Casting gold alloys

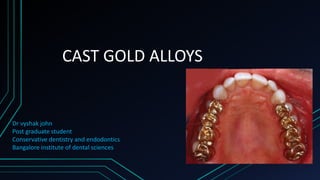

- 1. CAST GOLD ALLOYS Dr vyshak john Post graduate student Conservative dentistry and endodontics Bangalore institute of dental sciences

- 2. CONTENTS 1. Introduction 2. History 3. Terminology 4. Alloys 5. Classification 6. Composition 7. Properties of Gold Alloys

- 3. 8.Desirable properties of casting gold alloys 9.Advantages and Disadvantages 10.Indications and Contraindications 11.Conclusions 12.Refrences

- 4. Introduction • Casting is one of the most widely used methods for the fabrication of indirect restorations outside the mouth. • They are most effective to replace areas of stress concentration within a tooth and reinforce weakened tooth structure. • Cast gold restorations have a long history of success as they are strong,inert and reproduce precise details. • The fabrication of cast gold restorations require careful treatment planning and operative skills.

- 5. • Until recently gold based alloys are used extensively to restore large carious lesion such as inlays,onlays,and single crown restoration since they contain 75% of gold and platinum group of metals. • Gold is combined with other metals to produce alloys with adequate properties for dental applications.

- 6. HISTORY The practice of using gold crowns and bridges date back to 700-500 BC. In dentistry credit is given to Dr.SWASEY(1890)introduced a technique where a solid gold inlay could be prepared . In his technique,the gold foil was first adapted to the shape and contour of the tooth,then removed ,invested and filled with 20k gold.

- 7. • Dr. PHIL BROOK in 1897 ,was the first to introduce inlay in dentistry who gave the concept of forming investment around wax pattern,eliminating the wax,and filling resultant mould with a gold alloy. • TAGGART’s presentation to the New York Odontological group in 1907 on the fabrication of cast inlay restorations often has been acknowledged as the first reported application of the lost wax technique in dentistry.

- 8. An alloy with the brand name of vitallium was introduced in 1930 and is a cobalt chromium alloy. In 1932, the dental materials group at the National Bureau of standards surveyed the alloys being used and classified them as • Type I (Soft , VHN between 50 and 90) • Type II (Medium VHN between 90 and 120) • Type III (Hard VHN between 120 and 150) • Type IV (Extra hard, VHN 150) • ANSI/ADA Specification no.5 • ISO standard 15592.

- 9. 1933 – Cobalt – chromium Partial Denture Alloys 1. Base metal removable partial denture alloys were introduced in the 1935. Since that time, both nickel – chromium and cobalt – chromium formulations have become increasingly popular compared with conventional Type IV gold alloys 2. The advantages of the base metal alloys are their lighter weight, greater stiffness, other beneficial mechanical properties, and reduced costs. 3. For these reasons, nickel – and cobalt – based alloys have largely replaced noble metal alloys for removable partial denture.

- 10. In 1948,metallurgists experimenting with various alloys were able to decrease the gold content while maintaining their resistance to tarnish. This breakthrough was due to palladium.It counteracted the tarnish potential of silver. 1950-Developments of resin veneers for gold alloys. 1959-Introduction of porcelain fused to metal technique. In the late 1950s, there was the successful Veneering of a metal substructure with dental porcelain. Until that time, dental porcelain had a markedly lower coefficient of thermal expansion than did gold alloys. This thermal mismatch often led to impossible to attain a bond between the two structural components.

- 11. It was found that adding both platinum and palladium to gold lowered the coefficient of thermal expansion/contraction of the alloy sufficiently to ensure physical compatibility between the porcelain Veneer and the metal substructure. In 1968-Palladium based alloys as alternative to gold alloys. In 1971-nickel based alloys as alternative to gold alloys. 1971 – The Gold Standard

- 12. • The United States abandoned the gold standard in 1971. • Prices of gold increased, in response to that, new dental alloys were introduced through the following charges. • In some alloys, gold was replaced with palladium. • In other alloys, palladium eliminated gold entirely. • Base metal alloys with nickel as the major element eliminated the exclusive need for noble metals.

- 13. Palladium-silver alloy type was introduced to the US market in 1974 as the first gold free noble alloy available for metal ceramic restorations. The first alloy of the gold palladium type (group V according to ADA)Olympia was introduced in 1977 by JF JELENKO AND CO.

- 14. 1980’s –Introduction of All ceramic technologies. Using a mesh screen pattern as a castability monitor,WHITLOCK ET AL in 1985 measured percent castability values of fourteen metal –ceramic alloys. 1999-Gold alloys as alternatives to palladium based alloys.

- 15. • Thus the history of dental casting alloys has been influenced by 3 major factors: 1.The Technologic changes of dental prosthesis. 2.Metallurgic Advancements. 3.Price changes of Noble metals since 1968.

- 16. TERMINOLOGY • NOBLE METALS • The periodic table of the elements show eight noble metals. • They are GOLD,PLATINUM,PALLADIUM,RHODIUM,RUTHENIUM,IRIDIUM,OSMIUM and SILVER

- 17. • They are used traditionally for inlays,crowns and bridges.Currently only gold,palladium and platinum are of most importance in dental casting alloys.

- 18. • PRECIOUS METALS • Contains metals of high economic value and traditionally as a group include all of the noble metals and silver. • SEMIPRECIOUS METAL ALLOYS • Generally refers to alloys that are based either on palladium or on silver.Alloys that contain atleast 50 wt% palladium include palladium-silver,palladium- copper-gallium,palladium-cobalt-gallium,palladium-gallium-silver,and palladium –gold.

- 19. • LOW GOLD ALLOYS • Low gold alloys contain 3 to 50 weight percent gold or other noble metal elements.Low gold alloys are attempts at producing lower cost alloys that still retain some of the qualities of premium priced gold based alloys. • Gold substitute alloys • They are precious metal alloys that do not contain gold.The best examples are Ag-Pd systems and other Pd alloys.

- 20. • BASE METAL ALLOYS • Base metal alloys are based on active metallic elements that corrode but develop corrosion resistance via surface oxidation that produces a thin, tightly adherent film that inhibits further corrosion. Alloys are formulated with 18%to 28% by weight Cr that produces films of chromium oxide that passivate the surface oxidation of other elements ,such as Ni and Co,to produce superficial oxides,but chromium oxide is principally responsible for the corrosion resistance.

- 21. • KARAT • It is parts of pure gold in 24 parts of alloy. • For eg.22 carat gold is pure gold with the remaining two parts consisting of other metals.

- 22. • FINENESS • It is the parts per 1000 of pure gold.The dental gold alloys vary from 21-6- 14.4carat and 900-600 fine. • Pure gold is 1000 fine and thus if three fourths of alloy is pure gold is 750 fine. • Percentage gold=karat × 100/24.

- 24. ALLOYS DEFINITION: • An alloy is defined as a metal body containing two or more elements ,atleast one of which is metal and all of which are mutually soluble in the molten state. • Most alloys solidify over a range of temperature rather than at a single temperature as does a pure metal. • Within in this temperature range two phases,solid and liquid exists.

- 25. • Solid solutions • The greater number of alloys used for dental restoration is solid solutions. • When two metals are soluble in one another in the solid state,the solvent in that metal whose space lattice persists and the solute in the other metal. • So solvent may be definied as the metal whose atoms occupy more than one half the total numbers of portions in the space lattice.

- 26. • The configuration of space lattice may be of several types. In the substantial type the atoms of the solute occupy the space lattice positions that normally are occupied by the solvent atom in the pure metal. • In the interstitial solid solution the solute atoms are present in the portion between the solvent atoms. • This type of solid solution ordinarily requires that the solute atoms be much smaller than the solvent atoms.

- 27. • Conditions for solid solubility; • There are atleast four factors that determine the extent of solid solubility of two metals ATOM SIZE VALENCE CHEMICAL AFFINITY LATTICE TYPE

- 28. • ATOM SIZE: • If the size of the two metallic atoms differ by less than approximately 15% they posses favorable size factor for solid solubility. • If the size is greater than 15% multiple phases occur during solidification. • VALENCE: • Metals of same size and valence are more likely to form extensive solid solutions than are metals of different valencies. • If the valencies differ ,the metal with the higher valence may be more soluble than a metal of lower valence.

- 29. • CHEMICAL AFFINITY: • When two metals exhibit a high degree of chemical affinity,they tend to form an intermetallic compound on solidification rather than a solid solution. • LATTICE TYPE: • Only metals with same type of crystal lattice can form a complete series of solid solutions ,particularly if the size factor is less than 8%.

- 30. CLASSIFICATION • In 1984 ADA proposed a simple classification based on the noble metal content: High Noble (HN) -Must contain 40 wt% Au And 60 wt% of noble metal elements (Au, Pt, Pd, Rh,Ru,Ir, Os) Noble (N)-Must contain 25wt% of noble metal elements (Au, Pt, Pd, Rh, Ru, Ir, Os) Predominantly Base Metal (PB)-Contain 25 wt% of noble metal elements

- 31. • According to number of alloys present: BINARY TERNARY QUATERNARY • According to major element present: Gold alloys Silver alloys Palladium alloys

- 32. Nickel alloys Cobalt alloys Titanium alloys Copper alloys • According to the dominant phase system: Single phase(isomorphous) Eutectic Peritectic Intermetallic

- 33. • According to three major elements: Gold palladium silver Palladium silver tin Nickel chromium molybdenum Cobalt chromium molybdenum Iron nickel chromium Titanium aluminum

- 34. • Based on materials:(ACCORDING TO MARZOUK) Class 1: These are gold and platinum group based alloys in accordance with the ADA specification #5.They are type 1,2,3,4 Gold alloys. Class 2: These are low gold alloys ,with gold content less than 50%,some may contain as little as 5% gold. Class3: These are non gold palladium based alloys Class 4:Nickel-chromium based alloys Class 5 :Castable ,moldable ceramics.

- 35. • According to yield strength and percentage elongation ADA/ANSI specification no.5 has classified as- Alloy Type Minimum yield strength (0.2%) or proof stress of nonproportional elongation (Mpa) Minimum elongation after fracture (%) TYPE 1 Soft 80 18 TYPE 2 Medium 180 10 TYPE 3 Hard 270 5 TYPE 4 EXTRA HARD 360 3

- 36. • Casting alloys for metal and metal ceramic restorations:(ANUSAVICE) Alloy TYPE ALL METAL REST. METAL CERAMIC REST. HIGH NOBLE Au-Ag-Pd Pure AU(99.7%) AU-Pd-Cu-Ag Au-Pt-Pd High noble metal Au-Pd-Ag(5-12WT%Ag) Ceramic alloys Au-Pd-Ag Au-pd NOBLE Ag-Pd-Au-Cu Pd-Au Ag-Pd Pd-Au-Ag Noble Metal Pd-Ag Ceramic Alloys Pd-Cu-Ga Pd-Ga-Ag

- 37. Base metal Cp Ti Cp Ti Ti-Al-V Ti-Al-V Ni-Cr-Mo-Be Ni-Cr-Mo-Be Ni-Cr-Mo,Co-Cr-Mo Ni-Cr-Mo,Co-Cr-Mo Co-Cr-W,Cu-Al Co-Cr-W

- 38. • Description of the classification: • Type 1- soft alloy:These alloys are easily burnishable ,used in low strength castings which are subjected to a very slight stress i.e;small inlays,class 3 and class 5 cavities. • They are quite ductile and exhibit a low proportional limit. • They have a high melting point.

- 39. • Type 2: Medium alloys: • These are used in medium strength castings that are subjected to moderate stress • They are mainly used in Inlays subjected to moderate stress. Thick ¾ crowns Abutments Pontics Full crowns and some times soft saddles. • They are harder than type 1 alloys.

- 40. • Type 3 Hard alloys: • Hard alloys are used in high strength castings that are subjected to high stress. • They are used in Inlays Onlays Thin cast backings Pontics Full crowns

- 41. Saddles Thick veneer crowns Short span FPD. • Because of increased use of composite and ceramic inlays,the type 1 and type 2 inlay alloys are rarely used these days. • TYPE 4 –EXTRA HARD ; • They are used in extra high strength castings that are subjected to very high stress and thin cross sections.

- 42. • They are mainly used in: Saddle bars Clasps Thimbles Unit castings Thin veneer crowns Long span fpd and rpd frame works. • Although they are strongest and hardest, it is necessary to provide a comparatively a low fusion temperature,since a considerable amount of alloy must be melted at one time.

- 43. COMPOSITION • Dental casting alloys are alloyed commonly with copper,silver,platinum,nickel and zinc. • Alloying gold with these metals not only improves its physical and mechanical properties but also reduces its cost. • Increase in the platinum,palladium,and silver content of modern alloys have resulted in whiter coloured gold alloys. • Thus there are yellow gold alloys and white gold alloys. • The rise in gold prices also has led to the availability of alloys with low gold content.These are the low golds. • Each metal when added to gold contributes to certain physical and chemical properties to the alloy:

- 44. Gold: The chief contribution of gold is to increase tarnish resistance of the alloy. Yellow in colour It also contributes to ductility of the alloy and is a factor in heat treatment principally in combination with copper.

- 45. Copper It is the second most important constituent of the alloy ,since it increases the hardness and strength. Copper tends to reduce the corrosion resistance of the alloy. It imparts reddish colour to the alloy which may be displeasing to both patient and dentist

- 46. Lowers fusion temperature Reduces dentisity of the alloy Forms solid solution with gold

- 47. SILVER Silver is likely to be somewhat neutral in its effect on the alloy. It tends to whiten the alloy . It may enrich the yellow colour of gold by partially neutralizing the reddish colour contributed by the copper. Forms solid solution with gold and partial solubility with copper.

- 48. PLATINUM • It is the best hardener and strengthener of gold even better than copper. • It increases the tarnish and corrosion resistance of the alloy as does gold. • As it increases the melting temperature quite radically its use in casting gold is limited to approximately 3-4%. • Whitens the alloy

- 49. PALLADIUM • Similar to platinum in its effects. • It hardens and whitens the alloy. • It also raises the fusion temperature and provides tarnish resistance. • It is less expensive than platinum, thus reducing the alloy cost. • Absorbs gases formed during casting thus reduces porosity.

- 50. ZINC • It acts as a scavenger for oxygen. • While the alloy is molten, ready to cast ,the zinc may combine with any oxygen present and be converted to zinc oxide, which floats off in the air. • Thus it aids in preventing oxidation of the alloy during casting procedure.

- 51. • CALCIUM: • It is added to compensate for the decreased coefficient of thermal expansion when the alloy is made silver free. • IRIDIUM ,RUTHENIUM,AND RHODIUM: • As a little as 0.005% they can reduce the grain size of the gold alloy.

- 52. PROPERTIES OF GOLD ALLOYS • COLOUR: • Traditionally the gold alloys are gold coloured. • The colour of the modern gold alloys can vary from gold to white depending on the amount of whitening elements present in the alloy.

- 53. • MELTING RANGE: • Ranges between 920⁰-960⁰C. • It indicates the type of investment required and the type of heating source needed to melt the alloy. • DENSITY: • It gives an indication of the number of dental castings that can be made from a unit weight of the metal. • Gold alloys are lighter than pure gold(19.3g/cm) • Type 3-15.5g/cm, Type 4 -15.2 g/cm.

- 54. • HARDNESS: • The hardness indicates the ease with which these alloys can be cut,ground/polished. • Gold alloys are generally mere user friendly than the base metal alloys which are extremely hard. • For Type 3-121mpa and Type 4-149mpa. • ELONGATION AND YEILD STRENGTH: • These are the measures of the deformability (Burnishability)of the material and the forces needed to achieve the deformability.

- 55. • It indicates the ductility of the alloy. • A reasonable amount is to be deformed during clinical use and clasp adjustment for RPD,margin adjustment and burnishing of crowns and inlays. • Alloys with low elongation are very brittle. • Type 1 alloys are easily burnished. • Age hardening decreases ductility • Type 3-30-40% and Type 4-30-35%. • Type 3 -207 MPA and Type4-275MPA.

- 56. • MODULUS OF ELASTICITY: • This measures the rigidity of the alloy. • Gold alloys are least rigid while ceramics are the most rigid materials . • Rigidity is a factor in abrasion resistance of the material • It indicates the stiffness /flexibility of the material. • Elastic modulous of gold based alloys is 75-110GPA.

- 57. • Biocompatibility: • The material must tolerate oral fluids and not release any harmful products into the oral environment. • Gold alloys are relatively biocompatible. • TARNISH AND CORROSION RESISTANCE: • Tarnish is a thin film of a surface deposit or an interaction layer that is adherent to the metal surface. These films are generally found on gold alloys with relatively high silver content or on silver alloys.

- 58. • Due to their high noble metal content, gold alloys are resistant to tarnish and corrosion. • Corrosion is the physical dissolution of a material in an environment. • Corrosion resistance is derived from the material components being either too noble to react in the oral environment (e.g., gold and palladium) or by the ability of one or more of the metallic elements to form an adherent passivating surface film, which inhibits any subsurface reaction. • Most precious alloys begins to corrode if gold content is less than 75%.

- 59. • CASTING SHRINKAGE: • The casting shrinkage in gold alloys is less (1.24-1.64%)when compared to base metal alloys. • Shrinkage affects the fit of the restoration.Therefore ,it must be controlled and compensated for the casting technique. • The shrinkage occurs in 3 stages : Thermal contraction of the liquid metal. Contraction of the metal changing from liquid to solid state. Thermal contraction of solid metal as it reaches room temperature.

- 60. • Linear solidification shrinkage of casting alloys: • Type 1 -1.56% • Type 2-1.37% • Type 3-1.42%

- 61. • GRAIN STRUCTURE: • Gold alloys seen under the microscope show the crystal or grain structure and any porosity present. • Fine grained alloys have relatively large grains. • Fine grained alloys are generally stronger and are more ductile than coarse grained alloys of the same general composition.

- 62. • The average grain size in a gold casting is about 300 microns as compared with only 60 microns for a fine grained alloy. • Iridium is frequently added as a grain refiner.

- 63. HEAT TREATMENT OF GOLD ALLOYS • Heat treatment of gold alloys is done in order to alter its mechanical properties. • Gold alloys can be heat treated if it contains sufficient amount of copper. • Only type 3 and type4 gold alloys can be heat treated. • There are two types of heat treatment 1. Softening heat treatment(solution heat treatment) 2. Hardening heat treatment(age hardening).

- 64. • SOFTENING HEAT TREATMENT: • It increases the ductility ,but reduces tensile strength,proportional limit and hardness. • INDICATIONS: • It is indicated for appliances that are to be ground,shaped or otherwise cold worked in or outside the mouth.

- 65. • METHOD: • The usual softening heat treatment is to heat the alloy in an electric furnance for 10 minutes at a temperature of 700⁰c(1209⁰F)and then quench it in water. • During this period all intermediate phases are changed to a disordered solid solution and then rapid quenching prevents ordering from occurring during cooling.

- 66. • HARDENING HEAT TREATMENT: • It increases strength,proportional limit and hardness but decreases ductility. • It is the copper present in gold alloys which helps in the age hardening process • INDICATIONS: For strengthening metallic dentures,saddles ,bridges and other similar structures before use in the mouth. It is not employed for small structures such as inlays.

- 67. • METHOD: • The alloys can be cooled slowly from 700⁰c instead of being quenched. • Such treatment allows the proper super lattice transformation to takes place. • This phenomenon is solid to solid transformation. • Since the transformation usually occur at a temperature lower than 700 ⁰c ,another heat treatment called the oven cooling treatment which is to cool the alloy from 450⁰c to 250⁰ c over a period of 30minutes in the furnance and then quench it in water.

- 68. • The most practical method is to soak or age the alloy at a definite temperature for a definite time before it is quenched. • This treatment is often known as the" AGING HEAT TREATMENT”(350⁰c - 450⁰c). • The time required for such treatment is usually 15 minutes. • During this aging at the proper temperature ,solid to solid transformations takes place and are governed in amount by the time of the treatment.

- 69. • The proper temperature depends on the composition of the alloy and is specified by the manufacturer. • Generally ,when such treatment are used , the structure is given a softening heat treatment first , after which it is contured ,bent,or cold worked in any manner while its ductility at its maximum. • The structure can then be given a hardening heat treatment.

- 70. • LOW GOLD ALLOYS: • Also known as economy gold . • They are crown and bridge alloys having gold content below 60%(generally 42- 55%).However gold must be the major element. • The low gold alloys were developed because of the increase in gold prices. • However reducing gold content increased tarnish and corrosion. • This problem was overcome by two discoveries-

- 71. • Palladium –which made the silver in gold alloy more tarnish resistant. • 1%palladium was required for every 3% of silver. • The silver copper ratio had to be carefully balanced to yield a low silver rich phase in the microstructure.

- 72. • WHITE GOLD ALLOYS: • White gold alloys have been used since the 1930’s . • They have lower percentage of gold (30%) and greater amounts of palladium (10-35%),silver (35-65%) and copper (6-25%). • Palladium acts as a potent whitener but absorbs gases during melting that can produce porous castings.

- 73. • Reprensentative gold casting alloys • PENTRON 1(84%). • FIRMALAY (74.5%) • MODULAY (77%) • STERNGOLD100(60%)

- 74. • METHODS TO REUSE GOLD ALLOYS: • There will be always be surplus metal which is detached from the casting during the process of finishing. • Owing to the intrinsic value of the metals in the casting alloys net loss of the casting can be substantially reduced if the scrap can be recycled. • Noble metal casting alloys are sufficiently stable that they can be recast two or three times without appreciable changes in the composition.

- 75. • The only elements likely to be lost are more volatile base metals such as zinc, Tin,Iridium and Iron. • Melt the clean,pickled scrape on a charcoal block. • Add equal amount of new alloy or restore burnt out elements but do not mix different types of alloys. • Alloy scrap should be carefully cleaned and foreign material removed before reuse

- 76. DESIRABLE PROPERTIES OF CASTING GOLD ALLOYS All cast metals in dentistry have some basic common requirements Not tarnish and corrode in the mouth Sufficiently strong for the intended purpose. Biocompatible Easy to melt,cast cut and grind.

- 77. Flow well and duplicate fine details during casting Minimal shrinkage on cooling after casting Easy to solder Polishable to produce a satisfactory surface finish Minimal reactivity with the mold metal

- 78. Good wear resistance,high strength,and sag resistance . Melting range must be low enough to form smooth surfaces with the mold wall of the casting investment. Generally type 2 and type 3 gold alloys represent the standards against which the performance of others is judged.

- 79. ADVANTAGES Casting techniques and materials are capable of reproducing precise form and minute detail. Casting restorations have fewer voids,no layering effect,less internal stresses,fairly even stress patterns, maximum bonding between component phases. They are not significantly affected by tarnish and corrosion as they contain a noble or passivated metal which improves longevity ,esthetics.

- 80. Yeild strength, tensile strength and shear strength of alloys used for cast dental restorations are greater than those of any other materials used intra orally. They can finished ,polished or glazed outside the oral cavity without endangering P-D organ.

- 81. DISADVANTAGES Being a cemented restoration,several interphases will be created at the tooth cement casting junction.These interphases and the leakage accompanying them ,will become more significant. They require extensive tooth involvement in preparation creating possible hazard for vital dental tissues. The cathodic nature of cast dental alloys towards other metals used in the same mouth may lead to galvanic deterioration.

- 82. Procedure is length requiring more than one visit,with temporary restoration between visits. Cast alloys are expensive than other restorative materials. Natural teeth maybe abraded more easily due to abrasive differential leading to teeth shifting ,tilting or rotating.

- 83. INDICATIONS • 1.EXTENSIVE TOOTH INVOLVEMENT • Cast restorations are the ultimate in both efficiently replacing lost tooth structure and supporting remaining tooth structure. • 2.AS AN ADJUNCT TO SUCESSFUL PERIODONTAL THERAPY BY CORRECTION OF TOOTH ANOMALIES WHICH PREDISPOSE TO PERIODONTAL PROBLEMS • cast restorations do this by-

- 84. Physiologically restoring and permanently maintaining the dimensions of the contact,contour,marginal ridges and embrasures. Splinting teeth loosened by periodontitis to a better bone supported tooth or teeth. 3.Correction of occlusion • Cast restorations are ideal for planned changes of the occlusal table or occluding parts of a tooth.

- 85. • 4.Restoration of endodontically treated teeth: • Crown of endodontically treated teeth lose strcture and become brittle requiring a reinforcing restoration. • 5.Support for and preparatory to partial and complete dentures: • Most removable prosthesis will need cast restorations on or in the abutment teeth to hold or accommodate the retainers for denture.

- 86. • 6.Retainers for fixed prosthesis; • Cast restorations is used as a retainer for abutment tooth in a fixed bridge. • 7.partially subgingival restorations: • Poorly finished and polished cast alloys are the restorative materials most compatible with the periodontium.They are considered most practical for subgingival lesions,espically if a rubber dam cannot be applied.

- 87. • 8.Low incidences of plaque accumulation or decay: • Patients receving a cast restoration should have their plaque accumulation under rigid control to avoid problems. • 9.Cracked teeth: • They are most efficient way of restoring and splinting the cracked segments of a tooth.

- 88. • 10.Esthetics: • Properly fitted cast restorations are most pleasant esthetically and have no tendency to discolour the remaining tooth structure.

- 89. • 11.Dissimilar metals: • When cast restorations are prevalent in mouth ,new restorations should be fabricated in similar metals to minimize galvanism,premature abrasion,anodic dissolution of any other less noble materials or mechanical failure of other less qualified restorative materials.

- 90. CONTRAINDICATIONS • 1.Developing and deciduous teeth: • Growth or resorption may be affected by traumatic nature of the procedures for cast restorations. • 2.High plaque /caries indices: • Patients with uncontrollable plaque and high caries and periodontal indices are not candidates for such restorations.

- 91. • 3.Occlusal disharmony: • Cast restorations should not be used in patients with occlusal interference or other defects in the stomatognathic system. • 4.Dissimilar metals: • Cast alloy restorations are not to be used in proximal contact or in occlusion with an amalgam restoration as this will be detrimental.

- 92. CONCLUSION The diversity of alloys available to the dental practitioner has never been more extensive.We now have the opportunity to select the alloys based on the individual patient’s specific biologic,functional,and economic requirements.There is no one alloy suitable for all applications,because in metallurgy there is a constant trade off in properties as changes in formulations are made. To make optimal uses of the choices available,and for ethical and medicolegeal considerations,it is incumbent upon the practitioner to be aware of the identity and composition of the alloys prescribed.

- 93. REFRENCES • .PHILIPS SCIENCE OF DENTAL MATERIALS -11th EDITION, BY ANUSAVICE. • RESTORATIVE DENTAL MATERIALS-13th EDITION ,BY ROBERT G.CRAIG • OPERATIVE DENTISTRY MODERN THEORY AND PRACTICE- BY M.A.MARZOUK • STURDEVANT’S ART AND SCIENCE OF OPERATIVE DENTISTRY-5th EDITION,BY THEODORE M ROBERSON • CLINICAL OPERATIVE DENTISTRY-BY Dr. RAMYA RAGHU. • CASTING ALLOYS: THE MATERIALS AND "THE CLINICAL EFFECTS"H.F. MORRIS1* M. MANZ2 W. STOFFER3 D. WEIR4 , MI 48105Adv Dent Res 6:28-31, September, 1992

- 94. • Gold in Dentistry: Alloys, Uses and PerformanceHelmut Knosp, Consultant, Pforzheim, Germany Richard J Holliday, World Gold Council, London, UK Christopher W. Corti, World Gold Council, London, UK.