Steel (contd…) Steel Grade Designation Grade 300, fy = 300 MPa Grade 40 Grade 420, fy = 420 MPa Grade 60 Grade 520, fy = 520 MPa Grade 70 FPS Strain Grade 300 Grade 420 Grade 520 Stress For hot rolled steel bars Cold twisted steel bars are available in grade 420 For hot rolled steel bars

- 14. 14 Plain & Reinforced Concrete-1 Reinforcing Steel (contd..) For simplification the stress strain diagram is consider bilinear because after yielding cracks appear and concrete becomes in effective. Strain Stress Bilinear Curve