Welding

•Télécharger en tant que PPT, PDF•

9 j'aime•4,435 vues

welding, model engineering.

Signaler

Partager

Signaler

Partager

Recommandé

Contenu connexe

Tendances

Tendances (20)

Dissimilar Metal Welding - Issues, Solution & Techniques

Dissimilar Metal Welding - Issues, Solution & Techniques

En vedette

To determine the mechanical properties of Super duplex stainless steel (AISI 2507) during welding processes (Tungsten Inert Gas Welding & Shielded Metal Arc Welding).

To plot the thermal distribution curves in a simulation software using the data acquired with the help of sensors during the welding processes.Effct of Tungsten Inert Gas Welding & Shielded Metal Arc Welding Processes on...

Effct of Tungsten Inert Gas Welding & Shielded Metal Arc Welding Processes on...Suryaprakash Shanmugam

Pagan Evaluate The Metal Inert Gas Welding Process Using Activated Flux On SS316L B...

Evaluate The Metal Inert Gas Welding Process Using Activated Flux On SS316L B...International Center for Research & Development

En vedette (20)

Optimization of Process Parameters of Tungsten Inert Gas Welding by Taguchi M...

Optimization of Process Parameters of Tungsten Inert Gas Welding by Taguchi M...

Effct of Tungsten Inert Gas Welding & Shielded Metal Arc Welding Processes on...

Effct of Tungsten Inert Gas Welding & Shielded Metal Arc Welding Processes on...

Evaluate The Metal Inert Gas Welding Process Using Activated Flux On SS316L B...

Evaluate The Metal Inert Gas Welding Process Using Activated Flux On SS316L B...

A SHORT REVIEW ON ALUMINIUM ANODIZING: AN ECO-FRIENDLY METAL FINISHING PROCESS

A SHORT REVIEW ON ALUMINIUM ANODIZING: AN ECO-FRIENDLY METAL FINISHING PROCESS

Similaire à Welding

Similaire à Welding (20)

Soldadura gtaw, saw y electroescoria (1) soldadura mixta

Soldadura gtaw, saw y electroescoria (1) soldadura mixta

Dernier

💉💊+971581248768>> SAFE AND ORIGINAL ABORTION PILLS FOR SALE IN DUBAI AND ABUDHABI}}+971581248768

+971581248768 Mtp-Kit (500MG) Prices » Dubai [(+971581248768**)] Abortion Pills For Sale In Dubai, UAE, Mifepristone and Misoprostol Tablets Available In Dubai, UAE CONTACT DR.Maya Whatsapp +971581248768 We Have Abortion Pills / Cytotec Tablets /Mifegest Kit Available in Dubai, Sharjah, Abudhabi, Ajman, Alain, Fujairah, Ras Al Khaimah, Umm Al Quwain, UAE, Buy cytotec in Dubai +971581248768''''Abortion Pills near me DUBAI | ABU DHABI|UAE. Price of Misoprostol, Cytotec” +971581248768' Dr.DEEM ''BUY ABORTION PILLS MIFEGEST KIT, MISOPROTONE, CYTOTEC PILLS IN DUBAI, ABU DHABI,UAE'' Contact me now via What's App…… abortion Pills Cytotec also available Oman Qatar Doha Saudi Arabia Bahrain Above all, Cytotec Abortion Pills are Available In Dubai / UAE, you will be very happy to do abortion in Dubai we are providing cytotec 200mg abortion pill in Dubai, UAE. Medication abortion offers an alternative to Surgical Abortion for women in the early weeks of pregnancy. We only offer abortion pills from 1 week-6 Months. We then advise you to use surgery if its beyond 6 months. Our Abu Dhabi, Ajman, Al Ain, Dubai, Fujairah, Ras Al Khaimah (RAK), Sharjah, Umm Al Quwain (UAQ) United Arab Emirates Abortion Clinic provides the safest and most advanced techniques for providing non-surgical, medical and surgical abortion methods for early through late second trimester, including the Abortion By Pill Procedure (RU 486, Mifeprex, Mifepristone, early options French Abortion Pill), Tamoxifen, Methotrexate and Cytotec (Misoprostol). The Abu Dhabi, United Arab Emirates Abortion Clinic performs Same Day Abortion Procedure using medications that are taken on the first day of the office visit and will cause the abortion to occur generally within 4 to 6 hours (as early as 30 minutes) for patients who are 3 to 12 weeks pregnant. When Mifepristone and Misoprostol are used, 50% of patients complete in 4 to 6 hours; 75% to 80% in 12 hours; and 90% in 24 hours. We use a regimen that allows for completion without the need for surgery 99% of the time. All advanced second trimester and late term pregnancies at our Tampa clinic (17 to 24 weeks or greater) can be completed within 24 hours or less 99% of the time without the need surgery. The procedure is completed with minimal to no complications. Our Women's Health Center located in Abu Dhabi, United Arab Emirates, uses the latest medications for medical abortions (RU-486, Mifeprex, Mifegyne, Mifepristone, early options French abortion pill), Methotrexate and Cytotec (Misoprostol). The safety standards of our Abu Dhabi, United Arab Emirates Abortion Doctors remain unparalleled. They consistently maintain the lowest complication rates throughout the nation. Our Physicians and staff are always available to answer questions and care for women in one of the most difficult times in their lives. The decision to have an abortion at the Abortion Cl+971581248768>> SAFE AND ORIGINAL ABORTION PILLS FOR SALE IN DUBAI AND ABUDHA...

+971581248768>> SAFE AND ORIGINAL ABORTION PILLS FOR SALE IN DUBAI AND ABUDHA...?#DUbAI#??##{{(☎️+971_581248768%)**%*]'#abortion pills for sale in dubai@

Dernier (20)

Powerful Google developer tools for immediate impact! (2023-24 C)

Powerful Google developer tools for immediate impact! (2023-24 C)

Web Form Automation for Bonterra Impact Management (fka Social Solutions Apri...

Web Form Automation for Bonterra Impact Management (fka Social Solutions Apri...

Apidays New York 2024 - The value of a flexible API Management solution for O...

Apidays New York 2024 - The value of a flexible API Management solution for O...

Apidays New York 2024 - Accelerating FinTech Innovation by Vasa Krishnan, Fin...

Apidays New York 2024 - Accelerating FinTech Innovation by Vasa Krishnan, Fin...

TrustArc Webinar - Stay Ahead of US State Data Privacy Law Developments

TrustArc Webinar - Stay Ahead of US State Data Privacy Law Developments

Apidays New York 2024 - The Good, the Bad and the Governed by David O'Neill, ...

Apidays New York 2024 - The Good, the Bad and the Governed by David O'Neill, ...

ICT role in 21st century education and its challenges

ICT role in 21st century education and its challenges

Automating Google Workspace (GWS) & more with Apps Script

Automating Google Workspace (GWS) & more with Apps Script

Apidays New York 2024 - Scaling API-first by Ian Reasor and Radu Cotescu, Adobe

Apidays New York 2024 - Scaling API-first by Ian Reasor and Radu Cotescu, Adobe

A Beginners Guide to Building a RAG App Using Open Source Milvus

A Beginners Guide to Building a RAG App Using Open Source Milvus

+971581248768>> SAFE AND ORIGINAL ABORTION PILLS FOR SALE IN DUBAI AND ABUDHA...

+971581248768>> SAFE AND ORIGINAL ABORTION PILLS FOR SALE IN DUBAI AND ABUDHA...

Emergent Methods: Multi-lingual narrative tracking in the news - real-time ex...

Emergent Methods: Multi-lingual narrative tracking in the news - real-time ex...

Mastering MySQL Database Architecture: Deep Dive into MySQL Shell and MySQL R...

Mastering MySQL Database Architecture: Deep Dive into MySQL Shell and MySQL R...

Welding

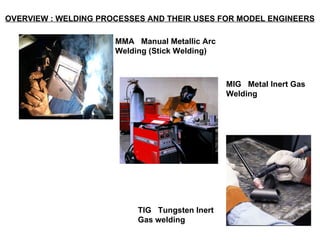

- 1. OVERVIEW : WELDING PROCESSES AND THEIR USES FOR MODEL ENGINEERS MMA Manual Metallic Arc Welding (Stick Welding) MIG Metal Inert Gas Welding TIG Tungsten Inert Gas welding

- 5. COMMON ELECTRIC ARC WELDING PROCESSES (Stick Welding) The operator can adjust the arc length manually Consequently the voltage will increase and the amperage will decrease Diagram shows the electrode provides a gaseous shield from the decomposition or the coating around the electrode arc and produces a slag covering on the hot weld deposit

- 6. AC verses DC current Heat in the work piece Heat in the electrode Straight polarity (ACEN) electrode negative Reverse polarity (ACEP) electrode positive Good for welding Stainless steel Deep penetration

- 8. DC Direct Current:- Arc is established at lower voltages (50/55volts) enabling easier arc striking and arc maintaining qualities (especially on thin sheet steels) DC+) Versatile for heavy and light gauge materials Excellent for out of position welding (Lower welding currents) Greater range of electrode types Voltage drop across the Arc adjustable by means of a field regulator DC current electrode ve+ Excellent for welding Carbon steels, Stainless Steel, Alloys, and dissimilar metals, DC current excellent for TIG (Tungsten Inert Gas) Welding almost all metals ve+ and ve- Mild steel, low alloys, Stainless steel, Copper and Copper alloys, Aluminum and Aluminum Alloys, Nickel and Nickel Alloys, Magnesium and Magnesium Alloys, Titanium, and others. Welding equipment very expensive compered to AC plant Voltage drop higher than AC on long cable distance work Arc Blow can disrupt the weld area caused by magnetic fields (especially troublesome when welding in corners the arc may stray or fluctuate in direction AC verses DC current

- 9. (Experimentation of the arc began in the early 1800's) Development of Covered Electrodes First electric weld British patent 1865 During the 1890's welding was accomplished using bare metal electrodes Welds produced where porous and brittle due to large absorption of oxygen and nitrogen from the atmosphere Observations of improvements were noticeable by using rusty electrodes or wrapping the rod with paper These improvements shielded the arc from the atmosphere to some degree In the early twentieth century the importance of shielding the arc from the atmosphere was recognized

- 12. CLASSIFICATION OF WELDING RODS (Selection Criteria) Type of Base Metal (Carbon Steel/ Stainless steel etc) Position of the Weld (All position/ flat etc) Available Equipment AC or DC :- For deepest penetration, use DC reverse polarity (Electrode Positive) For lower penetration and higher deposition rate, use DC straight polarity (Electrode Negative) For freedom of arc blow, use AC. Plate Thickness (Heavy gauge and lower gauge electrodes) Fit-Up (Gaps and poor Fits etc) Welding Costs (Dependent on quality)

- 13. IDENTIFICATION MARKING ON ELECTRODES Let’s take the first rod in the photo E6010

- 15. HEAT AFFECTED ZONE IN A WELD JOINT HEAT AFFECTED ZONE THE HEAT AFFECTED ZONE IS THE AREA OF THE WELD JOINT THAT DID NOT BECOME MOLTEN IN THE WELDING PROCESS THIS ZONE NOW BECOMES WEAK DUE TO THE CHANGE IN GRAIN STRUCTURE SOLIDIFIED WELD METAL HEAT AFFECTIVE ZONE UNAFFECTED BASE METAL

- 16. HEAT AFFECTED ZONE IN A WELD JOINT HEAT AFFECTED ZONE BASE METAL UNDER BEAD CRACKING CAUSED BY HYDROGEN BEARING COMPOUNDS (WATER& MINERALS) OR CHEMICALS PRESENT IN THE ELECTRODE COATING THE HYDROGEN IS CONVERTED INTO ATOMIC HYDROGEN INISHIATED BY THE HEAT OF THE ARC 4000°C TREMENDAS PRESSURE IS DEVELOPED WHICH OPENS CRACK DEFECTS IN THE HEAT AFFECTED ZONE WELD METAL HYDROGEN INDUCED CRACKS