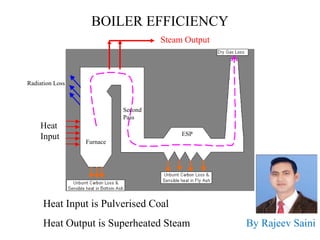

Boiler efficiency by loss Method

- 1. Heat Input Radiation Loss Steam Output BOILER EFFICIENCY Heat Input is Pulverised Coal Heat Output is Superheated Steam By Rajeev Saini Furnace Second Pass ESP

- 2. Some important facts on Boiler Efficiency 1. Sec Air temp increased by 20*C =1% Fuel saving. 2. Flue gas temp reduced by 25*C = 1% Fuel saving. 3. Feed water temp increased by 5*C = 1% Fuel saving. 4. Oxygen % at APH I/L increased by 1%=0.32% Fuel Loss

- 3. Boiler Use of low air pressure "film burners" helps save oil upto 15% in furnaces. IBR Steam Boilers means any closed vessel exceeding 22.75 liters.

- 5. Efficiency Calculations Standards Standard Applied :- ASME Standard PTC 4.1 IS 8753: Indian Standard for Boiler Efficiency Testing British standards, BS845: 1987

- 6. The Indirect Method Testing/Loss Method L1. Loss due to dry flue gas (sensible heat) L2. Loss due to hydrogen in fuel (H2) L3. Loss due to moisture in fuel (H2O) L4. Loss due to moisture in air (H2O) L5. Loss due to carbon monoxide (CO) L6. Loss due to surface radiation, convection and other unaccounted L7. Unburnt losses in fly ash (Carbon) L8. Unburnt losses in bottom ash (Carbon) Boiler Efficiency by indirect method = 100 - (L1 + L2 + L3 + L4 + L5 + L6 + L7 + L8)

- 7. This is also known as ‘input-output method’ due to the fact that it needs only the useful output (steam) and the heat input (i.e. fuel) for evaluating the efficiency. This efficiency can be evaluated using the formula Q--Quantity of steam generated per hour in kg/hr. q--Quantity of fuel used per hour in kg/hr. GCV--gross calorific value of the fuel in kCal/kg of fuel

- 8. =[(11.6 x 38.16)+{34.8 x (2.03-(6.28/8))}+(4.35x0.53)]/100 = 4.882 Kg/Kg of Coal =[(3.49)/(21-3.49)]X100 =19.9 % =[1+(19.9/100)]X100 Kg/Kg of Coal = 5.8535 Kg/Kg of Coal

- 9. L1:- =[(0.467 X 44/12) +0.008+(5.885X 77/100) + (5.885-4.882)X23/100] Kg/Kg of Coal = 6.274 Kg/Kg of Coal L1= =[(6.274) X0.23X(149-33)X100]/3300 = 5.07 %

- 10. L2:- =[9X0.0203 X{584 +0.45 X(149-33)X100]/3300 = 3.52 % L3:- =[5.5X{584 +0.45 X(149-33)X100]/3300 = 1.06 %

- 11. L4:- L5:- =[5.885X0.0204 X0.45 X(149-33)X100]/3300 = 0.19 % =[(0.55X0.3816)/(0.55+17)] X[5744*100/3300] = 2.08 %

- 12. L6:- = 0.184 % L7:- = 0.80 X0.467 X 452.5 X 100/ 3300 = 0.424 %

- 13. L8:- = 0.80 X0.467 X 452.5 X 100/ 3300 = 1.152 % = 100- (5.07+3.52+0.19+2.08+0.424+1.152) = 86.320%

- 14. Merits and Demerits of Direct Method Merits . Plant people can evaluate quickly the efficiency of boilers . Requires few parameters for computation . Needs few instruments for monitoring Demerits . Does not give clues to the operator as to why efficiency of system is lower . Does not calculate various losses accountable for various efficiency levels . Evaporation ratio and efficiency may mislead, if the steam is highly wet due to water carryover

- 15. How to Improve efficiency of boiler Oxygen Trim Systems Flue gas outlet temperature MS temp HRH temp Feed Water Temp Blowdown control Blowdown heat recovery Flash Steam Recovery Steam Trap Leaks Exhaust Draft Control The effect of coal blending on combustion performance Air to fuel ratio control

- 16. Factors Affecting Boiler Performance The various factors affecting the boiler performance are listed below: . Periodical cleaning of boilers . Periodical soot blowing . Proper water treatment programme and blow down control . Draft control . Excess air control . Percentage loading of boiler . Steam generation pressure and temperature . Boiler insulation . Quality of fuel