3 Welded joints

- 2. 1) INTRODUCTION 2) ADVANTAGES & DISADVANTAGES OF WELDED CONNECTIONS 3) TYPES OF WELDING PROCESSES 4) TYPES OF WELDED JOINTS 5) STRESSES & STRESS CONCENTRATION FACTORS OF WELDED JOINTS 6) ANALYSIS OF UNSYMMETRICAL WELDED SECTIONS WHICH ARE AXIALLYLOADED 7) SPECIAL CASES OF FILLET JOINTS 8) SOLVED EXAMPLES

- 3. The process of permanently joining two or more metal parts by the fusion of edges of the metals with or without applying pressure and a filler material is called welding If pressure is applied Forge welding Without pressure, with a separate weld metal Fusion welding In a fusion welding, heat of melting is obtained by two ways:- a) Gas heating b) Electric arc

- 4. Advantages:- 1. Comparatively lighter than riveted structures 2) Greater strength compared to riveted joints 3) Addition and alterations can be done easily 4) Better finish than riveted joints. Hence maintenance costs and painting costs are less 5) Lesser time consuming 6) Tension members are not weakened in welded joints compared to riveted joints

- 5. Disadvantages:- 1) Requires skilled labour 2) Possibility of additional stress development due to uneven heating and cooling. Or in other words, the members may get distorted 3) Testing is difficult. 4) As there is no provision for expansion or contraction of joints, cracks may develop and propogate

- 7. Fusion welding is a welding in which the parts to be jointed are held in position while the molten metal is supplied to joint The molten metal may come from the parts themselves (ie parent metal) or filler metal which normally have the composition of the parent metal The fusion welding can be classified into three types based on the method of heat generation. Viz Thermit welding, electric arc resistance welding and gas welding

- 8. Thermit welding: Thermit= Aluminium + Iron oxide Thermit is heated, melted and then poured into a mould made around the joint and fuses with the parts to be welded Advantages of thermit welding Simultaneous melting of thermit and parts Uniform cooling of molten metals and thermit.

- 9. No residual stresses Fundamentally, thermit welding= melting +casting Applications:- Fabrication of rails, locomotive frames, stern frames, rudder frames. Repair applications:- Replace broken teeth, weld necks on rolls or pinions, repair broken shears.

- 10. Gas welding: Applying flame of an oxy-acetylene or hydrogen gas from a welding torch upon the surfaces of the prepared joint The intense heat at the white cone of the flame heats up the local surfaces to fusion point and using the welding rod supplies metal for the weld Heating rate is slow and hence is used for thinner metals

- 11. Electric arc welding Base metal is melted using arc stream forming a pool of molten metal. This molten metal is forced out of the pool by the blast from arc A small depression is formed in the base metal and the molten metal is deposited around the edge of this depression, which is called arc crater

- 12. There are two types of arc welding Unshielded arc welding:-Larger filler rod is used Here the weld metal in molten state mix with oxygen and nitrogen in the atmosphere forming a relatively weaker joint It has lower ductility and corrosion resistance

- 13. In shielded metal arc welding (SMAW),thewelding rods are coated with solid material This coating helps in focusing the arc stream, which protects the globules of metal from air Prevents the absorption of large amounts of harmful oxygen and nitrogen

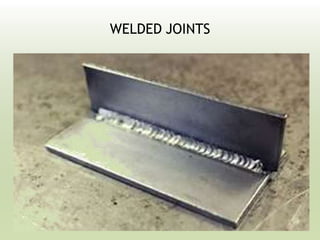

- 14. The two important types of welded joints are:- 1. Butt weld 2. Lap (Fillet joint) 3.1) Butt weld joint:- If the edges of the two plates are touching each other and are joined by welding, then the joint is called butt weld joint

- 15. Let l= length ofweld t= Depth of weld F=Tensile force σt= Allowable tensile stress The tensile force, F= σt x A= σt x l x t

- 16. Types of butt welds are A) Single V butt joint B) Double V butt joint C) Single U butt joint D) Double U butt joint

- 17. Fillet weld or lap joint When the two members are overlapped and joined by welding, then the joint is called fillet weld joint

- 18. Let l= length ofweld t= Throat thickness s= Size of weld F=Tensile force σt= Allowable tensile stress for wedmetal

- 25. Throat thickness= AB sin45=s x 0.707 Throat area (minimum area of weld)= Length of weld x throat thickness= l x s x 0.707 Tensile strength of the joint/ maximum tensile force which the fillet joint can take P=Allowable tensile stress of the weld x throat area= σt x0.707 x l x s Tensile strength of the joint for double fillet weld= 2 x σt x0.707 x l x s= 1.414 x σt xl x s

- 26. Strength of parallel fillet joint Parallel fillet welds are designed for shear strength Consider a double parallel fillet joint as shown below

- 27. If τ is the allowable shear stress of the weld metal, then the weld strength (shear strength) of the joint is F= Allowable shear stress x throat area= 2 x 0.707 x s x l x τ Consider a combination of transverse fillet weld and parallel fillet weld

- 28. If τ is the allowable shear stress of the weld metal and σt is the allowable tensile stress of the weld metal, then the weld strength (shear strength) of the joint is F = σt x l1 x 0.707 x s + τ x l2 x 1.414 x s For re-inforced welded joints, the throat dimensions may be taken as 0.85 times the plate thickness

- 30. Consider an unsymmetrical section (angle) welded on flange edges subjected to an axial loading Let la = length of the weld at the top lb = length of weld at the bottom L= total length of weld= la+lb

- 31. P= Axial load a= Distance of the top weld from an axis passing through the CG of the angle (known as the gravity axis) b= Distance of the bottom weld from gravity axis. f= Resistance offered by the weld per unit length. Resistance offered by top weld= f x la

- 32. Moment of the resistance offered by top weld about the gravity axis= f x la x a Similarly the moment of resistance offered by the bottom weld about the gravity axis= f x lb x b For equilibrium, sum of these moments should be zero. Hence f x la x a= f x lb x b => la x a= lb x b; l= la +lb Hence la= l x b / (a+ b) and lb = l x a/(a + b)

- 33. Circular fillet weld subjected to torque/ torsion Consider a circular rod connected to a rogid plate by a fillet joint as shown below.

- 34. Let d= Diameter of the rod r= Radius of the rod T= Torque applied s=Size of weld/ weld leg size t= Throat thickness J= Polar moment of inertia of the weld section= ∏d³t/4

- 35. According to torsion equation, Maximum shear stress generated due to torsion τ=T.r/J τ= T x2/∏d²t. Throat thickness, t=s x 0.707 Hence τ= 2T/(∏d² x sx0.707) => τ=2.83T/∏d²s 6.2) Circular fillet weld subjected to bending moment Consider a circular rod connected to a rigid plate by a fillet weld as shown below

- 36. Let M be the bending moment to which the weld/rod is subjected to and Z be the section modulus. Z=∏d²t/4 Bending stress σb= M/Z= (4 x M)/ ∏d²t t=s x0.707 Hence b=5.66M/ ∏d²s

- 37. Two steel plates 10cm wide and 1.25cm thick are to be joined by double lap weld joint. Find the length of the weld if the maximum tensile stress is not to exceed 75 N/mm² and maximum tensile load carried by the plates is 100kN. Soln) Given:- Width of the plate= 0.1m Thickness of the plate, s= weld leg size=(1.25/100) m Length of weld, l= ? σt= Maximum tensile stress= 75 x 10^6 N/m² Maximum tensile load, F= 10^6 N l= F/ (1.414 x σt x t) => l= 0.7544m= 75.44cm

- 38. Two plates of width 15cm and thickness 1.25cm are welded by a single V butt joint. If the safe stress in the weld is 135MPa, find the permissible load carried by the plates. Soln) Given: s= 1.25/100 m σt= 135 x10^6 N/m² P= (σt x s x l)= 135 x10^6 x 1.25/100 x 0.15 (Length of weld= width of plate)= 253125N= 253.125kN

- 39. A plate 10cm wide and 1.15cm thick is joined with another plate by a single fillet weld and a double parallel fillet weld as shown below. The maximum tensile and shear stresses are 75N/mm² and 55N/mm² respectively. Find the length of each parallel fillet if the joint is subjected to a load of 80kN.

- 40. Given:- σt= 75MPa, τ= 55MPa, Width of plate, b= 100mm Length of single fillet weld, l1= width of plate=100mm Thickness of plate= weld leg size= 1.15/100 m l2= Length of each parallel fillet weld. F1= Force carried by single fillet weld= 0.707 x σt x l1 x s= 60978.75N F2= Load carried by double parallel fillet weld= 1.414 x l2 x s x τ= 894355 x l2 F= F1+F2 => 80000=60978.75 + F2 => l2= 0.02127m= 2.13cm

- 41. A 200mm x 150mm x 10mm angle carrying a load of 250kN, is to be welded to a steel plate by fillet welds as shown below. Find the length of the weld at the top and bottom if the allowable shear stress in the weld is 102.5kPa. The distance between the neutral axis and the edges of the angle section are 144.7mm and 55.3mm respectively Given: a= 144.7mm, b= 55.3mm, F= 250kN= F1 + F2 l=l1+ l2 F= τ x (l1 + l2) x 0.707 xs => (l1+ l2)= 0.345m l1= l x b/(a+b)= 0.345 x55.3/200 =0.0954=9.54cm l2= l – l1= 24.96cm