Fluid loss control additives

- 1. 1 Drilling Engineering TITLE: Fluid Loss Control Additives Author name: Mahmood Abdul-Jabbar hebah

- 2. 2 Acknowledgement “I would like to express my deepest appreciation to all those who provided me the possibility to complete this experiment. I would also like to show my deepest gratitude to my lecturer, Dr. Mahmood for giving me a good guideline for this experiment throughout numerous consultations. Moreover, I would like to appreciate the crucial role of the staff of APU University who gave the permission to use all equipment and necessary materials to complete the laboratory, and also a special thanks goes to my group who did well in the lab to success in this experiment. Last but not least, many thanks go to the head of the APU University whose have invested his full effort in guiding the students to achieving their goals.”

- 3. 3 Abstract “The aim of this experiment is to study the properties of loss control additives and its effect towards mud properties and to test what different additives do to the behaviour of drilling mud in terms of mud cake formation and filtrate loss. Guar gum has been used extensively in the oil industry as a viscosity for different applications due to its unique rheological properties. In this paper, we explore how the rheologic al behaviour of guar-based fluids can be used to control fluid loss. a range of instruments were used such Mud mixer, Mud balance, Thermometer, Remoter, Filter press, Graduated cylinder, pH meter / pH paper, Aging cell, Rotating oven and litter cup, Viscometer and Venire calliper. All these materials were used in order to understand the reasons why the mud varies and to know with precision the different properties that the fluids have. overall, at this experiment was conducted by using Bentonite of 15g, soda ash of 0.2g and guar gum of 0.3g mixed with water of 350ml to control the fluid loss of the mud. After that compare the results of experiment 1 with experiment 4.”

- 4. 4 Table of Contents Abstract ......................................................................................................................................3 1.0 Introduction.....................................................................................................................6 2.0 Objective .........................................................................................................................7 1.0 Theory and Literature Review ........................................................................................8 1.0 Apparatus & Materials:.................................................................................................10 1.1 Mud mixer.....................................................................................................................10 1.2 Weighing balance..........................................................................................................10 1.3 Mud Balance .................................................................................................................11 1.4 Rheometer .....................................................................................................................11 1.5 Thermometer.................................................................................................................12 1.6 Filter Press.....................................................................................................................12 1.7 Graduated Cylinder.......................................................................................................13 1.8 pH scale.........................................................................................................................13 1.9 Aging cell......................................................................................................................13 1.10 Vernier Caliper..............................................................................................................14 1.11 Materials used ...............................................................................................................14 3.0 Procedure ......................................................................................................................15 4.0 Results...........................................................................................................................16 5.0 Discussion.....................................................................................................................18 6.0 Conclusion ....................................................................................................................21 7.0 Reference ......................................................................................................................23

- 5. 5 List of figures Figure 1: Mud loss .....................................................................................................................6 Figure 2: Mud mixer ................................................................................................................10 Figure 3: Weighing balance. ....................................................................................................10 Figure 4:Mud Balance..............................................................................................................11 Figure 5:Rheometer..................................................................................................................11 Figure 6:Thermometer .............................................................................................................12 Figure 7: Filter Press................................................................................................................12 Figure 8: Graduated Cylinder ..................................................................................................13 Figure 9: pH scale ....................................................................................................................13 Figure 10: Aging Cell ..............................................................................................................13 Figure 11: Vernier Caliper .......................................................................................................14 Figure 12: Filtrate volume (cc) vs Time (mins).......................................................................19 List of tables Table 1:parameters used in this experiment.............................................................................17 Table 2: Comparison between experiment (4) and experiment (1) .........................................19

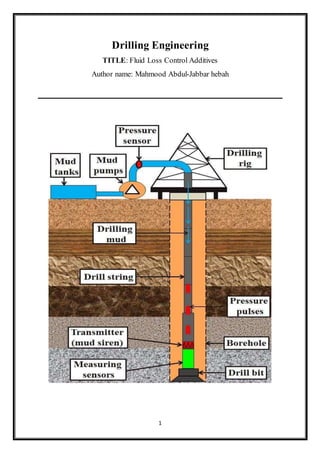

- 6. 6 1.0 Introduction “Fluid loss is one of the problems related to the drilling operation that will lead to the formation damage. It occurs when the formation pressure is lower than the hydrostatic pressure, thus let the invasion of the formation fluid taking place into the wellbore. Fluid loss from drilling mud during drilling process of borehole occurs when the drilling mud Loss or filtration can occur under static condition (e.g. during tripping) or dynamic (when mud is circulating in the hole). Fluid loss can cause several troubles. Firstly, invasion of filtrate may form a reduced permeability zone around the wellbore and may result in lower production rate and secondly, the filtrate may penetrate shale sections of the formation and cause swelling and subsequently sloughing into the wellbore which could lead to the pipe sticking problem. Additives are substances that are added to cement slurry in order to improve its quality and properties. The rate of leak off is of critical importance during drilling, completion operations and stimulation treatments, such as acid treatments and hydraulic fracturing. In all of these cases, fluid loss control has been achieved by two basic mechanisms:” 1. “Increasing the overall viscosity of the fluid using high polymer concentrations or by crosslinking the polymer.” 2. “Developing an internal and/or external filter cake using fluid loss additives to plug the pore-throats of the formation.” Figure 1: Mud loss

- 7. 7 “Both fluid loss control mechanisms may result in a loss of permeability when flow is initiated in the production mode. Furthermore, if fluid loss additives are not used properly, they can cause significant loss of permeability due to their plugging mechanism if they enter the formation. Guar gum has been used extensively as a viscosifier in the oil field for drilling, drill-in and completion fluids due to its unique rheological properties.7 In this paper we explore the rheological properties of Guar- based fluids in Berea sandstone rocks and how these properties can be used to control fluid loss. Prior attempts to simulate the flow of non-Newtonian fluids in porous media have not been entirely satisfactory because of the lack of an adequate correlation between the deformation rates inside the pore-throats and the velocity of the fluid. 3,8,9 Linear and radial flow tests were performed in 100 to 1,000 md rocks. The rheological behaviour of Guar gum was measured in linear core flow tests. This constitutive flow behaviour was used in a radial flow simulator to predict the invasion profile of Guar gum in the formation. The effect of fluid loss additives, such as starch and sized CaCO3 was also studied in radial flow leak-off tests. The damage left over associated with those additives was quantified and compared to pure Guar-based fluids.” “Filtrate is the liquid portion of the mud system that is driven through a filter cake and into the formation by the differential between the hydrostatic pressure of the mud column and the formation pressure. An experimental investigation was carried out to study the effect of fly ash on the rheological and filtration properties of water-based drilling fluids with the objective of the development of environmentally acceptable non- damaging and inhibitive drilling fluid system to drill sensitive formations. Initially, different drilling fluids combinations were prepared using carboxy methyl cellulose (low viscosity grade), polyanionic cellulose, Guar gum, and potassium chloride. (Western, 2012.).” 2.0 Objective “To study the properties of fluid loss control additives and its effect towards mud properties.”

- 8. 8 1.0 Theory and Literature Review “Fluid loss prevention is a key performance attribute of drilling fluids. For water-based drilling fluids, significant loss of water or fluid into the formation can cause irreversible changes in the drilling fluid properties, such as density and rheology, which can create instability in the borehole. Fluid loss control is measured in the laboratory according to a standard procedure for testing drilling fluids Mud circulation lost occurs when a certain amount of mud enters the formation during a drilling process. This process will create a thin layer of mud cake which can prevent further circulation lost. The equation to describe the flow through the mud cake is given below:” Where, q = Flowrate, cc/sec A = Mud cake cross sectional area, cm2 Δp = Pressure different across mud cake, psi μ = Mud viscosity, cp t = Mud cake thickness, cm k = Permeability, mD “For certain cross-sectional area, pressure different and constant viscosity, velocity is a function of mud cake thickness and mud cake permeability. For a static condition, the increase in mud cake thickness does not mean the flowrate is reduced. The flowrate also defined by mud cake permeability. For example, the filtration of attapulgite mud will give thicker mud cake but at the same time will give high filtration flowrate. Mud filtrate is a measure of solid material ability in the mud to form a thinner mud cake with low permeability. The thicker mud cake means more solid materials settled at formation wall and more filtration lost to the formation. The thicker mud cake normally easier to collapse and cause other problem during drilling activity such as the hole becomes smaller. The mud cake thickness normally measures in 1/32 inch or mm.” “Their property is defined as hard, soft, tough, rubbery or firm. Fluid lost through filtered medium at certain differential pressure, temperature, time and certain properties is defined by the equation below:”

- 9. 9 Where, Vw = Fluid lost, cc t = Time, minute Δp = Pressure different, psi μ = Filtrate viscosity, cp Vs = Volume of solid material in mud cake, cc k = Mud cake constant t = Time, minute μ = Filtrate viscosity, cp k = Mud cake constant By definition: “From this equation, fluid lost is proportional to square root of time, mud cake thickness, pressure different and inverse proportional towards filtrate viscosity. To calculate the fluid lost for a certain period, the equation below is used:” Where, V1 = Fluid lost at time t1, cc V2 = Fluid lost at time t2, cc “Mud filtration test can be done at low pressure of 100 psi and at room temperature for a period of 30 minutes. High pressure high temperature test can be done at pressure different of 500 psi and temperature up to 300 oF. There are many fluid lost control agents available and each of them has their own advantage and disadvantage. Among the fluid loss control additives available are:” a. Bentonite b. HEC (hydroxy-ethyl cellulose) c. Sodium carboxymethyl cellulose (CMC) d. Starch e. Guar gum f. Xanthan gum

- 10. 10 1.0 Apparatus & Materials: 1.1 Mud mixer “The mixer is used to prepare the mud sample with given some of bentonite or other chemicals that has been use in this experiment. Most drilling fluid formulations contain a base liquid and additives which must be dissolved or mechanically dispersed into the liquid to form a homogenous fluid.” Figure 2: Mud mixer 1.2 Weighing balance “Use to measure the amount of bentonite and barite, which is very sensitive measurement too.” Figure 3: Weighing balance.

- 11. 11 1.3 Mud Balance “A device to measure density (weight) of mud, cement or other liquid or slurry. A mud balance consists of a fixed-volume mud cup with a lid on one end of a graduated beam and a counterweight on the other end. A slider-weight can be moved along the beam, and a bubble indicates when the beam is level.” Figure 4:Mud Balance 1.4 Rheometer “The main objective is to find the apparent viscosity, plastic viscosity, yield point and true yield point for the given mud sample and gel strength.” Figure 5:Rheometer

- 12. 12 1.5 Thermometer “Using a thermometer to check your temperature in mud fluid after has been mad it by the mixer. A rise in your temperature is usually caused by an infection. When using any kind of thermometer, make sure you read and follow the instructions that come with the thermometer.” Figure 6:Thermometer 1.6 Filter Press “A filtration presses with the cylinder of the nitrogen use to measure the water on the mud by measuring the time it takes around 30 mins to measure how much liquid in this mud, also it measures the permeability and the water loss of the mud, therefore, the test is done to determine the thickness of the mud cake.” Figure 7: Filter Press

- 13. 13 1.7 Graduated Cylinder “The graduated cylinder uses to measure the water loses on the mud, by using the filter press, it has been measured the water losses at 30 mins each 5 mins it has been recorded. it will mention the data in brief below on the calculation.” Figure 8: Graduated Cylinder 1.8 pH scale “The ph paper use to determine the pH of the given sample.” Figure 9: pH scale 1.9 Aging cell “Container that is used to measure the mud cake thickness and filtrate volume.” Figure 10: Aging Cell

- 14. 14 1.10 Vernier Caliper “The Vernier use to measure the mud cake thickness of the mud.” Figure 11: Vernier Caliper 1.11 Materials used a. Bentonite b. Soda ash c. Water d. Barite e. Guar gum

- 15. 15 3.0 Procedure 1.2 Bentonite of 15g, soda ash of 0.2g and 350 cc of water were prepared and added to the 15g bentonite. Bentonite, soda ash and water were stirred and mixed thoroughly using mud mixer for 10 seconds. 1.3 Guar Gum of 0.3g was added into the mud, after that the machine switched on ageing to mix the mud that has been added with Guar Gum for 15 mins. 1.4 The mud properties were tested below, and the mud temperature was measured 1.5 Ph of the mud was measured using the ph scale paper. 1.6 Mud balance was used to measure the density the mud balance was checked to ensure it is cleaned and dried. The mud fluid was poured into the mud cup. Replaced the lid of the cup. Some of the drilling 4-mud escaped through the opening on the lid. Wipe off all excess mud from the opening and the side. 1.7 The mud balance was placed on the fulcrum and the rider was adjusted until the bubble balanced. 1.8 The mud density reading was recorded. 1.9 The viscometer supplied should have 6 speed settings: 3rpm, 6 rpm, 100rpm, 200rpm, 300rpm, and 600rpm. There is a diagram on how to operate each rpm mode in combination with 3 gear settings and 2 speed settings. 1.10The viscometer was switched on and measured the viscosity of the mud in different speed rpm and the process has repeated till all the rpm settings are done. 1.11Once the readings have been obtained, a gel strength test is to be done. 1.12 The viscometer was turned off for 10 seconds and the reading was obtained. 1.13The viscometer was turned on in 3 rpm and the reading was taken to be 5.5. After that the viscometer turned off for 10 minutes and the reading was obtained. 1.14The viscometer was turned on in 600 rpm for 10 seconds then turned off for 10 seconds and the reading was taken to be 6. 1.15After the gel strength readings were obtained, the mud was put into the mud cell, and fixed it into the base with strong Tighten screw and make sure all valves are closed. 1.16Injected nitrogen gas to the filter press at high pressure and the volume was measured in each step started from 5 minutes till 30 minutes. 1.17The mud thickness was measured by using Vernier caliper.

- 16. 16 4.0 Results “This section will be all about the results determined within this experiment in terms of density, pH, temperature, viscosity, plastic viscosity, apparent viscosity, yield strength, Gel strength, filtrate volume and mud cake thickness for a mud made of five ingredients, water (350ml), soda ach (0.2), bentonite (15g), barite(28.43g) and guar gum (0.2).” “The equation needed to calculate the plastic viscosity,” Plastic viscosity (cp)= [600 rpm reading] – [300 rpm reading] “The equation needed to calculate the Apparent viscosity,” Apparent viscosity (cp) = [600 rpm reading] / 2 “The equation needed to calculate the Yield Point,” Yield Point (Ib/1002) = [300rpm reading] – Plastic viscosity

- 17. 17 Table 1:parameters used in this experiment. No. Apparatus Property Result 1 Thermometer Temperature (°C) 30.9 °C 2 Mud Balance Density (ppg) 9.15 ppg 3 pH Meter / pH Paper pH Value 8 4 Rotational Viscometer Rheology (cP) 3 rpm 23 cP 6 rpm 23 cP 100 rpm 27 cP 200 rpm 30 cP 300 rpm 31 cP 600 rpm 36 cP Plastic Viscosity (cP) Plastic viscosity (cp)= [600 rpm reading] – [300 rpm reading] 36 – 31 = 5 cP Apparent Viscosity (cP) Apparent viscosity (cp) = [600 rpm reading] / 2 36 ÷ 2 = 18 cP Yield Point (lb/100 ft2) Yield Point (Ib/1002) = [300rpm reading] – Plastic viscosity 31 – 5 = 26 lb/100 ft2 Gel Strength (lb/100 ft2) 3(10 sec) 23 lb/100 ft2 3 (10 min) 25 lb/100 ft2 5 LPLT Filter Press Filtrate Volume (cc) 5 min 3.75 (cc) 10 min 5.6 (cc) 15 min 7.25 (cc) 20 min 8 (cc) 25 min 8.75 (cc) 30 min 10.25 (cc) 6 Vernier Caliper Mud cake Thickness (mm) 3.12 mm

- 18. 18 5.0 Discussion “The main objective of fluid loss control additives is to decrease the filtrate volume of the drilling mud that consist of 15g of bentonite, 0.2 soda ash, 0.2 guar gum and water of 350ml. to manipulate the physical properties of the mud to meet the requirements of less mud filtrate volume. The temperature of the both experiments were almost the same which is the room temperature. The density in experiment 3 was obtained to be 8.75 ppg however, it increased in experiment 4 to be 9.15 ppg due to adding the some additive such as bentonite, soda ach, and guar gum which increased the density of the bentonite. The addition of guar gum has affected the viscosity of the mud and that it increases due to the addition of guar gum in the volume of the mud. Plastic viscosity, apparent viscosity and yield point show an obvious increase as shown in table (2) from 3cp, 6.5 cp and 7 lb/100 ft2 to 7 cp , 27 cp and 20 lb/100 ft2 for plastic viscosity , apparent viscosity and yield point respectively. . The increase on the concentration of the mud ingredients increase the viscosity and the yield point. The plastic viscosity (PV) depends mainly on the concentration of solids and the viscosity of the base liquid and the yield point (YP) is a measure of the degree of non-Newtonian shear thinning behaviour of the mud system. It can be deduced from table (1). in experiment 4 the drilling mud behaved optimally as viscosifiers for the water-based mud systems under ambient temperature. In addition, on the other hand the drilling mud viscosity was less in experiment 3 at almost the same temperature which is 30C.” “Gel strength also got effected by the addition of the fluid loss agent and has increased from 4 lb/100 ft2 in 3 sec and 4 lb/100 ft2 in 10 mins to 23 lb/100 ft2 in 13 sec and 25 lb/100 ft2 in 10 mins. The gel strength that is showed in table (1) indicates that the guar gum was the reason that increased the gel strength in experiment 4. Fluid loss refers to the volume of filtrate lost to the permeable material due to the process of filtration. The filtrate mud shown in the table 1 and compared with experiment 3 the fluid loss in experiment 4 has been reduced more than the excrement number 3 table 2 below shows the cotorsion between excrement 3 and 4.”

- 19. 19 Table 2: Comparison between experiment (4) and experiment (1) Properties Experiment 3 Experiment 4 Temperature (°C) 30.3C 30.9C Density (ppg) 8.75ppg 9.15 ppg pH value 8 8 Rheology (3.6.100.200.300.600 rpm respectively) (cP) (4,4,6,8,10,15,) (23,23,27,30,31,36) Plastic Viscosity (cP) 5 5 Apparent Viscosity (cP) 7.5 18 Yield Point (lb/100 ft2) 5 26 Gel Strength (10 sec, 10 min) (lb/100 ft2) (4,4) (23,25) Filtrate Volume (5,10,15,20,25,30 min respectively) (cc) (5,7,9,14,17.5,19.5) ml (3.75,5.6,7.25,8,8.75,10.25 ) ml Mud thickness 1.65mm 3.12mm Figure 12: Filtrate volume (cc) vs Time (mins) “The obtained mud cake thickness was 3.12mm which consider to be a good shape that will not cause any sticking pipes or high torque situations. On the other hand, 0 2 4 6 8 10 12 0 5 10 15 20 25 30 35 Filtrate Volume (cc) Time (mins) LPLT Filter Press

- 20. 20 filtration process of drilling mud takes place as the drilling operation in carried out under a certain condition called overbalanced conditions, which means that the pressure of drilling mud injected is higher than the pressure of the formations. Due to this differential in pressure, drilling fluids will tend to be invaded into the porous part of the formation; where by the smaller particles of the drilling fluid will invade further into the formation, while the larger particles will accumulate at front surface of the pore size, creating a layer of mud cake. The measured mud thickness in experiment 3 was 1.65mm which less than experiment 4 due to the filtrate loss control agent (guar gum) that was used in experiment 4.”

- 21. 21 6.0 Conclusion “In this experiment, the drilling mud physical properties was modified by adding the fluid loss control agent (Guar gum). the density of excrement 3 was decreased comparing to experiment 4. The guar gum worked on changing the physical properties of the mud. The density increased from 8.75 to 9.15ppg. viscosity showed a clear indication of increasing by 26, 5 and 18% for yield point, plastic viscosity and apparent viscosity respectively. The obtained mud filtrate after 30 minutes was less than the mud filtrate in experiment 3 and it changed by 29.9% Therefore the mud thickness measured by using the Vernier caliper was obtained to be 1.65mm in experiment (3) and 3.12mm in experiment (4). Mud thickness of 3.12mm is a good shape of mud in the scale of API or HTHP fluid loss test that declare the safety and effectiveness of using the mud to avoid any stuck piping, causing mud cake and other problems. The experiment was successfully done, and it has achieved the aim of it as well as we learn how to deal with drilling fluid to reduce its density.”

- 22. 22 Errors “Human error occurred in the experiment that effected the main objective of the series of experiment to compare experiment with the coming after experiments that 40g of bentonite, 20 soda ash and 300 ml of water. On other hand in this experiment 15g of bentonite, 0.2 soda ash and 350ml of water. The change of amounts used affected the results of experiment two.” “Human error occurred in the experiment that the barite was forgotten and was not included in the mixer where this experiment was meant to be compared with experiment (4).” Suggestions “Drilling fluid has good fluid loss property, it will show a thin and impermeable mud cake. because at the surface condition the test demonstrates very good fluid loss and a very thin filter cake. When the drilling mud is in a downhole condition, wellbore temperature and pressure can dramatically change drilling fluid properties. The best way to test the fluid loss is to simulate wellbore condition at high pressure high temperature in order to see what the fluid loss property will be.” “Since this experiment is based on the bentonite density in this experiment which was 9.15 ppg at 30.9 degree Celsius, the change in temperature should considered due to its ability to affect density.”

- 23. 23 7.0 Reference Global driling fluid and chemicals LTD, n.d. Global driling fluid and chemicals LTD. [Online] Available at: http://www.oil-drilling-fluids.com/k2/oil-based-mud-additives- obm/obm-mud-thinner [Accessed 25 2 2021]. Oilfield Glossary, n.d. Oilfield Glossary. [Online] Available at: https://www.glossary.oilfield.slb.com/en/Terms/a/apparent_viscosity.aspx [Accessed 25 2 2021]. Philips, A., 2016. drillingformulas. [Online] Available at: http://www.drillingformulas.com/yield-point-yp-of-drilling-fluids/ [Accessed 25 2 2021]. Western, R. W. A. (. W. C. |. J. R. B. (., 2012. One Petro. [Online] Available at: https://www.onepetro.org/conference-paper/SPE-5005- MS?sort=&start=0&q=application+of+guar+gum+&from_year=&peer_reviewed=&publishe d_between=&fromSearchResults=true&to_year=&rows=25# [Accessed 25 2 2021].