Gaurav Kumar's Resume for Chemical Engineer Roles

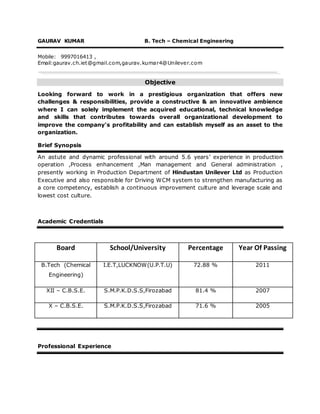

- 1. GAURAV KUMAR B. Tech – Chemical Engineering Mobile: 9997016413 , Email:gaurav.ch.iet@gmail.com,gaurav.kumar4@Unilever.com Objective Looking forward to work in a prestigious organization that offers new challenges & responsibilities, provide a constructive & an innovative ambience where I can solely implement the acquired educational, technical knowledge and skills that contributes towards overall organizational development to improve the company's profitability and can establish myself as an asset to the organization. Brief Synopsis An astute and dynamic professional with around 5.6 years’ experience in production operation ,Process enhancement ,Man management and General administration , presently working in Production Department of Hindustan Unilever Ltd as Production Executive and also responsible for Driving WCM system to strengthen manufacturing as a core competency, establish a continuous improvement culture and leverage scale and lowest cost culture. Academic Credentials Board School/University Percentage Year Of Passing B.Tech (Chemical Engineering) I.E.T,LUCKNOW(U.P.T.U) 72.88 % 2011 XII – C.B.S.E. S.M.P.K.D.S.S,Firozabad 81.4 % 2007 X – C.B.S.E. S.M.P.K.D.S.S,Firozabad 71.6 % 2005 Professional Experience

- 2. Hindustan UNILEVER Limited Barotiwala (H.P.) 16- May-16 to Present HUL Barotiwala is the largest Soap manufacturing unit of HUL and the second largest in the world for Unilever. The factory had a total capacity of 1, 30,000 TPA of soap. Company Profile: Unilever is a British-Dutch multinational corporation that owns many of the world's consumer product brands in foods, beverages, cleaning agents and personal care products. In India, Unilever is known as Hindustan Unilever Limited which is India's largest consumer goods company based in Mumbai, Maharashtra. British-Dutch company Unilever controls 52% majority stake in HUL. Its products include foods, beverages, cleaning agents and personal care products. HUL was formed in 1933 as Lever Brothers India Limited and came into being in 1956 as Hindustan Lever Limited through a merger of Lever Brothers, Hindustan Vanaspati Mfg. Co. Ltd. and United Traders Ltd. It is headquartered in Mumbai, India and has an employee strength of over 16,500 employees and contributes to indirect employment of over 65,000 people. The company was renamed in June 2007 as “Hindustan Unilever Limited Designation: Production Executive Job Responsibilities: Understanding of the product, process and technology and its application for operating & bringing in continuous improvements to optimize production process while meeting safety, quality & environmental requirements:- 1. Responsible for the safety and health of my team members as well as environment. 2. Responsible for the production targets as an operation team member as per scheduled plans. 3. Prepare Report of daily activities and production status along with analyzing and acting upon losses. 4. Responsible for maintaining safety and quality standard throughout the process. 5. Manpower utilization as per Plan. 6. Handling more than 60 employees in a shift. 7. Keeping a regular check on machine maintenance and machine utilization 8. Maintaining good housekeeping with work as a team spirits by implementing GMP guidelines 9. Improve skills of operators by training them on quality, Safety and machines operation etc

- 3. 10.Responsible for optimization of plant operation with a view to minimize energy consumption thereby reducing operating cost 11.Responsible for conduction of circle meeting of shop floor employees and training. 12. Adherence to PM schedule of machines ,coordination with maintenance department. 13.Participate in daily Quality meeting and Production meeting 14.Maintaining Quality of the product during the shift and taking required action in case of any variation. 15.Training to the Employees for trouble shooting at lines and quick changeover. 16.Handling of shop floor to reduce change over times, machine set up time, waste generated in the process, MTTR and energy consumption while increasing MTBF, OR and OEE of the plant 17. Doing Process audit,System audit,SAM,Area audit,5S audit as per schedule. 18. Part of team deals with union members regarding IR issues and member of different committee (Transportation,canteen,cultural,sports) 19.Drive the WCM culture on shop floor. 20.Maintain discipline in shifts and handling grievances of shop floor employees. Projects Executing: 1.Working on the projects to improve the OEE of the plant by minimizing process losses. 2.Working as a WCM FI, AM pillar team member on different project related to quality and productivity. 3.RM / PM tech eff. Control to minimize the cost. 4.Calculating and eliminating all non-value added activities 5.5’s implementation for safe and Productive environment Organization: Henkel , Rudrapur, (Uttrakhand) Duration: AUG’ 2011 – May’2016 Department: Production Company Profile: Henkel operates worldwide with leading brands & technologies in three business areas: Laundry & Home Care, Beauty Care & Adhesive Technologies counts 114 plants with involvement of over 47000 employees. Henkel holds globally leading market positions with both in consumer & industrial business with well-known brands such as Persil, Schwarzkopf and Loctite.

- 4. Certification:IS0 9001:2008,ISO 14001:2004,OHSAS 18001:2007 Certified Company Manufacturing: Speciality Chemicals (Adhesives- WBA, Hot Melt & Pressure Sensitive Hot Melt) using Batch process. Specialties chemicals are particular products which provide wide variety of effects on which many other industry sectors rely. They are used on the basis of their performance and function. They can be unique molecules or mixture of molecules known as formulation. Customers: P&G, Johnson & Johnson, Kimberly Clarke, HUL, Pepsi, Coke, ITC, NESTLE etc. Principal Accountabilities- 1. Ensure adherence to the EHS procedures and practices in shift production activities with a specific focus on EHS Reporting (Accident / Near Miss/). Risk Assessment and Control on Shop floor Onsite Emergencies during Operation. Focus on BBS. 2. Drive administration with a focus on Manpower deployment in shifts. Shifts Communication to Shop floor. Administration of discipline issues in the Shifts. Grievance handling in the Shifts. 3. Drive a Skill & Competence building program at the shop floor to achieve consistent shop floor practices focusing on Basic Product Knowledge. Standard Operating Procedure. Basic EHS (HIRA, PSRA, JSA,FI, PTW, PPE). Basic Equipment knowledge & team maintenance. 4. Reports & Documentation Output Confirmation in SAP (SAP verification at Shift End). Calculation of OEE. Manufacturing Log. EHS Incident Report. Yield report daily Quality Non Conformity Report. Month end closing. 5. Build Cost Consciousness in the shift team and deliver Production as per schedule

- 5. Control Material Waste in shift. Control rework /off spec material generation. Control on production consumables. 6. Audits in Partnership with QA and EHS Function Process cum Product audit (PCPA) Audit. Equipment Operating Condition Audit. Hygiene Audit. Rework generation / usage audit. Corporate safety audit according to Henkel and Global safety norms. Customer audits Legal compliance audit wrt to operation. 7. Lean Drive 5S coordinator at plant level. Elimination of wastes from process-TIMWOODS Standardization of process and SOP. Implementation of A3 –Problem solving tool OEE calculation. Selection of projects using RBPS matrix. Participation in Six sigma projects CI workshop time to time. Implementation of Visual management throughout the plant. Changeover time reduction Error proofing initiative Autonomous maintenance culture Pull system drive with the help of Planner and customer service Major Responsibilities – Working knowledge of independent handling of shift production, including Managing of direct and indirect employees. Effective implementation & monitoring of daily production plan Control of manpower as per shift schedule To assist the Manager (Operations) during the preparation of MIS Reports Shift planning to achieve targets with best quality products Reports & documentation like Batch sheet generation & Confirmation in SAP. Inter departmental communication for planning & change. Ensure adherence to the EHS procedures and practices in shift production activities Responsible for coordinating with all the departments in the factory to ensure resource availability for the plant.

- 6. Monitor and maintain all parameters as per SOPs and ensure strict compliance with GMP and safety norms Root cause analysis and problem investigation Trouble shooting of process and operational issues on shop floor Provide Job trainings to team to develop process task. Responsible for upkeep & GHP of plant. Evaluating the performance of the staff for appraisals and increments. Lead auditee in Production Department. Continuous Improvements/Cost Saving Projects: Part of six sigma project batch cycle time reduction from 290 min to 240 minutes which generate saving of 6 thousand Euro. Cleaning oil cost reduction which generate 12 T Euro. Cost avoidance saving of 0.6 T Euro by reuse of Quality sample at the end of ageing time. Successful implementation of kaizen at shop floor which improves Quality, Safety, Productivity, ECSL, Equipment Availability. Technical Exposure: Familiar with Equipment’s like Pumps, Blender, mixer, Drier, Heat Exchanger, Belt conveyor, TF Boiler, Bag filter. Knowledge of SCADA based batch operation process Familiar with blending, mixing operation. Familiar with Polymer (EVA, LLDPE, Rubber, PVA), Resin, Additives, hydrocarbon oil Familiar with chemicals Sodium hydroxide, Boric acid, Sodium benzoate, Ammonium zirconium carbonate, Ammonium hydroxide .Foam master, Kath one LXE, Amylok, Agitan305, vinapass EP 705, calcite. Titanium dioxide. Training and Projects Programs Attend One day training on problem solving and decision making. Attended workshop on VSM, Standardized work, OEE, MTA concept, Changeover time reduction, Visual management, 5S ,Problem solving and other Lean initiatives. 1 month training in Mohan gold water Breweries ltd Beer manufacturing, at Lucknow. Part of team in different project Execution and installation like New Chubb machine. Oil dosing system, conveying system. IT Exposure Operation and installation of Microsoft office. (Word Document preparations, Graphs in Excel sheet, Power Point Presentations). Operation and installation of Windows XP, Vista & Window 7. Well versed with internet access, and SAP.

- 7. Extracurricular Activities Played as Vice-captain of Team secured 1st rank in Cricket tournament, in Shauryotsav’09.3rd Declared Man of the match” in final match of cricket tournament held in Shauryotsav’09. Secured 3rd position in Discuss and shotput throw held in Shauryotsav’09, annual sports event of IET Lucknow. Donate blood at Blood donation camp organized by Department of transfusion medicine, SGPGIMS, Lucknow. Personal Details Permanent Address: Vill-Naitor,Post-Vilahana, Distt-Firozabad Pin-283203 (U.P) Father’s Name : Mr. Ramnivas verma Mother’s Name : Mrs. Bhoodevi verma Date of Birth : 05 June 1990 Sex : Male Marital Status : Un-Married Linguistic Ability : English, Hindi. Nationality : Indian Hobbies : Playing cricket and Doing physical exercise. Declaration I, hereby declare that all the information given above is true and correct as per my knowledge and belief. GAURAV KUMAR Place: Baddi, (Himachal) Date: