Contenu connexe

Similaire à 7.1.6 Joining Clip

Similaire à 7.1.6 Joining Clip (10)

Plus de MEZ-TECHNIK air system products

Plus de MEZ-TECHNIK air system products (20)

7.1.6 Joining Clip

- 1. 7.1 PIPE CONNECTIONS

7.1

PIPE CONNECTIONS, PIPE ASSEMBLING, FLEXIBLE TUBES

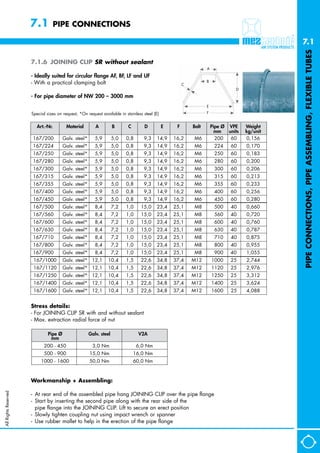

7.1.6 JOINING CLIP SR without sealant

A

- Ideally suited for circular flange AF, BF, LF and UF

- With a practical clamping bolt B

C

D

- For pipe diameter of NW 200 – 3000 mm

E

Special sizes on request, *On request available in stainless steel (E) F

Art.-Nr. Material A B C D E F Bolt Pipe Ø VPE Weight

mm units kg/unit

167/200 Galv. steel* 15,9 15,0 0,8 19,3 14,9 16,2 1M6 1200 60 0,156

167/224 Galv. steel* 15,9 15,0 0,8 19,3 14,9 16,2 1M6 1224 60 0,170

167/250 Galv. steel* 15,9 15,0 0,8 19,3 14,9 16,2 1M6 1250 60 0,183

167/280 Galv. steel* 15,9 15,0 0,8 19,3 14,9 16,2 1M6 1280 60 0,200

167/300 Galv. steel* 15,9 15,0 0,8 19,3 14,9 16,2 1M6 1300 60 0,206

167/315 Galv. steel* 15,9 15,0 0,8 19,3 14,9 16,2 1M6 1315 60 0,213

167/355 Galv. steel* 15,9 15,0 0,8 19,3 14,9 16,2 1M6 1355 60 0,233

167/400 Galv. steel* 15,9 15,0 0,8 19,3 14,9 16,2 1M6 1400 60 0,256

167/450 Galv. steel* 15,9 15,0 0,8 19,3 14,9 16,2 1M6 1450 60 0,280

167/500 Galv. steel* 18,4 17,2 1,0 15,0 23,4 25,1 1M8 1500 40 0,660

167/560 Galv. steel* 18,4 17,2 1,0 15,0 23,4 25,1 1M8 1560 40 0,720

167/600 Galv. steel* 18,4 17,2 1,0 15,0 23,4 25,1 1M8 1600 40 0,760

167/630 Galv. steel* 18,4 17,2 1,0 15,0 23,4 25,1 1M8 1630 40 0,787

167/710 Galv. steel* 18,4 17,2 1,0 15,0 23,4 25,1 1M8 1710 40 0,875

167/800 Galv. steel* 18,4 17,2 1,0 15,0 23,4 25,1 1M8 1800 40 0,955

167/900 Galv. steel* 18,4 17,2 1,0 15,0 23,4 25,1 1M8 1900 40 1,055

167/1000 Galv. steel* 12,1 10,4 1,5 22,6 34,8 37,4 M12 1000 25 2,744

167/1120 Galv. steel* 12,1 10,4 1,5 22,6 34,8 37,4 M12 1120 25 2,976

167/1250 Galv. steel* 12,1 10,4 1,5 22,6 34,8 37,4 M12 1250 25 3,312

167/1400 Galv. steel* 12,1 10,4 1,5 22,6 34,8 37,4 M12 1400 25 3,624

167/1600 Galv. steel* 12,1 10,4 1,5 22,6 34,8 37,4 M12 1600 25 4,088

Stress details:

- For JOINING CLIP SR with and without sealant

- Max. extraction radial force of nut

Pipe Ø Galv. steel V2A

mm

200 - 450 13,0 Nm 16,0 Nm

500 - 900 15,0 Nm 16,0 Nm

1000 - 1600 50,0 Nm 60,0 Nm

Workmanship + Assembling:

All Rights Reserved

- At rear end of the assembled pipe hang JOINING CLIP over the pipe flange

- Start by inserting the second pipe along with the rear side of the

pipe flange into the JOINING CLIP. Lift to secure an erect position

- Slowly tighten coupling nut using impact wrench or spanner

- Use rubber mallet to help in the erection of the pipe flange

- 2. 7.1 PIPE CONNECTIONS

7.1

PIPE CONNECTIONS, PIPE ASSEMBLING, FLEXIBLE TUBES

7.1.6 JOINING CLIP SR with Polyethylene sealant

- Ideally suited for circular flange AF, BF, LF and UF A

- With polyethylene sealant in the channel of the JOINING CLIP

B

- With a practical clamping bolt C

D

- For pipe diameter of NW 200 – 3000 mm

E

F

*On request available in stainless steel (E)

Art.-Nr. Material A B C D E F Bolt Pipe Ø VPE Weight

mm units kg/unit

168/200 Galv. steel* 15,9 15,0 0,8 19,3 14,9 16,2 1M6 1200 60 0,160

168/224 Galv. steel* 15,9 15,0 0,8 19,3 14,9 16,2 1M6 1224 60 0,173

168/250 Galv. steel* 15,9 15,0 0,8 19,3 14,9 16,2 1M6 1250 60 0,190

168/280 Galv. steel* 15,9 15,0 0,8 19,3 14,9 16,2 1M6 1280 60 0,210

168/300 Galv. steel* 15,9 15,0 0,8 19,3 14,9 16,2 1M6 1300 60 0,217

168/315 Galv. steel* 15,9 15,0 0,8 19,3 14,9 16,2 1M6 1315 60 0,225

168/355 Galv. steel* 15,9 15,0 0,8 19,3 14,9 16,2 1M6 1355 60 0,247

168/400 Galv. steel* 15,9 15,0 0,8 19,3 14,9 16,2 1M6 1400 60 0,263

168/450 Galv. steel* 15,9 15,0 0,8 19,3 14,9 16,2 1M6 1450 60 0,283

168/500 Galv. steel* 18,4 17,2 1,0 15,0 23,4 25,1 1M8 1500 40 0,675

168/560 Galv. steel* 18,4 17,2 1,0 15,0 23,4 25,1 1M8 1560 40 0,725

168/600 Galv. steel* 18,4 17,2 1,0 15,0 23,4 25,1 1M8 1600 40 0,775

168/630 Galv. steel* 18,4 17,2 1,0 15,0 23,4 25,1 1M8 1630 40 0,787

168/710 Galv. steel* 18,4 17,2 1,0 15,0 23,4 25,1 1M8 1710 40 0,875

168/800 Galv. steel* 18,4 17,2 1,0 15,0 23,4 25,1 1M8 1800 40 0,963

168/900 Galv. steel* 18,4 17,2 1,0 15,0 23,4 25,1 1M8 1900 40 1,063

168/1000 Galv. steel* 12,1 10,4 1,5 22,6 34,8 37,4 M12 1000 25 2,800

168/1120 Galv. steel* 12,1 10,4 1,5 22,6 34,8 37,4 M12 1120 25 3,032

168/1250 Galv. steel* 12,1 10,4 1,5 22,6 34,8 37,4 M12 1250 25 3,368

168/1400 Galv. steel* 12,1 10,4 1,5 22,6 34,8 37,4 M12 1400 25 3,712

168/1600 Galv. steel* 12,1 10,4 1,5 22,6 34,8 37,4 M12 1600 25 4,180

POLYETHYLENE-SEALING:

Pipe Ø A B

mm mm mm A

200 - 499 5,0 17,0

B

500 - 999 6,0 10,0

1000 - 3000 8,0 14,0

Technical Specifications:

- Polymerised foam sealant, grey

All Rights Reserved

- Closed-cell – non-ageing and offers durability against all climatic conditions

- Is resistant against oil and fuel

- Silicone-free

- As per fire protection classification B3 under

DIN 4102 – temperature-resistant from -70°C till +60°C

- 3. 7.1 PIPE CONNECTIONS

7.1

PIPE CONNECTIONS, PIPE ASSEMBLING, FLEXIBLE TUBES

7.1.6 JOINING CLIP G SR with Ceramic fibre sealant

- Ideally suited for circular flange AF, BF, LF and UF A

- With ceramic fibre sealant in the channel of the JOINING CLIP

B

- With a practical clamping bolt C

D

- For pipe diameter of NW 200 – 3000 mm

E

F

*On request available in stainless steel (E)

Art.-Nr. Material A B C D E F Bolt Pipe Ø VPE Weight

mm units kg/unit

168/200 H Galv. steel* 15,9 15,0 0,8 19,3 14,9 16,2 1M6 1200 60 0,160

168/224 H Galv. steel* 15,9 15,0 0,8 19,3 14,9 16,2 1M6 1224 60 0,173

168/250 H Galv. steel* 15,9 15,0 0,8 19,3 14,9 16,2 1M6 1250 60 0,190

168/280 H Galv. steel* 15,9 15,0 0,8 19,3 14,9 16,2 1M6 1280 60 0,210

168/300 H Galv. steel* 15,9 15,0 0,8 19,3 14,9 16,2 1M6 1300 60 0,217

168/315 H Galv. steel* 15,9 15,0 0,8 19,3 14,9 16,2 1M6 1315 60 0,225

168/355 H Galv. steel* 15,9 15,0 0,8 19,3 14,9 16,2 1M6 1355 60 0,247

168/400 H Galv. steel* 15,9 15,0 0,8 19,3 14,9 16,2 1M6 1400 60 0,263

168/450 H Galv. steel* 15,9 15,0 0,8 19,3 14,9 16,2 1M6 1450 60 0,283

168/500 H Galv. steel* 18,4 17,2 1,0 15,0 23,4 25,1 1M8 1500 40 0,675

168/560 H Galv. steel* 18,4 17,2 1,0 15,0 23,4 25,1 1M8 1560 40 0,725

168/600 H Galv. steel* 18,4 17,2 1,0 15,0 23,4 25,1 1M8 1600 40 0,775

168/630 H Galv. steel* 18,4 17,2 1,0 15,0 23,4 25,1 1M8 1630 40 0,787

168/710 H Galv. steel* 18,4 17,2 1,0 15,0 23,4 25,1 1M8 1710 40 0,875

168/800 H Galv. steel* 18,4 17,2 1,0 15,0 23,4 25,1 1M8 1800 40 0,963

168/900H Galv. steel* 18,4 17,2 1,0 15,0 23,4 25,1 1M8 1900 40 1,063

168/1000H Galv. steel* 12,1 10,4 1,5 22,6 34,8 37,4 M12 1000 25 2,800

168/1120H Galv. steel* 12,1 10,4 1,5 22,6 34,8 37,4 M12 1120 25 3,032

168/1250H Galv. steel* 12,1 10,4 1,5 22,6 34,8 37,4 M12 1250 25 3,368

168/1400H Galv. steel* 12,1 10,4 1,5 22,6 34,8 37,4 M12 1400 25 3,712

168/1600H Galv. steel* 12,1 10,4 1,5 22,6 34,8 37,4 M12 1600 25 4,180

CERAMIC FIBRE SEALANT:

Pipe Ø A B

mm mm mm A

200 - 499 5,0 17,0

B

500 - 999 6,0 10,0

1000 - 3000 8,0 14,0

Technical Specifications: Workmanship + Assembling:

- Single-sided self-adhesive, white - Stick self-adhesive sealing tape onto the dead centre of the pipe flange

- Asbestos-free - At rear end of the assembled pipe hang JOINING CLIP over the pipe

All Rights Reserved

- Temperature-resistant till flange

approx. +400°C - Start by inserting the second pipe along with the rear side of the

pipe flange into the JOINING CLIP. Lift to secure an erect position

- Slowly tighten coupling nut using impact wrench or spanner

- Use rubber mallet to help in the erection of the pipe flange