Oxy-Acetylene Welding Lab Report

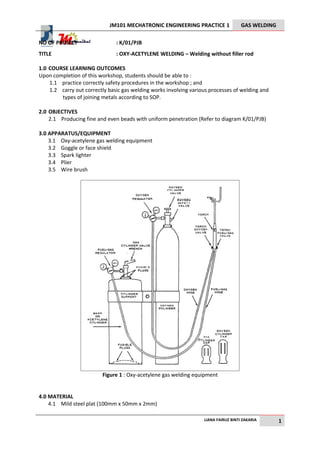

- 1. JM101 MECHATRONIC ENGINEERING PRACTICE 1 GAS WELDING NO OF PROJECT : K/01/PJB TITLE : OXY-ACETYLENE WELDING – Welding without filler rod 1.0 COURSE LEARNING OUTCOMES Upon completion of this workshop, students should be able to : 1.1 practice correctly safety procedures in the workshop ; and 1.2 carry out correctly basic gas welding works involving various processes of welding and types of joining metals according to SOP. 2.0 OBJECTIVES 2.1 Producing fine and even beads with uniform penetration (Refer to diagram K/01/PJB) 3.0 APPARATUS/EQUIPMENT 3.1 Oxy-acetylene gas welding equipment 3.2 Goggle or face shield 3.3 Spark lighter 3.4 Plier 3.5 Wire brush Figure 1 : Oxy-acetylene gas welding equipment 4.0 MATERIAL 4.1 Mild steel plat (100mm x 50mm x 2mm) LIANA FAIRUZ BINTI ZAKARIA 1

- 2. JM101 MECHATRONIC ENGINEERING PRACTICE 1 GAS WELDING List out the apparatus/equipment and material Draw the apparatus/equipment and material used in the workshop LIANA FAIRUZ BINTI ZAKARIA 2

- 3. JM101 MECHATRONIC ENGINEERING PRACTICE 1 GAS WELDING 5.0 SAFETY AND HEALTH It is the individual’s responsibility to practice the following general safety guidelines at all times and keep your workspace reasonably tidy. 5.1 Always know the hazards associated with the equipment/materials that are being utilized in the workshop. 5.2 Always wear appropriate protective clothing and equipment. 5.3 Confine long hair and loose clothing. Do not wear high-heeled shoes, open-toed shoes, sandals or shoes made of woven material. 5.4 Be familiar with the location of emergency equipment such as fire alarm and fire extinguisher. Know the appropriate emergency response procedures. 5.5 __________________________________________________________________________ _________________________________________________________________________ 5.6 __________________________________________________________________________ _________________________________________________________________________ 5.7 __________________________________________________________________________ _________________________________________________________________________ 5.8 __________________________________________________________________________ __________________________________________________________________________ 5.9 __________________________________________________________________________ __________________________________________________________________________ 6.0 INTRODUCTION 6.1 Theory Oxy- acetylene welding is one of the oldest welding processes. Its use has declined somewhat in popularity in recent years, but it is still widely used for welding pipes and tubes, as well as for repair work. Oxy-acetylene welding does not require electricity and is typically used for maintenance, in body shops, and in the repair of small parts where other welding processes are too expensive. Oxy-acetylene welding can be used to join iron, steel, cast iron, copper, brass, aluminum, bronze and other metals. Often, dissimilar metals such as steel and cast iron, brass and steel, copper and iron, and brass and cast iron can be joined with oxy- acetylene welding. Oxy- acetylene welding equipment can also be used for preheating, cutting metal, case hardening, annealing, soldering and brazing. Oxy-acetylene welding uses the heat from the combustion of a mixture of oxygen and acetylene (the fuel gas) to fuse base metals and filler metal together. This mixture produces flame temperatures in the range of 5800°F to 6300°F, which can be used to weld a variety of metals. Oxy-acetylene welding processes are used with or without filler rod/metal. If filler rod/ metal is not used in the joint, the weld is autogenous. An autogenous weld is a fusion weld made without filler rod/metal. LIANA FAIRUZ BINTI ZAKARIA 3

- 4. JM101 MECHATRONIC ENGINEERING PRACTICE 1 GAS WELDING 7.0 PROCEDURES 7.1 Clean the surface of the work piece with wire brush. 7.2 Prepare the gas welding equipment. 7.3 Open the cylinder valve and set the acetylene regulator from 5 bar to 8 bar and for oxygen from 8 bar to 10 bar. 7.4 Make sure the work piece is underlay to provide air space at the bottom of the welded work piece. 7.5 Ignite and adjust the flame until producing oxidation flame. 7.6 Determine the angle of welding torch between 60° to 70°. 7.7 Heat the work piece surface for preheat purpose to avoid the work piece from warp. 7.8 Begin the welding work with forward welding technique. 7.9 Heat the work piece at one point until melt and move the welding torch to get enough molten weld pool. 7.10 Dip the molten weld pool to get the penetration. 7.11 To get good penetration, control the molten weld pool so that it’s not too wide or too small. 7.12 Make sure the distance between inner cone flame and molten weld pool is within 2mm to 4mm. 7.13 Repeat the process(7.6 to 7.12) for next weld pass until all part completely welded. 7.14 After completion, clean the work piece with wire brush. LIANA FAIRUZ BINTI ZAKARIA 4

- 5. JM101 MECHATRONIC ENGINEERING PRACTICE 1 GAS WELDING PROCEDURES DIAGRAM (with label) LIANA FAIRUZ BINTI ZAKARIA 5

- 6. JM101 MECHATRONIC ENGINEERING PRACTICE 1 GAS WELDING PROCEDURES DIAGRAM (with label) LIANA FAIRUZ BINTI ZAKARIA 6

- 7. JM101 MECHATRONIC ENGINEERING PRACTICE 1 GAS WELDING 8.0 RESULT Draw the work piece with the dimension. 9.0 DISCUSSION 9.1 How much should the cylinder valve be opened on an acetylene cylinder? On the oxygen cylinder? ___________________________________________________________________________ ___________________________________________________________________________ ___________________________________________________________________________ ___________________________________________________________________________ 9.2 What is a tip cleaner? When and why should it be used? ___________________________________________________________________________ ___________________________________________________________________________ ___________________________________________________________________________ ___________________________________________________________________________ 9.3 Why is it dangerous to light a torch with match or a lighter? ___________________________________________________________________________ ___________________________________________________________________________ ___________________________________________________________________________ ___________________________________________________________________________ 9.4 What type of protective clothing is commonly worn when oxy-acetylene welding? ___________________________________________________________________________ ___________________________________________________________________________ ___________________________________________________________________________ ___________________________________________________________________________ LIANA FAIRUZ BINTI ZAKARIA 7

- 8. JM101 MECHATRONIC ENGINEERING PRACTICE 1 GAS WELDING 10.0CONCLUSION __________________________________________________________________________________ __________________________________________________________________________________ __________________________________________________________________________________ __________________________________________________________________________________ __________________________________________________________________________________ __________________________________________________________________________________ __________________________________________________________________________________ __________________________________________________________________________________ __________________________________________________________________________________ __________________________________________________________________________________ 11.0 REFERENCES 11.1 B.J Moniz and R.T. Miller (2010).Welding Skills Fourth Edition. American Technical Publishers. Orland Park, Illinois. 11.2 ________________________________________________________________________ ________________________________________________________________________ 11.3 ________________________________________________________________________ ________________________________________________________________________ LIANA FAIRUZ BINTI ZAKARIA 8

- 9. JM101 MECHATRONIC ENGINEERING PRACTICE 1 GAS WELDING PROJECT MARKING SCHEME MARK(S) GIVEN MARKING MARK(S) MAXIMUM ASSESSMENT CRITERIA FACTOR OBTAINED MARKS 4 3 2 1 0 Uniform width and height of weld beads 4 16 Fine and even weld beads 4 16 Concave shape of weld beads 4 16 Penetration along the weld beads 4 16 Even starting and finishing 4 16 No leakage at weld beads parts 4 16 Clean and neat work piece 1 4 TOTAL MARKS 100 REPORT MARKING SCHEME MARK(S) MAXIMUM ASSESSMENT CRITERIA COMMENT OBTAINED MARKS Front cover 5 Apparatus/equipment and material 15 - list out and draw the diagram correctly Safety and health 15 Procedures 25 - write the procedures in order and use passive sentences Result 5 - draw the work piece with dimension Discussion - Question 9.1 5 - Question 9.2 5 - Question 9.3 5 - Question 9.4 5 Conclusion 5 References 5 Report neatness 5 TOTAL MARKS 100 Lecturer’s Signature, ___________________ Date : LIANA FAIRUZ BINTI ZAKARIA 9