Gp 6 clay ppt final

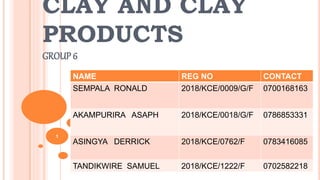

- 1. CLAY AND CLAY PRODUCTS GROUP 6 NAME REG NO CONTACT SEMPALA RONALD 2018/KCE/0009/G/F 0700168163 AKAMPURIRA ASAPH 2018/KCE/0018/G/F 0786853331 ASINGYA DERRICK 2018/KCE/0762/F 0783416085 TANDIKWIRE SAMUEL 2018/KCE/1222/F 0702582218 1

- 2. DEFINITION OF CLAY, ITS COMPOSITION AND FORMATION CLAY is an earthy material that is plastic when moist but hard when fired, that is composed mainly of fine particles of hydrous aluminum silicates and other minerals, and that is used for making bricks, tiles, and pottery. Clay is mainly composed of silica (SiO2) and alumina (Al203) and some other minerals which exist in small quantities. Clays were formed by two processes Erosion: This involves washing and wearing of rocks by agents of erosion like water wind and others to form different soils of which clay is part. These rocks may include sedimentary rocks. Weathering: This process involve physical and chemical disintegration of rocks containing clay minerals forming clay deposits. 2

- 3. CLASSIFICATION OF CLAY Clay is basically classified according to the following 1. Basing on the mode of formation o Residual clays, known as Kaolin or China clay, are formed from the decay of underlying rocks and are used for making pottery. o Transported or sedimentary clays result from the action of weathering agencies. These are more disperse, contain impurities, and free from large particles of mother rocks. 2. Basing on dominant characteristics o China clay: This is the purest kind of clay containing a very high percentage of kaolin “Al2Si2O5(OH)4” and is used in making porcelain , fire resisting cement and white Portland cement. 3

- 4. CONTINUATION o Fire refractory clays: These contain silica and alumina in very high proportions and are capable of withstanding very high temperatures without deforming in shapes. o Vitrifying clays: These clays are rich in fluxing compounds like iron oxide and carbonates of calcium and magnesium. They can not withstanding very high temperatures. They are also called hard burning clays and are used for making facing bricks, flooring tiles, sewer pipes and other ornamental clay products. o Brick clays : Are also called brick earth and are of low grade having a variety of compound of silica, alumina, oxides of iron, lime magnesia and organic matter. They are majorly transported clays and are used for making building bricks and ordinary load bearing and partition tiles. 4

- 5. PROPERTIES OF CLAY Physical properties Plasticity: is the property of wetted clay to be permanently deformed without cracking. High tensile strength Texture: The texture of clay is measured by the fineness of its grains. Size and shape: The size and shape of clay is too small or too thin to be seen thus determined by electron micrographs. Porosity: This is the ratio of the volume of pore space to the dry volume. Thus large pores allow water to evaporate more easily than small pores. Solubility: the solubility depends on the nature , temperature, and concentration of the acid or base where it is applied Chemical properties Ion exchange: This is the ability of clay minerals to absorb certain cations and anions and retain them around the outside of the structural unit in an exchangeable state without affecting the basic silicate structure. Reaction with organic and inorganic compounds: some cationic organic molecules may replace inorganic exchangeable cations present in the interlayer of expansible minerals to form complexes. And some clay minerals can accommodate relatively large inorganic cations between the layers of clay. Water affinity: water retention ability of clay. The water may be held in pores or at the surface of clay mineral structures and may be removed by drying under ambient conditions.5

- 6. CLAY PRODUCTS AND EXAMPLES Clay products are materials made from clay Examples of clay products may include; 1. Clay bricks /brick earth 2. Clay tiles 3. Refractory bricks 4. Earthen ware 5. Stoneware 6

- 7. BRICKS Building bricks may be defined as structural units of rectangular shape and convenient size that are made from a suitable type of clays by molding, drying and burning. They are used for building interior and exterior walls, partitions, piers, footings, and other load Bering structures. The standard dimension of a brick are 215*102.5*65mm. 7

- 8. REQUIREMENTS OF A GOOD BRICK EARTH Homogeneous: The brick should have a uniform deep red or cherry colour indicating uniformity in chemical composition and thoroughness in the burning of the brick. It should be free from stones, lime or kankars, pebbles, grit, vegetables, organic matter, and alkaline salts. It should have proper proportions of sand silt and clay It should have sufficient plasticity for proper moulding. Water absorption should not exceed 20 % of its dry weight. The brick should have uniform size and size. 8

- 9. TYPES OF BRICKS They include; Common bricks: These are manufactured economically without special reference to appearance. These may vary greatly in strength and durability and are used for internal walls where appearance is of no consequence and may also be used as an aggregate in concrete when crushed. Facing bricks: These are used for decoration and are durable under severe exposure and are used in fronts of building walls for which a pleasing appearance is desired. They do not require any further surface finish. Engineering bricks: "heavy duty bricks” are a type of bricks used where high strength, high durability, low water porosity or acid (flue gas) resistance are needed. Engineering bricks can be used for damp-proof courses, bridge structure, industrial foundations and other heavy engineering works. 9

- 10. CLASSIFICATION OF BRICKS They are four main classifications; 1) First Class Bricks: These bricks are of standard shape and size. They are burnt in kilns. They fulfill all desirable properties of bricks and 12–15% water absorption of it dry weight. 2) Second Class Bricks: These bricks are ground moulded and burnt in kilns. The edges may not be sharp and uniform. The surface may be somewhat rough. Such bricks are commonly used for the construction of walls which are going to be plastered. 3) Third Class Bricks: These bricks are ground moulded and burnt in clamps. Their edges are somewhat distorted. They produce dull sound when struck together. They are used for temporary and unimportant structures. 4) Fourth Class Bricks: These are the over burnt bricks. They are dark in colour. The shape is irregular. They are used as aggregates for concrete in foundations, floors and roads. 10

- 11. COMPOSITION OF GOOD BRICK EARTH, FUNCTIONS AND EFFECTS. 1. Alumina or clay (20 - 30%) by weight: It is the principal constituent of brick earth. It imparts plasticity to the brick earth which is essential for proper moulding of bricks Alumina or Clay in brick earth shrinks and cracks on drying. It also wraps and becomes very hard on burning unless mixed with sand. 2. Silica or sand (35 - 50%):Sand or silica in brick earth prevents the shrinkage, cracking and wrapping of bricks it also makes the bricks durable. Excess of silica makes the bricks brittle and weak. 3. Silt (20 - 30%): The total content of clay and Silt shall not be less than 50%. 4. Remaining ingredients include; Lime (Cao) Oxide of iron Magnesia oxide 11

- 12. CONTINUATION Lime: About 10%, It helps to bind the particles of brick earth together. It also reduces shrinkage of bricks. Excess of lime causes the brick to melt and the brick looses its shape. Oxide of Iron: Present in small quantities and acts as a flux. It helps the grains of sand to melt and binds the particles of clay together. It also provides the required red colour to the bricks on burning. But excess of oxide of iron makes the bricks dark blue. Magnesia oxide: Present in small quantities and makes the brick of yellowish colour and reduces shrinkage. But excess of magnesia leads to decay of bricks. 12

- 13. HARMFUL SUBSTANCES IN BRICK EARTH LIME: If in excess, it changes the colour of the brick from red to yellow. When lime is present in lumps, it absorbs moisture, swells and causes disintegration of the bricks. Therefore, lime should be present in finely divided states and lumps. PEBBLES AND GRAVELS: Pebbles and Gravels do not allow the clay to be mixed thoroughly and spoil the appearance of the brick. Bricks with pebbles and gravels may crack while working. IRON PYRITES: This tends to oxidize and decompose the brick during burning. The brick may split into pieces. ALKALIS: When present in excess, alkali makes the clay unsuitable for bricks. They melt the clay on burning and make the bricks unsymmetrical. When bricks come in contact with moisture, water is absorbed and the alkalis crystallize. On drying, the moisture evaporates, leaving behind grey or white powder deposits on the brick which spoil the appearance. ORGANIC MATTER: On burning green bricks, the organic matter gets charred and leave pores making the bricks porous; the water absorption is increased and the strength is reduced. CARBONACEOUS MATERIALS: Its presence causes a black core. 13

- 14. MANUFACTURING OF BRICKS It involves the following; 1. Preparation of clay: Choosing site, additives eg fly ash and sand loam brought near, top soil layer is eliminated, weathering and blending. 2. Molding of clay Hand molding of bricks: Using a wooden form and table. Machine molding of bricks: Using a machine to mould the bricks. 3. Drying of raw bricks natural drying. artificial drying. 4. Burning of bricks at about 11000C in kilns. 14

- 15. DRYING OF BRICKS Natural drying: Also called hack drying and involves arranging wet bricks in rows on their edges on raised ground called hack and also little space for circulation of air is left for each brick. artificial drying: This method is done using special driers called tunnels which receive heat from special furnaces. It is used when bricks are required on a large scale and at a rapid rate. 15

- 16. WAYS OF BURNING BRICKS A. Open/clamp kiln: The bricks and fuel are placed in alternate layers. The amount of fuel is reduced successively in the top layers. Each brick tier consists of 4–5 layers of bricks. Some space is left between bricks for free circulation of hot gasses. After 30 per cent loading of the clamp, the fuel in the lowest layer is fired and the remaining loading of bricks and fuel is carried out hurriedly. The top and sides of the clamp are plastered with mud. Then a coat of cow dung is given, which prevents the escape of heat. 16

- 17. ADVANTAGES AND DISADVANTAGES OF OPEN KILN advantages Burning of bricks is cheap and economical The clamp is not affected by wind or rain. Skilled labour is not required for consideration of clamps It saves fuel. Bricks produced are tough and strong. disadvantages Slow proress because it requires a lot of time during burning The bricks produced are not of regular shape. Bricks are likely to burn un evenly. Quality of bricks produced is not uniform due to non-uniform burning of the bricks. 17

- 18. B. INTERMITTENT KILN This is sometimes known as periodic kiln and consists of a single firing chamber. Here, the bricks to be fired are placed into the kiln. The kiln is closed, and the internal temperature increased according to a schedule. After the firing is completed, both the kiln and the bricks are cooled. The bricks are removed and the kiln is cleaned and the next cycle begins. 18

- 19. ADVANTAGES AND DISADVANTAGES OF INTERMITTENT KILN Advantages. Brick supply is intermittent. Disadvantages. Burning of bricks is not uniform. The supply is not continuous. There is a loss of heat from top most layers of bricks. There is waste of fuel heat as the kiln is to be cooled down. The cost of manufacture is more. 19

- 20. C. CONTINUOUS KILN These are a series of connected kilns or one continuous chamber through which a fire travels bricks being set ahead of the fire and this kiln runs day and night. From the cool entrance, bricks are slowly transported through the kiln, and its temperature is increased steadily as it approaches the central, hottest part of the kiln. From there, it continues through the kiln, and the surrounding temperature is reduced until it exits the kiln nearly at room temperature. 20

- 21. ADVANTAGES AND DISADVANTAGES OF CONTINUOUS KILN Advantages Continuous production, short production cycle, high yield, high quality. High thermal efficiency so it saves fuel. Save labor. The firing operation is simple, loaded kiln and kiln operations are carried out in the kiln. So it is also very convenient, improves the working conditions of the operator, and reduces the labor intensity. Uniform burning of bricks. Disadvantages Construction of the kiln needs more materials and equipment hence High initial cost of construction 21

- 22. TESTS CARRIED OUT ON BRICKS 1. Water Absorption Test: Six bricks weighed are dried in oven at 105 °C and cooled at the room temperature. They are then immersed in water for 16 hours. Thereafter dried with a dump cloth and weighed. Absorption in % = W2-W1 *100% W1 where, W1 and W2 are the respective weights of dry and the immersed specimens and it should not exceed 20% 2. Crushing Strength or Compressive Strength: It is done by placing the specimen between the plates of a compression test machine, the load is applied axially at a uniform rate of 14N/mm2 and the maximum load at which the specimen fails is noted Compressive strength= maximum load at failure loaded area of brick 22

- 23. CONTINUATION 3. Hardness Test on Bricks: 4. Shape and Size Test: 20 bricks of standard size are randomly got and stacked lengthwise along the width and height. The results should not vary so much from 190*90*90 5. Color Test of Bricks: Usually brown 6. Soundness: It is done by striking two bricks together, they should not break and should have a clear ringing sound. 7. Structure of Bricks: It should be homogeneous and compact and non porous. 8. Efflorescence Test: It is done by immersing the brick in water for 24 hours, put out and allowed to dry in the shade and tested with sodium hydroxide. If soluble salts are present on its surface, it shows grey or white deposits on its surface. 23

- 24. DEFECTS IN BRICKS 1. Over burning of bricks :When bricks are over-burn, soft molten mass is produced and the brick will lose its shape along with other designated requirements. 24

- 25. CONTINUATION 2. Under burning of bricks: When bricks are not burnt to cause complete vitrification, the clay is not softened because of insufficient heat and the pores are not closed. Consequently, bricks with low compressive strength and high-water absorption will be produced. They produce a dull sound when struck against each other. Finally, such bricks are not recommended for construction works. 25

- 26. CONTINUATION 3.Black core: Improper burning is the major cause of brick black core. Bricks, which contains bituminous matter or carbon and they are not completely removed by oxidation, will commonly experience such problem. 26

- 27. CONTINUATION 4. Efflorescence Presence of drying grey or white powder patches on the brick surface is the efflorescence indicator. This defect is caused because of alkalis present in bricks. When bricks come in contact with moisture, water is absorbed and the alkalis crystalize. Efflorescence can be minimized by selecting proper clay materials for brick manufacturing, providing waterproof coping to prevent moisture and by using water repellent materials in mortar and by providing damp proof course. 27

- 28. CONTINUATION 5. Frost attack/damage: It is a common problem that usually occurs in older bricks, and those that were under burnt during the firing process. In newer construction, failure through frost attack tends to be confined to areas of severe exposure, or where the frost resistance of the brick was incorrectly specified. When water turns to ice, there is a 9% increase in its volume. This expansion can produce stress within the brick which causes spalling, with the brick face flaking off and/or crumbling. 28

- 29. CLAY TILES AND TYPES Roof tiles are designed mainly to keep out rain, and are traditionally made from locally available materials such as terracotta or slate. Modern materials such as concrete and plastic are also used and some clay tiles have a waterproof glaze. Clay tiles include; roofing tiles Flooring tiles Wall tiles Drain tiles Glazed earthenware tiles. 29

- 30. EXAMPLES OF ROOFING TILES 1) Flat tiles: This is the simplest type, which are laid in regular overlapping rows. Flat roof tiles are usually made of clay but also may be made of stone, wood, plastic, concrete, or solar cells. 2) Pot tiles: Also called pan tiles with an S-shaped profile, allowing adjacent tiles to interlock. These result in a ridged pattern resembling a ploughed field. for example, the "double Roman tile “. 30

- 31. CONTINUATION 3) Allahabad tiles: These have different shapes . flat tiles are laid side by side and the joints between covered with half round pot tiles. 4) Mangalore tiles: These are the most common and have a top locking to improve protection from water and wind. 31

- 32. CONTINUATION 5) Ridge valley tiles: Are basically for sloped roofs. 6) Corrugated tiles: These have corrugations and when placed in position, a side lap of two corrugations is produced. 32

- 33. CHARACTERISTICS OF A GOOD ROOFING TILE. The following are the qualities of a good roofing tile; It should be resistant to atmosphere and dampness It should be durable It should absorb less than 15% of water It should be free from defects like flaws , cracks and non-uniform burning It should have a uniform texture It should be accurate in size and shape. 33

- 34. MANUFACTURE OF ROOFING TILES. They are prepared in the same way as bricks but are thinner and lighter, so require greater care. Preparation of clay Moulding of tiles. Drying of tiles Burning of tiles. 34

- 35. TESTS ON CLAY TILES. 1) Warpage test: This should not exceed 2% along edges and 1.5% along the diagonal for the case of flooring tiles. 2) Transverse strength: Consists of applying the load along the Centre line at right angles to the length of the tile (which has been immersed in water for 24 hours)supported on the rounded edges of wood bearers. Six tiles are tested and the average breaking load should not be less than 450- 550 N/min. 3) Water absorption: Six tiles are dried in oven at 105 ± 5°C and cooled at the room temperature. They are then immersed in water for twenty four hours. Thereafter dried with a dump cloth and weighed. Absorption in % = W2-W1 *100% W1 where, W1 and W2 are the respective weights of dry and the immersed specimens. 35

- 36. APPLICATIONS OF CLAY PRODUCTS Aggregate for concrete. Creamsite (manufactured from low-heat clay), a light weight porous material forms excellent aggregate for light weight concrete. Acid-resistant lining items. The examples are common acid-resistant brick, acid- resistant and heat-and-acid-resistant ceramic shaped tiles for special purposes, ceramic acid resistant pipes and companion shapes. Roof materials. The examples are common clay roof tiles for covering slopes of roofs, ridge tiles for covering ridges and ribs, valley tiles for covering valleys, end tiles ("halves" and "jambs") for closing row of tiles, special tiles. Clay products for interior decoration. The examples are tiles for facing walls, built- in parts, large floor tiles and mosaic floor tiles. Brick for special purposes. The example are curved clay brick, stones for sewage installations (underground sewer pipes) brick for road surface. Facade decoration. The examples are glazed or non-glazed varieties subdivided into facing brick and ceramic stones, floor ceramics, small-size ceramic tiles, ceramic plates for facades and window-sill drip stones. 36 THE END

- 38. 38 Machine moulding Hand moulding