PhD Open Seminar (Sajan Kumar Chourasia - 15EXTPHDE148).pptx

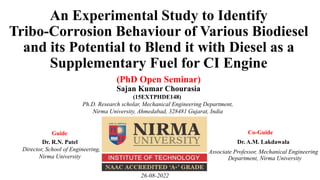

- 1. An Experimental Study to Identify Tribo-Corrosion Behaviour of Various Biodiesel and its Potential to Blend it with Diesel as a Supplementary Fuel for CI Engine Dr. A.M. Lakdawala Associate Professor, Mechanical Engineering . Department, Nirma University Sajan Kumar Chourasia . (15EXTPHDE148) Ph.D. Research scholar, Mechanical Engineering Department, Nirma University, Ahmedabad, 328481 Gujarat, India Co-Guide Dr. R.N. Patel Director, School of Engineering, Nirma University Guide (PhD Open Seminar) 26-08-2022

- 2. Outline of the Presentation Introduction Motivation and literature review Objectives of work Selection of optimum biodiesel bland using MCDM techniques Water in oil emulsification analysis Corrosion analysis Tribological analysis Life cycle analysis (LCA) - Long run endurance test 2 22-12-2022 PhD Open Seminar

- 3. 3 Introduction 22-12-2022 PhD Open Seminar

- 4. 4 •Biodiesel is defined as mono-alkyl esters of long chain fatty acids. •The main benefit of biodiesel is that it can be described as ‘carbon neutral’. •Biodiesel can be produced from vegetable oil/ animal fats / waste cooking oil. •6.5 million diesel engines are existing in Indian farming and construction. •Can be used as an alternative in the CI engines in pure or blended form. •Foreign crude oil import (212.2 million tonnes - $119 billion - FY21-22). •Increases India's economy. Agriculture sector contributes GDP (20.2% - FY21-22). •Indian OMC increases procurement from 1.1 to 10.56 crore litres - 2019-20. •Government allowed direct sale of Biodiesel (B100) for bulk consumers. •Domestic production will increase the job openings. 22-12-2022 PhD Open Seminar What and Why Biodiesel ?

- 5. Motivation of Study • Dual crises - Fossil fuel reduction and Environmental degradation. • Dependency on petroleum product. • Stringent emission norms requirement (Trem Stage V and CEV Stage V). • Biodiesel produced from renewable sources. • Pure biodiesel or their blends with diesel have shown many long-term problems. • Reduction of pollutants like NOx, CO and HC by means of emulsion of biodiesel. • Impact of biofuel on friction and wear on engine components. • Impact of use of biofuels on engine components in terms of corrosion. • Effect of dual biodiesel on engine outputs and tribo-corrosion. 5 22-12-2022 PhD Open Seminar

- 7. 7 MCDM Techniques : PROMETHEE, TOPSIS, MOORA, AHP, ANP, VIKOR etc. Fuel Optimization with MCDM Techniques: Engine Performance, Combustion, Emission Fuel Optimization by MCDM Technique Literature Review Corrosion Behaviour of Biodiesel & their Emulsified Fuel Blend on Metal Surface: Corrosion Rate, Weight Loss, Surface Roughness, Physical Visualization, Surface Microscopic Analysis Tribological Behaviour of Biodiesel & their Emulsified Fuel Blend on Metal Surface: Coefficient of Friction, Friction Force, Wear Rate, Material, Volume Loss, Worn-out Surface Microscopic Analysis. Corrosion Behaviour of Biodiesel Tribological Behaviour of Biodiesel Stability of Emulsified Fuel: Surfactant, Water %, Stirring Speed & Time Effect of Emulsified fuel on Engine Output: Engine Performance, Combustion, Emission Engine Output with Emulsified Fuel Effect of Dual Biodiesel on Fuel Properties: Viscosity, Density, Tribo-Corrosion, Stability Effect of Dual Biodiesel on Engine Output: Engine Performance, Combustion, Emission Engine Output with Dual Biodiesel 22-12-2022 PhD Open Seminar

- 8. Conclusion from Literature Review • Mixing of various biodiesel will reduce dependency. • Optimization of fuel can be performed using MCDM technique based on engine output. • Multiple mixing of biodiesel can reduce engine emission. • Emulsified fuel combust more evenly and provide high ηthe%. • Emulsification of biodiesel with diesel can be a possible way to reduce engine emission. • Some crop of biodiesels are highly corrosive. • Biodiesels are more corrosive than diesel. • Corrosiveness of biodiesel can be reduced by blending them with low corrosive biodiesel. • Biodiesels have potential as a self-lubricating fuel/lubricant. • Multiple biodiesel blended fuel has potential to reduce engine wear. • With the addition of biodiesel in petroleum lubricant can degrade lubricating properties. 8 22-12-2022 PhD Open Seminar

- 9. Objectives of Work 1. To find out an optimum dual biodiesel blend with diesel based on engine performance combustion and emission using MCDM techniques. 2. To see emulsification effect of optimum blend on engine combustion, performance and emission. 3. To identify the corrosive properties of biodiesels with engine materials. 4. To check the feasibility of biodiesel as self-lubricating fuel/lubricant with CI engine components material. 9 22-12-2022 PhD Open Seminar

- 10. Selection of Biodiesel • Based on Properties (Physical & Chemical) • GC-MS & FT-IR • Based on Availability • Based on Tribo- Corrosion Properties Corrosion Analysis • Selection of Metal • Static Immersion Test • Physical Visualization • Weight Loss Analysis • Surface Roughness & SEM Analysis Tribological Assessment • Selection of Metal • Pin-on-Disc Setup • CoF Analysis • Wear Rate Analysis • SEM Analysis Engine Performance Analysis • CI Engine Test Rig • Performance Analysis • Combustion Analysis • Emission Analysis • Normalization as Per IS 10000 –IV • MCDM Techniques Water Emulsification • Synthesis of Emulsified Blend • Stability of Blend • Performance, Combustion & Emission Analysis Process Plan 10 22-12-2022 PhD Open Seminar

- 11. Selection of Optimum Biodiesel Blend Using MCDM Techniques *Optimization of Dual Biodiesel-Diesel Blend Using MCDM Technique Base on Experimental Engine Performance, Combustion and Emission Characteristics. (Under Review) Sādhanā – Academy Proceedings in Engineering Science (Springer)

- 12. 12 22-12-2022 PhD Open Seminar

- 13. Physical and Chemical Properties of Biodiesels 13 22-12-2022 PhD Open Seminar

- 14. Selection of Possible Blends of Biodiesels (First Phase) 1 – Blending, 0 – No Blending For each blend, 50% Diesel remains constant 14 22-12-2022 PhD Open Seminar

- 15. Line Diagram of Engine Setup T1 - Engine water inlet temperature (oC). T2 - Engine water outlet temperature (oC). T3 - Calorimeter water inlet temperature (oC). T4 - Calorimeter water outlet temperature (oC). T5 - Temperature of exhaust gas before calorimeter (oC). T6 - Temperature of exhaust gas after calorimeter (oC). F1 - Fuel consumption measurement unit. F2 - Air flow measurement unit. PT - Pressure transducer. EGA - Exhaust gas analyser. N - Engine speed measurement. 15 22-12-2022 PhD Open Seminar

- 16. VCR Engine Test Rig Specification 16 22-12-2022 PhD Open Seminar

- 17. Emission Analyser Specification 17 22-12-2022 PhD Open Seminar

- 18. Load Factors at Respective Loading Conditions Engine Load factor : 0.59 [United States environmental protection agency “Median life, annual activity, and load factor values for nonroad engine emissions modelling NR-005b” (SCC -2270005055)] Engine Operating Condition Engine speed : 1500 RPM Engine load conditions are: 0% (0 kg), 25% (3 kg), 50% (6 kg), 75% (9 kg) and 100% (12 kg) Injection timing: 20⁰ BTDC Temperature condition: Room temperature (20 to 25°C) Compression ratio: 18:1 Injection pressure: 220 bar 18 22-12-2022 PhD Open Seminar

- 19. Notations Used for Diesel-Duel-Biodiesel Blends 19 22-12-2022 PhD Open Seminar

- 20. Performance Analysis 20 22-12-2022 PhD Open Seminar Neem-Linseed Linseed-Jatropha Neem-Linseed Linseed-Jatropha

- 21. Combustion Analysis 21 22-12-2022 PhD Open Seminar Canola-Karanja Palm-Neem Canola-Castor Palm-Castor

- 22. Emission Analysis 22 22-12-2022 PhD Open Seminar Canola-Palm Linseed-Rapeseed Linseed-Jatropha Neem-Linseed Palm-Castor Castor-Rapeseed

- 23. Decision Matrix Representing Performance, Combustion and Emission Results for The First Phase of Experiments Carried out With 28 Dual Biodiesel Blends 0.250 23 22-12-2022 PhD Open Seminar

- 24. 24 22-12-2022 PhD Open Seminar

- 25. • The full form of TOPSIS is Technique for Order Preference by Similarity to Ideal Solution. • The base concept of this method is that the optimum alternative should have the minimum distance from the ideal solution and the maximum distance from negative ideal solution. o Step - 1 𝐷 = 𝐴1 𝐴2 ⋮ 𝐴𝑚 𝑥11 𝑥12 … 𝑥1𝑛 𝑥21 ⋮ 𝑥22 … ⋮ 𝑥2𝑛 ⋮ 𝑥𝑚1 𝑥𝑚2 … 𝑥𝑚𝑛 TOPSIS Method 25 **Where, A1,A2,...,Am= m number of alternatives, x11,x12,...,x1n= values of n no. of attributes for alternative 22-12-2022 PhD Open Seminar

- 26. o Step – 2 Normalized decision matrix, 𝑟𝑖𝑗 𝑟𝑖𝑗 = 𝑥𝑖𝑗 𝑖=1 𝑚 𝑥𝑖𝑗 2 o Step – 3 Apply relative weightage to attributes. Construct the weighted normalized decision matrix. 𝐷 = 𝐴1 𝐴2 ⋮ 𝐴𝑚 𝑤1𝑟11 𝑤2𝑟12 … 𝑤𝑛𝑟1𝑛 𝑤1𝑟21 ⋮ 𝑤2𝑟22 … ⋮ 𝑤𝑛𝑟2𝑛 ⋮ 𝑤1𝑟𝑚1 𝑤2𝑟𝑚2 … 𝑤𝑛𝑟𝑚𝑛 26 22-12-2022 PhD Open Seminar

- 27. o Step – 4 Determine ideal and negative ideal solutions 𝐴+ = 𝑚𝑎𝑥 𝑖 𝑣𝑖𝑗| 𝑗 ∈ 𝐽 , 𝑚𝑖𝑛 𝑖 𝑣𝑖𝑗| 𝑗 ∈ 𝐽′ | 𝑖 = 1, 2, … , 𝑚 𝐴+ = 𝑣1 + , 𝑣2 + , 𝑣3 + , … , 𝑣𝑗 + , … , 𝑣𝑛 + 𝐴− = 𝑚𝑖𝑛 𝑖 𝑣𝑖𝑗| 𝑗 ∈ 𝐽 , 𝑚𝑎𝑥 𝑖 𝑣𝑖𝑗| 𝑗 ∈ 𝐽′ | 𝑖 = 1, 2, … , 𝑚 𝐴− = 𝑣1 − , 𝑣2 − , 𝑣3 − , … , 𝑣𝑗 − , … , 𝑣𝑛 − Where, 𝐽 = 𝑗 = 1, 2, … , 𝑛| 𝑗 𝑎𝑠𝑠𝑜𝑐𝑖𝑎𝑡𝑒𝑑 𝑤𝑖𝑡ℎ 𝑏𝑒𝑛𝑒𝑓𝑖𝑡 𝑐𝑟𝑖𝑡𝑒𝑟𝑖𝑎 𝐽′ = 𝑗 = 1, 2, … , 𝑛| 𝑗 𝑎𝑠𝑠𝑜𝑐𝑖𝑎𝑡𝑒𝑑 𝑤𝑖𝑡ℎ 𝑐𝑜𝑠𝑡 𝑐𝑟𝑖𝑡𝑒𝑟𝑖𝑎 **Ideal solution A+ and negative ideal solution A- 27 22-12-2022 PhD Open Seminar

- 28. o Step – 5 Calculate the separation from ideal and negative ideal solution Ideal separation, 𝑆𝑖 + = 𝑗=1 𝑛 𝑣𝑖𝑗 − 𝑣𝑗 + 2 𝑖 = 1, 2, … , 𝑚 Negative ideal separation, 𝑆𝑖 − = 𝑗=1 𝑛 𝑣𝑖𝑗 − 𝑣𝑗 − 2 𝑖 = 1, 2, … , 𝑚 28 22-12-2022 PhD Open Seminar

- 29. o Step – 6 • Calculate the relative closeness coefficient to the ideal solution 𝐶𝑖 ∗ = 𝑆𝑖 − 𝑆𝑖 + + 𝑆𝑖 − , 0 < 𝐶𝑖 ∗ < 1, 𝑖 = 1, 2, … , 𝑚 If 𝐶𝑖 ∗ = 1, then 𝐴𝑖 = 𝐴+(Ideal solution) If 𝐶𝑖 ∗ = 0, then 𝐴𝑖 = 𝐴− (Negative ideal solution) o Step – 7 Assign the ranking to the alternatives on the basis of descending value of 𝐶𝑖 ∗ . 29 22-12-2022 PhD Open Seminar

- 30. The Relative Closeness Coefficient and The Rank Obtained by TOPSIS. 30 22-12-2022 PhD Open Seminar 𝐶𝑖 ∗ = Relative closeness coefficient

- 31. o The full form of PROMETHEE is Preference Ranking Organization Method of Enrichment Evaluation. o Step - 1 𝐷 = 𝐴1 𝐴2 ⋮ 𝐴𝑚 𝑥11 𝑥12 … 𝑥1𝑛 𝑥21 ⋮ 𝑥22 … ⋮ 𝑥2𝑛 ⋮ 𝑥𝑚1 𝑥𝑚2 … 𝑥𝑚𝑛 • Negative sign is multiplied with the attributes having level of satisfaction as minimization. • Take the transpose of the decision matrix. PROMETHEE Method 31 **Where, A1,A2,...,Am= m number of alternatives, x11,x12,...,x1n= values of n no. of attributes for alternative 22-12-2022 PhD Open Seminar

- 32. 𝐷𝑇 = 𝐶1 𝐶2 ⋮ 𝐶𝑛 −𝑥11 −𝑥21 … −𝑥𝑚1 𝑥12 ⋮ 𝑥22 … ⋮ 𝑥𝑚2 ⋮ −𝑥1𝑛 −𝑥2𝑛 … −𝑥𝑚𝑛 o Step - 2 • Compute the pairwise difference between the attribute values of each alternative. 𝐷𝑇 = −𝑥11 +𝑥11 −𝑥11 +𝑥21 … −𝑥11 + 𝑥𝑚1 𝑥12 − 𝑥12 ⋮ 𝑥12 − 𝑥22 … ⋮ 𝑥12 − 𝑥𝑚2 ⋮ −𝑥1𝑛 + 𝑥1𝑛 −𝑥1𝑛 + 𝑥2𝑛 … −𝑥1𝑛 + 𝑥𝑚𝑛 • For ‘m’ alternatives and ‘n’ attributes, we will have ‘n’ pairwise difference matrices of n x m. 32 22-12-2022 PhD Open Seminar

- 33. The Multi Criteria Reference Index Matrix 33 22-12-2022 PhD Open Seminar

- 34. o Step – 3 • Select the appropriate preference function from usual, quasi, gaussian and linear preference with or without indifference area. • In the usual criterion, the preference function value of 0 is for negative pairwise difference and the preference function value of 1 is for positive pairwise difference. • Apply relative weightage to attributes. • Calculate the multi-criterion preference index, π 𝐴𝑚, 𝐶𝑛 𝜋 𝐴𝑚, 𝐶𝑛 = 𝑗=1 𝑛 𝑤𝑗𝑃𝑗 𝑚, 𝑛 𝑗=1 𝑛 𝑤𝑗 34 22-12-2022 PhD Open Seminar

- 35. o Step – 4 • Calculate the outranking index 𝜑+(𝑚) and outranked index 𝜑−(𝑚). 𝜑+ 𝑚 = 𝐴 π 𝐴𝑚, 𝐶𝑛 𝑚 − 1 𝜑− 𝑚 = 𝐴 π 𝐶𝑛, 𝐴𝑚 𝑚 − 1 𝜑 𝑚 = 𝜑+ 𝑚 − 𝜑− 𝑚 o Step – 5 • The ranking to the alternatives (biodiesel blends) is assigned on the basis of decreasing value of 𝜑 𝑚 . 35 22-12-2022 PhD Open Seminar

- 36. The Outranking Flow and The Rank Obtained Using PROMETHEE 36 22-12-2022 PhD Open Seminar

- 37. The Comparison of The Ranks (First Phase) Obtained by TOPSIS and PROMETHEE Method and Their Absolute Deviation 37 22-12-2022 PhD Open Seminar

- 38. 38 22-12-2022 PhD Open Seminar

- 39. • Spearman's rank correlation coefficient ' 𝜌 ' is the non-parametric monotonic relation between the two sets of quantitative variables. The value of '𝜌 ' lies from −1 to +1. 𝜌 = 1 − 6 𝑑𝑖 2 𝑛 𝑛2 − 1 • Where, ‘𝑑𝑖’ is the pairwise difference between the ranks given by two optimization methods and ‘𝑛’ is the number of variables in associated with the problem. 𝐹𝑜𝑟 1𝑠𝑡 𝑝ℎ𝑎𝑠𝑒 𝑜𝑓 𝑒𝑥𝑝𝑒𝑟𝑖𝑚𝑒𝑛𝑡𝑠, 𝜌 = 0.85 Spearman’s Rank Correlation 39 22-12-2022 PhD Open Seminar

- 40. PROMETHEE & TOPSIS Method Rank The value of spearman's rank correlation coefficient ρ for the ranks of these two methods is coming as 0.85 Rank 1 Fuel 40 22-12-2022 PhD Open Seminar

- 41. Decision Matrix of Second Phase Experiments g Dual Biodiesel Fuel Properties Experimental Matrix for Evaluating the Optimum Percentage of Two Best Biodiesel 41 22-12-2022 PhD Open Seminar

- 42. Performance Analysis 42 1- 70D5CA25R 2- 70D10CA20R 3- 70D15CA15R 4- 70D20CA10R 5- 70D25CA5R 22-12-2022 PhD Open Seminar

- 43. Combustion Analysis 43 1- 70D5CA25R 2- 70D10CA20R 3- 70D15CA15R 4- 70D20CA10R 5- 70D25CA5R 22-12-2022 PhD Open Seminar

- 44. Emission Analysis 44 22-12-2022 PhD Open Seminar 1- 70D5CA25R 2- 70D10CA20R 3- 70D15CA15R 4- 70D20CA10R 5- 70D25CA5R

- 45. Decision Matrix for Second Phase (Castor and Rapeseed) 45 22-12-2022 PhD Open Seminar Comparison of Ranks (Second Phase) - TOPSIS and PROMETHEE Method 0.250

- 46. PROMETHEE & TOPSIS Method Rank The value of spearman's rank correlation coefficient ρ for the ranks of these two methods is coming as 0.94 Rank 1 Fuel 46 22-12-2022 PhD Open Seminar

- 47. Emulsification Analysis (Water in Oil) 47 22-12-2022 PhD Open Seminar *Selection of Optimum Castor-Rapeseed Emulsified Fuel Based on Engine Performance, Combustion and Emission Analysis. (2nd International Conference on Recent Advances in Mechanical Infrastructure 2020 - Springer proceedings-Lecture Notes in Intelligent Transportation and Infrastructure) DOI: 10.1007/978-981-33-4176-0_24

- 48. Schematic Diagram of Water in Oil Emulsion Fuel During The Micro-explosion Phenomenon 48 22-12-2022 PhD Open Seminar

- 49. Castor Biodiesel Rapeseed Biodiesel Diesel Water SPAN 80 TWEEN 80 15%Castor + 15% Rapeseed 70D15CA15R WC15R15 (W 1-5, 10%) Mechanical Stirrer Stability Test CI Engine Test Rig Performance, Combustion and Emission Analysis 49 22-12-2022 PhD Open Seminar

- 50. Test Matrix of Water in Oil Emulsification % of Water % of Surfactant Speed of blending HLB Type of Surfactant 1 2 3 4 5 10 1 2 3 1500 RPM 4.3 5 6 SPAN 80 (Ls) & TWIN 80 (Hs) Stability Analysis Performance Analysis Combustion Analysis Emission Analysis (Hydrophilic lipophilic balance) HLB = 20𝑀ℎ 𝑀ℎ+𝑀𝑙 50 22-12-2022 PhD Open Seminar

- 51. Stability Analysis for 5&10 % Water 51 22-12-2022 PhD Open Seminar

- 52. Stability Analysis for 1-5% Water Stability study of an emulsified water-biodiesel-diesel blend containing water varying from 1 to 5 %, respectively. Figure (a) (1% water) to (e) (5% water), HLB: 6 and Surfactant: 2%. 52 22-12-2022 PhD Open Seminar

- 53. Performance Analysis 53 1- Diesel 2- C15R15 3- W1S2HLB6 4- W2S2HLB6 5- W3S2HLB6 6- W4S2HLB6 7- W5S2HLB6 22-12-2022 PhD Open Seminar

- 54. Combustion Analysis 54 22-12-2022 PhD Open Seminar

- 55. Combustion Analysis 55 1- Diesel 2- C15R15 3- W1S2HLB6 4- W2S2HLB6 5- W3S2HLB6 6- W4S2HLB6 7- W5S2HLB6 22-12-2022 PhD Open Seminar

- 56. Emission Analysis 56 1- Diesel 2- C15R15 3- W1S2HLB6 4- W2S2HLB6 5- W3S2HLB6 6- W4S2HLB6 7- W5S2HLB6 1- Diesel 2- C15R15 3- W1S2HLB6 4- W2S2HLB6 5- W3S2HLB6 6- W4S2HLB6 7- W5S2HLB6 22-12-2022 PhD Open Seminar

- 57. *Note: NOx: Nitrogen oxide, HC: Hydrocarbon, SO: Smoke opacity, BSFC: Break specific fuel consumption, BTE: Break thermal efficiency, DP: Delay period, Pmax: Maximum in cylinder pressure. Final Result After Applying The Load Factor NOx HC SO BSFC BTE DP Pmax (ppm) (ppm) (%) (Kg/kWh) (%) (°CA) (bar) 1 Diesel 212 23.4 40 0.15 18.29 9.4 35.9 2 C15R15 173 21.9 40.8 0.165 18.88 9.1 33.7 3 W1S2HLB6 154 21.8 42.1 0.172 19.77 8.7 33 4 W2S2HLB6 124 21 42.6 0.176 20.06 8.3 31.9 5 W3S2HLB6 109 21.4 43 0.18 20.05 8 30.4 6 W4S2HLB6 92 21.9 43.7 0.185 20.65 7.7 30.8 7 W5S2HLB6 83 20.1 44 0.193 21.24 7.1 29 Sr No Fuel/Blends 57 22-12-2022 PhD Open Seminar

- 58. Corrosion Analysis 22-12-2022 PhD Open Seminar 58 *Corrosion Analysis of CI Engine Components by Using Dual Blend of Biodiesel. (ICRPMSME-2021: International Conference on Recent Progress in Material Science and Mechanical Engineering) *The Corrosion Analysis of Diesel Engine Parts on Application of Dual Biodiesel Blend. (ICAER-2022: 8th International Conference on Advances in Energy Research – IIT-.Bombay) *Corrosion Behaviour of Various Biodiesel and Diesel on Metal Surface Used for the Manufacturing of Various Components of CI Engine. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science (Sage Journals) DOI: 10.1177/0954406220970584

- 59. Static Immersion Selection of Biodiesel (Test Fuel) • Jatropha • Castor • Neem • Linseed • Karanja • Rapeseed • Palm • Canola • 70D15CA15R • W5S2HLB6 (Metal Coin) • Brass • Bronze • Copper • Iron • Aluminium GC-MS Maximum concentration of Palmitic (C16:0), Stearic (C18:0), Oleic (C18:1), Linoleic (C18:2) in biodiesels Physical Visualization Visual detection of oxides layer based on there colour (CuCO3, CuO, ZnCO3, FeO, Fe2O3, Al2O3) Corrosion Rate Highest corrosion is found in Karanja and Jatropha biodiesel while Rapeseed, Castor and Neem biodiesel shows lowest corrosion SEM De-alloying, Intergranular and Pitting type corrosion were found on metal surface, Copper metal surface shows maximum pitting corrosion . Surface Roughness Copper surface shows highest and lowest roughness with . Palm and Neem biodiesel. On another hand Palm biodiesel shows comparatively lowest roughness with others Experimental Methodology Results Physical Visualization Weight Loss Microscopic Surface Roughness GC-MS * Rapeseed and Caster Biodiesel produce less corrosion on all the metal surface Testing Method: ASTM G 1 ASTM G 31 59 22-12-2022 PhD Open Seminar

- 60. GC-MS Results of Test Fuels 60 22-12-2022 PhD Open Seminar

- 61. GC-MS Results of Test Fuels 61 Shimadzu GC-2010 Plus Type of Detector : Mass Detector (Mode - EI) Column Flow Rate : 1.5 ml/ min Column Details : RTX-5 Fused Silica (L: 30m and ID: 0.25mm) Injector Temperature : 220 °C, Oven Temperature : 50-300 °C Heating rate: 5 °C/min, Holding Time: 5min Film Thickness 0.25 μm, Mass Range : 30-700 amu 22-12-2022 PhD Open Seminar

- 62. Fatty Acid Composition of Biodiesels 62 22-12-2022 PhD Open Seminar

- 63. Metal Composition of Various Components of CI Engine 63 22-12-2022 PhD Open Seminar

- 64. Metal Composition of Various Components of CI Engine 64 22-12-2022 PhD Open Seminar

- 65. Static Immersion Test of Metal Coins Immersed in Biodiesel Static Immersion Test Coin samples Composition and Various Parameters 65 22-12-2022 PhD Open Seminar

- 66. Physical Visualization & Metallurgical Microscopic Image Deposit of Carbides and Oxides on The Metal Coupons 66 22-12-2022 PhD Open Seminar

- 67. Physical Visualization & Metallurgical Microscopic Image Deposit of Carbides and Oxides on The Metal Coupons 67 22-12-2022 PhD Open Seminar

- 68. Cleaning Methodology • As per As per ASTM G 1-90 which is “Standard Practice for Preparing, Cleaning, and Evaluating Corrosion Test Specimens”, samples are cleaned as per this method. 68 22-12-2022 PhD Open Seminar Aluminium and Aluminium Alloy………………..Nitric Acid (HNO3) Copper and Copper Alloy………………………...Hydrochloric Acid (HCL) Iron and Steel……………………………………..Hydrochloric Acid (HCL) Calculation of Corrosion Rate • As per As per which is “Laboratory Immersion Corrosion Testing of Metals” samples are tested by ASTM G 31-72 various means (detailed in appropriate specifications) to remove all deposits and corrosion products from the unreacted metal. After cleaning, the samples is weighed again and the corrosion rate is calculated from the weight loss. (Evaluation after Exposure)

- 69. Corrosion Rate of Metal Coupons Calculated Based on ASTM G31 After 150 Days of Static Immersion Test 1-Jatropha 2-Castor 3-Neem 4-Linseed 5-Karanja 6-Rapeseed 7-Palm 8-Canola 9-Diesel 10-70D15CA15R 11-W5S2HLB6 69 22-12-2022 PhD Open Seminar

- 70. 22-12-2022 PhD Open Seminar 70

- 71. SEM Analysis of Cleaned Metal Coin Surface After Static Immersion Test 71 22-12-2022 PhD Open Seminar

- 72. SEM Analysis of Cleaned Metal Coin Surface After Static Immersion Test 72 22-12-2022 PhD Open Seminar

- 73. Surface Roughness Analysis Measured After Static Immersion Test 73 1-Jatropha 2-Castor 3-Neem 4-Linseed 5-Karanja 6-Rapeseed 7-Palm 8-Canola 9-Diesel 10-70D15CA15R 11-W5S2HLB6 22-12-2022 PhD Open Seminar

- 74. Tribological Analysis 74 22-12-2022 PhD Open Seminar *Tribological Analysis of Automotive Material Under Wet Lubrication Condition Using Diesel, Biodiesel and Their Blend. (Advances in Thermal-Fluids Engineering 2021 - IOP Conference Series-Material science and Engineering) DOI: 10.1088/1757-899X/1146/1/012028

- 75. Material Selection (Pin & Disc) Selection of Fuel (Test Fuel) • Jatropha • Castor • Neem • Linseed • Karanja • Rapeseed • Palm • Canola • 70D15CA15R • W5S2HLB6 (Metal Pin) • Brass • Bronze • Copper • Iron • Aluminium (Metal Disc) ● EN31 Steel FT-IT Analysis C-H, N-H & C=O group are detected in all biodiesel. N-H group is absent in diesel and Castor biodiesel. Only in Castor biodiesel O-H group is detected. Weight Loss Analysis Neem and Castor biodiesel shows highest weight loss with every metal, while Jatropha biodiesel shows lowest weight loss in compare to all test fuels. Coefficient of Friction Analysis Neem and Castor biodiesel shows highest COF, while Jatropha biodiesel with Copper, Iron and Palm biodiesel with Aluminium, Bronze shows lowest CoF. Wear Volume Loss Analysis Except Iron Jatropha biodiesel provides lowest wear. Neem biodiesel shows highest volume loss in compared to all biodiesel on all metals except Copper and Brass, while Castor biodiesel provides highest wear with these metals. . SEM.Analysis Delamination wear, fractures and deep groves are found on the surface of metals with Neem biodiesel, while the metal surface with Jatropha, Castor biodiesel shows very lower abrasion and compound layer removal. Experimental Methodology Results Tribological Testing (Wet Lubrication) (Pin-on-Disc) FT-IR Microscopic Weight Loss *Jatropha, Palm and Canola biodiesel produces lowest wear compare to all test fuels. Testing Method: ASTM G 99 75 22-12-2022 PhD Open Seminar

- 76. FT-IR Results of Biodiesels 76 22-12-2022 PhD Open Seminar

- 77. Experimental Setup Schematic Diagram/View of Pin-on-Disc Wear Tester Experimental Setup Test variables Units Macro POD Normal force / Load N 2 to 200 Friction force N 0 to 200 Rotational speed rpm 0.3 to 3000 Linear wear (LVDT) µm 0 to 2000 Wear track diameter mm 0 to 160 Ball diameter mm 6 to 12 Pin diameter mm 6 to 12 Dick diameter mm 10 to 100 Operating temperature °C RT to 1000 Operating humidity % RH 30 to 75 Technical Specification of Pin-on-Disc Apparatus 77 22-12-2022 PhD Open Seminar

- 78. Elemental composition of metal stationary pins and rotating disc by EDS. 1 Sr. No Metal Shape Composition in Weight % 1 EN31 Disc Fe (97.15), C (1.00), Mn (0.40), Cr (1.25) and Si (0.20) 2 Iron Pin Fe (98.55), C (0.43), Mn (0.71) and S (0.048) 3 Copper Pin Cu (88.9), C (11.12), O2 (0.38) and Si (0.09) 4 Aluminium Pin Al (99.61), Fe (0.26), Si (0.08) and Zn (0.041) 5 Bronze Pin Cu (90), Zn (9.9), Fe (0.05) and P (0.05) 6 Brass Pin Cu (90.7), Pb (0.051), Fe (0.48) and Zn (8.79) 2 Elemental Composition of Metal Stationary Pins and Rotating Disc 78 22-12-2022 PhD Open Seminar

- 79. Pin on Disc Apparatus Input Parameters Aluminium Brass Bronze Copper Iron Test Fuel (Jatropha, Castor, Neem, Linseed, Karanja, Rapeseed, Palm, Canola, 70D15CA15R & W5S2HLB6) (ASTM: G99) Track Diameter RPM Tip Velocity (m/s) Lubricant Flow Rate Litre/Min Pin Metal Metal Density Kg/m3 Pin (L& D) Load (N) Sliding Distance (m) 95 ± 0.01 mm 1105 ± 1 5.5 0.333 ± 0.02 Max flow Aluminium 2700 ± 1 30 ± 0.01 mm & 10 ± 0.01 mm 40 ± 0.01 10000 ±1 105 ± 0.01 mm 1000 ± 1 Brass 8470 ± 1 115 ± 0.01 mm 913 ± 1 Bronze 8700 ± 1 125 ± 0.01 mm 840 ± 1 Copper 8940 ± 1 135 ± 0.01 mm 778 ± 1 Iron 7870 ± 1 79 22-12-2022 PhD Open Seminar

- 80. CoF vs Time 80 22-12-2022 PhD Open Seminar

- 81. Steady State CoF vs Time 81 22-12-2022 PhD Open Seminar

- 82. Wear Rate vs Time 82 22-12-2022 PhD Open Seminar

- 83. Steady State Wear Rate vs Time 83 22-12-2022 PhD Open Seminar

- 84. SEM Analysis of Worn Metal Pin Tip (500X) (ASTM G 99) 84 22-12-2022 PhD Open Seminar

- 85. SEM Analysis of Worn Metal Pin Tip (500X) (ASTM G 99) 85 22-12-2022 PhD Open Seminar

- 86. •The first phase of the analysis, both the MCDM method have suggested the Castor- Rapeseed dual biodiesel-diesel blend as the best blend in terms of engine performance, combustion and emission parameters based on weightage and loading factor. •The second phase of the analysis is carried out to identify the optimum percentage of Castor and Rapeseed biodiesel in the blend. According to the ranks given by these two MCDM methods based on weightage given to parameters, the 70D15CA15R (70% Diesel, 15% Castor and 15% Rapeseed) is found as an optimum blend in terms of engine performance, combustion and emission parameters. •It can be seen that BTE (ηth) is increased with an increase in water (1-5% v/v). The emission (NOx + HC) of the existing engine with 5 v/v % is found to be 2.95 g/kWh, which is two times less than allowable limit of Trem Stage V and CEV Stage V norms (NOx + HC) i.e., 7.5 g/kWh. Conclusions 86 22-12-2022 PhD Open Seminar

- 87. • The oxide formation in the case of Aluminium and Iron was lower as compared to Copper and Copper alloy. • Highest corrosion is found in Karanja and Jatropha biodiesel while Rapeseed, Castor and Neem biodiesel shows lowest corrosion. • Neem and Castor biodiesel showed highest CoF, while Jatropha biodiesel with Copper, Iron and Palm biodiesel with Aluminium, Bronze showed lowest CoF. • Delamination wear, fractures and deep groves were found on the surface of metals with Neem biodiesel, while the metal surface with Jatropha, Castor biodiesel showed very lower abrasion and compound layer removal. • It can be justified that the use of emulsified fuel containing 93% 70D15CA15R, 5% water, 2% surfactant and HLB 6 (W5S2HLB6) fulfils the objective of the research and can be proposed as a best compromised blend in terms of engine performance, corrosion and tribological properties. Conclusions cont… 87 22-12-2022 PhD Open Seminar

- 88. During the course of the present research work, it is felt that there are certain areas which required future attention. These areas are listed below: • A complete life cycle analysis (LCA) of CI engine fueled with dual biodiesel optimum blend (70D15CA15R) and dual biodiesel emulsified fuel blend (W5S2HLB6) as per IS 10000 Part V & IX. • Optical diagnostics of engine combustion and spray characteristics. As the viscosity of biodiesel is higher than the conventional diesel fuel, the spray characteristics of biodiesel-diesel blend is different than that of conventional diesel fuel. • Experimental investigations of biodiesel fuel sprays with respect to straight vegetable oils and their blends with mineral diesel for optimizing fuel injection equipment to lower engine exhaust emissions. • Experimental Investigations of HCCI/ PCCI combustion in a single cylinder research engine using biodiesel. Scope of Future Work 88 22-12-2022 PhD Open Seminar

- 89. International Publication 1. Study on tribological behaviour of biodiesel – Diethyl ether (B20A4) blend for long run test on compression . ignition engine. (Published on dated: 10/05/2018) Fuel (Elsevier) DOI: 10.1016/j.fuel.2018.05.055 2. Corrosion Behaviour of Various Biodiesel and Diesel on Metal Surface Used for the Manufacturing of Various . Components of CI Engine. (Published on dated: 09/10/2020) Proceedings of the Institution of Mechanical Engineers, Part C: Journal of . Mechanical Engineering Science (Sage Journals) DOI: 10.1177/0954406220970584 3. Optimization of Dual Biodiesel-Diesel Blend Using MCDM Technique Base on Experimental Engine . Performance, Combustion and Emission Characteristics. (Under Review) Sādhanā – Academy Proceedings in Engineering Science (Springer) 4. Comparison of Various Self-Lubricating Biodiesel Fuel for CI engine: A Tribological Analysis. (Draft copy . ready) 89 22-12-2022 PhD Open Seminar

- 90. International Conference 1. Selection of Optimum Castor-Rapeseed Emulsified Fuel Based on Engine Performance, Combustion and Emission Analysis. (2nd International Conference on Recent Advances in Mechanical Infrastructure 2020 - Springer proceedings-Lecture Notes in Intelligent Transportation and Infrastructure) DOI: 10.1007/978-981-33-4176-0_24 2. Tribological Analysis of Automotive Material Under Wet Lubrication Condition Using Diesel, Biodiesel and . Their Blend. (Advances in Thermal-Fluids Engineering 2021 - IOP Conference Series-Material science and . Engineering) . DOI: 10.1088/1757-899X/1146/1/012028 3. Corrosion Analysis of CI Engine Components by Using Dual Blend of Biodiesel. (ICRPMSME-2021: . International Conference on Recent Progress in Material Science and Mechanical Engineering) 4. The Corrosion Analysis of Diesel Engine Parts on Application of Dual Biodiesel Blend. (ICAER-2022: 8th . International Conference on Advances in Energy Research – IIT-.Bombay) . 3. 4. 90 22-12-2022 PhD Open Seminar

- 91. References 1. Indian standard IS 10000 Part IV Methods for Testing of Internal Combustion Engines. 2. Indian standard IS 10000 Part V Methods for Testing of Internal Combustion Engines. 3. S.S. Satputaley, D.B. Zodpe, N.V. Deshpande, Performance, Combustion and Emission Study on CI Engine Using Microalgae Oil and Microalgae Oil Methyl Esters, Journal of the Energy Institute (2016), doi: 10.1016/j.joei.2016.05.011. 5. Gokhan Tuccar , Tayfun Ozgur, Kadir Aydın. Effect of diesel–microalgae biodiesel–butanol blends on performance and emissions of diesel engine. Fuel, 10.1016/j.fuel.2014.04.074. 6. Gokhan Tuccar , Kadir Aydın, Evaluation of methyl ester of microalgae oil as fuel in a diesel engine. Fuel 112 (2013) 203–207. 7. Haozhong Huang , Qingsheng Liu, Qingxin Wang, Chengzhong Zhou, Chunlan Mo, Xueqiang Wang.Experimental investigation of particle emissions under different EGR ratios on a diesel engine fueled by blends of diesel/gasoline/n-butanol. Energy Conversion and Management 121 (2016) 212–223. 8. Jaffar Hussain , K. Palaniradja, N. Alagumurthi, R. Manimaran. Effect of Exhaust Gas Recirculation (EGR) on Performance and Emission characteristics of a Three Cylinder Direct Injection Compression Ignition Engine. Alexandria Engineering Journal (2012) 51, 241–247. 9. Avinash kumar agrawal, Shrawan kumar singh, Shailendra sinha and Mritunjay kumar shukla. effect of egr on the exhaust gas temperature and exhaust opacity in compression ignition engines. sadhana vol. 29, part 3, june 2004, pp. 275–284. 10. A. Bulent Koc , Mudhafar Abdullah. Performance and NOx emissions of a diesel engine fueled with biodiesel-diesel-water nanoemulsions. Fuel Processing Technology 109 (2013) 70–77. 11. A. Alahmer, J. Yamin, A. Sakhrieh, M.A. Hamdan. Engine performance using emulsified diesel fuel. Energy Conversion and Management 51 (2010) 1708–1713. 12. Anna Lif , Krister Holmberg. Water-in-diesel emulsions and related systems. Advances in Colloid and Interface Science 123–126 (2006) 231–239. 13. M. Abu-Zaid. Performance of single cylinder, direct injection Diesel engine using water fuel emulsions. Energy Conversion and Management 45 (2004) 697–705. 14. Ankur Nalgundwar , Biswajit Paul , Sunil Kumar Sharma. Comparison of performance and emissions characteristics of DI CI engine fueled with dual biodiesel blends of palm and jatropha. 10.1016/j.fuel.2016.01.022. 15. Please cite this article as: Iqbal MA, Varman M, Hassan MH, Kalam MA, Hossain S, Imtenan S, Tailoring fuel properties using jatropha, palm and coconut biodiesel to improve CI engine performance and emission characteristics, Journal of Cleaner Production (2015), doi: 10.1016/j.jclepro.2015.04.011. 16. Devendra Singh a,⇑, S.K. Singal a, M.O. Garg a, Pratyush Maiti b, Sandhya Mishra b, Pushpito K. Ghosh . Transient performance and emission characteristics of a heavy-duty diesel engine fuelled with microalga Chlorella variabilis and Jatropha curcas biodiesels. Energy Conversion and Management 106 (2015) 892–900. 91 22-12-2022 PhD Open Seminar

- 92. 17. Odi-Owei S 1989 Tribological properties of some vegetable oils and fats. Lubr. Eng. 45 pp 685–90 18. Hadley J W, Owen G C and Mills B 2016 SAE TECHNICAL Evaluation of a high frequency reciprocating wear test for measuring diesel fuel lubricity 932692 19. Baskar S and Sriram G 2014 Tribological behavior of journal bearing material under different lubricants Tribol. Ind. 36 pp 127–33 20. Jain A K and Suhane A 2014 Investigation of Tribological characteristics of non edible castor and mahua oils as bio lubricant for maintenance applications Proc. 5th Int. & 26th All India Manufacturing Technology Con. on Design and Research (IIT Guwahati) (Assam: AIMTDR 2014) pp 1–6 21. Suhane A, Rehman A and Khaira H K 2013 Tribological investigation of mahua oil based lubricant for maintenance applications Int. J. Eng. 3 pp 2367–71 22. Shanta S M, Molina G J and Soloiu V 2011 Tribological effects of mineral-oil lubricant contamination with biofuels: A pin-on-disk tribometry and wear study Adv. Tribol. 2011 pp 1-7 23. Shahabuddin M, Masjuki H H and Kalam M A 2013 Experimental investigation into tribological characteristics of biolubricant formulated from Jatropha oil Procedia Eng. 56 pp 597–606 24. Stachowiak G W and Batchelor A W 2005 Engineering Tribology, 3rd edn (UK: Elsevier Butterworth-Heinemann) p 744 25. Eychenne V and Mouloungui Z 1998 Relationships between structure and lubricating properties of neopentylpolyol esters Ind. Eng. Chem. Res. 37 pp 4835–43 26. ASTM Standard 2006 G99, Standard test method for wear testing with a pin-on-disk apparatus ASTM Int. West Conshohocken, PA v pp 1–5 27. U.S. EPA 2010 Median life, Annual activity, and load factor values for nonroad engine emissions modeling EPA-420-R-10-016. NR-005d. U.S. Environ. Prot. Agency pp 1–47 28. Konishi T and Perez J M 1997 Properties of polyol esters–-lubrication of an aluminum silicon alloy Tribol. Trans. 40 pp 500–6 29. Chattopadhyay R and Park M 2001 Surface Wear: Analysis, Treatment, and Prevention, ed C Terman and N Hrivnak (USA: ASM International) 30. Knothe G. S K R 2005 Lubricity of components of biodiesel and petrodiesel Energy & Fuels 19 pp 1192–200 31. M. Goumas, V. Lygerou, An Extension of the PROMETHEE method for decision making in fuzzy environment: Ranking of alternative energy exploitation projects, Eur. J. Oper. Res. 123 (2000) 606–613. https://doi:10.1016/S0377-2217(99)00093-4. 32. S. Yedla, R.M. Shrestha, Multi-criteria approach for the selection of alternative options for environmentally sustainable transport system in Delhi, Transp. Res. Part A Policy Pract. 37 (2003) 717–729. https://doi:10.1016/S0965-8564(03)00027-2. 33. K.G. Tsita, P.A. Pilavachi, Evaluation of alternative fuels for the Greek road transport sector using the analytic hierarchy process, Energy policy. 48 (2012) 677-686. https://doi.org/10.1016/j.enpol.2012.05.079. 34. M. Majid, M. Hassan, A. Khalkhali, A hybrid method of modi fi ed NSGA-II and TOPSIS to optimize performance and emissions of a diesel engine using biodiesel, Appl. Therm. Eng. 59 (2013) 309–315. https://doi:10.1016/j.applthermaleng.2013.05.041. 35. G. Sakthivel, M. Ilangkumaran, G. Nagarajan, A. Raja, P.M. Ragunadhan, J. Prakash. A hybrid MCDM approach for evaluating an automobile purchase model, International journal of information and decision sciences. 5 (2013) 50-85. https://doi: 10.1504/IJIDS.2013.052017. 92 22-12-2022 PhD Open Seminar

- 93. 31. G. Tuzkaya, S. Önüt, U.R. Tuzkaya, B. Gülsün, An analytic network process approach for locating undesirable facilities: An example from Istanbul, Turkey. J. Environ. Manage. 88 (2008) 970–983. https://doi:10.1016/j.jenvman.2007.05.004. 32. S. Kim, K. Lee, J.K. Cho, C.O. Kim, Agent-based diffusion model for an automobile market with fuzzy TOPSIS-based product adoption process, Expert Syst. Appl. 38 (2011) 7270–7276. https://doi:10.1016/j.eswa.2010.12.024. 33. A. Yıldız, E.U. Ergul, Usage of fuzzy multi-criteria decision making method to solve the automobile selection problem, Journal of Engineering and Fundamentals. 1 (2014) 1–10. https://doi:10.1016/j.jengtecman.2010.06.008. 34. A. Mayyas, M.A. Omar , M.T. Hayajneh, Eco-material selection using fuzzy TOPSIS method, Int. J. Sustain. Eng. 9 (2016) 292–304. https://doi:10.1080/19397038.2016.1153168. 35. A. Perimenis, H. Walimwipi, S. Zinoviev, F. Müller-Langer, S. Miertus, Development of a decision support tool for the assessment of biofuels, Energy Policy. 39 (2011) 1782–93. https://doi:10.1016/j.enpol.2011.01.011. 36. S. Paul, B. Sarkar, P.K. Bose, Eclectic decision for the selection of tree borne oil (TBO) as alternative fuel for internal combustion engine, Renew. Sustain energy. Rev. 48 (2015) 256–263. https://doi:10.1016/j.rser.2015.03.060. 37. K.G. Tsita, P.A. Pilavachi, Evaluation of alternative fuels for the Greek road transport sector using the analytic hierarchy process, Energy Policy. 48 (2012) 677–686. https://doi:10.1016/j.enpol.2012.05.079. 38. G. Sakthivel, M. Ilangkumaran, A hybrid multi-criteria decision making approach of ANP and TOPSIS to evaluate the optimum fuel blend in IC engine, International Journal of Decision Support Systems. 1 (2015) 268–293. https://doi:10.1504/IJDSS.2015.070170. 39. M.C.H. Lim, G.A. Ayoko, L. Morawska, Z.D. Ristovski, E.R. Jayaratne, Influence of fuel composition on polycyclic aromatic hydrocarbon emissions from a fleet of in-service passenger cars, Atmos. Environ. 41 (2007) 150–160. https://doi:10.1016/j.atmosenv.2006.07.044. 40. Maru M M, Lucchese M M, Legnani C, Quirino W G, Balbo A, Aranha I B, Costa L T, Vilani C, De Sena L A, Damasceno J C, Cruz T S, Lidízi L R, Silva R F, Jorio A, Achete C A. Biodiesel compatibility with carbon steel and HDPE parts. Fuel Processing Technology 2009;90:1175–1182. 41. Kaul S, Saxena R C, Kumar A, Negi M S, Bhatnagar A K, Goyal H B, Gupta A K. Corrosive behavior of biodiesel from seed oils of Indian origin on diesel engine parts. Fuel Processing Technology 2007; 88:303–307. 42. Diaz Ballote L, Lopez Sansores J F, Maldonado Lopez L, Garfias Mesias L F. Corrosion behavior of Aluminum exposed to a biodiesel. Electrochemistry Communications 2009;11:41–44. 43. Hasimoglu C, Ciniviz M, Ozsert I, Icingu Y, Parlaka A, Salman M S. Performance characteristics of a low heat rejection diesel engine operating with biodiesel. Renewable Energy 2008;33:1709–1715. 44. Huang T J, Tsai D H. CO oxidation behavior of Copper and Copper oxides. Catalysis Letters 2003;87: 3–4. 45. Haseeb A S M A, Fazal M A , Jahirul M I , Masjuki H H. Compatibility of automotive materials in biodiesel: a review. Fuel 2011;90:922–931. 46. Rajasekar A, Maruthamuthu S, Palaniswamy N, Rajendran A. Biodegradation of corrosion inhibitors and their influence on petroleum product pipeline. Microbiological Research 2007;162: 355–368. 93 22-12-2022 PhD Open Seminar

- 94. 47. Agarwal A K, Khurana D, Dhar A. Improving oxidation stability of biodiesels derived from Karanja, Neem and Jatropha: step forward in the direction of commercialization. J. Clean. Prod. 2015;107:646-652. 48. Fazal M A, Jakeria M R, Haseeb, A S M A, Rubaiee S. Effect of antioxidants on the stability and corrosiveness of Palm biodiesel upon exposure of different metals. Energy 2017;135:220-226. 49. Silva W L G, Salomao AA, Vila M M D C, Tubino M. Influence of water and ultraviolet irradiation on the induction period of the oxidation of biodiesel. J. Braz. Chem. Soc. 2017;28:676-680. 50. Salaheldeen M, Aroua MK, Mariod AA, Cheng SF, Abdelrahman MA, Atabani AE. Physicochemical characterization and thermal behavior of biodiesel and biodiesel–diesel blends derived from crude Moringa peregrina seed oil. Energy Convers Manage 2015;92:535–42. 51. Haseeb A, Sia S, Fazal M, Masjuki H. Effect of temperature on tribological properties of Palm biodiesel. Energy 2010;35:1460–4. 52. Sørensen G, Pedersen DV, Nørgaard AK, Sørensen KB, Nygaard SD. Microbial growth studies in biodiesel blends. Bioresour Technol 2011;102:5259–64. 53. Haseeb A, Masjuki H, Ann L, Fazal M. Corrosion characteristics of Copper and leaded Bronze in Palm biodiesel. Fuel Process Technol 2010;91:329–34. 54. Fazal M, Haseeb A, Masjuki H. Degradation of automotive materials in Palm biodiesel. Energy 2012;40:76–83. 55. Agrawal, A.K.: Bio fuels (alcohols and biodiesel) applications as fuels for internal combus-tion engines. Progress in Energy and Combustion Science 33, 233-271 (2007). 56. Syed, A.B., Rajagopal, K.: A review of the effects of catalyst and additive on bio-diesel pro-duction, performance, combustion and emission characteristics. Renewable and Sustainable Energy Reviews 16, 711-717 (2012). 57. Vellaiyan, S., Amirthagadeswaran, K.S.: The role of water-in-diesel emulsion and its addi-tives on diesel engine performance and emission levels: A retrospective review. Alexandria Engineering Journal 55(3), 2463-2472 (2016). 58. Selim, M.Y.E., Ghannam, M.T.: Performance and engine roughness of a diesel engine run-ning on stabilized water diesel emulsion. SAE Pap., 2007-24-01 (2007). 59. Bertola, A., Li, R., Boulouchos, K.: Influence of water-diesel fuel emulsions and EGR on combustion and exhaust emissions of heavy duty DI-diesel engines equipped with common-rail injection system. SAE Pap., 2003-01-31 (2003). 64. Daly, D. T., Langer, D. A.: Future fuels and fuel additives for vehicle emissions control. In: International Proceedings of the 219th American Chemical Society National Meeting, pp. 26–31. American Chemical Society, San Francisco (2000). 65. Patel, P. D., Lakdawala, A,, Patel, R. N.: Box–Behnken response surface methodology for optimization of operational parameters of compression ignition engine fuelled with a blend of diesel, biodiesel and diethyl ether. Biofuels 7:2, 87-95 (2016). 66. Worldwide, M.I. Dynamic Light Scattering, Common Terms Defined; Inform White Paper; Malvern Instruments Limited: Malvern, UK, 1–6 (2011). 67. Melo, E., Piloto, R., Tobio, I., Goyos, L., Verhelst, S.: Performance of a single cylinder die-sel engine fuelled with emulsified residual oleins and standard diesel fuel. Renewable Ener-gies and Power Quality Journal 12, 183-188 (2014). 68. Assessment and Standards Division EPA, Office of Transportation and Air Quality Median life, Annual Activity, and Load factor values for non-road engine emissions modeling. (2002). 94 22-12-2022 PhD Open Seminar

- 95. 95 22-12-2022 PhD Open Seminar

- 96. Life Cycle Analysis *Study on tribological behaviour of biodiesel – Diethyl ether (B20A4) blend for long run test on compression ignition engine. Fuel (Elsevier) DOI: 10.1016/j.fuel.2018.05.055

- 97. Long Run Endurance Test Life Cycle Assessment (LCA) of CI Engine Fueled with Diesel 97 • Loading cycle for preliminary runs for a constant speed diesel engine, showing load (% of rated load) vs running time (hour) provided by IS 10,000 Part - V • Loading cycle for long - run endurance test for a constant speed diesel engine, showing load (% of rated load) vs. running time (hour) including warm-up period provided by IS 10,000 Part - IX 22-12-2022 PhD Open Seminar

- 98. Visual Inspection of CI Engine Components 98 22-12-2022 PhD Open Seminar

- 99. Quantitative Analysis 99 Dimension and Weight Analysis 22-12-2022 PhD Open Seminar

- 100. Quantitative Analysis 100 Surface Roughness and Microscopic Image Analysis 22-12-2022 PhD Open Seminar