kapok fibre

•

11 j'aime•8,656 vues

Introduction,structure,processing,properties and end uses of kapok fibre

Signaler

Partager

Signaler

Partager

Recommandé

Recommandé

Contenu connexe

Tendances

Tendances (20)

Cotton fiber manufacturing, physical and chemical properties

Cotton fiber manufacturing, physical and chemical properties

Mechanical Properties Of Fiber | Mechanical Properties Of Textile Fiber

Mechanical Properties Of Fiber | Mechanical Properties Of Textile Fiber

Similaire à kapok fibre

Similaire à kapok fibre (20)

Different Types Of Fibers With Pictures & Their Properties

Different Types Of Fibers With Pictures & Their Properties

processing Physical_and_Chemical_Properties_of_Wool (1).ppt

processing Physical_and_Chemical_Properties_of_Wool (1).ppt

Presentation about various cellulose those are uncommon in fabric industry

Presentation about various cellulose those are uncommon in fabric industry

Plus de Farhan ullah baig

Plus de Farhan ullah baig (20)

Evaluation of operation management in Textile Industry

Evaluation of operation management in Textile Industry

Dernier

Dernier (20)

Seal of Good Local Governance (SGLG) 2024Final.pptx

Seal of Good Local Governance (SGLG) 2024Final.pptx

Mixin Classes in Odoo 17 How to Extend Models Using Mixin Classes

Mixin Classes in Odoo 17 How to Extend Models Using Mixin Classes

Z Score,T Score, Percential Rank and Box Plot Graph

Z Score,T Score, Percential Rank and Box Plot Graph

Unit-IV; Professional Sales Representative (PSR).pptx

Unit-IV; Professional Sales Representative (PSR).pptx

Unit-V; Pricing (Pharma Marketing Management).pptx

Unit-V; Pricing (Pharma Marketing Management).pptx

Basic Civil Engineering first year Notes- Chapter 4 Building.pptx

Basic Civil Engineering first year Notes- Chapter 4 Building.pptx

kapok fibre

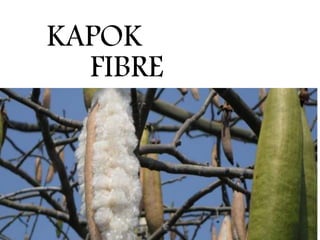

- 1. KAPOK FIBRE

- 2. Introduction: • A natural, plant, cellulosic fiber. • Obtained from seed of kapok plant Ceilbapentandra. • Also known as silk cotton or java cotton. • Smooth, unicellular, cylindrically shaped, twist less fibre. • Mostly found in Africa and Central America was transported to Asia where it was cultivated to get Kapok’s Fiber. • Kapok fibers on their own are not suitable for spinning into yarn, as they are too smooth, slippery and brittle. • Kapok tree can grow up to 4 meters (13 feet) per year, eventually reaching a height of 50 meters (164 feet). • The fibers are 0.8 to 3.2 cm (0.3 to 1.25 inches) long. • Composed of both lignin (a woody plant substance) and cellulose (a carbohydrate).

- 3. Structure: • Kapok fibre shows homogenous circular cross section with wide air filled lumen having wall thickness of about 1-2µm. • Its cell wall is thin and covered with a thick layer of wax. • By the microscope observation kapok fibres are transparent with characteristic air bubbles in the lumen. • The cross section of fibres is oval to round.

- 4. Processing of Kapok: Kapok harvesting process requires a lot of manpower, as each step is done mostly by hand. The processing of kapok starts with: • Harvesting • Removing hulls • Removing seeds • Drying • Bailing and packing

- 5. Harvesting: • The ripe unopened pods are normally harvested by knocking them off the tree, but they can also be cut from the tree or harvested when they fall to the ground . Removing hulls: • Kapok fiber is left in sunlight for drying of hulls. • The fruits are hulled and seed and fibres were removed from the pods by hand. Removing seeds: • The seeds lie loose in the floss and, with the help of some beating they fall to the bottom of the container where they are easily separated.

- 6. Drying • Kapok fibre is dried under the sun for 3 to 5 hours for complete drying. Bailing and packing • Kapok fibers are then packed in the form of bales and dispatched for further processing.

- 7. Properties: 1. Appearance Kapok fibres are lustrous, yellowish brown and made of a mix of lignin and cellulose. 2. Fineness 0.4-0.7 denier 3. Tenacity 1.4-1.74 gram/denier 4. Elongation at break 1.8-4.23 5. Absorbency The hydrophobic characteristics of the kapok fibre could be attributed to its waxy surface while its large percent of lumen contributed to its excellent oil absorbency and retention capacity.

- 8. 6. Thermal behavior of kapok The heat retention of kapok was better than that of other fibres due to the static immobile air held in the large lumen region of kapok. 7. Light weight 8 times lighter than cotton by volume. 8. Effect of Acids Kapok shows good resistance to alkalis and it is not damaged by alkali. 9. Effect of Alkalis Kapok shows good resistance to alkalis and it is not damaged by alkali. 10. Effect of Microorganisms Because of lignin micro organism shows no effect.

- 9. Chemical Composition of Kapok: 64% cellulose, 13% lignin and 23% pentose. Advantages: • Light weight, • Hydrophobic and the good buoyancy effect, • Comfortable • Thermal insulator • Bio degradable Dis advantages: • The fibres are fragile and break easily • Not suitable for weaving or spinning • Irritant to lungs and needs extra care during work • Highly inflammable.

- 10. End uses: • Mattress/Pillow stuffing • Clothing • Life-saving equipment • construction of thermally insulated and soundproof covers and walls, • Technical textiles Yachts and boats furnishing, insulating materials in refrigeration systems • Substitute of cotton in surgery • By products such as Kapok seed oil.