FAMI-QS Audit CHECKLIST.doc

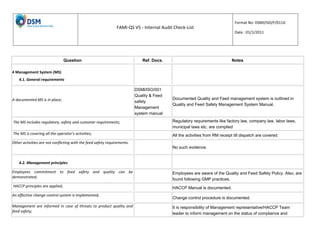

- 1. FAMI-QS V5 - Internal Audit Check-List Format No: DSMI/ISO/F/011A Date : 01/1/2011 Question Ref. Docs. Notes 4 Management System (MS) 4.1. General requirements A documented MS is in place; DSMI/ISO/001 Quality & Feed safety Management system manual Documented Quality and Feed management system is outlined in Quality and Feed Safety Management System Manual. The MS includes regulatory, safety and customer requirements; Regulatory requirements like factory law, company law, labor laws, municipal laws etc. are complied The MS is covering all the operator’s activities; All the activities from RM receipt till dispatch are covered. Other activities are not conflicting with the feed safety requirements. No such evidence. 4.2. Management principles Employees commitment to feed safety and quality can be demonstrated; Employees are aware of the Quality and Feed Safety Policy. Also, are found following GMP practices. HACCP principles are applied; HACCP Manual is documented. An effective change control system is implemented; Change control procedure is documented. Management are informed in case of threats to product quality and feed safety; It is responsibility of Management representative/HACCP Team leader to inform management on the status of compliance and

- 2. FAMI-QS V5 - Internal Audit Check-List Format No: DSMI/ISO/F/011A Date : 01/1/2011 implementation of system in factory. A system is in place to ensure that management is kept up‐dated on all relevant legislation, feed and food safety issues, and other relevant guidelines. QA manager is responsible for collecting relevant legislative requirements, keeping team updated with feed safety issues and other relevant guidelines. 4.3. General documentation requirements A written quality and safety policy exists; DSMI/ISO/003 Rev. 01, Eff. Dt: 1/04/12 Policy is documented in Quality and Feed safety manual also it is displayed at strategic locations. • A Quality Manual is in place; DSMI/ISO/003 Rev. 01, Eff. Dt: 1/04/12 Documented and available with MR. • Documented procedures and records are available; • The scope of the MS is defined; DSMI/ISO/003 Rev. 01, Eff. Dt: 1/04/12 “Manufacturing and Supply of Feed Premixes/Additives/Supplements” • Quality procedures are established as part of the MS; Quality procedures are documented and estalibhed in System procedure manual • Quality procedures cover the prerequisite program in support of the HACCP program; Procedures are documented for Pest Control, Disposal of scrap etc.

- 3. FAMI-QS V5 - Internal Audit Check-List Format No: DSMI/ISO/F/011A Date : 01/1/2011 • HACCP procedures are sufficient to ensure feed safety; HACCP Manual documented which details all the related procedures. Procedures are sufficient to ensured feed safety. • Specifications and testing procedures for incoming materials and finished products are documented; Specificatins for raw materials are documented. Checked for Copper Sulphate Pentahydrate, Specifications are documented in Format No.: DSMI/QA/SPEC/002, Analysis of Copper (Copper Assay) is performed as per British Pharmacopoeia, also for heavy metals supplier COA is reffered. Checked Raw material testing report of minerals for Copper Sulphate Pentahydrate Dt: 28/01/12, Batch No. 24/01/11-12, COA is also available for the same. Finished product specs are documented as per product category. Checked Specs for Rovimix Vitamin & Mineral Premix (Format No.: DSMI/QC/SPEC/003). Checked for Rovimix 2010 FG inspection report for Batch No.: IN12030149, Dt: 14/03/12. • Master formulae and operating instructions for each product or group of products are in place; Recipes are available for each product. • Processing records for each batch of product are available; Processing records are maintained by production. Checked records of Batch No. IN 12040222, Product: Rovimix Broiler OVN TN, Product Code: IN10105192, Dt: 24/04/12. • Standard Operating Procedures (SOPs) for all activities under the scope of the MS are documented; DSMI/ISO/SP/01 DSMI/ISO/SP/02 DSMI/ISO/SP/03 DSMI/ISO/SP/04 DSMI/ISO/SP/05 SOP’s are documented under sope of MS. Checked procedure for Control of documentes, control of records, Internal audit, Control of Non-Conforming product, Corrective action etc. • Documents are unambiguous and include title, nature and purpose; All the procedures have title in header, its purpose written at the beginning under Purpose heading. Checked procedure for Control of

- 4. FAMI-QS V5 - Internal Audit Check-List Format No: DSMI/ISO/F/011A Date : 01/1/2011 documents (DSMI/ISO/SP/01) Documents are approved, signed and dated by appropriate authorised persons. All the documents are signed by person preparing it and person authorizing it. All documents are kept up to date. All the records checked were up to date. Seive Integrity checklist for the same. Updated till 2nd -May-12. Documents in use are of current revision Checked procedure of Emergency preparedness (DSMI/MR/SP/08) Eff. Date: 1/11/11 Rev.00 5 Management Responsibility 5.1. Management commitment Management commitment to feed safety and quality can be demonstrated It can be demonstrated through documented Quality and Feed safety policy, provision of necessary resources etc. 5.2. Quality and safety policy • The quality and safety policy specifies the operators objectives including regulatory and customer requirements; DSMI/ISO/003 Rev. 01, Eff. Dt: 1/04/12 Quality & Feed safety policy states the objectives of complying with statutory and customer requirements. • The policy is adequately communicated; Policy is distributed to all department heads and same is displayed in local language (Marathi) at strategic locations for better understanding of workmen.

- 5. FAMI-QS V5 - Internal Audit Check-List Format No: DSMI/ISO/F/011A Date : 01/1/2011 • The operator has the basic resources necessary to fulfil the stated objectives; Minor NC: Feed safety related objective not stated. • Management and HACCP systems are documented, reviewed, updated and communicated to key staff. DSMI/ISO/003 Rev. 01, Eff. Dt: 1/04/12 Quality and Feed safety management is documented and same is outlined in Quality and Feed Safety Management System Manual. 5.3. Responsibility, authority and communication • A suitably qualified HACCP team leader is appointed; HACCP Manual, Rev. 00, Eff. Dt: 1/11/2011 Mr. Rajesh Patkar (QA Manager) is appointed as HACCP Team leader. • The scope of the HACCP system is clearly defined; DSMI/ISO/003 Rev. 01, Eff. Dt: 1/04/12 “Manufacturing and Supply of Feed Premixes/Additives/Supplements” • Job descriptions exist for each individual or group of individuals; HACCP Manual, Rev. 00, Eff. Dt: 1/11/2011 Job description of HACCP Team leader and Team members is documented in HACCP Manual. Also the responsibilities of various functionaries are defined in Quality and Feed Safety Management System Manual. • A system is in place to identify and correct problems within the management and HACCP systems; DSMI/ISO/SP/003 Internal audits are carried out at six monthly frequency where all the aspects of management and HACCP systems are verified. • A suitably qualified person is appointed to ensure compliance with regulatory requirements; DSMI/ISO/003 Rev. 01, Eff. Dt: 1/04/12 Manager QA is appointed to ensure legal compliance. Evident from Quality and Feed safety management system manual heading 5.5.1.5. • An organisational chart is available. DSMI/ISO/003 Rev. 01, Eff. Dt: Organizational chart is documented in Quality & Feed Safety Management system Manual

- 6. FAMI-QS V5 - Internal Audit Check-List Format No: DSMI/ISO/F/011A Date : 01/1/2011 1/04/12 5.4. Management representative A management representative with responsibility for quality and safety is appointed. HACCP Manual Mr. Rajesh Patkar is appointed as MR and HACCP Team Leader. Same is evident in HACCP Manual as well as appointment letter is also provided to him. • The management representative reports to top management. It is responsibility of MR to report on the implementation and compliance of system to the Top management. Evident in appointment letter. • The responsibility includes promotion of awareness towards customer requirements. Responsibility of MR includes promotion of awareness towards customer requirements. 5.5. Management review A documented procedure exists for management to review the suitability and effectiveness of the MS and HACCP; DSMI/ISO/SP & DSMI/ISO/001 Agenda includes discussion on MS & HACCP • Records of this review are available; DSMI/ISO/009, Rev.0 This is first round of Internal audit and Management review will be carried out after this audit. MRM record is available as per the agenda point of ISO Dt: 20/12/11 • The review is done periodically at predefined intervals; DSMI/ISO/SP Six monthly as per procedure for management review.

- 7. FAMI-QS V5 - Internal Audit Check-List Format No: DSMI/ISO/F/011A Date : 01/1/2011 • Conclusions drawn and actions taken are documented as part of the review; Action plan is recorded checked MRM dt: 20/12/11 • Any actions are communicated to key personnel within the organisation. Actions are communicated to key personnel via emails or meetings. 6 Resource management 6.1. Provision of resources • An organisational chart exists and is updated; DSMI/ISO/003 Rev. 01, Eff. Dt: 1/04/12 Orgainization chart is documented in Quality and Feedsafety Manual and is up to date. • Appropriate persons have been assigned responsibilities to comply with external requirements; Marketing is responsible for colletting customer requirements. QA manager is responsible for collecting legal requirements. • The design is appropriate. Design is appropriate 6.2. Human resources 6.2.1. Competence, awareness and training Training Plan is Available for Jan 2012 to Dec 2012 ( training Record Check for Feet safety awareness date : 04/01/12 ) • The staff is sufficient and skilled to comply with expected tasks and requirements; Competence mapping record are available ( record Check Rajesh Patkar DSMI/HR/F/012 ) • Job descriptions are available and updated. Job descriptions are available and updated. ( Record Checked For QA Chemist )

- 8. FAMI-QS V5 - Internal Audit Check-List Format No: DSMI/ISO/F/011A Date : 01/1/2011 6.2.2. Personal Hygiene Ensure that personnel hygiene facilities are clearly and suitably designated Hand washing facilities is provided Provide appropriate work wear such as protective clothing and safety footwear Uniform and safety footwear are provided to all If gloves are worn control that there is no risk of contamination of the finished product from them Gloves are worn to control no risk of contamination of the finished product and raw material Establish clear rules on smoking and eating/drinking on site. If necessary No smoking is allowed in factory premises and canteen is provided for eating and drinking 6.3. Infrastructure Adequate ventilation; controlable humidity and temperature temperature setting; lighting and hygienic design of plants and equipment shall be provided. Adequate ventilation is provided, Humidity control is in place at critical areas like RM storage and Micro dispensing. Sufficient lighting is provided, plant is designed and maintained in hygienic manner. 6.3.2. Requirements for facilities, production areas and equipment Facility is well maintained. Production areas are enclosed and equipments found clean and in good condition. The lay‐out, design, construction and size of the facilities and equipment shall:

- 9. FAMI-QS V5 - Internal Audit Check-List Format No: DSMI/ISO/F/011A Date : 01/1/2011 a) permit adequate cleaning and/or disinfection; Minor NC: Adequate cleaning may not be possible of the production floor as damaged floor is evident in production area near Buhler Mixer infront of dispatch area. b) be such as to minimise the risk of error and to avoid contamination, cross‐contamination and any generally adverse effects on the safety and quality of the feeds. It is designed in a way to prevent risk of errors like mixups, contamination, cross contamination and any adverse effects on quality and feed safety. 6.3.2.1. Facilities & production Areas Where necessary, ceilings and overhead fixtures must be designed, constructed and finished to prevent the accumulation of dirt and to reduce condensation Ceiling is well finished and does not allow accumulation of dirt. Planned cleaning schedules ensure that its always maintained in good order. Ventilation systems and devices shall be sufficient in number and capacity to prevent grease or condensation from collecting on walls and ceiling. Ventilation in the production area is ensured with the help of turbo ventilators. Areas like micro dispensing and RM storage are provided with exhausts and blowers. Water used in feed manufacture shall be of suitable quality. No water is used in the manufacture of feed quality. It should be ensured that drainage lines and sewage systems are watertight and of sufficient capacity. Drainage lines are such that they handle dry powder and can be assessed and cleaned 6.3.2.2. Equipment Manufacturing equipment should be located, designed, constructed and maintained to suit the manufacture of the products concerned. Buhler system is specifically designed for manufacturing of animal nutritional products.

- 10. FAMI-QS V5 - Internal Audit Check-List Format No: DSMI/ISO/F/011A Date : 01/1/2011 The equipment must be designed to facilitate manual or Cleaning In Place (CIP) and/or disinfection by having surfaces that are smooth, free of sharp angles, corners, crevices or smooth welds. CIP is done by flushing with soda lime etc and is specifically designed for the equipment. 6.4. Maintenance and control of monitoring and measuring devices A formal calibration system is in place; Equipments are calibrated as per calibration plan • This includes items to be calibrated; All the monitoring and measuring equipments are listed on calibration plan. Checked for Oven, ID No.- OV-01 • Appropriate calibration intervals are defined; Calibration due dates are defined. Next calibration due date of Oven (OV-01) is 10/03/2013. • Calibration results are documented; Calibration certificates are available which has details of calibration results. Checked Calibration Certificate No. 12/5944. • A formal preventive maintenance system exists; Preventive maintenance plan is available for year 2012 • Appropriate maintenance intervals are defined; Appropriate frequency is defined • Maintenance work is documented; Procedures for maintenance is documented (DSMI/MAINT/SP/05) • Maintenance work does not interfere with product safety. Maintenance work does not Interfere with Product Safety

- 11. FAMI-QS V5 - Internal Audit Check-List Format No: DSMI/ISO/F/011A Date : 01/1/2011 6.5. Cleaning A formal cleaning program exists, covering: Cleaning Schedule is available o Daily house‐keeping; Daily house – keeping record are available ( Record checked for compress room (DSMI/PRO/F/004) Date May 3, 2012) o Periodic deep cleaning; Deep Cleaning is done every day With washing scrubber machine o Cleaning after maintenance; Minor NC: Record keeping is not done for the cleaning activity performed after maintenance work. • The program defines responsibility. Store officer • Post evaluation is covered. Record are Evidence with verified signature • Cleaning records are filled‐in currently. Yes • Procedures on cleaning of equipment exist, and support hygiene and feed safety. Procedures of Cleaning of equipment is available ( DSMI/STR/SP/05) Employees are trained in cleaning procedures and the training is Training Record are available ( Record Checked for month march DSMI/SHE/TRG/007)

- 12. FAMI-QS V5 - Internal Audit Check-List Format No: DSMI/ISO/F/011A Date : 01/1/2011 documented. 6.6. Pest control • A formal (documented) preventive pest control system is in place. Pest control system is in place documented are evidence • The responsibility: In‐house or contracted. Contracted ( PCI) Pest Control India Pvt Ltd. • Ensure that relevant preventive measures are taken, re.: Minor NC: Gaps were evident below emergency exit near Buhler control room. Shutter near local RM storage area is not closing properly leaving a gap. From these gaps pest / rodent activity is possible. o Rodents, outside and inside; Record Are available for rodent Control ( Last Visit was done on 03/03/12 ) o Insects, flying and crawling; Control Measures are taken for insect, flying and lizard ( last visit done 21/01/2012 ) o Birds; There were no evidence birds in factory. o Other relevant pests. No other pest was evidence

- 13. FAMI-QS V5 - Internal Audit Check-List Format No: DSMI/ISO/F/011A Date : 01/1/2011 • Ensure a map or schematics of preventive measures showing the locations exist and is updated. Map is available showing location of rodent bait station with roban cake and rodent bait station with trubbel gum • Pest activities are documented. Procedure for pest Control is documented (DSMI/QC/SP/16) 6.7. Waste control Waste materials are properly identified to avoid mix‐up with production materials; Waste materials are properly identified and to avoid mixup with production materials. • Waste is handled properly to avoid risks for workers or environment, both internally and externally. Waste is disposed off in local effluent treatment facility. Also waste is segregated as per local laws. E.g. waste chemicals in lab are collected separately and disposed off with the help of legal authority. 7 Product realisation 7.1. Product requirements A system to identify external requirements is implemented; System is in place. Externala i.e. customer requirements are identified in the form of customer specifications. • The external requirements are communicated and complied with; Customer requirements are communicated to CSO which are then communicated to Plant manager through SAP system.

- 14. FAMI-QS V5 - Internal Audit Check-List Format No: DSMI/ISO/F/011A Date : 01/1/2011 • Requirements and compliance are documented; Customer requirements i.e. formuation is available on SAP and compliance is documented through COA generated by QC in SAP. • Requirements specified by customers are controlled and implemented. All the orders are processed only after the approval of formulation by customer and Same are processed by production team and inspected by QC. 7.1.2. Compliance of the product to the requirements NA 7.1.3. Customer communication product information; Product information is communicated in the form of COA. enquiries, contracts or order handling, including amendments; and Marketing is responsible for all these acitivities. customer feedback, including complaints. Customer feedback is collected annually. Records available. 7.2. HACCP Program

- 15. FAMI-QS V5 - Internal Audit Check-List Format No: DSMI/ISO/F/011A Date : 01/1/2011 HACCP Plan HACCP Manual Eff. Dt: 1/11/2011 Hazard assessment is carried out for all the processes. One CCP identified at mixing step. Sieving and metal detection. As per plan CCP monitoring records available. Checked sieve integrity checklist(DSM/QC/F/005), Dt: 2/05/12, and Magnet cleaning Check list (DSM/QC/F/004) Dt: 27/04/12. 7.3. Design and development 7.3.1. Development of new products and processes NA 7.3.2. Change control A formal change control procedure exists; DSMI/QC/SP/22 Eff. Date: 01/04/12 Checked documented change control procedure • Changes are approved before implementation; DSMI/QC/SP/22 As per procedure for change control, Changes must be approved before implementation. • Changes are controlled and documented; DSMI/QC/SP/22 As per procedure changes must be controlled and documented. • Changes implemented are reviewed, verified and archived; DSMI/QC/SP/22 As per procedure, changes implemented must be reviewed and verified for its effective implementation. Records of the same must be kept. • Safety, quality and regulatory requirements covered by the change control procedure. DSMI/QC/SP/22 All safety, quality and regulatory requirements are covered by the change control procedure.

- 16. FAMI-QS V5 - Internal Audit Check-List Format No: DSMI/ISO/F/011A Date : 01/1/2011 7.4. Handling of incoming materials 7.4.1. Sourcing of incoming materials Procedures is available for Purchase ( DSMI/PUR/SP/02) New suppliers are covered by an approval process; Procedures For Selection of supplier is available (DSMI/PUR/SP/01) • Approved suppliers are documented, reviewed, re‐evaluated and the documentation is up‐to‐date; List of approved suppliers available ( DSMI/PUR/F/002) Record Checked Aroma Agencies Date :25-10-10 • The review is done periodically at a predetermined interval; Evaluation is Done Every Year ( Supplier Evaluation form is Available (DSMI/PUR/F/001) • Purchased incoming material has an agreed specification; QC Approved the Sample and then Purchase manager communicated with supplier for Delivery • Specifications comply with feed safety topics and legislative requirements. Specification Comply With Feed Safety topics 7.4.2. Verification of incoming materials • A written procedure on handling of incoming materials exists. DSMI/STR/SP/01 Procedure is documented for handling of incoming material. Eff. Date: 2/01/12, Rev.01 • Incoming materials are registered uniquely and include: o Supplier’s name and lot/batch number; Suppliers Name and Lot no. is registered in SAP

- 17. FAMI-QS V5 - Internal Audit Check-List Format No: DSMI/ISO/F/011A Date : 01/1/2011 o Operator’s lot/batch number; DSM generates batch no. for local items where lot no. is not generated by suppliers. And receipt ID is generated for each and every raw material through SAP. o Name of material; Material name is registered and also available on identification labels o Quantity and date of receipt; Quantity and receipt date records are maintained in SAP o Possible expiry date. Expiry dates are mentioned on identification label and also same is fed in PIC system. • Incoming bulk materials are stored according to adequate separation procedures. Incoming bulk materials are stored separately in controlled manner as per procedure for storage of Vitamins. • Materials are inspected before, during and after unloading. Materials are inspected before, during and after unloading. • The inspection includes contamination, pest infestation and documentation of findings. Visual inspection includes check for packaging integrity which is recorded in Raw material and Packaging material register. Same is recorded for material received on 02/05/12, Product Niacin. • Non‐conformities are recorded. Non conformities are recorded in Product NCR (DSMI/ISO/F/006A). Checked PNCR dt: 29/03/12, product – Rice husk, customer: Sayli Agro. 1200kg material rejected. 7.5. Production of finished goods 7.5.1. Quality Control and Production

- 18. FAMI-QS V5 - Internal Audit Check-List Format No: DSMI/ISO/F/011A Date : 01/1/2011 • Production areas are accessible to authorized personnel only; • Production is run according to formal production planning; Sales representative sends the customer order to production and production manager plans the job based on availability of equipment, raw materials and dispatch schedule. Checked for Rovimix Broiler OVN TN Product code: IN10105192 dt: 21/4/12. • The production plan is distributed to relevant persons; Production plan is immediately marked to stores for issue of raw material as per recipe. • Production records are kept prove compliance with master formula; Production records available in system. Checked for Process order no. 2137003763 dt: 24/04/12. • Cross‐contamination is prevented or controlled; Total setup is an enclosed line and does not allow any contamination. Also cross contamination is avoided by doing flushing after changeover of product category. • Each product has a specification, unique name and/or Code Each product is given unique product code no. also the every order produced has unique batch no. Checked for Rovimix Broiler OVN TN, batch no.: IN12040222 • Each product has a predefined label; Product has predefined label which contains Product name, qty and batch no. written on it. • Finished products are clearly marked and identified; All finished products are properly identified as per the customer requirements. Especially it is ensured that labels contain batch no. • Each product has a predefined packaging instruction; Packaging instruction related to pack size, labels etc are given by customer. • The packaging process is controlled to avoid contamination and mix‐up; Packaging process was well managed and no risk of contamination.

- 19. FAMI-QS V5 - Internal Audit Check-List Format No: DSMI/ISO/F/011A Date : 01/1/2011 • Deliveries are inspected prior to dispatch; Deliveries are inspected prior to dispatch for contamination and pest infestation. • This inspection is documented; Pre dispatch inspection is documented on Dispatch Information (format No.: DSMI/QC/F/016). Checked for Rovimix SPL, dispatched on 16.02/12, Batch No. IN12020143. • Non‐conforming products are segregated and stored in a manner to prevent failures; Non conforming products are segregated and kept in Reject area. Product NCR is prepared for the same. Checked Product NCR of Rovimix SKFBSC Batch No. IN12010248 Dt: 27/01/12/ • Storage facilities are adequate to the purpose; Adequate storage facility is available with enough storage capacity. • Storage facilities are operated in a manner to prevent failures during handling; Proper storage temperatures are maintained by providing adequate ventilation to the storage area. Temperatures and humidity monitored on predetermined frequency. • Storage facilities are suitable to the purpose, e.g. cleanliness, ventilation, dry, and temperature controlled; Storage areas found clean. Humidity and temperature controls are placed and monitored. • A defined stock rotation system is in place, e.g. FIFO; FIFO is followed. Expiry dates of material are tacked and followed. 7.5.2. Verification of processes for production • A written verification procedure is in place; DSMI/QC/SP/15 Procedure is documented for verification activity, named as validation protocol Eff. Dt: 11/01/11

- 20. FAMI-QS V5 - Internal Audit Check-List Format No: DSMI/ISO/F/011A Date : 01/1/2011 • Verification data demonstrates all production processes achieve planned results; Verification data shows that all the planned results achieved. • Verification data demonstrates carry over is controlled. Verification is perofomed as per the Validation protocol mentioned in procedure. It shows that carry over is controlled. 7.5.3. Identification and traceability • A traceability system is in place, including tracing back from the final product through quality control data and batch records to the raw materials used and the suppliers; Traceability system is in place. Raw materials are given unique no. which helps in traceability. Finished product is given batch no. which can be traced till raw materials. • Deliveries can be traced to customers, including customer name, date, batch and amount. Delivery can be traced to the cusomter name, date and batch no. etc. 7.5.4. Preservation of product A stability program is defined and on‐going; Stability studies are done as per product groups. Checked for Vitamin Premix, Product name: Rovimix OVN AB 1000, Dt: 23/12/2011, Batch No. IN11030008.

- 21. FAMI-QS V5 - Internal Audit Check-List Format No: DSMI/ISO/F/011A Date : 01/1/2011 • Product environment is controlled during storage to preserve conformance with quality and safety requirements. Critical raw materials are stored in temperature & humidity controlled storage areas. Micro dispensing room is used for handling open product while dispensing raw materials which is temperature and humidity controlled. 7.6. Transport Agreements with subcontracted transporters are documented; Agreements are documented for subcontracted transporters. Checked agreement copy with VRL Logistics Ltd. Contract Date:1/08/11 • Selection of transporters takes into consideration their ability to fulfill the operators requirements as certified by this Code; Transporters are leaders in their field and all quality and safety related requirements are communicated to them. • Transporters are controlled, evaluated and meet expected quality and safety requirements; Minor NC: Evaluation of transporters (VRL Logistics Ltd.) is not evident. Requirements in this Code are applied by the operator also to transports arranged by the buyer. Hari Om transporter is buyer specific contractor, recommended by Geco Vetchem, however transport agreement exists with the transporter dt: 22/11/2010. 7.6.2. Transport of packaged goods

- 22. FAMI-QS V5 - Internal Audit Check-List Format No: DSMI/ISO/F/011A Date : 01/1/2011 • Procedures are in place to ensure product integrity during transport DSMI/PROD/SP/08 Vehicles are inspected before dispatching for cleanliness. Product is packed as per procedure for packing of the finished goods to ensured product integrity during transport. • Packaging provides adequate protection for the raw material or finshed goods Packing provides adequate protection to the finished goods packed in it. 7.6.3. Transport of bulk products • Procedures are in place to control all relevant risks found in the operators HACCP; In Hazard analysis risks like foreign objects in vehicles and possible contamination from previous loads on the same vehicle etc. are identified as hazard and procedure like vehicle inspection before loading and contract agreements with contractors are implemented. • If cleaning is required, the cleaning certificates shall include all relevant information needed to evaluate if the supplied container is suitable for loading; Outgoing vehicle inspection checklist includes relevant information. • Procedures are in place to safeguard against unwanted or forbidden contaminants. Vehicle inspection ensures that finished product will not get contaminated due to improper vehicles during transit. 8 System Review 8.1. General requirements

- 23. FAMI-QS V5 - Internal Audit Check-List Format No: DSMI/ISO/F/011A Date : 01/1/2011 • A formal review system exists; QFMS review system is in place. • The system includes collection of data; Data is collected as per sent objectives. • The system includes analysis of the data; Data is anlaysed to checked whether the objectives are achieved. • The system includes a conclusion; Based on data analysis action plans are prepared and implemented. 8.2. Internal audits DSMI/ISO/F/011 This is first round of internal audit against the requirements of FAMI- QS. However, Last ISO audit was carried out on 7/03/12. Total 13 NC’s identified and are closed. 9 Control of non‐conforming products DSMI/ISO/SP/04 Procedure is in place for control of non conforming products. Non conforming products are recorded in Product NCR (DSMI/ISO/F/006A). Checked PNCR dt: 29/03/12, product – Rice husk, customer: Sayli Agro. 1200kg material rejected. 9.2. Complaint handling system DSMI/MKT/SP/05 Procedure is documented for customer complaint management. 9.3. Recall DSMI/SP/QC/06 Procedure is documented for product recall, which can be initiated at any point of time. 9.4. Crisis Management DSMI/SP/MR/08 Procedure is documented for emergency preparedness and response which details various crisis situations and actions to be taken to

- 24. FAMI-QS V5 - Internal Audit Check-List Format No: DSMI/ISO/F/011A Date : 01/1/2011 ensured feed safety during such crisis. 10 Statistical techniques Audit Findings: 1. Minor NC: Feed safety related objective not stated. 2. Minor NC: Adequate cleaning may not be possible of the production floor as damaged floor is evident in production area near Buhler Mixer infront of dispatch area. 3. Minor NC: Record keeping is not done for the cleaning activity performed after maintenance work. 4. Minor NC: Gaps were evident below emergency exit near Buhler control room. Shutter near local RM storage area is not closing properly leaving a gap. From these gaps pest / rodent activity is possible. 5. Minor NC: Evaluation of transporters (VRL Logistics Ltd.) is not evident. Sr. No. Auditor Audited Clauses Date 1. Sushant Katkar (Investe Consulting) 4, 5, 6.3, 6.7, 7.1, 7.2, 7.3, 7.4, 7.5, 7.6, 8, 9 3rd & 4th May 2012 2. Sanjay D’Costa (Investe Consulting) 6.1, 6.2, 6.4, 6.5, 6.6 3rd & 4th May 2012