3. Assessment Practical.docx

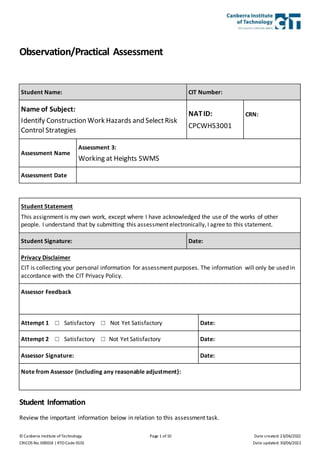

- 1. © Canberra Institute of Technology Page 1 of 10 Date created: 23/06/2022 CRICOS No. 00001K | RTO Code 0101 Date updated: 30/06/2022 Observation/Practical Assessment Student Name: CIT Number: Name of Subject: Identify Construction Work Hazards and SelectRisk Control Strategies NATID: CPCWHS3001 CRN: Assessment Name Assessment 3: Working at Heights SWMS Assessment Date Student Statement This assignment is my own work, except where I have acknowledged the use of the works of other people. I understand that by submitting this assessment electronically, I agree to this statement. Student Signature: Date: Privacy Disclaimer CIT is collecting your personal information for assessment purposes. The information will only be used in accordance with the CIT Privacy Policy. Assessor Feedback Attempt 1 ☐ Satisfactory ☐ Not Yet Satisfactory Date: Attempt 2 ☐ Satisfactory ☐ Not Yet Satisfactory Date: Assessor Signature: Date: Note from Assessor (including any reasonable adjustment): Student Information Review the important information below in relation to this assessment task.

- 2. © Canberra Institute of Technology Page 2 of 10 Date created: 23/06/2022 CRICOS No. 00001K | RTO Code 0101 Date updated: 30/06/2022 Instructions You are required to develop a Safe Work Method Statement (SWMS) for Removing and Replacing a window on the second level of a home. In consultation with the teacher and class you will determine legislative requirement for the preparation of a SWMS. You will be taken by your teacher to the work site, and you will identify all risks and site hazards. You will complete the SWMS ensuring compliance with Federal, State and Territory legislation, Australian Codes of Practice, Australian and Industry standards. When completed and assessed the JSA must be uploaded into Ready Skills Time Allowed 2 hours Assessment Conditions Assessment will be always conducted in simulated work environment CIT Bruce under teacher supervision. If at any stage the assessor deems the assessment to be unsafe it will be stopped, and this will count as your first attempt. Access to all resources, manual and standards is permitted. All mobile phones are to be switch off. Materials Provided by CIT All materials and tools required to complete the task will be provided. Materials You Need Personal protective equipment (PPE), and a device that can access Ready Skills Attempts You may have at least two (2) attempts for this assessment. If your first attempt is not successful, your teacher will discuss your results with you and will arrange a second attempt. If your second attempt is not successful, you may be required to re-enrol in this unit. Please refer to the CIT Assessment Policy if you have any questions.

- 3. © Canberra Institute of Technology Page 3 of 10 Date created: 23/06/2022 CRICOS No. 00001K | RTO Code 0101 Date updated: 30/06/2022 Observation/Practical Checklist You must successfully complete the following skills in the Observation/Practical checklist. (Please Note: Students only need to complete grey boxes. Your teacher will provide you with feedback and advise whether your work is Satisfactory or Not Yet Satisfactory). Student Name: CIT Number: During the task the following skills were demonstrated satisfactorily: Attempt 1 Attempt 2 Date (Optional) Date (Optional) Observation/Practical Checklist Items S* NYS* S* NYS* 1. Review requirements of work health and safety legislation for preparation of safe work method statements (SWMS). ☐ ☐ ☐ ☐ 2. Determine work site conditions and job task requirements for working safely at heights. ☐ ☐ ☐ ☐ 3. Determine and record high-risk work site and task hazards relevant to working safely at heights. ☐ ☐ ☐ ☐ 4. Break job task into logical steps, document the required tools, equipment, and materials to be used for each step, and record on SWMS. ☐ ☐ ☐ ☐ 5. Identify high-risk work site and task-related hazards and levels of risk relating to each step, and record on SWMS. ☐ ☐ ☐ ☐ 6. Apply hierarchy of controls to determine risk control strategies for each high-risk hazard in each step of the job task, discuss and confirm with relevant personnel, and record on SWMS ☐ ☐ ☐ ☐ 7. Review work site and job task immediately before starting work and discuss SWMS with relevant personnel to confirm as still applicable ☐ ☐ ☐ ☐ 8. Review SWMS and amend as required. ☐ ☐ ☐ ☐ 9. Store SWMS securely on site in accordance with compliance requirements. ☐ ☐ ☐ ☐ *S –Satisfactory, NYS – Not Yet Satisfactory

- 4. © Canberra Institute of Technology Page 4 of 10 Date created: 23/06/2022 CRICOS No. 00001K | RTO Code 0101 Date updated: 30/06/2022 Canberra Institute ofTechnology Building and EnvironmentCentre GPO Box 826 Canberra ACT 2601 T: 6207 7458 Principal Contractor (PC) Works Manager: Work Location: P Block High Risk Facility Bruce CIT Bruce High Risk training compound - Contact Phone: Building and Environment Centre Work Activity: EWP (<11m) Up to 11m including Scissor Lift High Risk Work involves: Risk of falls from greater than 2 metres Work on a telecommunications tower Demolition of load-bearing structure Likely to involvedisturbing asbestos Temporary load-bearing support structures Work in confined spaces Work in or near shaft or trench with an excavated depth greater than 1.5m or a in tunnel Useof Explosives Work on or near pressurised gas pipes or mains Work on or near chemical, fuel or refrigerant lines Work on or near energised electrical installations or services Work in an area with contaminated or flammable atmosphere Work with tilt up or pre-cast concrete Work on, in or adjacent to road, rail shipping or other major traffic corridor Work in an area with movement of powered mobileplant Work in or areas with artificial extremes of temperature Work in or near a drowning risk Diving work Other [please specify]: ...................................................................................................................................................................................................................... Has the SWMS been developed based on a site-specific risk assessment? YES NO [Note: A WorkSafe ACTinspector may ask to sight evidence of this risk assessment] Have workers been consulted about the SWMS? Workers: YES NO

- 5. © Canberra Institute of Technology Page 5 of 10 Date created: 23/06/2022 CRICOS No. 00001K | RTO Code 0101 Date updated: 30/06/2022 Name[s] of workers consulted Date received: Worker signature[s] Person Responsible for ensuring compliance with SWMS Date SWMS Provided to PC: Person(s) Responsible for reviewing the SWMS Last SWMS Review Date: Date received: Signature:

- 6. © Canberra Institute of Technology Page 6 of 10 Date created: 23/06/2022 CRICOS No. 00001K | RTO Code 0101 Date updated: 30/06/2022 PROJECT NAME: CIT HR Training Centre Bruce ACT 2601 PROJECT NUMBER: Site Supervisor Responsible for the implementation of this SWMS Personnel Qualifications and Experience Required Training to be provided Licenses Required to Operate Plant & Equipment PPE Warning signs and protective barriers equipment to be used Legislation, Codes of Practices Relevant to this Work Process AS/NZS Applicable to this Work Process Plant and Equipment Required Plant and Equipment Maintenance Required Engineering details/Certificates/WorkCover approvals: List of other documents/Attachments (drawings, sketches, diagrams) SWMS recorded and stored

- 7. © Canberra Institute of Technology Page 7 of 10 Date created: 23/06/2022 CRICOS No. 00001K | RTO Code 0101 Date updated: 30/06/2022 What are the tasks involved? What are the hazards and risks? (What is the problem?) What are the control measures? (Describe the control measures and how they will be used) Think about the workplace and each stage of the work, including preparation and clean-up. Identify the hazards and risks that may cause harm to workers or the public. Describe what will be done to control the risk. What will you do to make the activity as safe as possible?

- 8. © Canberra Institute of Technology Page 8 of 10 Date created: 23/06/2022 CRICOS No. 00001K | RTO Code 0101 Date updated: 30/06/2022 Implementation How have relevant workers been provided with information and instruction so that they understand the hazards arising from this work, understand and can implement the identified control measures, and know what to do if the work is not being conducted in accordance with this SWMS? All workers have acquired skill and knowledge through a combination of training, qualification and experience to safely and efficiently carryout HR tasks as described in the SWMS sequential steps. All workers are: 1. Inducted into the General Lifts SWMS. 2. Encouraged to actively participate in, and review and monitor actual work processes at all times. 3. By signing the SWMS, acknowledge that they have understood the SWMS procedures and hazards associated with tasks. 4. That they are fit for work to the best of their ability and are not increasing the risk to others in the team or themselves due to the influence of alcohol or drugs. What measures are in place to ensure that work is being carried out in accordance with the SWMS once work commences? 1. Continuous monitoring and review of SWMS by crane crew and site supervisor 2. Consultation and communication between crew and major contractor through site safety walks and scheduled site safety committee meetings 3. Stop and review work where task and work activity differ. Toolbox safe solution with all personnel. NOTE: A SWMS must be kept and be available for inspection until at least the high-risk construction work is completed. Where a SWMS is revised, all versions should be kept. If a notifiable incident occurs in relation to the high-risk construction work to which the SWMS relates, then the SWMS must be kept for at least 2 years from the date of the notifiable incident.

- 9. © Canberra Institute of Technology Page 9 of 10 Date created: 23/06/2022 CRICOS No. 00001K | RTO Code 0101 Date updated: 30/06/2022 Recommended steps for filling out the SWMS template 1. Consult with relevant workers, contractors and health and safety representatives involved with the high-risk construction work, the activities involved, and associated hazards, risks and controls. 2. In the ‘What is the high-risk construction work?’ column, identify the high-risk construction work for the construction work activity that will be undertaken. 3. In the ‘What are the hazards and risks?’ column, list the hazards and risks for each high-risk construction work activity. 4. Identify the workplace circumstances that may affect the way in the high-risk construction work will be done. Examples of workplace circumstances that may impact on the hazards and risks include: information relating to the design of the structure, the workplace (e.g., location, access, transport), and information contained in the WHS Management Plan information on any ‘essential services’ located on or near the workplace confirmation that the regulator has been advised of any ‘notifiable work’ (e.g., demolition work involving explosives) safe work methods and plant to be used. 5. In the ‘How will the hazards and risks be controlled?’ column, select an appropriate control or combination of controls by working through the hierarchy of controls. It is important that you can justify why the selected control measure is reasonably practicable for the specific workplace. Selecting control measures 1. Eliminate the risks so far as is reasonably practicable 2. If this is not reasonably practicable, minimise them so far as reasonably practicable by applying the following hierarchy of control measures: i. minimise the risk by doing one or more of the following: o substituting the hazard o isolating the hazard o implementing engineering controls ii. if the risk remains, minimise the remaining risk by implementing administrative controls iii. if the risk remains, minimise the remaining risk by ensuring the provision and use of suitable personal protective equipment (PPE).

- 10. © Canberra Institute of Technology Page 10 of 10 Date created: 23/06/2022 CRICOS No. 00001K | RTO Code 0101 Date updated: 30/06/2022 SWMS implementation and compliance (information, monitoring and review) 1. Brief each team member on the SWMS before commencing work. Ensure team knows work is to stop if the SWMS is not followed. 2. Observe the work being carried out and monitor compliance with the SWMS. Review risk controls regularly: before a change occurs to the work itself, the system of work or the work location if a new hazard associated with the work is identified when new or additional information about the hazard becomes available when a notifiable incident occurs in relation to the work when risk controls are inadequate, or the SWMS is not being followed. In all the above situations stop the work, review the SWMS, adjust as required and re-brief the team. Keep the SWMS in a readily available location for the duration of the high-risk construction work and for at least 2 years after a notifiable incident occurs. SWMS Review Register – continuous improvement Review # Review Date Name/s Comments / Section Change / Amendment Sign / HR # 1 11.5.17 KW Update hazard controls – IAW Prac assessment KW HR 104565 2 15.5.17 KW Update Format / SWMS Title KW HR 104565 3 15.5.17 KW Update Link – SWMS – Prac Assess – Teacher Guide KW HR 104565