Co cu mould and die -lulus-24julai2013

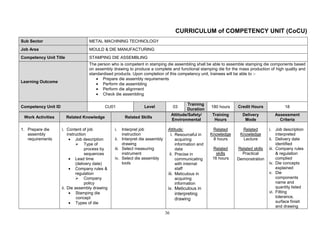

- 1. 36 CURRICULUM of COMPETENCY UNIT (CoCU) Sub Sector METAL MACHINING TECHNOLOGY Job Area MOULD & DIE MANUFACTURING Competency Unit Title STAMPING DIE ASSEMBLING Learning Outcome The person who is competent in stamping die assembling shall be able to assemble stamping die components based on assembly drawing to produce a complete and functional stamping die for the mass production of high quality and standardised products. Upon completion of this competency unit, trainees will be able to :- • Prepare die assembly requirements • Perform die assembling • Perform die alignment • Check die assembling Competency Unit ID CU01 Level 03 Training Duration 180 hours Credit Hours 18 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria 1. Prepare die assembly requirements i. Content of job instruction • Job description Type of process by sequences • Lead time (delivery date) • Company rules & regulation Company policy ii. Die assembly drawing • Stamping die concept • Types of die i. Interpret job instruction ii. Interpret die assembly drawing iii. Select measuring instrument iv. Select die assembly tools Attitude: i. Resourceful in acquiring information and data ii. Precise in communicating with internal staff iii. Meticulous in acquiring information iv. Meticulous in interpreting drawing Related Knowledge 8 hours Related skills 16 hours Related Knowledge Lecture Related skills Practical Demonstration i. Job description interpreted ii. Delivery date identified iii. Company rules & regulation complied iv. Die concepts explained v. Die components name and quantity listed vi. Fitting tolerance, surface finish and drawing

- 2. 37 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria Components names and quantity • Fitting tolerance • Surface finish • Drawing symbols iii. Measuring instrument iv. Type of tools • Allen key • Copper mallet symbols identified and explained vii. Measuring instrument functionality explained viii.Measuring instrument selected ix. Type of tools identified, listed and selected 2. Perform die assembling i. Types of die • Single die • Compound die • Progressive die • Hot stamping die ii. Types of stamping processes such as • Blanking • Piercing • Bending iii. Die components • Components name • Components function • Components material • Components dimension i. Select types of die ii. Select types of stamping processes iii. Identify type of die components iv. Check components dimension v. Identify types of die component material vi. Identify die references (datum) vii. Apply die fitting technique by sequence viii. Assemble upper die components ix. Assemble lower die components Attitude: i. Exacting when using measuring instrument ii. Alert to electrical supply iii. Attentive in handling die components and tools iv. Adhere to safe handling technique Safety: i. Ensure personal Related Knowledge 28 hours Related skills 56 hours Related Knowledge Lecture Related skills Practical Demonstration i. Types of dies selected ii. Types of stamping processes explained iii. Type of die components and standard parts listed iv. Type of die components and standard parts functions explained v. Die components material listed vi. Components dimension checked and

- 3. 38 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria iv. Type of standard parts and functions such as :- • Guide post • Guide bush • Spring • Stripper bolts • Dowel pin v. Type of die component materials such as: • SKD11/XW42 • SKS3/DF2 • SKD61 vi. Die references (datum) • Refer from drawing • Refer from die components • Mark components vii. Die fitting technique • Sliding fit • Tight fit viii. Upper die assembly • Guide bush to top plate • Punch to punch holder • Punch holder, backing plate to top plate ix. Lower die assembly • Guide post to protective equipment (PPE) meet Safety Regulation & Standard ii. Beware of sharp edges & pinch point confirmed vii. Die references (datum) checked and marked viii. Die fitting technique applied accordance with fitting requirements. ix. Upper die components assembled in accordance with assembly drawing x. Lower die components assembled in accordance with assembly drawing xi. Safety precaution applied in performing die assembling

- 4. 39 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria bottom plate • Die block, backing plate to bottom plate 3. Perform die alignment i. Die clearance • Die calculation ii. Type of gauges/ matching agent • Filler gauge • Shim • Blue matching • Die light iii. Die align method • Forming area Matching agents application Matching force application • Clearance area Guide post align to guide bush Filler gauge to check Punch and die clearance application iv. Transfer hole location v. Safety precaution on die alignment i. Identify die clearance ii. Identify gauges/ material agents iii. Select gauges/material agent iv. Apply die alignment method v. Align upper and lower die vi. Drill and ream dowel hole Attitude: i. Exacting when using measuring instrument ii. Alert to electrical supply iii. Attentive in handling die components and tools iv. Adhere to safe handling technique Safety: i. Ensure personal protective equipment (PPE) meet Safety Regulation & Standard ii. Beware of sharp edges & pinch point Related Knowledge 16 hours Related skills 40 hours Related Knowledge Lecture Related skills Practical Demonstration i. Die clearance identified and confirmed ii. Type of gauges / matching agents selected iii.Die alignment method applied iv.Upper and lower die set align demonstrated and confirmed. v. Dowel pin assembled vi.Safety precaution applied in performing die alignment

- 5. 40 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria 4. Check die assembling for verification i. Die assembly drawing • Type of stamping die • Die operation ii. Die set assembly iii. Die alignment process iv. Die assembly check sheet i. Interpret die assembly drawing ii. Check die set assembly iii. Check die alignment iv. Update die assembly check sheet Attitude: i. Resourceful in acquiring information and data ii. Precise in communicating with internal staff iii. Meticulous in acquiring information Related Knowledge 4 hours Related skills 12 hours Related Knowledge Lecture Related skills Practical Demonstration i. Die assembly drawing interpreted ii. Die components tighten confirmed iii. Die alignment confirmed iv. Die assembly check sheet updated

- 6. 41 Employability Skills Core Abilities Social Skills 01.07 Utilize database applications to locate and process information 01.08 Utilize spreadsheets applications to locate and process information 01.09 Utilize business graphic application to process information 01.10 Apply a variety of mathematical techniques 01.11 Apply thinking skills and creativity 02.09 Prepare flowcharts 02.10 Prepare reports and instructions 02.11 Convey information and ideas to people 03.09 Manage and improve performance of individuals 03.10 Provide consultation and counselling 03.11 Monitor and evaluate performance of human resources 03.12 Provide coaching/on-the job training 03.13 Develop and maintain team harmony and resolve conflicts 03.14 Facilitate and coordinate teams and ideas 03.15 Liaise to achieve identified outcomes 03.16 Identify and assess client/customer needs 03.17 Identify staff training needs and facilitate access to training 04.06 Allocate work 04.07 Negotiate acceptance and support for objectives and strategies 05.01 Implement project/work plans 05.02 Inspect and monitor work done and/or in progress 06.07 Develop and maintain networks 1. Communication skills 2. Conceptual skills 3. Interpersonal skills 4. Learning skills 5. Leadership skills 6. Multitasking and prioritising 7. Self-discipline 8. Teamwork

- 7. 42 Tools, Equipment and Materials (TEM) ITEMS RATIO (TEM : Trainees) 1. Job Instruction 2. Assembly drawing 3. Hand tools 4. Measuring instruments 5. Matching agent 6. Stamping die components 7. Die spotting machine 8. Inspection check sheet 9. Personal Protective Equipment (PPE) 1:1 1:1 1:1 1:1 1:1 1:5 1:25 1:1 1:1 References REFERENCES 1. Jerry Arnold (2000), Die Maker Handbook, Industrial Press, Inc., ISBN 0-831-3132-2 2. James A. Szumera (2003), The Metal Stamping Process, Industrial Press, Inc. ISBN 0-8311-3164-0 3. Vokota Boljanovic (1987), Die design fundamentals, Industrial Press Inc., ISBN 0-8311-1172-0 4. Donald A. Peterson (1994), Progressive Dies Principles and Practices of Design, Society of Manufacturing Engineers, ISBN 0-87263-448-5 5. Vukota Boljanovic (2004), Sheet Metal Forming Processes and Die Design, Industrial Press Inc., ISBN 0-8311-3182-9 6. David A Smith (1990), Die design Handbook, Society of manufacturing engineers (SME), ISBN 0-87263-375-6

- 8. 43 CURRICULUM of COMPETENCY UNIT (CoCU) Sub Sector METAL MACHINING TECHNOLOGY Job Area MOULD & DIE MANUFACTURING Competency Unit Title PLASTIC INJECTION MOULD ASSEMBLING Learning Outcome The person who is competent in plastic injection mould assembling shall be able to assemble plastic injection mould components based on assembly drawing to produce a complete and functional mould for the mass production of high quality and standardised products. Upon completion of this competency unit, trainees will be able to :- • Prepare plastic injection mould assembly requirements • Perform mould assembling • Perform mould matching • Check mould assembling Competency Unit ID CU02 Level 03 Training Duration 180 Hours Credit Hours 18 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria 1. Prepare plastic injection mould assembly requirements i. Job instruction • Job description Type of process by sequences • Lead time (delivery date) • Company rules & regulation Company policy ii. Mould assembly drawing • Mould concepts • Types of plastic injection moulds • Part names and quantity i. Interpret Job instruction ii. Interpret Mould assembly drawing iii. Select measuring instruments iv. Select type of tools Attitude: i. Meticulous in interpreting drawing ii. Exacting when using measuring instrument iii. Attentive in handling mould components and tools iv. Adhere to safe handling technique Related Knowledge 8 hours Related skills 16 hours Related Knowledge Lecture Related skills Practical Demonstration i. Type of job description interpreted ii. Delivery date identified iii. Company rules & regulation complied iv. Mould concepts explained v. Mould components name and quantity listed vi. Fitting tolerance, surface finish and drawing symbols

- 9. 44 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria • Fitting tolerance • Surface finish • Drawing symbols iii. Measuring instruments iv. Type of tools and function • Allen key • Copper mallet • Oil Stone Safety: i. Ensure personal protective equipment (PPE) meet Safety Regulation & Standard ii. Beware of sharp edges identified vii. Measuring instrument identified and selected viii.Type of tools identified, listed and selected 2. Perform mould assembling i. Types of plastic injection moulds and function • Two-plate mould With side core without side core • Three-plate mould With side core without side core • Hot runner system ii. Mould components and functions • Top plate • Core plate • Core insert • Cavity plate • Cavity insert • Spacer block • Ejector retainer plate • Ejector back plate i. Identify type mould and function ii. Identify element of mould and function iii. Identify type of mould standard parts and functions iv. Identify type of mould components material v. Check mould references (datum) vi. Assemble moving half vii. Assemble fixed half viii. Identify types of cooling system ix. Fix ejector system x. Fix feed system xi. Check mould perpendicular xii. Check mould levelling xiii. Apply Safety precaution Attitude: i. Meticulous in interpreting drawing ii. Exacting when using measuring instrument iii. Alert to electrical supply iv. Attentive in handling mould components and tools v. Adhere to safe handling technique Related Knowledge 28 hours Related skills 56 hours Related Knowledge Lecture Related skills Practical Demonstration i. Types of plastic injection moulds explained ii. Type of mould components and standard parts listed iii. Type of mould components and standard parts functions explained and differentiated iv. Mould components material listed v. Components dimension confirmed vi. Mould references (datum) confirmed

- 10. 45 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria • Bottom plate iii. Type of standard parts and functions such as :- • Locating ring • Sprue bush • Guide pillar • Guide bush • Spring • Ejector pin • Return pin iv. Type of mould components material such as: • Stavax • 718 • Rmax v. Mould references (datum) • Refer from drawing • Refer from components • Mark component vi. Mould fitting technique • Moving half Core insert Core plate Ejector plate Ejector pin Return pin Support plate Spacer block Bottom plate • Fixed half Safety: i. Ensure personal protective equipment (PPE) meet Safety Regulation & Standard ii. Beware of sharp edges & pinch point vii. Mould fitting technique demonstrated viii. Moving half assembled ix. Fixed half assembled x. Types of cooling system identified xi. Ejector system fixed xii. Feed system fixed xiii. Mould perpendicular checked and confirmed xiv. Mould Level checked and confirmed xv. Safety precaution applied in performing mould assembly

- 11. 46 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria Cavity insert Cavity plate Top plate Sprue bush Locating ring vii. Types of cooling system • Direct • Buffle • Spiral viii. Types of injector system • Pin • Stripper • Slant block ix. Feed system • Sprue • Runner • Gate x. Mould fitting method • Perpendicular • Flatness xi. Safety precaution on mould assembling 3. Perform mould matching i. Mould matching area ii. Type of gauges/ matching agent such as:- • Filler gauge • Shim • Blue matching • Lead • Modelling clay • Wax i. Identify mould matching area ii. Identify type of gauges/ matching agent iii. Select gauges/ matching agent iv. Identify mould parting line v. Identify Wall thickness Attitude: i. Exacting when using measuring instrument ii. Alert to electrical supply iii. Attentive in handling Related Knowledge 16 hours Related skills 40 hours Related Knowledge Lecture Related skills Practical Demonstration i. Mould matching area checked and confirmed ii. Type of gauges/ matching agent listed and selected iii. Mould parting

- 12. 47 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria iii. Mould matching method • Parting line • Wall thickness iv. Matching process • Matching agents • Die spot force • Surface contact area v. Safety precaution on mould matching vi. Apply matching agent vii. Apply matching force viii. Check match area transferred mould components and tools iv. Adhere to safe handling technique Safety: i. Ensure personal protective equipment (PPE) meet Safety Regulation & Standard ii. Beware of sharp edges & pinch point line identified and confirmed iv. Wall thickness identified v. Matching agent applied vi. Matching force applied vii. Matching area transfer, checked and confirmed viii. Safety precaution applied in performing mould matching 4. Check mould assembling i. Mould assembly drawing • Type of mould • Mould operation ii. Mould assembly set iii. Mould matching process iv. Mould assembly check sheet i. Interpret mould assembly drawing ii. Check mould set assembly iii. Check mould matching iv. Mould assembly check sheet Attitude: i. Resourceful in acquiring information and data ii. Precise in communicating with internal staff iii. Meticulous in acquiring information Related Knowledge 4 hours Related skills 12 hours Related Knowledge Lecture Related skills Practical Demonstration i. Mould assembly drawing interpreted ii. Mould components tighten confirmed iii. Mould matching checked and confirmed iv. Mould assembly check sheet updated

- 13. 48 Employability Skills Core Abilities Social Skills 01.07 Utilize database applications to locate and process information 01.08 Utilize spreadsheets applications to locate and process information 01.09 Utilize business graphic application to process information 01.10 Apply a variety of mathematical techniques 01.11 Apply thinking skills and creativity 02.09 Prepare flowcharts 02.10 Prepare reports and instructions 02.11 Convey information and ideas to people 03.09 Manage and improve performance of individuals 03.10 Provide consultation and counselling 03.11 Monitor and evaluate performance of human resources 03.12 Provide coaching/on-the job training 03.13 Develop and maintain team harmony and resolve conflicts 03.14 Facilitate and coordinate teams and ideas 03.15 Liaise to achieve identified outcomes 03.16 Identify and assess client/customer needs 03.17 Identify staff training needs and facilitate access to training 04.06 Allocate work 04.07 Negotiate acceptance and support for objectives and strategies 05.01 Implement project/work plans 05.02 Inspect and monitor work done and/or in progress 06.07 Develop and maintain networks 1. Communication skills 2. Conceptual skills 3. Interpersonal skills 4. Learning skills 5. Leadership skills 6. Multitasking and prioritising 7. Self-discipline 8. Teamwork

- 14. 49 Tools, Equipment and Materials (TEM) ITEMS RATIO (TEM : Trainees) 1. Job Instruction 2. Assembly drawing 3. Hand tools 4. Measuring instruments 5. Matching agent 6. Mould components 7. Die spotting machine 8. Inspection check sheet 9. Lifting equipment 10. Personal Protective Equipment (PPE) 1:1 1:1 1:1 1:1 1:1 1:5 1:25 1:1 1:25 1:1 References REFERENCES 1. Gunter Mennig (1998), Mould Making Handbook, Hanser / Gardner publication, ISBN 1-56990-261-5 2. Eric V. Buckleitner (1995), Plastics Mold Engineering Handbook, Chapman & Hall, ISBN 0-412-98951-4 3. Georg Menges/Paul Mahren (1993), How to make Injection Molds, Hanser Publishers, ISBN 3-446-16305-0 4. Donald V. Rosato/Dominick V. Roasato (1995), Injection Molding Handbook, Chapman & Hall, ISBN 0-412-99381-3 5. E. Lindner and P. Unger (1993), Injection Mold 108 Proven Designs, Hanser Publishers, ISBN 3-446-15682-8 6. Michael L. Berins (1991), Plastics Engineering Handbook, Chapman & Hall, ISBN 0-412-99181-0

- 15. 50 CURRICULUM of COMPETENCY UNIT (CoCU) Sub Sector METAL MACHINING TECHNOLOGY Job Area MOULD & DIE MANUFACTURING Competency Unit Title STAMPING DIE TRY-OUT & TROUBLESHOOT Learning Outcome The person who is competent in stamping die try-out & troubleshoot shall be able to setup the stamping die to machine to ensure the stamping die is functional in accordance with design requirements and to produce samples that meet product specifications. Upon completion of this competency unit, trainees will be able to :- • Prepare stamping die try-out requirements • Set up stamping die to machine • Set up machine parameters • Produce product sample • Inspect product sample • Check die try out and troubleshooting Competency Unit ID CU03 Level 03 Training Duration 160 Hours Credit Hours 16 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria 1. Prepare stamping die try-out requirements i. Content of job instruction • Job description Type of process by sequences • Lead time (delivery date) • Company rules & regulation Company policy ii. Product drawing • Product dimensions • Product material iii. Measuring instruments i. Interpret job instruction ii. Interpret product drawing iii. Select measuring instruments iv. Select type of tools v. Identify stamping die vi. Identify stamping machine specification vii. Identify stamping machine and Attitude: i. Resourceful in acquiring information and data ii. Precise in communicating with internal staff iii. Meticulous in acquiring information iv. Meticulous in interpreting drawing Related Knowledge 8 hours Related skills 16 hours Related Knowledge Lecture Related skills Practical Demonstration i. Job instruction interpreted ii. Product dimensions identified iii. Product material selected iv. Measuring instrument selected v. Type of tools listed and selected vi. Type of stamping die identified and selected vii. Stamping machine

- 16. 51 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria • Micrometer • Vernier calliper • Pin gauges iv. Type of tools such as: • Allen key • Copper mallet • Oil stone v. Type of stamping die vi. Stamping machine & accessories • Machine specification • Machine function • Type of accessories accessories functional specification identified and selected viii. Stamping machine function explained 2. Set up stamping die on stamping machine i. Stamping machine and accessories • Machine tonnage • Machine Shut- height • Machine and accessories conditions • Type of feeders ii. Type of clamping devices iii. Stamping die setting method • With shank • Without shank • Clamping technique iv. Machine safety precaution i. Check stamping machine and accessories conditions ii. Select stamping machine and accessories iii. Select type of feeders iv. Select type of clamping devices v. Set stamping die on machine Attitude: i. Exacting when using measuring instrument ii. Alert to electrical supply iii. Attentive in handling die components and tools iv. Adhere to safe handling technique Safety: i. Ensure personal protective Related Knowledge 16 hours Related skills 32 hours Related Knowledge Lecture Related skills Practical Demonstration i. Machine & accessories conditions confirmed ii. Stamping machine tonnage and shut- height selected and confirmed iii. Type of feeders selected iv. Type of clamping devices selected v. Stamping die clamp to machine secured vi. Machine safety precaution complied in performing die setup

- 17. 52 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria equipment (PPE) meet Safety Regulation & Standard ii. Beware of sharp edges & pinch point 3. Set up machine parameters i. Die shut height • Top dead centre • Bottom dead centre ii. Machine pressure • Air pressure inlet • Machine tonnage • Cushion pressure iii. Test run • Stamping die condition • Stamping machine condition iv. Feeder system • Manual feeder • Roller • Transfer v. Safety devices • Sensor • Mechanical safety devices i. Set die shut height ii. Set machine pressure iii. Perform test run iv. Check stamping die functionality v. Confirm machine condition vi. Set feeder system vii. Set safety devices Attitude: i. Resourceful in acquiring information and data ii. Alert to electrical supply iii. Attentive in handling die and tools iv. Adhere to safe handling technique Related Knowledge 8 hours Related skills 16 hours Related Knowledge Lecture Related skills Practical Demonstration i. Top dead centre identified ii. Bottom dead centre confirmed iii. Air pressure inlet adjusted and confirmed iv. Machine tonnage set v. Cushion pressure set and confirmed vi. Stamping die functionality checked and confirmed vii. Stamping machine condition confirmed viii. Feeder system set ix. Safety devices set

- 18. 53 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria 4. Produce product sample i. Product material • Type of material • Material specification ii. Product Sample • Product appearance • Product profile iii. Type of product defect • Burrs • Wrinkle • Crack iv. Causes of product defects v. Corrective actions • Rework Touch up Re-grind Re-machining • Replace i. Select strip material ii. Produce product sample iii. Check product abnormalities iv. Identify type of product defect v. Identify type of causes vi. Identify problem solving vii. Perform corrective actions Attitude: i. Meticulous in interpreting drawing ii. Exacting when using measuring instrument iii. Alert to electrical supply iv. Attentive in handling die components and tools v. Adhere to safe handling technique Safety: i. Ensure personal protective equipment (PPE) meet Safety Regulation & Standard ii. Beware of sharp edges & pinch point Related Knowledge 8 hours Related skills 24 hours Related Knowledge Lecture Related skills Practical Demonstration i. Product material selected ii. Product sample produced iii. Type of product abnormality checked, identified and listed iv. Type of causes listed v. Problem solving listed and explained vi. Corrective actions applied vii. Safety precaution applied during producing product sample

- 19. 54 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria 5. Inspect product sample i. Product Drawing • Product dimension • Product profile • Product specification ii. Type of measuring instrument • Micro meter • Vernier calliper • Go No Go gauge • Profile projector iii. Product sample • Dimension • Profile • Appearance iv. Product inspection check sheet i. Interpret product drawing ii. Select type of measuring instrument iii. Check product sample dimension iv. Check product sample profile v. Check product sample appearance vi. Fill up product inspection check sheet Attitude: i. Meticulous in interpreting drawing ii. Exacting when using measuring instrument iii. Alert to electrical supply iv. Attentive in handling mould components and tools v. Adhere to safe handling technique Safety: i. Ensure personal protective equipment (PPE) meet Safety Regulation & Standard ii. Beware of sharp edges Related Knowledge 4 hours Related skills 8 hours Related Knowledge Lecture Related skills Practical Demonstration i. Product drawing interpreted ii. Type of measuring instrument listed and functional described iii. Product sample dimension checked and confirmed iv. Product sample profile checked and confirmed v. Product sample appearance checked and confirmed vi. Measurement method applied vii. Product inspection check sheet Filled up

- 20. 55 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria 6. Check die try out & troubleshoot i. Stamping Die set up ii. Machine parameter set up iii. Product quality • Product sample • Product check sheet iv. Die try out check sheet i. Check stamping die set up ii. Confirmed machine parameter set up iii. Check product quality iv. Update die try out check sheet Attitude: i. Resourceful in acquiring information and data ii. Precise in communicating with internal staff iii. Meticulous in acquiring information Related Knowledge 4 hours Related skills 16 hours Related Knowledge Lecture Related skills Practical Demonstration i. Stamping Die set up checked and clamp secured ii. Machine parameter set up confirmed iii. Product quality checked and confirmed iv. Die try out check sheet updated

- 21. 56 Employability Skills Core Abilities Social Skills 01.07 Utilize database applications to locate and process information 01.08 Utilize spreadsheets applications to locate and process information 01.09 Utilize business graphic application to process information 01.10 Apply a variety of mathematical techniques 01.11 Apply thinking skills and creativity 02.09 Prepare flowcharts 02.10 Prepare reports and instructions 02.11 Convey information and ideas to people 03.09 Manage and improve performance of individuals 03.10 Provide consultation and counselling 03.11 Monitor and evaluate performance of human resources 03.12 Provide coaching/on-the job training 03.13 Develop and maintain team harmony and resolve conflicts 03.14 Facilitate and coordinate teams and ideas 03.15 Liaise to achieve identified outcomes 03.16 Identify and assess client/customer needs 03.17 Identify staff training needs and facilitate access to training 04.06 Allocate work 04.07 Negotiate acceptance and support for objectives and strategies 05.01 Implement project/work plans 05.02 Inspect and monitor work done and/or in progress 06.07 Develop and maintain networks 1. Communication skills 2. Conceptual skills 3. Interpersonal skills 4. Learning skills 5. Leadership skills 6. Multitasking and prioritising 7. Self-discipline 8. Teamwork

- 22. 57 Tools, Equipment and Materials (TEM) ITEMS RATIO (TEM : Trainees) 1. Job Instruction 2. Assembly drawing 3. Hand tools 4. Measuring instruments 5. Matching agent 6. Stamping die components 7. Die spotting machine 8. Inspection check sheet 9. Personal Protective Equipment (PPE) 1:1 1:1 1:1 1:1 1:1 1:5 1:25 1:1 1:1 References REFERENCES 1. Jerry Arnold (2000), Die Maker Handbook, Industrial press, Inc., ISBN 0-831-3132-2 2. James A Szumera (2003), The Metal Stamping Process, Industrial press, Inc. ISBN 0-8311-3164-0 3. Richard M. Lead (2002), Tool and Die Making Troubleshoot, Society of Manufacturing Engineers, ISBN 978-0-87263-643-9 4. Vokota Boljanovic (1987), Die design fundamentals, Industrial Press Inc., ISBN 0-8311-1172-0 5. Donald A. Peterson (1994), Progressive Dies Principles and Practices of Design, Society of Manufacturing Engineers, ISBN 0-87263-448-5 6. Vukota Boljanovic (2004), Sheet Metal Forming Processes and Die Design, Industrial Press Inc., ISBN 0-8311-3182-9 7. David A Smith (1990), Die design Handbook, Society of manufacturing engineers (SME), ISBN 0-87263-375-6

- 23. 58 CURRICULUM of COMPETENCY UNIT (CoCU) Sub Sector METAL MACHINING TECHNOLOGY Job Area MOULD & DIE MANUFACTURING Competency Unit Title PLASTIC INJECTION MOULD TRY-OUT & TROUBLESHOOT Learning Outcome The person who is competent in Plastic Injection Mould Try-Out & Troubleshoot shall be able to setup injection moulding machine to ensure the mould is functional in accordance with design requirements and to produce samples that meet product specifications. Upon completion of this competency unit, trainees will be able to :- • Prepare plastic injection mould try-out requirements • Set up plastic injection mould to machine • Carry out pre-heating • Set up machine parameters • Produce product sample • Inspect product sample • Perform surface finishing process • Check mould try out and troubleshooting Competency Unit ID CU04 Level 03 Training Duration 240 Hours Credit Hours 24 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria 1. Prepare plastic injection mould try-out requirements i. Content of job instruction • Job description Type of process by sequences • Lead time (delivery date) • Company rules & regulation Company policy ii. Product drawing • Product i. Interpret job instruction ii. Interpret product drawing iii. Select measuring instrument iv. Identify type of tools v. Select type of tools vi. Identify plastic injection mould vii. Identify moulding machine specification viii. Identify moulding machine and Attitude: i. Resourceful in acquiring information and data ii. Precise in communicati ng with internal staff iii. Meticulous in acquiring information Related Knowledge 8 hours Related skills 16 hours Related Knowledge Lecture Related skills Practical Demonstration i. Job instruction interpreted ii. Product dimensions identified iii. Product material selected iv. Measuring instrument selected v. Type of tools listed and selected

- 24. 59 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria dimensions • Product material iii. Measuring instrument • Micrometer • Vernier calliper iv. Type of tools such as: • Allen key • Copper mallet • Oil stone v. Type of plastic injection mould vi. Moulding machine • Machine specification • Machine function • Type of auxiliary accessories functional vi. Type of plastic injection mould identified vii.Moulding machine specification identified viii. Moulding machine function explained 2. Set up mould on injection moulding machine i. Moulding machine • Machine tonnage • Mould platen and tie-bar size • Machine and auxiliary condition ii. Type of clamping devices iii. Plastic injection mould preparation set up • Nozzle radius • Nozzle length • Locating ring size • Resin • Cooling system • Hydraulic Core System i. Select moulding machine and auxiliary ii. Select type of clamping devices iii. Check mould preparation set up iv. Set plastic injection mould to machine v. Comply machine safety precaution Attitude: i. Alert to electrical supply ii. Attentive in handling die components and tools iii. Adhere to safe handling technique Safety: i. Ensure personal protective equipment (PPE) meet Related Knowledge 16 hours Related skills 32 hours Related Knowledge Lecture Related skills Practical Demonstration i. Machine tonnage identified and confirmed ii. Moulding machine & auxiliary conditions checked and confirmed iii. Type of clamping devices selected iv. Mould preparation set up checked and

- 25. 60 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria • Ejector machine system Location Size Length iv. Mould set up • Mould align to machine • Machine nozzle align to mould sprue bush • Mould clamping v. Machine safety precaution Safety Regulation & Standard ii. Beware of sharp edges & pinch point confirmed v. Plastic injection mould set to machine secured vi. Machine safety precaution complied in performing mould setup 3. Carry out pre- heating i. Product material (Resin) • Type of resin Polypropylene (PP) Acrylonitrile Butadene Styrene (ABS) Polyamide (PA6GF Nylon) Master batch • Resin specification Melt temperature Melting point Shrinkage • Material characteristic Flow Speed i. Identify type of resin ii. Identify resin specification iii. Identify material (resin) characteristic iv. Set temperature range v. Set pre-heat duration vi. Carry out resin pre- heating vii. Carry out machine pre-heating viii. Carry out mould pre- heating Attitude: i. Meticulous in interpreting drawing ii. Alert to electrical supply iii. Attentive in handling mould components and tools iv. Adhere to safe handling technique Safety: iii. Ensure personal protective equipment Related Knowledge 8 hours Related skills 16 hours Related Knowledge Lecture Related skills Practical Demonstration i. Type of resin identified ii. Resin specification identified iii. Resin (material) characteristic identified iv. Temperature set v. Pre-heat duration set vi. Resin pre- heating carried out vii. Machine pre- heating carried out viii. Mould pre- heating carried

- 26. 61 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria Strength Stiffness ii. Pre-heating process requirements • Temperature range • Duration iii. Resin pre-heating iv. Machine pre-heating v. Mould pre-heating (PPE) meet Safety Regulation & Standard out ix. Safety precaution applied during pre-heating process 4. Set up machine parameters i. Clamping adjustment • Clamping force • Ejector stroke • Mould opening ii. Part weight iii. Dosage/metering iv. Injection speed v. Injection pressure vi. Cooling time vii. Safety devices • Sensor • Mechanical i. Set clamping force ii. Set ejector stroke iii. Set mould opening iv. Identify Part weight v. Set dosage / metering vi. Set injection speed vii. Adjust injection pressure viii. Set cooling time ix. Set safety devices Attitude: i. Alert to electrical supply ii. Attentive in handling mould components and tools iii. Adhere to safe handling technique Safety: i. Ensure personal protective equipment (PPE) meet Safety Regulation & Standard Related Knowledge 8 hours Related skills 16 hours Related Knowledge Lecture Related skills Practical Demonstration i. Clamping force set demonstrated ii. Ejector stroke set demonstrated iii. Mould opening set demonstrated iv. Part weight identified v. Dosage / metering set vi. Injection speed pressure set vii. Injection pressure adjusted viii. Cooling time Set ix. Safety devices set

- 27. 62 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria 5. Produce product sample i. Product resin ii. Plastic injection mould conditions iii. Material purging • Material viscosity • Discard remaining iv. Product sample condition / abnormalities • Sink mark • Burn mark • Flushing • Short shot v. Causes of product defects vi. Corrective actions • Rework Touch up Re-grind Re-machining • Replace i. Confirm product resin ii. Check plastic injection mould condition iii. Measure material temperature iv. Check material viscosity v. Ensure discard remaining vi. Carry out material purging vii. Produce product sample viii. Check Product abnormalities ix. Identify type of product defect x. Identify type of causes xi. Identify problem solving xii. Perform corrective actions Attitude: i. Meticulous in interpreting drawing ii. Exacting when using measuring instrument iii. Alert to electrical supply iv. Attentive in handling mould components and tools v. Adhere to safe handling technique Safety: i. Ensure personal protective equipment (PPE) meet Safety Regulation & Standard ii. Beware of sharp edges & pinch point Related Knowledge 8 hours Related skills 24 hours Related Knowledge Lecture Related skills Practical Demonstration i. Product resin checked and confirmed ii. Plastic injection mould conditions checked and confirmed iii. Material temperature confirmed iv. Material viscosity checked v. Discard remaining ensured vi. Product sample defect identified vii. Type of defect listed viii. Problem solving listed and explained ix. Corrective actions demonstrated x. Safety precaution applied during producing product sample

- 28. 63 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria 6. Inspect product sample i. Type of measuring instrument • Micro meter • Vernier calliper • Go No Go gauge • Profile projector ii. Product sample • Dimension • Profile • Appearance iii. Product inspection check sheet i. Select type of measuring instrument ii. Check product sample appearance iii. Check product sample profile iv. Check product sample dimension v. Fill up product inspection check sheet Attitude: i. Meticulous in interpreting drawing ii. Exacting when using measuring instrument iii. Alert to electrical supply iv. Attentive in handling mould components and tools v. Adhere to safe handling technique Safety: i. Ensure personal protective equipment (PPE) meet Safety Regulation & Standard ii. Beware of sharp edges Related Knowledge 4 hours Related skills 8 hours Related Knowledge Lecture Related skills Practical Demonstration i. Type of measuring instrument listed and functional described ii. Product sample dimension identified iii. Product sample profile identified iv. Product sample appearance identified v. Measurement method applied vi. Product inspection check sheet Filled up

- 29. 64 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria 7. Perform surface finishing process i. Type of surface finish • Polishing • Surface finish treatment Texture Etching Chrome plating ii. Surface area iii. Type of abrasive paper and grit size iv. Polishing kits and grit size v. Polishing technique • Selection of grit size • Polishing direction vi. Dispose schedule waste i. Identify type of surface finish ii. Arrange for surface finish treatment iii. Identify surface area to be polished iv. Select abrasive paper and grit size v. Select polishing kits and grit size vi. Carry out polishing process vii. Practice waste disposal Attitude: i. Exacting when using measuring instrument ii. Alert to electrical supply iii. Attentive in handling mould components and tools iv. Adhere to safe handling technique Safety: i. Ensure personal protective equipment (PPE) meet Safety Regulation & Standard ii. Beware of sharp edges iii. Comply with Environmental Management System (EMS) Related Knowledge 16 hours Related skills 40 hours Related Knowledge Lecture Related skills Practical Demonstration i. Type of surface finish identified and confirmed ii. Surface finish treatment arranged iii. Surface area identified and confirmed iv. Abrasive paper and grit size selected v. Polishing kits and grit size selected vi. Polishing process carried out vii. Polishing technique demonstrated viii. waste disposal procedure are adhered to ix. Polishing process in compliance with Environmental Management System (EMS)

- 30. 65 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria 8. Check mould try out and troubleshoot i. Plastic injection mould set up ii. Machine parameter set up iii. Product sample iv. Product inspection check sheet v. Mould surface finish vi. Mould try out check sheet i. Check plastic injection mould set up ii. Confirm machine parameter set up iii. Check product sample quality iv. Check mould surface finish v. Update mould try out check sheet Attitude: i. Resourceful in acquiring information and data ii. Precise in communicati ng with internal staff iii. Meticulous in acquiring information Related Knowledge 4 hours Related skills 16 hours Related Knowledge Lecture Related skills Practical Demonstration i. Plastic injection mould set up checked and clamp secured ii. Machine parameter set up confirmed iii. Product sample quality checked iv. Mould surface finish checked and confirmed v. Mould try out check sheet updated

- 31. 66 Employability Skills Core Abilities Social Skills 01.07 Utilize database applications to locate and process information 01.08 Utilize spreadsheets applications to locate and process information 01.09 Utilize business graphic application to process information 01.10 Apply a variety of mathematical techniques 01.11 Apply thinking skills and creativity 02.09 Prepare flowcharts 02.10 Prepare reports and instructions 02.11 Convey information and ideas to people 03.09 Manage and improve performance of individuals 03.10 Provide consultation and counselling 03.11 Monitor and evaluate performance of human resources 03.12 Provide coaching/on-the job training 03.13 Develop and maintain team harmony and resolve conflicts 03.14 Facilitate and coordinate teams and ideas 03.15 Liaise to achieve identified outcomes 03.16 Identify and assess client/customer needs 03.17 Identify staff training needs and facilitate access to training 04.06 Allocate work 04.07 Negotiate acceptance and support for objectives and strategies 05.01 Implement project/work plans 05.02 Inspect and monitor work done and/or in progress 06.07 Develop and maintain networks 1. Communication skills 2. Conceptual skills 3. Interpersonal skills 4. Learning skills 5. Leadership skills 6. Multitasking and prioritising 7. Self-discipline 8. Teamwork

- 32. 67 Tools, Equipment and Materials (TEM) ITEMS RATIO (TEM : Trainees) 1. Job Instruction 2. Plastic injection mould 3. Moulding machine 4. Mould assembly drawing 5. Product drawing 6. Measuring instruments 7. Hand tools 8. Product material (resin) 9. Polishing kits 10. Check sheet 11. Personal Protective Equipment (PPE) 1 : 1 1 : 5 1 : 5 1 : 1 1 : 1 1 : 5 1 : 1 As required As required 1 : 1 1 : 1 References REFERENCES 1. Richard M. Lead (2002), Tool and Die Making Troubleshoot, Society of Manufacturing Engineers, ISBN 978-0-87263-643-9 2. Gunter Mennig (1998), Mould Making Handbook, Hanser / Gardner publication, ISBN 1-56990-261-5 3. Eric V. Buckleitner (1995), Plastics Mold Engineer Handbook, Chapman & Hall, ISBN 0-412-98951-4 4. Georg Menges/Paul Mahren (1993), How to make Injection Molds, Hanser Publishers, ISBN 3-446-16305-0 5. Donald V. Rosato/Dominick V (1995), Roasato, Injection Molding Handbook, Chapman & Hall, ISBN 0-412-99381-3 6. E. Lindner and P. Unger (1993), Injection Mold 108 Proven Designs, Hanser Publishers, ISBN 3-446-15682-8 7. Michael L. Berins (1991), Plastics Engineering Handbook, Chapman & Hall, ISBN 0-412-99181-0

- 33. 68 CURRICULUM of COMPETENCY UNIT (CoCU) Sub Sector METAL MACHINING TECHNOLOGY Job Area MOULD & DIE MANUFACTURING Competency Unit Title STAMPING DIE MAINTENANCE Learning Outcome The person who is competent in Stamping Die Maintenance shall be able to carry out preventive and corrective maintenance exercise that ensures the stamping die is in good operational condition. Upon completion of this competency unit, trainees will be able to :- • Prepare stamping die maintenance requirements • Carry out stamping die maintenance activities • Perform stamping die assembly activities • Perform stamping die try-out • Inspect product sample • Check stamping die maintenance activity Competency Unit ID CU05 Level 03 Training Duration 180 Hours Credit Hours 18 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria 1. Prepare stamping die maintenance requirements i. Job instruction • Assembly drawing • Job description Type of process by sequences • Lead time (delivery date) • Company rules & regulation Company policy ii. Die maintenance schedule • Type of maintenance (corrective/ i. Interpret Job instruction ii. Interpret die maintenance schedule iii. Identify type of Die iv. Identify type of stamping processes v. Select maintenance tools vi. Obtain product sample Attitude: i. Resourceful in acquiring information and data ii. Precise in communicating with internal staff iii. Meticulous in acquiring information Related Knowledge 8 hours Related skills 16 hours Related Knowledge Lecture Related skills Practical Demonstration i. Assembly drawing interpreted ii. Job description explained iii. Delivery date identified iv. Company rule & regulation complied v. Die maintenance schedule interpreted vi. Type of die

- 34. 69 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria preventive) • Replaced parts. • Modified part iii. Product samples • Product defect • Master sample iv. Type of Die • Single die • Compound die • Progressive die v. Types of stamping processes such as • Blanking • Piercing • Bending vi. Type of tools and consumables • allen key, • copper mallet • shim • abrasive paper • oil stone listed vii. Type of stamping process explained viii. Type of tools listed and selected ix. Product samples obtained

- 35. 70 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria 2. Carry out stamping die maintenance activities i. Defected product sample • Type of defect • Type of abnormality ii. Type of die components such as:- • Upper plate • Punch plate • Stripper plate • Punch block • Die block • Lower plate iii. Type of die standard parts such as :- • Guide post • Guide bush • Spring • Stripper bolts iv. Type of die component defects such as :- • Scratch • Dented • Wear and tear v. Counter problem techniques such as:- • Touch up • Regrind • Replace i. Identify type of product defect ii. Dismantle die components iii. Dismantle die standard parts iv. Identify die components defect v. Identify die standard parts defect vi. Carry out touch up die component vii. Carry out regrind die component viii. Carry out replacement of die component Attitude: i. Meticulous in interpreting drawing ii. Exacting when using measuring instrument iii. Alert to electrical supply iv. Attentive in handling die components and tools v. Adhere to safe handling technique Safety: i. Ensure personal protective equipment (PPE) meet Safety Regulation & Standard ii. Beware of sharp edges & pinch point Related Knowledge 16 hours Related skills 40 hours Related Knowledge Lecture Related skills Practical Demonstration i. Type of product defect listed ii. Die components listed iii. Die standard parts listed iv. Die component defects identified and listed v. Touch up die component performed vi. Regrind die component performed vii. Replacement of die component performed viii. Safety precaution applied in performing die maintenance

- 36. 71 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria 3. Perform stamping die assembly activities i. Assembly drawing • Drawing symbol • Die datum • Upper die set • Lower die set ii. Die assemble technique • Upper die set assembly Guide post to top plate Punch to punch holder Punch holder, backing plate to top plate • Lower die set assemble Guide bush to bottom plate Die block, backing plate to bottom plate iii. Die assembly method • Perpendicular • Flatness iv. Die alignment • Matching agent • Matching surface area i. Interpret assembly drawing ii. Apply die assembly technique iii. Perform die assembly iv. Perform die alignment Attitude: i. Meticulous in interpreting drawing ii. Exacting when using measuring instrument iii. Alert to electrical supply iv. Attentive in handling die components and tools v. Adhere to safe handling technique Safety: i. Ensure personal protective equipment (PPE) meet Safety Regulation & Standard ii. Beware of sharp edges & pinch point Related Knowledge 8 hours Related skills 24 hours Related Knowledge Lecture Related skills Practical Demonstration i. Assembly drawing interpreted ii. Die assembly technique demonstrate iii. Die assembly performed iv. Matching agent selected v. Matching surface area confirmed vi. Die alignment performed xii. Safety precaution applied in performing die assembly

- 37. 72 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria 4. Perform stamping die try-out i. Stamping machine and accessories • Machine tonnage • Machine and accessories conditions • Type of feeders ii. Type of clamping devices iii. Stamping die setting method iv. Die shut height • Top dead centre • Bottom dead centre v. Safety devices • Sensor • Mechanical safety devices vi. Test run • Stamping die condition • Stamping machine condition vii. Feeder system • Manual feeder • Roller • Transfer viii. Product material • Type of material • Material specification ix. Die conditions x. Product sample i. Identify stamping machine and accessories ii. Identify type of clamping devices iii. Clamp stamping die to machine iv. Set die shut height v. Set safety devices vi. Perform test run vii. Set feeder system viii. Select product material ix. Check die conditions x. Produce product sample xi. Identify type of product defect xii. Apply countermeasure xiii. Apply corrective actions Attitude: i. Meticulous in interpreting drawing ii. Exacting when using measuring instrument iii. Alert to electrical supply iv. Attentive in handling die components and tools v. Adhere to safe handling technique Safety: i. Ensure personal protective equipment (PPE) meet Safety Regulation & Standard ii. Beware of sharp edges & pinch point Related Knowledge 16 hours Related skills 24 hours Related Knowledge Lecture Related skills Practical Demonstration i. Machine tonnage confirmed ii. Machine and accessories conditions checked and confirmed iii. Type of feeders selected iv. Type of clamping devices selected v. Stamping die set to machine secured vi. Die shut height checked and confirmed vii. Safety devices set viii. Die conditions checked and confirmed ix. Feeder system set x. Product material confirmed xi. Product sample produced xii. Type of

- 38. 73 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria xi. Type of stamping fault and countermeasure such as:- • Burrs • Wrinkle • Crack xii. Causes of product defects xiii. Corrective actions product defect identified xiii. Counter measure listed xiv. Corrective actions applied xv. Safety precaution applied in performing die try out 5. Inspect product sample i. Type and usage of measuring instrument • Micro meter • Vernier calliper • Go No Go gauge • Profile projector ii. Product sample • Dimension • Profile • Appearance iii. Product inspection check sheet i. Select type of measuring instrument ii. Identify product sample dimension iii. Identify product sample profile iv. Identify product sample appearance v. Apply measurement method vi. Fill up product inspection check sheet Attitude: i. Resourceful in acquiring information and data ii. Precise in communicatin g with internal staff iii. Meticulous in acquiring information iv. Exacting when using measuring instrument Related Knowledge 4 hours Related skills 8 hours Related Knowledge Lecture Related skills Practical Demonstration i. Type of measuring instrument listed and functional described ii. Product sample dimension identified iii. Product sample profile identified iv. Product sample appearance identified v. Measurement method applied vi. Product inspection check sheet filled up

- 39. 74 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria 6. Check stamping die maintenance activity i. Type of die maintenance • Corrective • preventive ii. Assembly drawing • Type of die • Type of components iii. Product drawing • Product specification iv. Product inspection check sheet • Product inspection result • Die components condition • Die try –out result v. Die maintenance check sheet i. Confirm type maintenance ii. Confirm die to be maintain iii. Confirm die component defects iv. Confirm die assembly activities v. Confirm die try-out vi. Confirm Product quality vii. Update die maintenance check sheet Attitude: i. Resourceful in acquiring information and data ii. Precise in communicatin g with internal staff iii. Meticulous in acquiring information Related Knowledge 4 hours Related skills 12 hours Related Knowledge Lecture Related skills Practical Demonstration i. Type of maintenance Confirmed ii. Die to be maintain confirmed iii. Die component defects listed iv. Die assembly activities confirmed v. Die try-out confirmed vi. Product quality assured vii. Die maintenance check sheet updated

- 40. 75 Employability Skills Core Abilities Social Skills 01.07 Utilize database applications to locate and process information 01.08 Utilize spreadsheets applications to locate and process information 01.09 Utilize business graphic application to process information 01.10 Apply a variety of mathematical techniques 01.11 Apply thinking skills and creativity 02.09 Prepare flowcharts 02.10 Prepare reports and instructions 02.11 Convey information and ideas to people 03.09 Manage and improve performance of individuals 03.10 Provide consultation and counselling 03.11 Monitor and evaluate performance of human resources 03.12 Provide coaching/on-the job training 03.13 Develop and maintain team harmony and resolve conflicts 03.14 Facilitate and coordinate teams and ideas 03.15 Liaise to achieve identified outcomes 03.16 Identify and assess client/customer needs 03.17 Identify staff training needs and facilitate access to training 04.06 Allocate work 04.07 Negotiate acceptance and support for objectives and strategies 05.01 Implement project/work plans 05.02 Inspect and monitor work done and/or in progress 06.07 Develop and maintain networks 1. Communication skills 2. Conceptual skills 3. Interpersonal skills 4. Learning skills 5. Leadership skills 6. Multitasking and prioritising 7. Self-discipline 8. Teamwork

- 41. 76 Tools, Equipment and Materials (TEM) ITEMS RATIO (TEM : Trainees) 1. Job Instruction 2. Assembly drawing 3. Hand tools 4. Measuring instruments 5. Matching agent 6. Stamping die components 7. Die spotting machine 8. Inspection check sheet 9. Personal Protective Equipment (PPE) 1:1 1:1 1:1 1:1 1:1 1:5 1:25 1:1 1:1 References REFERENCES 1. David A Smith (2001), Die maintenance handbook, Society of manufacturing engineers (SME), ISBN 978-0-87263-528-9 2. Richard M. Lead (2002), Tool and Die Making Troubleshoot, Society of Manufacturing Engineers, ISBN 978-0-87263-643-9 3. Jerry Arnold (2000), Die Maker Handbook, Industrial press, Inc., ISBN 0-831-3132-2 4. James A Szumera (2003), The Metal Stamping Process, Industrial press, Inc. ISBN 0-8311-3164-0 5. Vokota Boljanovic (1987), Die design fundamentals, Industrial Press Inc., ISBN 0-8311-1172-0 6. Donald A. Peterson (1994), Progressive Dies Principles and Practicesof Design, Society of Manufacturing Engineers, ISBN 0-87263-448-5 7. David A Smith (1990), Die design Handbook, Society of manufacturing engineers (SME), ISBN 0-87263-375-6

- 42. 77 CURRICULUM of COMPETENCY UNIT (CoCU) Sub Sector METAL MACHINING TECHNOLOGY Job Area MOULD & DIE MANUFACTURING Competency Unit Title PLASTIC INJECTION MOULD MAINTENANCE Learning Outcome The person who is competent in Plastic Injection Mould Maintenance shall be able to carry out preventive and corrective maintenance exercise that ensures the Plastic Injection Mould is in good operational condition. Upon completion of this competency unit, trainees will be able to :- • Prepare mould maintenance requirements • Carry out plastic injection mould maintenance • Perform mould assembly activities • Perform mould try-out • Inspect product sample • Check mould maintenance activity Competency Unit ID CU06 Level 03 Training Duration 180 Hours Credit Hours 18 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria 1. Prepare mould maintenance requirements i. Job instruction • Assembly drawing • Job description Type of process by sequences • Lead time (delivery date) • Company rules & regulation Company policy ii. Mould maintenance schedule • Mould history • Type of maintenance (corrective/ i. Interpret job instruction ii. Interpret mould maintenance schedule iii. Identify type of mould iv. Identify mould construction v. Identify type of maintenance tools vi. Select maintenance tools vii. Select defected product Attitude: i. Resourceful in acquiring information and data ii. Precise in communicating with internal staff iii. Meticulous in acquiring information Related Knowledge 8 hours Related skills 16 hours Related Knowledge Lecture Related skills Practical Demonstration i. Assembly drawing interpreted ii. Job description explained iii. Delivery date identified iv. Company rule & regulation complied v. Mould maintenance schedule differentiate vi. Type of mould

- 43. 78 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria preventive) • Replaced parts. • Modified part iii. Type of mould • Two plate mould • Three plate mould iv. Mould construction • Side core • Stripper plate • Slant block v. Type of tools & consumables • allen key, • copper mallet • shim • abrasive paper • matching agent • oil stone vii. Product samples • Defective product • Master sample listed vii. Mould construction explained viii. Type of tools listed ix. Product defect selected 2. Carry out plastic injection mould maintenance i. Defected product sample • Type of defect • Type of abnormality ii. Mould components such as: • Top plate • Core plate • Core insert • Cavity plate • Cavity insert i. Identify type product defect ii. Identify type of product abnormality iii. Dismantle mould components iv. Dismantle mould standard parts v. Identify mould component defects vi. Carry out touch up mould component Attitude: i. Meticulous in interpreting drawing ii. Exacting when using measuring instrument iii. Alert to electrical supply iv. Attentive in Related Knowledge 16 hours Related skills 40 hours Related Knowledge Lecture Related skills Practical Demonstration i. Type of product defect identified and listed ii. Type of product abnormality identified and listed iii. Mould components dismantled iv. Mould standard parts

- 44. 79 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria • Spacer block • Ejector retainer plate • Ejector back plate • Bottom plate iii. Mould standard parts such as :- • Locating ring • Sprue bush • Guide pillar • Guide bush • Spring • Ejector pin • Return pin iv. Type of mould component defects such as :- • Scratch • Dented • Wear and tear v. Counter problem techniques such as:- • Touch up • Regrind • Replace vii. Carry out regrind mould component viii. Carry out replacement of mould component handling mould components and tools v. Adhere to safe handling technique Safety: i. Ensure personal protective equipment (PPE) meet Safety Regulation & Standard ii. Beware of sharp edges & pinch point dismantled v. Mould component defects checked and listed vi. Touch up mould component performed vii. Regrind mould component performed viii. Replacement of mould component performed ix. Safety precaution applied in performing mould maintenance 3. Perform mould assembly activities i. Assembly drawing • Drawing symbol • Mould datum • Mould components ii. Mould fitting technique • Fixed half • Moving half iii. Mould fitting method • Perpendicular i. Interpret drawing symbols ii. Identify mould references (datum) iii. Assemble moving half iv. Assemble fixed half v. Check mould perpendicular Attitude: i. Meticulous in interpreting drawing ii. Exacting when using measuring instrument iii. Alert to Related Knowledge 8 hours Related skills 24 hours Related Knowledge Lecture Related skills Practical Demonstration i. Assembly drawing interpreted ii. Mould fitting technique demonstrate iii. Mould fitting performed iv. Matching

- 45. 80 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria • Flatness iv. Mould matching • Matching agent • Matching surface area vi. Check mould flatness vii. Perform mould matching electrical supply iv. Attentive in handling mould components and tools v. Adhere to safe handling technique Safety: i. Ensure personal protective equipment (PPE) meet Safety Regulation & Standard ii. Beware of sharp edges agent selected v. Matching surface area confirmed vi. Mould matching performed vii. Safety precaution applied in performing mould assembly 4. Perform mould try-out i. Mould set up safety and procedure ii. Moulding machine and function • Machine specification • Machine parameter • Clamping devices iii. Pre heat procedure • Material • Mould • Machine iv. Mould set-up i. Comply to Mould set up safety and procedure ii. Identify Moulding machine and function iii. Perform pre heat procedure iv. Perform mould set- up v. Perform material purging vi. Optimised parameter Attitude: i. Meticulous in interpreting drawing ii. Exacting when using measuring instrument iii. Alert to electrical supply iv. Attentive in handling Related Knowledge 16 hours Related skills 24 hours Related Knowledge Lecture Related skills Practical Demonstration i. Mould set up safety and procedure complied ii. Moulding machine identified iii. Moulding machine function explained iv. Pre heat process listed

- 46. 81 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria • Mould clamping • Mould accessories • Parameter setting v. Material purging • Material viscosity • Discard remaining vi. Product sample • Specification • Appearance • Profile vii. Type of moulding fault and countermeasure such as:- • Short shot • Sink mark • Burn mark • Flashing viii. Causes of product defects ix. Corrective actions • Touch up • Re-grind • Re-machining vii. Produce product sample viii. Identify product abnormality ix. Apply Countermeasure x. Perform corrective action mould components and tools v. Adhere to safe handling technique Safety: i. Ensure personal protective equipment (PPE) meet Safety Regulation & Standard ii. Beware of sharp edges & pinch point v. Mould set-up performed vi. Material purging performed vii. Moulding machine parameter confirmed viii. Product sample produced ix. Product abnormality identified x. Moulding fault listed and parameter optimised xi. Counter measure listed xii. Corrective action performed xiii. Safety precaution applied in performing mould try out 5. Inspect product sample i. Type of measuring instrument • Vernier calliper • Micrometer • Go No Go Gauge ii. Product Drawing i. Select type of measuring instrument ii. Identify Product sample dimension iii. Identify Product sample profile Attitude: i. Resourceful in acquiring information and data ii. Precise in Related Knowledge 4 hours Related skills Related Knowledge Lecture Related skills Practical i. Type of measuring instrument listed and selected ii. Product sample

- 47. 82 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria • Dimension • Profile • Appearance iii. Product sample iv. Product inspection check sheet iv. Identify Product sample appearance v. Perform Product sample inspection vi. Fill up Product inspection check sheet communicating with internal staff iii. Meticulous in acquiring information iv. Exacting when using measuring instrument 8 hours Demonstration identified dimension iii. Product sample profile identified iv. Product sample appearance identified v. Product sample inspection performed vi. Product inspection check sheet updated 6. Check mould maintenance activity i. Type of maintenance • Corrective • preventive ii. Assembly drawing • Type of mould • Type of mould components iii. Product drawing • Product specification iv. Product inspection check sheet • Product inspection result • Mould components condition • Mould try –out result v. Mould maintenance check sheet i. Confirm type of mould maintenance ii. Confirm mould to be maintain iii. Confirm mould component defects iv. Confirm mould assembly activities v. Confirm mould try- out vi. Confirm product quality vii. Update mould maintenance check sheet Attitude: i. Resourceful in acquiring information and data ii. Precise in communicatin g with internal staff iii. Meticulous in acquiring information Related Knowledge 4 hours Related skills 12 hours Related Knowledge Lecture Related skills Practical Demonstration i. Type of maintenance Confirmed ii. Mould to be maintain confirmed iii. Mould component defects listed iv. Mould assembly activities confirmed v. Mould try-out confirmed vi. Product quality assured vii. Mould maintenance check sheet updated

- 48. 83 Employability Skills Core Abilities Social Skills 01.07 Utilize database applications to locate and process information 01.08 Utilize spreadsheets applications to locate and process information 01.09 Utilize business graphic application to process information 01.10 Apply a variety of mathematical techniques 01.11 Apply thinking skills and creativity 02.09 Prepare flowcharts 02.10 Prepare reports and instructions 02.11 Convey information and ideas to people 03.09 Manage and improve performance of individuals 03.10 Provide consultation and counselling 03.11 Monitor and evaluate performance of human resources 03.12 Provide coaching/on-the job training 03.13 Develop and maintain team harmony and resolve conflicts 03.14 Facilitate and coordinate teams and ideas 03.15 Liaise to achieve identified outcomes 03.16 Identify and assess client/customer needs 03.17 Identify staff training needs and facilitate access to training 04.06 Allocate work 04.07 Negotiate acceptance and support for objectives and strategies 05.01 Implement project/work plans 05.02 Inspect and monitor work done and/or in progress 06.07 Develop and maintain networks 1. Communication skills 2. Conceptual skills 3. Interpersonal skills 4. Learning skills 5. Leadership skills 6. Multitasking and prioritising 7. Self-discipline 8. Teamwork

- 49. 84 Tools, Equipment and Materials (TEM) ITEMS RATIO (TEM : Trainees) 1. Job Instruction 2. Maintenance schedule 3. Assembly drawing 4. Injection trouble shooting guidance/chart 5. Hand tools 6. Bunsen burner 7. Measuring instruments 8. Matching agent 9. Mould release agent 10. Plastic resin 11. Plastic injection mould 12. Die spotting machine 13. Plastic injection moulding machine 14. Inspection check sheet 15. Personal Protective Equipment (PPE) 1:1 1:1 1:1 1:1 1:1 1:5 1:25 1:1 As required As required 1:5 1:25 1:25 1:1 1:1 References REFERENCES 1. Richard M. Lead, Tool and Die Making Troubleshoot (2002), Society of Manufacturing Engineers, ISBN 978-0-87263-643-9 2. Gunter Mennig (1998), Mould Making Handbook, Hanser / Gardner publication, ISBN 1-56990-261-5 3. Eric V. Buckleitner (1995), Plastics Mold Engineer Handbook, Chapman & Hall, ISBN 0-412098951-4 4. Georg Menges/Paul Mahren (1993), How to make Injection Molds, Hanser Publishers, ISBN 3-446-16305-0 5. Donald V. Rosato/Dominick V. Roasato (1995), Injection Molding Handbook, Chapman & Hall, ISBN 0-412-99381-3 6. E. Lindner and P. Unger (1993), Injection Mold 108 Proven Designs, Hanser Publishers, ISBN 3-446-15682-8 7. Michael L. Berins (1991), Plastics Engineering Handbook, Chapman & Hall, ISBN 0-412-99181-0

- 50. 85 CURRICULUM of COMPETENCY UNIT (CoCU) Sub Sector METAL MACHINING TECHNOLOGY Job Area MOULD & DIE MANUFACTURING Competency Unit Title MOULD & DIE OPERATIONAL SUPERVISION Learning Outcome The person who is competent in mould & die supervision shall be able to supervise of group mould and die making to carry out assembly, try-out, troubleshooting and maintenance activities in accordance with standard operation procedure (SOP). Upon completion of this competency unit, trainees will be able to :- • Carry out daily briefing • Prepare work schedule • Carry out job distribution • Supervise work progress performance • Conduct section meeting • Carry out staff coaching • Control inventory • Prepare appraisal recommendation Competency Unit ID CU07 Level 03 Training Duration 180 Hours Credit Hours 18 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria 1. Carry out daily briefing i. Job scheduling/job order ii. Company’s policy, rules and regulation iii. Daily briefing objective iv. Daily briefing agenda v. Briefing feedback i. Interpret Job scheduling/job order ii. Comply to Company’s policy, rules and regulation iii. Identify daily briefing objective iv. Identify daily briefing agenda v. Execute daily briefing vi. Record briefing feedback Attitude: Meticulous in identifying requirement of jobs schedule/jobs order Related Knowledge 4 hours Related skills 8 hours Related Knowledge Lecture Related skills Practical Demonstration i. Job scheduling/job order Interpreted ii. Company’s policy, rules and regulation complied iii. Daily briefing objective listed iv. Daily briefing agenda listed

- 51. 86 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria v. Daily briefing conducted vi. briefing feedback recorded 2. Prepare work schedule i. Work scheduling format ii. Master schedule • Type of job • Delivery date iii. Type of work process requirements iv. Type of resources • Manpower • Machine • Material • Method v. Company target i. Identify schedule format ii. Interpret master schedule iii. Identify job requirement iv. Identify delivery date v. Identify work process vi. Identify Resources availability and capability vii. Identify company target viii. Plan manpower availability ix. Plan machine capacity x. Plan material receiving xi. Plan mould and die schedule xii. Produce mould and die schedule xiii. Submit mould and die schedule to superior Attitude: i. Resourceful in acquiring information and data ii. Precise in communicating with internal staff iii. Meticulous in acquiring information Related Knowledge 8 hours Related skills 24 hours Related Knowledge Lecture Related skills Practical Demonstration i. Schedule format ii. Master schedule interpreted iii. Job requirement identified iv. Work process identified v. Delivery date identified vi. Resources availability and capability identified vii. Company target identified viii. Manpower availability planned ix. Machine capacity planned x. Material receiving

- 52. 87 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria planned xi. Mould and die planned schedule xii. Mould and die schedule produced xiii. Mould and die schedule submitted to superior 3. Carry out job distribution i. Job distribution form ii. Work schedule • Lead time • Delivery date iii. Job distribution • Manpower availability • Machine availability i. Identify Job distribution form ii. Estimate lead time iii. Confirmed delivery date iv. Arrange Manpower v. Arrange machine Attitude: i. Resourceful in acquiring information and data ii. Precise in communicating with internal staff iii. Meticulous in acquiring information Related Knowledge 4 hours Related skills 8 hours Related Knowledge Lecture Related skills Practical Demonstration i. Job distribution form determined ii. Work schedule checked iii. Lead time estimated iv. Job distribution arranged v. Manpower and machine availability arranged 4. Supervise work progress performance i. Company organization chart ii. Job status iii. Recovery plan iv. Work progress check sheet format i. Coordinate with responsibility personnel ii. Check work status iii. Arrange recovery plan iv. Update work progress check Attitude: i. Resourceful in acquiring information and data ii. Precise in communicating with internal staff Related Knowledge 8 hours Related skills 16 hours Related Knowledge Lecture Related skills Practical Demonstration i. Authorised personnel / responsibility personnel / parties involved coordinated ii. Work progress checked

- 53. 88 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria sheet v. Submit work progress check sheet Meticulous in acquiring information iii. Recovery plan arranged iv. Work progress report produced v. Work progress report submitted 5. Conduct section meeting i. Group meeting requirement • Type of meeting • Meeting objective • Meeting frequency • Meeting documents • Company’s rule and regulation requirement ii. Group meeting activities • Meeting Plan • Meeting Agenda • Meeting participants • Meeting preparation • Effective meeting • Meeting minute i. Identify group meeting requirement ii. Plan group meeting activities group iii. Carry out group meeting iv. Record meeting minute v. Review achievement of meeting conducted vi. Compile group meeting documents Attitude: i. Observe procedure and condition during meeting Responsible and accountable in handling meeting condition Related Knowledge 8 hours Related skills 16 hours Related Knowledge Lecture Related skills Practical Demonstration i. Group meeting requirement Identified ii. Group meeting activities Planned iii. Group meeting Carried out iv. Meeting minute recorded for further action v. Achievement of meeting conducted reviewed vi. Group meeting documents Compiled 6. Carry out staff coaching i. Coaching objective ii. Skills matrix chart iii. Coaching material iv. Coaching facilities v. Coaching module i. Identify coaching objective ii. Interpret skills matrix chart iii. Prepare coaching material iv. Prepare coaching Attitude: i. Responsible and accountable in conducting training ii. Resourceful in interpret training Related Knowledge 8 hours Related skills 24 hours Related Knowledge Lecture Related skills Practical Demonstration i. Coaching objective explained ii. Staff skills assessed in accordance with skills matrix

- 54. 89 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria facilities v. Prepare coaching module vi. Perform internal staff coaching syllabus/title Safety: i. Adhere to safety requirement chart iii. Coaching materials prepared iv. Coaching facilities prepared v. Staff coaching performed 7. Control inventory i. Company rules & regulation • Company policy ii. Type of item / grouping • Raw material • Spare parts • Standard parts • Cutting tools • Hand tools iii. Type of document • Receiving form • Inventory record form • Request form iv. Inventory system • Storage media • Location • Labelling v. Stocktake • Stock balance • Stock requirements • Stock record form i. Comply to Company rules & regulation ii. Identify type of item iii. Identify type of document iv. Organise inventory system v. Organise stocktake vi. Update stock record form Attitude: i. Resourceful in acquiring information and data ii. Precise in communicating with internal staff iii. Meticulous in acquiring information Related Knowledge 8 hours Related skills 16 hours Related Knowledge Lecture Related skills Practical Demonstration i. Company rules & regulation complied ii. Type of item listed iii. Type of document explained iv. Items stored v. Stock record form updated

- 55. 90 Work Activities Related Knowledge Related Skills Attitude/Safety/ Environmental Training Hours Delivery Mode Assessment Criteria 8. Prepare appraisal recommendation i. Personnel appraisal form format ii. Subordinate job description iii. Personnel appraisal evaluation criteria iv. Subordinate performance assessment i. Identify Personnel appraisal form format ii. Identify Subordinate job description iii. Identify Personnel appraisal evaluation criteria iv. Assess Subordinate performance v. Forward personnel appraisal form to superior Attitude: i. Responsible in interpreting appraisal criteria Related Knowledge 8 hours Related skills 12 hours Related Knowledge Lecture Related skills Practical Demonstration i. Personnel appraisal form format Identified ii. Subordinate job description Identified iii. Personnel appraisal evaluation criteria Identified iv. Subordinate performance assessed v. Personnel appraisal form to superior forwarded